Pro's Kit SS-955 User manual

SS-955

Automatic Solder Feeder Soldering Station

1st Edition, 2022

©2022 Copyright by Prokit’s Industries Co., Ltd.

User’s Manual

1.Product introduction

Thank you for purchasing the SS-955 Automatic Solder Feeder Soldering Station;

This product optimize the combination of automatic solder wire feed control device

and soldering station; The solder wire output is accurate and can be flexibly adjust-

ed, the feeding speed, time and return quantity can be controlled to achieve excel-

lent effect, Suitable for all kinds of lead and lead-free operations, help you improve

productivity.

Please read this manual carefully before use and operate in accordance with the

instructions strictly. we will not bear any responsibility for product damage and

other losses caused by incorrect use. Please keep it properly for future reference.

2.Safety precautions

When the soldering iron is working, the tip of the soldering iron is at high tempera-

ture. If you want to replace the tip of the soldering iron or store the product, please

turn off the power supply and unplug the wire plug, and then replace or store the

soldering iron after it returns to room temperature, so as to avoid personal injury

and fire hazards.

·Please use correct voltage source for this product.

·Do not operate in humid environment.

·Do not operate in flammable and explosive environment.

·Please keep the product clean and dry.

·Turn off the power supply when unused or leaving to prevent fire.

·Careful to prevent scalding when the soldering iron is working.

·Do not expose the product to the water or touch with wet hands, prevent

electric leakage.

·Do not drop the product, or it may be damaged.

·Repaired and replaced must by professionals.

·Please use original parts when replacing.

warning

attention

滾滾長江東逝水

滾滾長江東逝水

3.Characteristic

·2 in 1 design, soldering iron+ automatic solder wire feed, can be used separately.

·LCD display with backlight.

·Chinese simplified, traditional and English interface are optional.

·Encoder used conveniently, reliable and long service life.

·Temperature range: 200 ~ 480 ℃.

·The feeding mechanism adopts brushless stepping motor to control the solder

wire output accurately.

·60W copper transformer.

·Digital temperature calibration function, accurate and convenient.

·The soldering iron uses ceramic heating core (9SS-900N-HT), with long service life

and fast heating up.

·The solder wire feed is controlled by handle or foot switch meet different require-

ment.

·Adopt aviation plug connected reliably.

·Design for anti-static operation with anti-static socket, grounding port, metal

case, etc.

1

·2 in 1 design, soldering iron+ automatic solder wire feed, can be used separately.

·LCD display with backlight.

·Chinese simplified, traditional and English interface are optional.

·Encoder used conveniently, reliable and long service life.

·Temperature range: 200 ~ 480 ℃.

·The feeding mechanism adopts brushless stepping motor to control the solder

wire output accurately.

·60W copper transformer.

·Digital temperature calibration function, accurate and convenient.

·The soldering iron uses ceramic heating core (9SS-900N-HT), with long service life

and fast heating up.

·The solder wire feed is controlled by handle or foot switch meet different require-

ment.

·Adopt aviation plug connected reliably.

·Design for anti-static operation with anti-static socket, grounding port, metal

case, etc.

