Operation and Maintenance Warnings:

- Never touch a live power terminal. This could cause a shock or machine malfunction.

- Due to the danger of an electric shock, confirm that the GLC’s power cord is un-

plugged before either cleaning the GLC or attaching/detaching the power terminal

screws.

- When replacing the GLC’s backlight, be sure to unplug the unit’s power cord to

prevent a shock, and wear gloves to prevent being burned.

- The GLC uses a lithium battery for backing up its internal clock and control memory

data. If the battery is incorrectly replaced (i.e. the + and - sides are reversed), the

battery may explode. Therefore, before changing the battery, Digital recommends

that you contact your local GLC distributor for battery replacement instructions.

- Do not attempt to modify the GLC’s internal parts or wiring in any way, since this

may lead to either a shock or fire.

CAUTIONS

Wiring Layout Cautions:

Be sure that all GLC input/output signal lines are isolated from all power wiring or

power cables, via a separate wiring duct. This is to prevent excessive noise, which can

cause a unit malfunction.

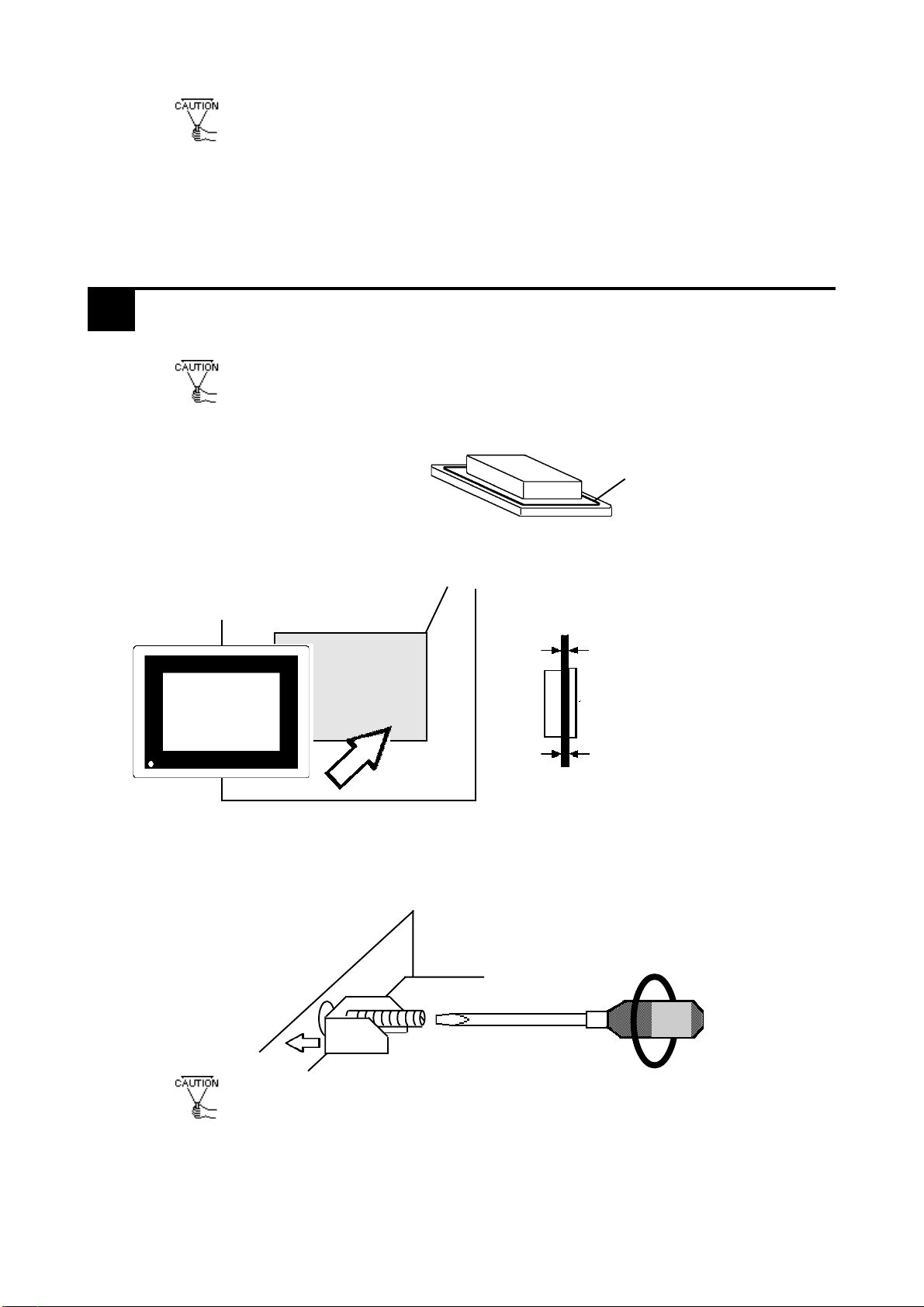

Installation Cautions:

- When attaching the I/O unit to the GLC, be sure that all the I/O unit’s attachment

screws are used and the unit is securely attached to the GLC. If the I/O unit is not

attached securely in place, the I/O unit may be damaged if it falls off the back of the

GLC, or a system-related malfunction or accident may occur due to I/O data signal

problems.

