ProFlow PF-OXY1 User manual

© 2016erie watertreatment TM-EN-PF-OXY-Rev2016.08

Technical Manual

WATER FILTER - Fe, Mn, H2S

Models:

PF-OXY1

PF-OXY+1

PF-OXY1,5

PF-OXY+1,5

TABLE OF CONTENT & INSTALLATION RECORD

Page 2

Table of content & Installation record..................................................................................Page 2

Warning & Safety instructions..............................................................................................Page 3

Operating conditions & Requirements.................................................................................Page 4

Assembly..............................................................................................................................Page 6

Installation...........................................................................................................................Page 8

Commissioning.....................................................................................................................Page 9

Electronic control panel.......................................................................................................Page 10

Maintenance........................................................................................................................Page 13

Troubleshooting...................................................................................................................Page 14

Electrical wiring diagrams ....................................................................................................Page 16

Default configuration parametersettings.............................................................................Page 17

Composition overview .........................................................................................................Page 18

Exploded view - PF-OXY1 & PF-OXY+1 - System ....................................................................Page 20

Exploded view - PF-OXY1 & PF-OXY+1 - Timer assembly.......................................................Page 22

Exploded view - PF-OXY1 & PF-OXY+1 - Valve body...............................................................Page 24

Exploded view - PF-OXY1,5 & PF-OXY+1,5 -System...............................................................Page 26

Exploded view - PF-OXY1,5 & PF-OXY+1,5 - Timer assembly..................................................Page 28

Exploded view - PF-OXY1,5 & PF-OXY+1,5 - Valve body.........................................................Page 30

Exploded view - PF-OXY1,5 & PF-OXY+1,5 - Piston assembly.................................................Page 32

Technical data - PF-OXY1 & PF-OXY+1...................................................................................Page 33

Technical data - PF-OXY1,5 & PF-OXY+1,5.............................................................................Page 34

WARNING & SAFETY INSTRUCTIONS

Page 3

Before you begin the installation of the appliance, we advise you read

andcarefully follow the instructions contained in this manual. It contains

importantinformationaboutsafety,installation,useandmaintenanceof

the product. The actual system that you have received, may differ from

the pictures/illustrations/descriptions in these Instructions.

Failure to follow the instructions could cause personal injury or damage

to the appliance or property. Only when installed, commissioned and

servicedcorrectly,theappliancewilloffer you manyyears oftrouble-free

operation.

The appliance is intended to ‘filter’ the water, meaning it will remove

specific undesired substances; it will not necessarily remove other

contaminants present in the water. The appliance will not purify polluted

water or make it safe to drink!

Installation of the appliance should only be undertaken by a competent

person, aware of the local codes in force. All plumbing and electrical

connections must be done in accordance with local codes.

Before setting up the appliance, make sure to check it for any externally

visible damage; do not install or use when damaged.

Use a hand truck to transport the appliance. To prevent accident or

injury, do not hoist the appliance over your shoulder. Do not lay the

appliance on its side.

Keep these Instructions in a safe place and ensure that new users are

familiar with the content.

The appliance is designed and manufactured in accordance with current

safety requirements and regulations. Incorrect repairs can result in

unforeseen danger for the user, for which the manufacturer cannot be

held responsible. Therefore repairs should only be undertaken by a

competent technician, familiar and trained for this product.

In respect of the environment, this appliance should be disposed of in

accordance with Waste Electrical and Electronic Equipment

requirements.Refertonational/locallawsandcodesforcorrectrecycling

of this appliance.

OPERATING CONDITIONS & REQUIREMENTS

Page 4

APPLICATION LIMITATIONS PF-OXY:

pH: for Iron removal: 6,8 - 9,0

for Manganese removal: 8,0 - 9,0

for Iron & Manganese removal: 8,0 - 8,5

maximum contaminant content:

Iron (Fe2+) 15 mg/L

Manganese (Mn2+) 2 mg/L

Hydrogen Sulfide (H2S) 5 mg/L

organic matter: max. 4,0 mg/L; higher level may hinder the correct operation of

the system.

chlorine: max. 1,0 mg/L

iron bacteria: if iron bacteria are present, frequent service may be necessary,

while the life of the system may be limited; by properly controlling the iron

bacteria with chlorine or another approved method of bacterial reduction, the

system will function properly.