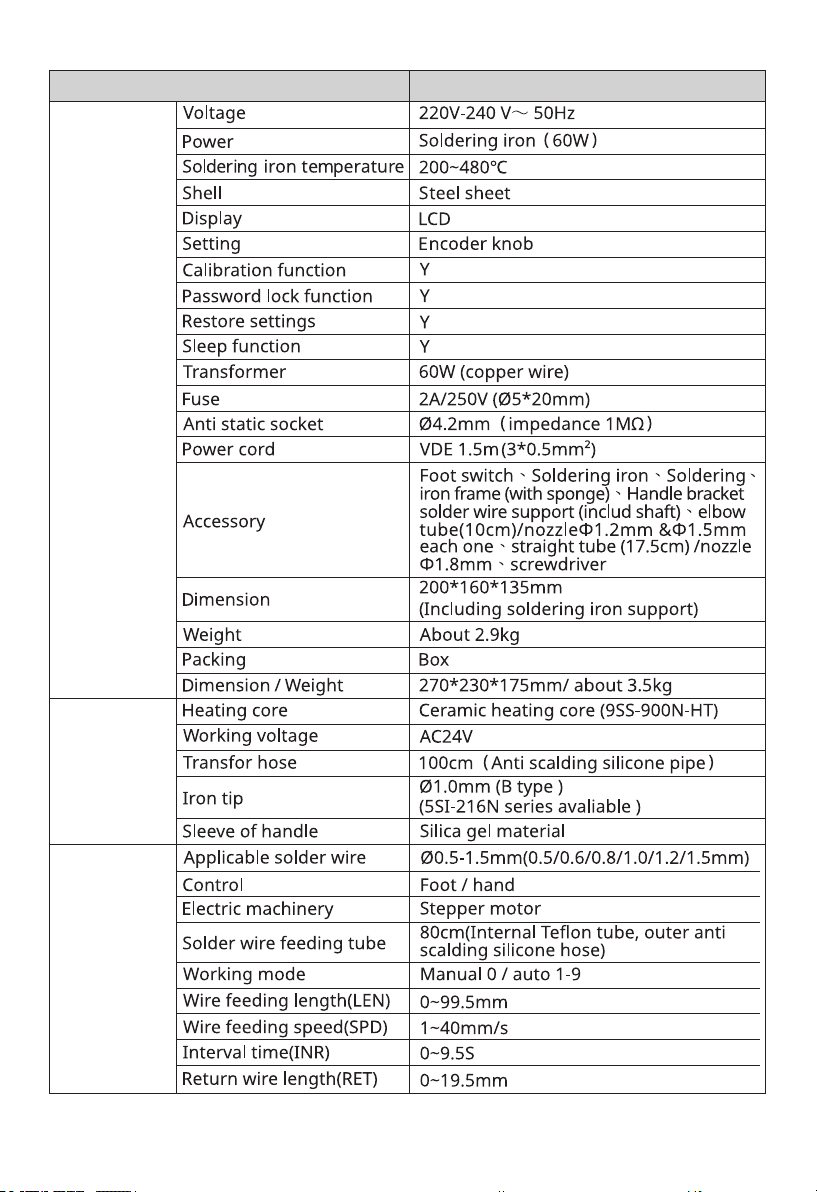

3.1 Specification

Automatic

solder feeder

Model SS-955B

Soldering iron

Solder wire

feed

※Any change without notice, please subject to the actual product.

※It is recommend not to set temperature than 450 ℃ for a long time use.