- Be sure any data cable attached to the GLC’s connector is securely attached. If the

cable and connector pins do not all make complete contact, incorrect input or output

signals can result.

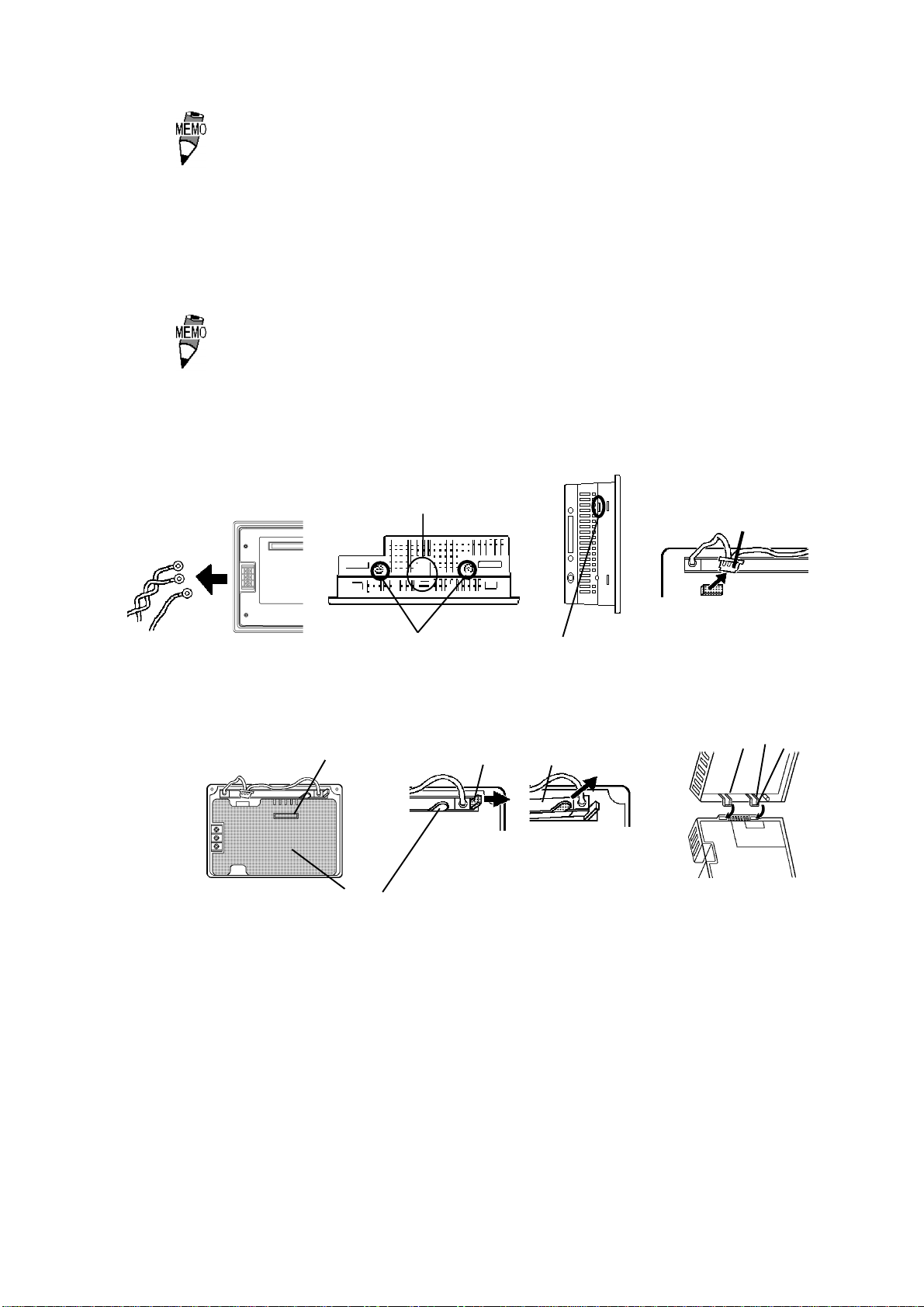

General Wiring Cautions

- To prevent shocks or malfunctions, GLC’s FG (earth) wire should be grounded ac-

cording to the following:

1) A maximum grounding resistance of 100 W or less.

2) A grounding wire of 2mm2or larger should be used.

- The GLC’s wiring should be checked to confirm both that the operating voltage and

wiring terminal locations are correct. If either the voltage or the wiring terminal loca-

tions are incorrect, it can cause a fire or accident.

- Be sure to secure all wiring terminal screws in place with the designated torque.

Screws and terminals that become loose can cause a short circuit, fire or accident.

- Be sure that metal filings or wiring remnants do not fall inside the GLC, since they

can cause a fire, accident, or malfunction.

GLC Operation and Maintenance Cautions

- Be sure to read the GLC’s manual and on-line help information carefully before per-

forming program changes, forced output, or utilizing the RUN, STOP or PAUSE

commands while the GLC is in operation. Mistakes concerning the use of these items

can cause a machine accident or damage.

GLC Unit Disposal Cautions

- The GLC unit should be disposed of in a manner appropriate to the user country’s

industrial machinery disposal standards.