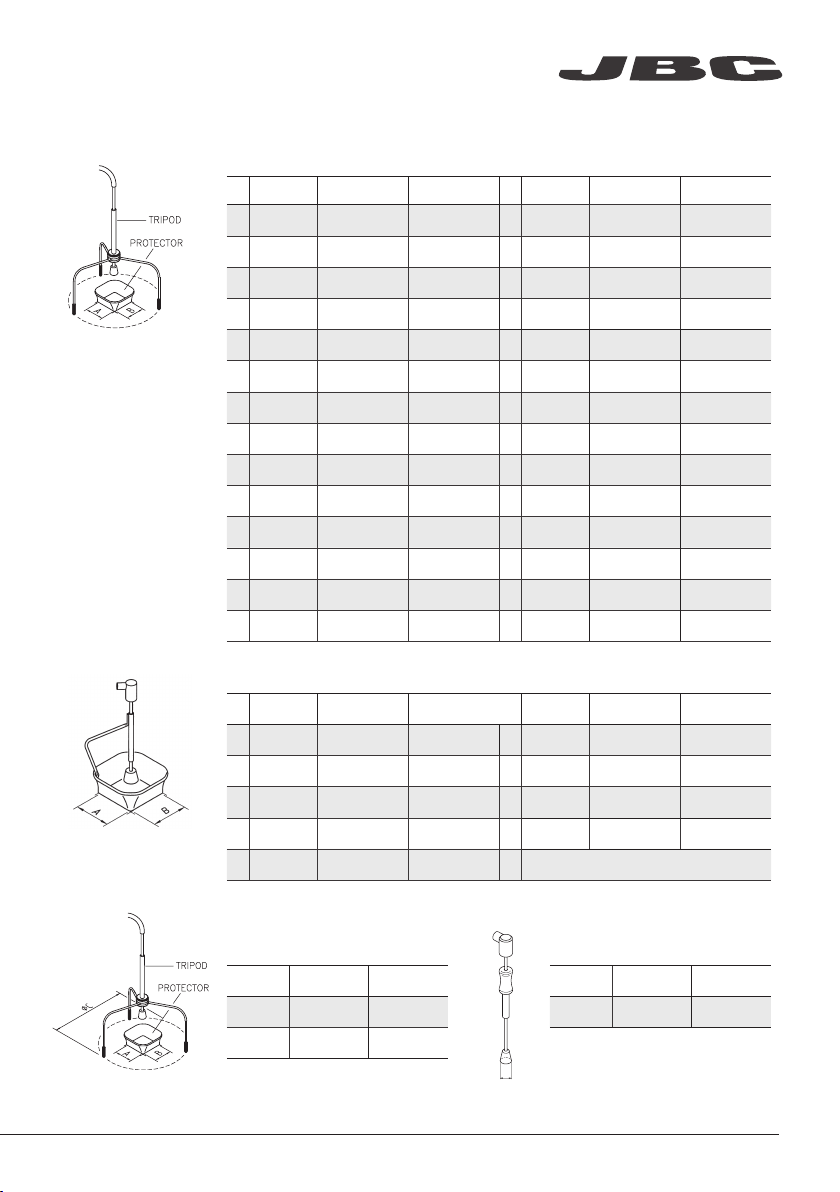

Protectors

*Ref. AxB (mm)AxB (in) *Ref. AxB (mm)AxB (in)

P3353 4,3 x 3 0.16 x 0.12 P1249 12 x 23 0.47 x 0.9

P3786 5,2 x 5,2 0.20 x 0.20 44 P4000 12,5 x 12,5 0.49 x 0.49

P3352 5,2 x 7,5 0.20 x 0.29 P3354 13,2 x 13,2 0.52 x 0.52

P3355 5,2 x 9,5 0.20 x 0.37 P4025 13,5 x 21,5 0.53 x 0.85

P3356 6,2 x 4,2 0.24 x 0.16 48 P2230 15 x 15 0.59 x 0.59

P3785 7, 2 x 7, 2 0.28 x 0.28 60 P4010 17 x 17 0.67 x 0.67

P3784 8,2 x 8,2 0.32 x 0.32 P4005 18 x 29 0.71 x 1.14

P4035 9 x 13 0.35 x 0.51 P4030 18,5 x 18,5 0.73 x 0.73

P4040 9,5 x 19 0.7 x 0 .74 P1068 18,5 x 24 0.73 x 0.94

P4080 9,5 x 21 9.5 x 0.83 P2685 28,5 x 28,5 1.12 x 1.12

32 P2220 10 x 10 0.39 x 0.39 P4085 31,5 x 31,5 1.24 x 1.24

P4045 10,5 x 21 0.14 x 0.82 P2672 33 x 46 1.30 x 1.18

P4090 11 x 16 0.43 x 0.63 P4002 50 x 50 1.97 x 1.97

24 P2235 12 x 17 0.47 x 0.67 P3357 52,5 x 14 2.06 x 0.55

øD

* Reference Desk

Tripods

Ref. øC (mm) øC (in)

T2050 39 1.53

T2250 85 3.35

Manual extractor

Ref. øD (mm) øD (in)

E2190 70.27

Extractors

*Ref. AxB (mm) AxB (in) * Ref. AxB (mm) AxB (in)

52 E2052 20 X 20 0.79 x 0.79 E4015 31,5 X 31,5 1.24 x 1.24

64 E2064 20 X 26 0.79 x 1.02 E2084 33 X 33 1.30 x 1.30

80 E2184 24 X 24 0.94 x 0.94 E2100 38 X 38 1.50 x 1.50

E2068 27 X 27 1.0 6 x 1.06 E2124 45 X 45 1.77 x 1.77

E4020 28,5 X 28,5 1.12 x 1.12

Accessories

www.jbctools.com

9