2

3.2 Soldering iron tips

Soldering iron :5SS-955-SI

Soldering iron heating core :9SS-900N-HT

Foot switch :5SS-955-TS

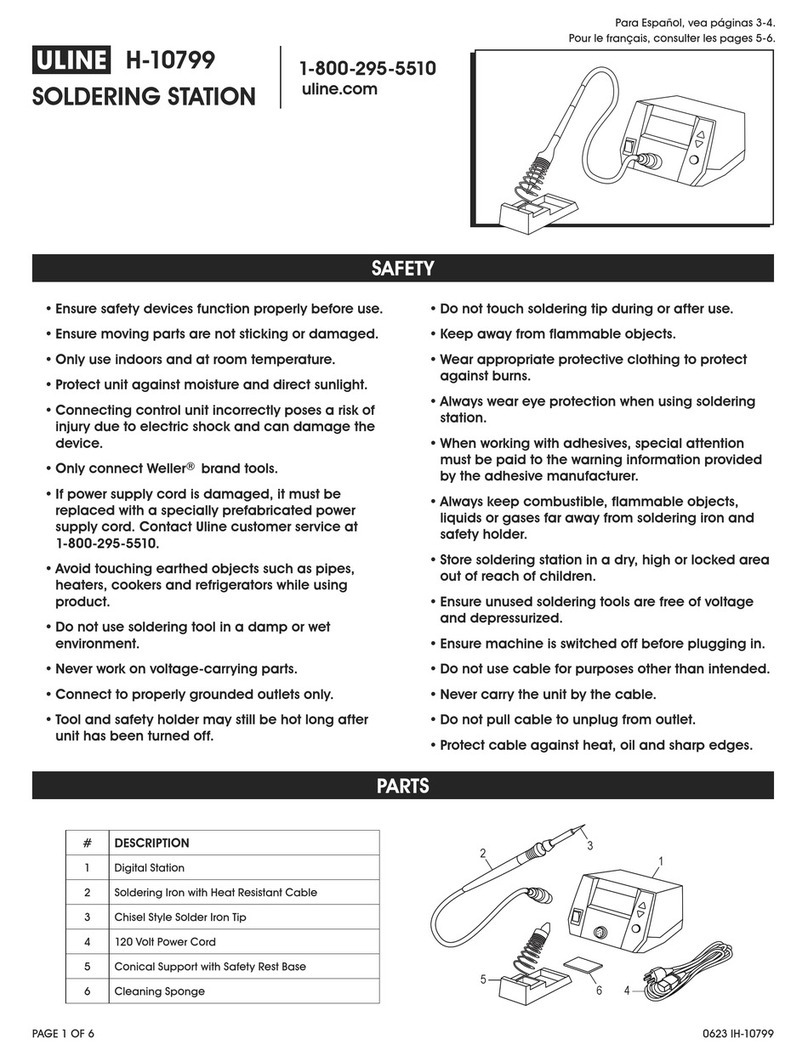

4.Packing list

5.Instructions

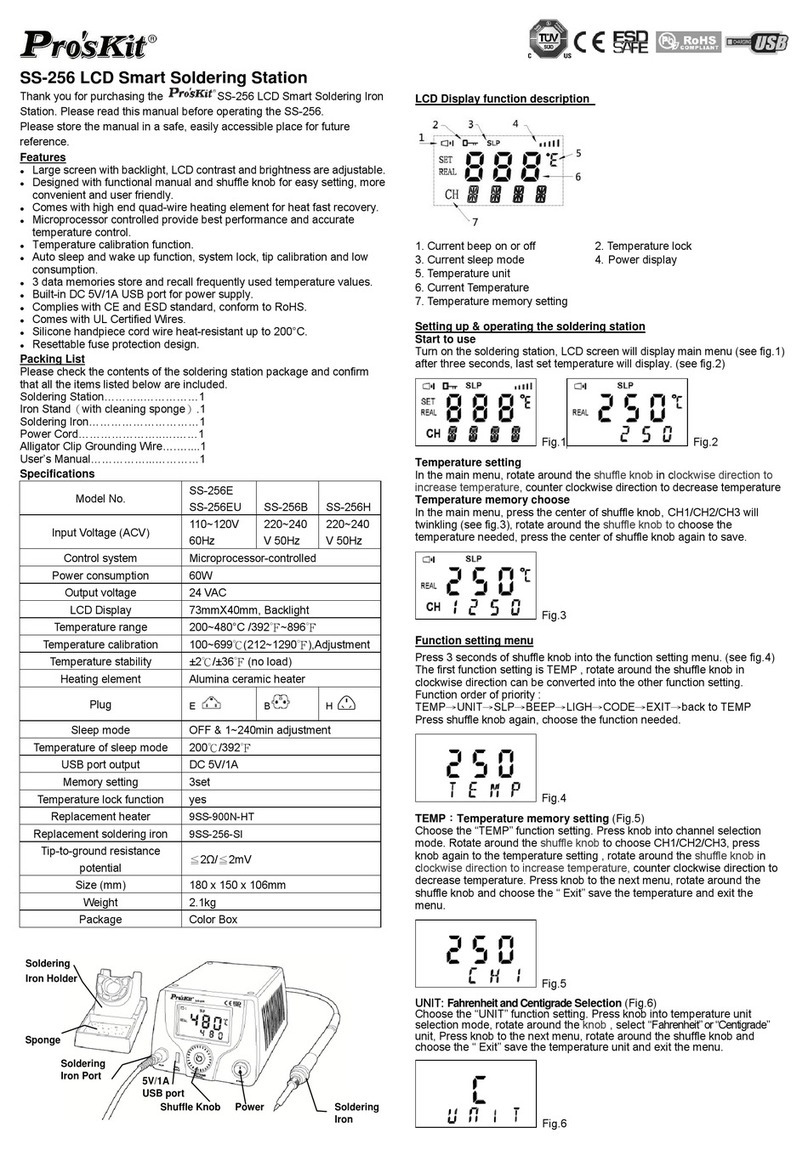

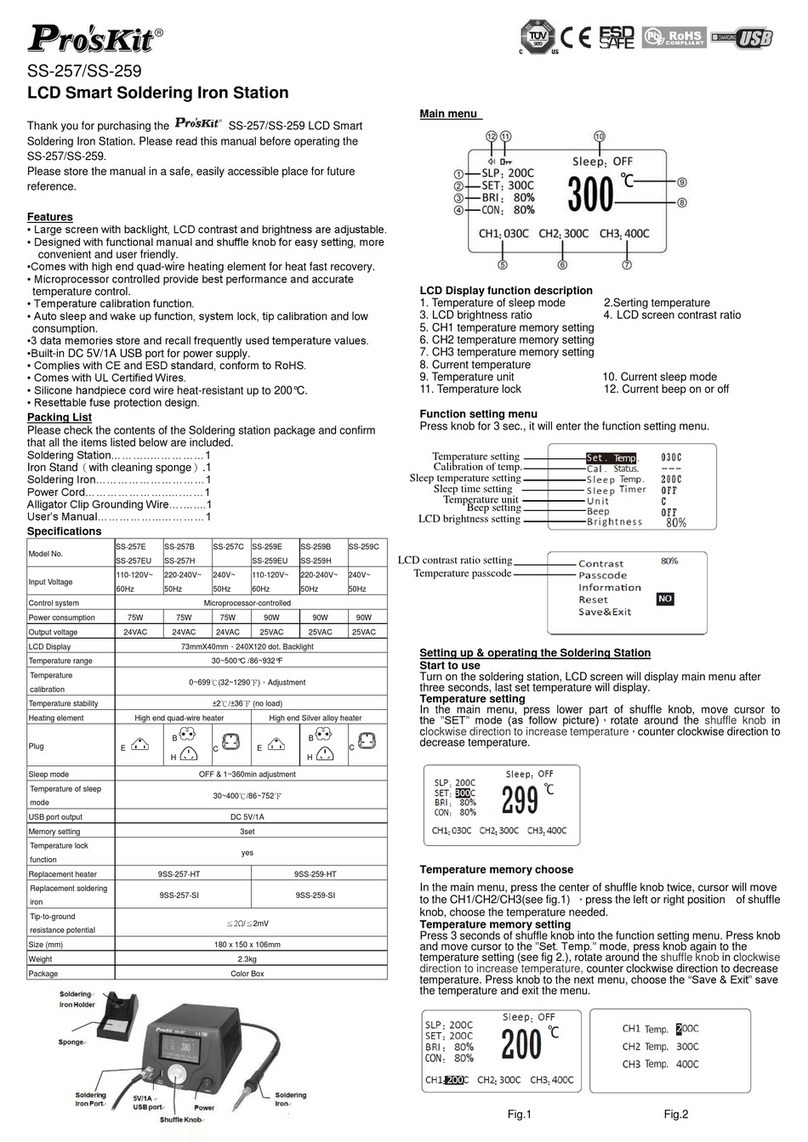

5.1 Function and display content

Function setting

1. Language setting

2. Temperature unit setting

3. Password setting

4. Calibration function

5. Restore settings

6. Sleep time setting

Parameter settings

1. Working mode setting

2. Temperature setting

3. Wire feeding length setting

4. return wire length Setting

5. Wire feeding interval setting

6. Wire feeding speed settin

3

5.2 Schematic diagram of rear panel

5.2.3 Structrue of feeding

solder wire input port

outlet joint

Bottom case

Motor

drive gear