APPLICATION LIMITATIONS PF-OXY+:

pH: 5,8 - 10,5

maximum contaminant content:

Iron (Fe2+) 70 mg/L

Manganese (Mn2+) 35 mg/L

Hydrogen Sulfide (H2S) 15 mg/L

organic matter: water should be free from organic matter.

iron bacteria: if iron bacteria are present, frequent service may be necessary,

while the life of the system may be limited; by properly controlling the iron

bacteria with chlorine or another approved method of bacterial reduction, the

system will function properly.

OPERATING PRESSURE MIN-MAX: 2,5-8,0 bar / 36-116 psi

low operating pressure may lead to insufficient backwash of the filter media,

resulting in an increase in pressure drop and/or a reduction of the filtration

capacity during the service cycle.

if installed on a well, verify that the well pump is powerful enough to provide

sufficient flow rate for the backwash cycle.

check water pressure regularly.

takeintoaccountthatnighttimewaterpressuremaybeconsiderablyhigherthan

day time water pressure.

install a pressure reducer ahead of the appliance if necessary.

OPERATING TEMPERATURE MIN-MAX: 4-48 °C / 39-120 °F

donot installthe applianceinanenvironment wherehighambienttemperatures

(e.g. unvented boiler house) or freezing temperatures can occur.

the appliance cannot be exposed to outdoorelements,such as direct sunlight or

atmospheric precipitation.

do not install the appliance too close to a water heater; keep at least 3 m (10 ft)

of piping between the outlet of the appliance and the inlet of the water heater;

OPERATING CONDITIONS & REQUIREMENTS

Page 5

water heaters can sometimes transmit heat back down the cold pipe into the

appliance; always install a check valve at the outlet of the appliance.

ELECTRICAL CONNECTION:

this appliance only works on 24 VAC; always use it in combination with the

supplied transformer.

in case of damage to the power supply cable of the transformer, immediately

disconnectthe transformer fromthe power outlet and replace the transformer.

make sure to plug the transformer into a power outlet, which is installed in a dry

location, with the proper rating and over-current protection.

ASSEMBLY

Page 6

CONTENT CHECK

Actualpartsthatyouhave received,maydifferfromthe

pictures/illustrations in these Instructions!

Only on systems with ≥3 cuft of filter media: for ease of

transportation and installation, the filter media is NOT

loaded in the pressure tank, but delivered in separate bags

of 1 cuft; it must be loaded on-site, after positioning of the

pressuretank.

Check the content of the system, using the Composition

Overview in these Instructions. Identify and lay-out the

different components to facilitate the assembly.

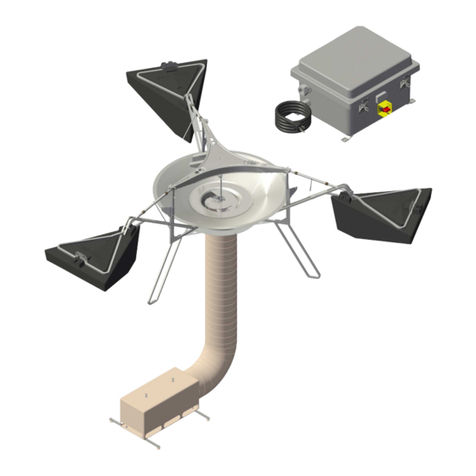

SIMPLEX

Picture 1.a, 2.a, 3.a

A Simplex system consists of 1 single filter module (pressure

tank, filter media, control valve).

Duringnormaloperation,the system deliverstreatedwater.

As soon as it initiates a regeneration, it automatically goes

into bypass, guaranteeing uninterrupted supply of untreated

water.

It ispossibletoinstall aso calledNormallyOpenService Valve

(e.g.asolenoidoperateddiaphragmvalve)intheoutletofthe

system, that is controlled by the electronic timer of the

system; this Service Valve will be activated during the entire

duration of the regeneration, to close-off the control valve's

standard 'untreated water bypass during regeneration'.

MULTIPLEX PARALLEL

Picture 4

A Multiplex PARALLEL system consists of 2 or more Simplex

systems, that:

-are hydraulically installedin parallel;

-are programmed for different times of regeneration;

-may have aso called Normally Open Service Valve (e.g. a

solenoid operated diaphragm valve) in the outlet of each

Simplex system, that is controlled by the electronic timer

of each Simplex system; this Service Valve will be

activated during the entire duration of the regeneration,

to close-off thecontrolvalve's standard 'untreated water

bypass during regeneration'.

During normal operation, all Simplex systemsare in service,

doubling/tripling/… the service flowrate!

In case of a power failure, all Service Valves will be

deactivated, meaningtheoutlet of allSimplexsystemswill be

open, guaranteeing uninterrupted supply of water.

