PRE / POST-ASSEMBLY CHECKLIST

The following checklist will help ensure proper installation techniques for the PF2200 Burner Management Sys-

tem, fuel train components, and burner components. This checklist should be consulted before and after install-

ation, to ensure requirements are met for the installation of the system.

1. Ensure that the BMS is mounted in a safe area for operation. Look for tripping, high heat exposure, and

other potential hazards.

2. Conduct pull tests on terminating wires in the BMS to ensure proper installation.

3. Install tags identifying that electrical seals have not been poured on electrical connectors entering the

PROFIRE BMS.

4. Ensure the Type K temperature inputs wire is used. (Yellow = positive and red = negative).

5. Point to point wiring is a must with temperature inputs wires (no cold junctions). A cold junction can cause

inaccurate temperature readings and therefore, poor temperature performance.

6. Do not hook up shield wires; this should be done in the field if necessary. It is common to terminate the

shield wires to earth ground or ground grid of each vessel skid; however, this can only be done upon field

installation. The temperature inputs are shipped loose and installed on location in the vessel. The wiring

is completed at that time.

7. For flame detection to work correctly, the flame must be in physical contact with both the flame detection

rod and the grounded pilot nozzle. This allows a current path from the flame detection rod through the

flame to ground. When nozzle velocity is high, the flame may not make contact with the nozzle. This situ-

ation is referred to as "poor flame anchoring." To resolve poor flame anchoring, add a second grounded

Kanthal rod can be placed further in front of the nozzle so that it catches the flame.

COMMISSIONING

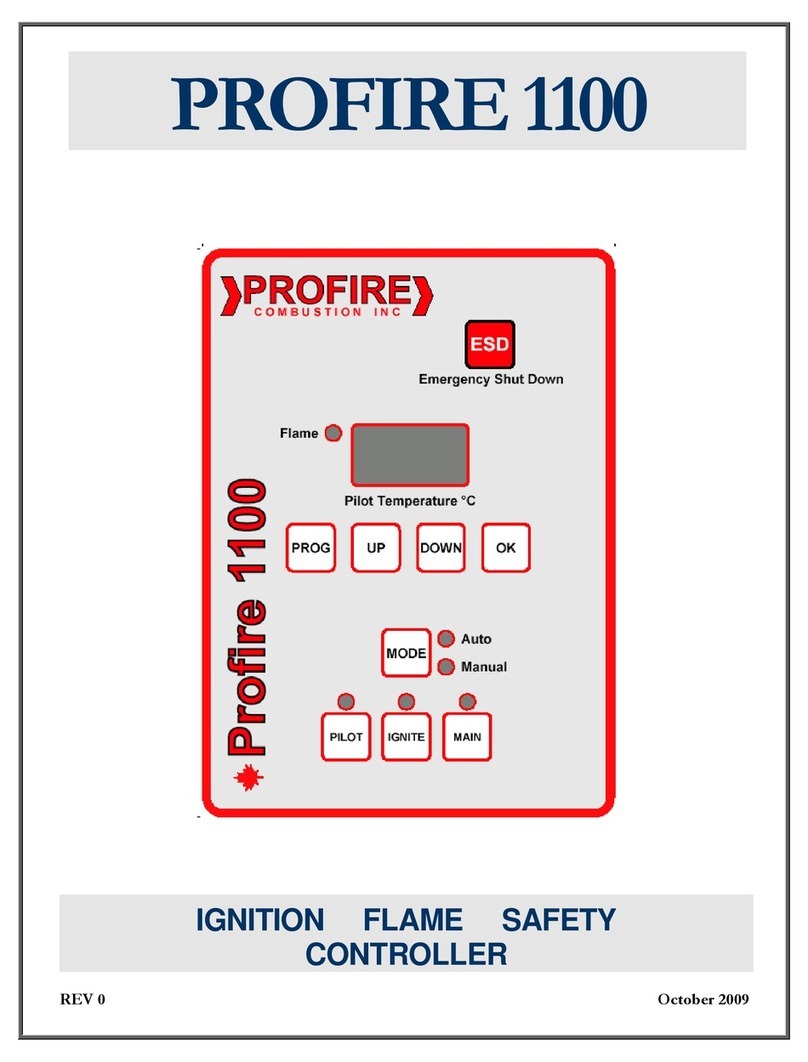

STARTING/STOPPING

Starting, and stopping the burner can be done by selecting the Start, or Stop button on the

PF2200. The system prompts for an acknowledgment of this action. Press the OK button to

continue with the safe start-up or shutdown of the burner. When shutting down the burner,

press the Stop button. The system prompts the user to confirm the shutdown, press OK.

When the shutdown process is complete, the system will prompt for an acknowledgment

that the shutdown is complete. Press OK to acknowledge the shutdown.

With the optional manual Start/Stop switch, startups and shutdowns of the burner are

achieved. This switch has three functional positions, as shown. When in the Stop position

the burner is shut down and de-energizes the system. Moving the switch from the run pos-

ition to the Ignite position, and holding the switch in the Ignite position for more than 2

seconds, starts the ignition sequence, and return to the Run position. By moving the switch

from Stop to Run positions, you can clear a lock state.

The optional Manual Switch (part# PFA-004260 ) mentioned above can be ordered by contacting Profire Energy.