pressure gear

clutch iron plate

pressure adjusting nut

clutch lever

pressure regulating spring

gap adjusting screw

fixing screw

5.2.4 Structure of soldering iron part

soldering iron

tight nut

handle tube separator

elbow tube

handle fixing clip

bracket

bracket fastener

transfer hose

hose connector

nozzle

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

4

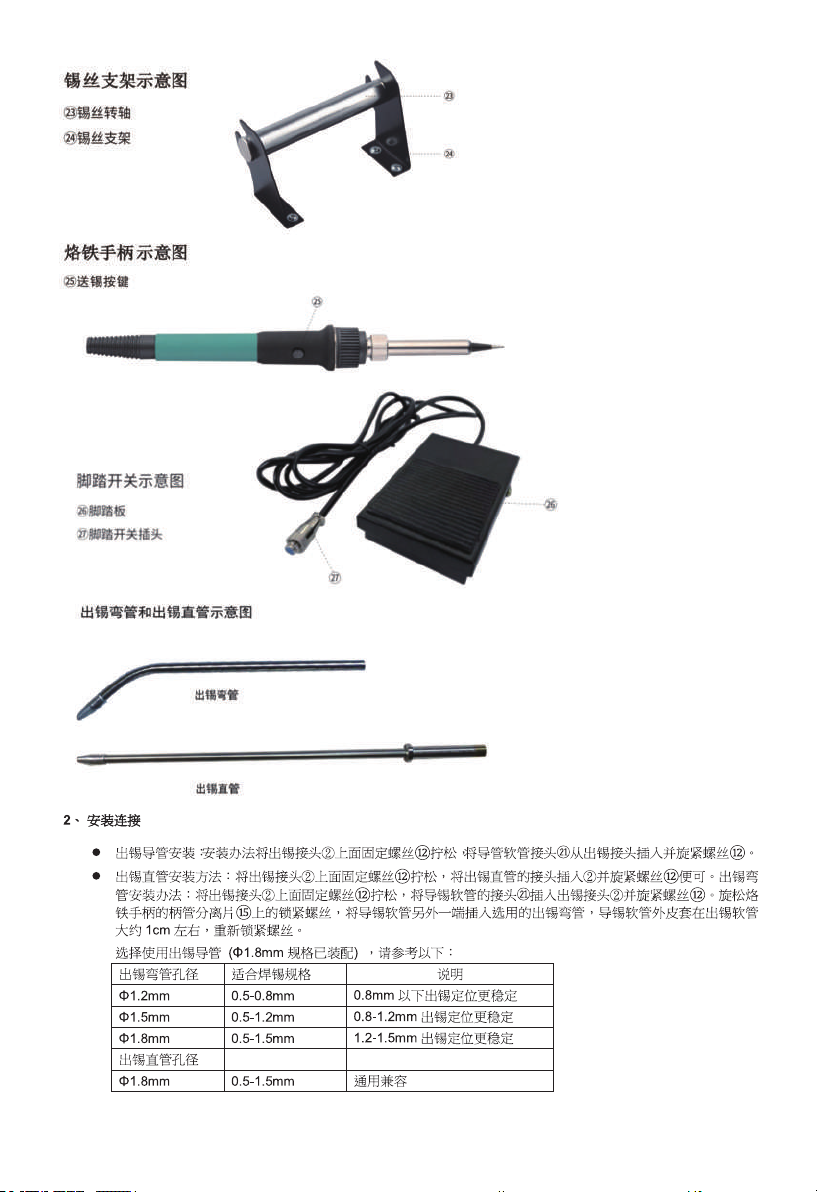

5.2.5 Solder wire support

shaft

metal support

5.2.6 Soldering iron

button for solder wire feeding

5.2.7 Foot switch

foot pedal

foot switch plug

5.2.8 elbow and straight tube

25

23

24

25

26

27

5.3 Install and connection

5.3.1 Straight tube install: loosen the fixing screw on the outlet joint , insert the

straight tube to the outlet joint and tighten the screw .