FILTER MEDIA LOADING

1. Move the pressure tank to the correct installation

location; position it on a flat and level surface. Make sure

to leave enough space for ease of service.

2. Position the riser assembly upright and centred in the

pressure tank; plug the top of the riser tube with a piece

of tapeor cleanrag, toprevent filter media fromentering

the tube.

3. Place a funnel on the pressure tank opening and fill the

pressure tank with filter media; make sure the riser

assembly remains centered in the pressure tank.

4. Rinse the pressure tank opening to remove any grains of

filter media from the threaded section.

5. Unplug the top of the riser tube.

CONTROL VALVE

only for PF-OXY1 & PF-OXY+1

1. Make sure the O-ring in the riser insert and the tank O-

ring(aroundthethreadedsectionofthecontrolvalve)are

in the correct position.

2. Screw the top distributor onto the control valve.

3. Lubricate the threaded section of the pressure tank, the

top of the riser tube and the tank O-ring of the control

valve; use a silicon-based lubricant.

4. Lowerthecontrolvalvestraightdownontotherisertube,

until the riser tube is correctly inserted in the riser insert;

then push it down firmly and screw it onto the pressure

tank.

only for PF-OXY1,5 & PF-OXY+1,5

Picture 5

1. On the brass valve seat:

makesuretheO-ringintheriserinsertisinthecorrect

position;

install the top distributor and fix it by means of the 2

stainless steel screws;

install the tank O-ring in the groove on the flange

around the threaded section.

2. Lubricate the threaded section of the pressure tank, the

top oftherisertube andthetank O-ring of the valve seat;

use a silicon-based lubricant.

3. Lower the valve seat straight down onto the riser tube,

until the riser tube is correctly inserted in the riser insert

inside the valve seat; then push it downfirmly and screw

it onto the pressure tank.

4. Install the valve seat O-ring in the groove on the valve

seat.

5. Install the control valve onto the valve seat; mind the

alignment pin!

6. Bolt the control valve tothe valveseat by means of the 4

stainless steel bolts; tighten firmly.

ASSEMBLY

Page 7

AIR INJECTION SYSTEM

only for PF-OXY1 & PF-OXY+1

Picture 6.a

Make sure the air injection system is installed in vertical

position, with the check valve and air intake filter screen

pointing upwards. Rotate it to this position if necessary.

only for PF-OXY1,5 & PF-OXY+1,5

Picture 6.b

1. Install the air injection systemon the control valve;

tighten the nut firmly by hand.

INSTALLATION

Page 8

INLET & OUTLET

We strongly recommend the use of flexible hoses to

connect the appliance to the water distribution system; use

hoses with a large diameter in order to limit the pressure

loss.

We strongly recommend the installation of a bypass

system (not included with this product!) to isolate the

appliance from the water distribution system in case of

repairs.Itallowstoturnoffthewatertotheappliance,while

maintaining full-flow(untreated) water supply to theuser.

To prevent air from escaping from the compressed air

chamber, make sure the inlet line runs vertically upwards

into the water filter. If this is not possible, install a check

valve in the inlet line.

only for PF-OXY1 & PF-OXY+1:

with factory bypass (optional)

Picture 1

= mains water supply (untreated water)

= inlet of control valve(untreated water)

= outlet of control valve (treated water)

= application (treated water)

1. Screw the factory bypass onto the in/out ports on the

control valve (&); make sure to install the gasket

seals. Tighten the nuts firmly by hand.

2. Screw the connection kit with nuts onto the factory

bypass (&); make sure to install the gasket seals.

Tighten the nuts firmly by hand.

3. Connect the mains water supply to the adaptor on the

inlet port of the factory bypass ().

4. Connect the application to the adaptor on the outlet port

of the factory bypass ().

only for PF-OXY1 & PF-OXY+1:

with 3-valveconnection kit (not included)

Picture 2

= inlet of control valve (untreated water)

= outlet of control valve (treated water)

1. Install the 3-valve connection kit.

2. Screw the connection kit with nuts onto the in/out ports

on the control valve (&); make sure to install the

gasket seals. Tighten the nuts firmly by hand.

3. Connect the IN valve of the 3-valve connection kit to the

adaptoron the inport of the control valve().

4. ConnecttheOUTvalveofthe3-valveconnectionkittothe

adaptor on the out port of the control valve ().

5. Connectthemainswatersupplytotheinletofthe3-valve

connection kit.