5.3.2 Elbow tube install: loosen the fixing screw on the outlet joint , insert the

hose connector into the outlet joint and tighten the screw . Loosen the

locking screw on the handle tube separator of the soldering iron, insert the

other end of the hose into the elbow tube, cover the outer skin about 1 cm around the

hose, and relock the screw.

212

15

21

2 12

12 2

212

5

Nozzle of the tube(Φ 1.8mm assembled), refer to the following:

corresponding solder wire

0.5-0.8mm

0.5-1.2mm

0.5-1.5mm

0.5-1.5mm

nozzle of elbow tube

Φ1.2mm

Φ1.5mm

Φ1.8mm

nozzle of straight tube

Φ1.8mm

5.3.3 adjustment of the solder wire and the soldering tip position: rotate the handle

tube separator to change the combined position of the nozzle and the tip, loosen

the locking screw of the elbow tube, and pull the tube to change the length of its

extension.

5.3.4 Foot switch install: insert the foot switch plug into the SW jack on the back

of the machine.

5.3.5 Solder wire install:

A、Thread the shaft into the solder wire , then put on the support .

B、Pull out the solder wire and thread it through the solder wire input port at

the back of the upper cover, push the clutch lever to increase the gap between the

two gears and to make the solder wire penetrate into the outlet joint, adjust the

gap adjusting screw and the pressure adjusting nut , the solder wire between

the drive gear and the pressure gear can be well fixed by the gear without slipping,

and the solder wire is not deformed due to too much extrusion.

C、Loosen the fixing screw of the outlet joint,pull off the hose connector ,

Insert the solder wire pass through the outlet joint into the hose connector , fasten-

ing the fixing screw .

D、Connect the power plug on the back of the machine to the power correctly, turn

on the power switch, straighten the transfer hose as possible, and press the switch

of the foot switch or handle button until the solder wire is sent to the nozzle.

5.3.6 bracket installation: loosen the bracket fastener on the machine, install the

bracket into the bracket seat hole, tighten the tight nut to fix it.

5.3.7 Solder iron installation: loosen the tight nut , remove the handle fixing clip,

, place the handle into the fixing clip, reinstall and tighten the tight nut , insert

the soldering iron aviation plug into the SOLDER socket on the back of the machine,

and lock the screws.

5.3.8 Soldering iron position adjustment: the bracket fastener

can adjust the

height of the handle, and the angle up or down (not too large to prevent the passage

of the solder wire, keep the solder wire in the appropriate position).

Note:

15 22

27

23 24

1

5 6

9

11 8

12

2

21

12

21

25 26

19

14

17 14

19

When unscrewing the handle tube separator, be more careful not to damage the heating

core; If the foot switch is pressed and the solder wire cannot be sent out automatically,

adjust the pressure adjusting nut ; The outlet joint shall not be excessively bent or forcibly

twisted to prevent the solder wire from blocking; If the soldering iron is installed, it will be

heated when the power switch is turned on (the display screen will be on). Please pay

attention to avoid scalding during installation.

8

26

6

5.3.9 operation mode: two operation modes can be selected as required, elbow

mode and straight mode.

(elbow mode) (Straight mode)

• Use of ESD socket for anti-static

This port provides the connection of anti-static working pad, wrist strap and other

similar devices.

• Use of Grounding port

1. This port provides a connection to a ground point.

2. Pay attention to the connection of power supply and grounding to ensure it is

reliable.

5.4 Operating instructions

5.4.1 Language and temperature unit setting:

Turn on the power, long press the panel knob to enter the function setting menu

first, rotate the encoder’s knob (here in after the knob). When the LCD interface

appears on the display screen, select the "ENG" language and press the knob

again to confirm.

Rotate the knob, and when the arrow indicator goes to the next column, it

indicates to "℃ / ℉", select the required temperature unit, and press the knob

again to confirm.

简 繁ENG

℃ ℉

简 繁ENG

℃ ℉

5.4.2 Working parameter setting:

Rotate the knob, and "TOOL " flashes on the right side of the second column (the

"TEMP" is displayed on the left), or "FEED" (related to wire feeding), indicating that

the working parameter setting state is entered. At this time, continue to rotate the

knob to set the data, and press the knob to enter the corresponding parameter.

On any parameter page, press the knob to directly enter the temperature setting

before entering the setting state。

1) Temperature setting: when "TEMP" is displayed in the second column on the left

of the display screen, press the knob to enter the temperature setting state, rotate

the knob to set the required temperature, adjustment range is 200 ~ 480 ℃, and

press the knob to save the setting.

7

XXX℃

TEMP XXX℃

XXX℃

SET XXX℃ TOOL

2) Feeding length: rotate the knob, when "LEN" is displayed in the second column

_ on the left, press the knob to set the feeding length, the adjustment range is

_0 ~ 99.5mm, and press the knob to save the setting;

3) Return length: rotate the knob, when "RET" is displayed in the second column

_ on the left, press the knob to set the return length, the adjustment range is

_ 0 ~ 19.5mm, and press the knob to save the setting;

4) Interval time: rotate the knob, and when the "INR" is displayed in the second

_ column on the left, press the knob to set the interval time, the adjustment range

_is 0 ~ 9.5s, and press the knob to save the setting;

5) Feeding speed: rotate the knob, when the "SPD" is displayed in the second

_ on the left, press the knob to set the output speed, with the adjustment range

_ of 1 ~ 40mm / s, and press the knob to save the setting;

6) Working mode: rotate the knob. When the "MODE" is displayed in the second

_ column on the left, press the knob to enter the working mode. The adjustment

_range is 0 ~ 9. Press the knob to save the setting;

• "0" is the manual working mode. The feeding time is manually controlled by

the foot switch or by the handle button.

• "1-9" is the automatic working mode. Just press the foot switch or handle

button to automatically complete the feeding according to the set length. When

the number is "1", it completes one automatic control cycle, and when the

number is set to "2", it completes two control cycles. The pause between cycles

is determined by setting the "interval time" parameter.

• set "1" and the feeding length is set "0", once working it will continues till the

foot switch or handle button press again to stop.

• The temperature set less than 200℃, the soldering iron will be closed , solder

wire feeding function can be use seperatly.

---℃

TEMP ---℃ 米 ━

5.4.3 Password setting:

Long press the knob and turn it to "PASSWORD". Press the knob to enter the pass-

word setting. only when “1 PWD” and “2 PWD” are the same number you can save

the setting parameters and exit after "LOCKED!" displayed. If the number input are

different, "FAIL!" will displayed.

PASSWORD

CALIB

PASSWORD 1PWD xxx

2PWD xxx

The LCD display show a symbol of “ ”under the Password Setting Mode, you can’t

set parameters and there will be “ENTER THE PWD!” required, enter the Password

setting and input the password to unlock, the symbol of “ ” disappeared and then

you can set parameters。

When “1PWD” input "0" and “2PWD” input "0", press the knob can clear the pass-

word set before. once you forget password, you can input number "166" to unlock.

8

2) Feeding length: rotate the knob, when "LEN" is displayed in the second column

_ on the left, press the knob to set the feeding length, the adjustment range is

_0 ~ 99.5mm, and press the knob to save the setting;

3) Return length: rotate the knob, when "RET" is displayed in the second column

_ on the left, press the knob to set the return length, the adjustment range is

_ 0 ~ 19.5mm, and press the knob to save the setting;

4) Interval time: rotate the knob, and when the "INR" is displayed in the second

_ column on the left, press the knob to set the interval time, the adjustment range

_is 0 ~ 9.5s, and press the knob to save the setting;

5) Feeding speed: rotate the knob, when the "SPD" is displayed in the second

_ on the left, press the knob to set the output speed, with the adjustment range

_ of 1 ~ 40mm / s, and press the knob to save the setting;

6) Working mode: rotate the knob. When the "MODE" is displayed in the second

_ column on the left, press the knob to enter the working mode. The adjustment

_range is 0 ~ 9. Press the knob to save the setting;

5.4.4 Temperature calibration:

First to measure the temperature of the soldering iron and record the reading

used by temperature tester. then long press the knob to enter the parameter

setting, select the "CALIB", at SET position input the data which setting tempera-

ture, and CAL position input the data which test value(reading), and click the knob

to save the setting and exit. (temperature calibration set 2 points,one higher than

350℃,another one lower than 350℃ which can obtain the linearity of a wide

temperature range).

PASSWORD

CALIB

CALIB SET xxx

CAL xxx

5.4.5 Restore settings:

Long press the knob and rotated to "RESTORE DEFAULT", press the knob again and

the parameters setting will automatically return to the initial state.

RESTORE DEFAULT

SLEEP TIME

RESTORE OK!

5.4.6 Sleep time setting:

Long press the knob and rotate to "SLEEP TIME". Press the knob to enter the sleep

setting, set turn off the sleep mode or sleep time from 1-240min according to

needs ; no operation (foot pedal, handle button) for a long time arrived sleep time

setting, the "SLEEPING" will be displayed on the LCD, the tip temperature is down

to 200℃. turn the knob, touch foot switch or handle button can wake up directly,

and the soldering iron will return to the working set quickly.

RESTORE DEFAULT

SLEEP TIME

SLEEP TIME

XXX MIN

Note:

It will not remember and exit automatically while no operations for 5 seconds of the knob.

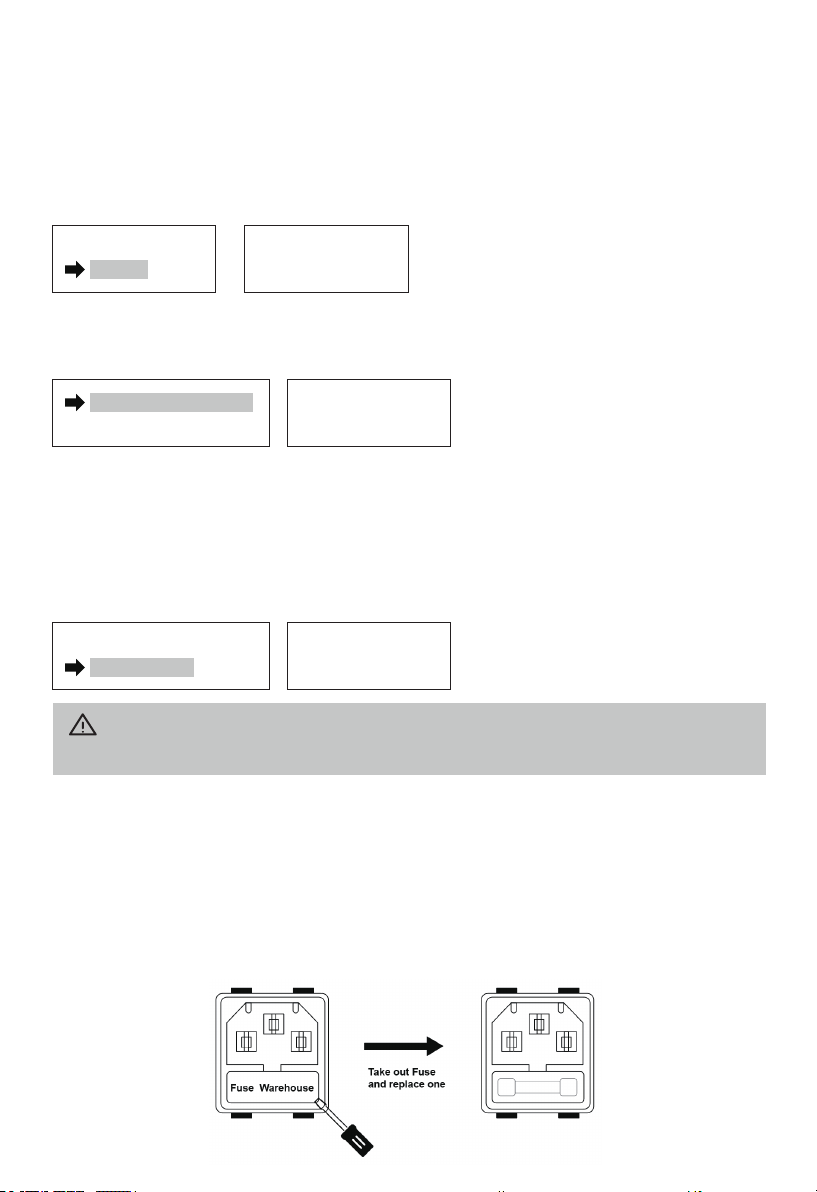

5.5 Fuse replacement

When fuse is blown, replace it with the same type of fuse(refer to the picture below).

1) Unplug the power cord from the power receptacle.

2) The fuse holder is located under the AC power receptacle. Use a slotted (–)

_screwdriver to open the fuse holder.

3) Replace the fuse with a new one (Φ 5*20mm 2A).

4) Put the fuse holder back in place.

9

Turn off the power and remove the power cord before maintenance, otherwise electric

shock may occur.

1) Unplug the power cord from the power receptacle.

2) The fuse holder is located under the AC power receptacle. Use a slotted (–)

_screwdriver to open the fuse holder.

3) Replace the fuse with a new one (Φ 5*20mm 2A).

4) Put the fuse holder back in place.

5.6 Troubleshooting

Causes SolutionFaults

Not work

Fuse blown

Power not connected

reliably

Replace the fuse (2A/250V)

Check the power connection

and plug it in

Shows“H-E”

“S-E”on display

Loose connection

The heating core is burned

or the assembly wire is

damaged

Reconnect the soldering iron

plug or replace the heating core

Reference the heating core

connection circuit

LCD display

confusion Chip failure Return to dealer

Unable to set

temperature Password set Enter password or clear it

Temperature

deviation of

soldering iron tip

Poor temperature

calibration Recalibration

Feeding failure

Chip or motor failure

Transfer hose is blocked

or deformed

Return to dealer

Rearrange the hose and

dredge it

Button switch failure

Foot switch failure

Replace switch component or

soldering iron

Replace the Foot switch

Soldering iron tip oxidized

The temperature of

soldering iron was set

too high

Clean or replace tips

Set temperature no more than

450℃ for long use.

The soldering

iron tip can not

adhere with tin

warning

Please contact the dealer beyond the above faults.

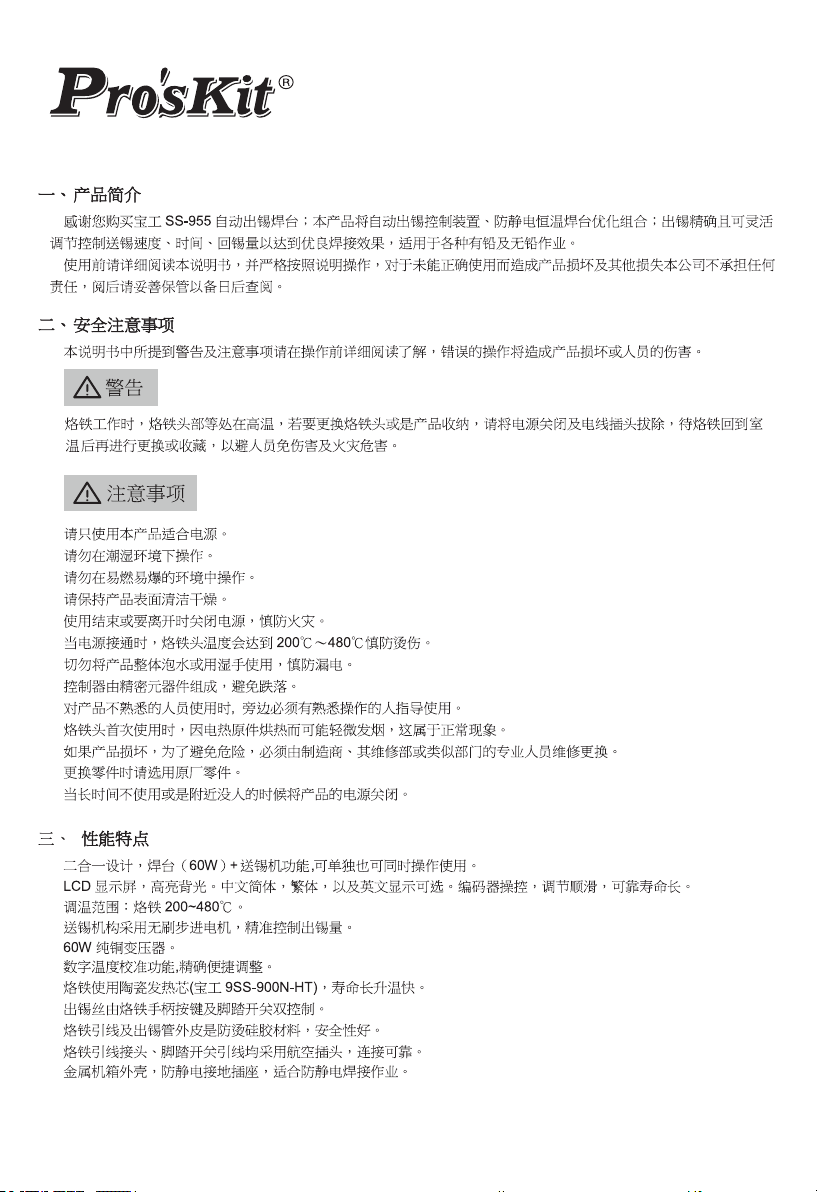

6. How to inspection the soldering iron

4~5 ( Heater ) ≈4Ω

1~2 ( Temperature sensor ) ≈50Ω

1~6 ( feeding switch ) ON

3~soldering iron tip( Earthing) <2Ω

Check the resistance between the pins of the connecting plug as follows:

10

1) The resistance value between the plug pins is different from the resistance

value in the table, disassembly the soldering iron to confirm whether the resis-

tance value of the PCB is correct.

2) The measured resistance value on PCB is correct, indicate that the soldering

iron wire is damaged, refer diagram to check the wire connect situation as below.

3) The resistance between the 3 pin of the plug and the soldering iron tip is greater

than the table value, wipe the point of junction where oxidized with sandpaper.

11

12

13

14

15

16

17

注意

18

19

Table of contents

Other Pro's Kit Soldering Gun manuals

Pro's Kit

Pro's Kit SS-968 User manual

Pro's Kit

Pro's Kit SN-396 User manual

Pro's Kit

Pro's Kit SS-979B User manual

Pro's Kit

Pro's Kit SS-257 User manual

Pro's Kit

Pro's Kit SS-256 User manual

Pro's Kit

Pro's Kit SS-257 User manual

Pro's Kit

Pro's Kit SS-256E User manual

Pro's Kit

Pro's Kit SS-331B User manual

Pro's Kit

Pro's Kit SS-331 User manual

Pro's Kit

Pro's Kit SS-956 User manual