6. Connect the application to the outlet of the 3-valve

connection kit.

only for PF-OXY1,5 & PF-OXY+1,5:

with 3-valveconnection kit (not incl.)

Picture 3

= inlet of control valve (untreated water)

= outlet of control valve (treated water)

1. Install the 3-valve connection kit.

2. Inserttheadaptorsinthein/outportsonthecontrolvalve

(&); make surenot todamagethe O-rings. Install the

nuts and tighten them firmly by hand.

3. Connect the IN valve of the 3-valve connection kit to the

adaptor on the in port of the control valve ().

4. ConnecttheOUTvalveofthe3-valveconnectionkittothe

adaptor on the out port of the control valve ().

5. Connectthemainswatersupplytotheinletofthe3-valve

connection kit.

6. Connect the application to the outlet of the 3-valve

connection kit.

DRAIN

We recommend the use of a stand pipe with air trap.

To prevent backflow from thesewerage system into the

appliance, always install and use an air gap (included with

PF-OXY1 & PF-OXY1+), to connect the drain hose to the

sewerage system.

Lay-out the drain hose in such a way that pressure loss

is minimized; avoid kinks and unnecessary elevations.

Make sure that the sewerage system is suitable for the

rinse water flow rateof the appliance.

only for PF-OXY1 & PF-OXY+1

Picture 7

1. Install the air gap to the sewerage system; it fits over a

32 mm pipe or inside a 40 mm pipe adaptor. Ensure a

permanent and watertight connection.

2. Connect a 13 mm hose to the drain connection of the

control valve (); secure it by means of a clamp.

3. Run the drain hose to the air gap and connect it to one of

the hose barbs; secure it by means of a clamp. This drain

lineoperatesunderpressure,soitmaybeinstalledhigher

than the appliance.

only for PF-OXY1,5 & PF-OXY+1,5:

Picture 8

1. Connectapipetothe1”BSPMaledrainconnectionofthe

control valve (); use an appropriate sealant.

2. Run the pipe to the sewerage system and connect it,

ensuring sufficient air gap between the end of the pipe

and the sewerage system. This drain line operates under

pressure,soit may beinstalled higher than the appliance.

SERVICE VALVE (optional)

Picture 9

1. Plug the DIN plug on the connection cable of the Service

Valve into the DIN socket at the back of the electronic

timer head of the control valve ().

COMMISSIONING

Page 9

ELECTRICAL

1. Connect the appliances power cord to the transformers

output.

2. Plug the transformer into an electrical outlet.

PRESSURIZING

1. Put the bypass system in 'bypass' position.

2. Make sure the electronic controller of the appliance is in

service mode.

3. Open the mains water supply.

4. Open a cold treated water faucet nearby the appliance

and let the water run for a few minutes until all air is

purged and all foreign material that may have resulted

from the installation is washed out; close the faucet.

5. Gently pressurizethe appliance, byputting it into service:

close the 'BYPASS' valve;

open the 'OUT' valve;

slowly open the 'IN' valve.

6. After 2-3 minutes, open a cold treated water faucet

nearby the appliance and let the water run for a few

minutesuntilallairispurgedfromtheinstallationandthe

filter media is rinsed (it is normal for the rinse water to

show some discoloration!); let the water run until the

rinse water is clear; close the faucet.

7. Check the appliance and all hydraulic connections for

leaks.

During the passage through the compressed air

chamber,the treated water will get highlyoxygenated. As a

consequence it may becomeslightly non-transparent (milky

appearance) when it flows from the tap into a glass. This is

totallyharmlessfor the qualityof thetreated water and will

disappear rapidly if thewater is left standing for a moment!

ELECTRONIC CONTROL PANEL

1. Program the electronic controller.

INITIATE A REGENERATION

We strongly recommend to postpone the execution of

this 'start-up' regeneration by 24 hours. The filter media

needs sufficient time to absorb water and reach its normal

service weight. If the regeneration is performed too soon,

the filter media may be pushed against the top distributor

duringthe backwash cycle, possiblyresulting in loss of filter

mediaor damageto the top distributor.

1. Manually initiate a regeneration, by pressing the scroll

button repeatedly until the display shows:

2. Leave the appliance in this position; the count-down

timer will count down to 0 sec and start a regeneration.

Regen in 10 sec

ELECTRONIC CONTROL PANEL

Page 10

Picture 10

symbol

button

function

SCROLL

to advance to the next

parameter

UP

to increase the value of the

parameter

DOWN

to decrease the value of the

parameter

POWER-UP

After power-up the display will show the installed software

version. After 5 seconds it will automatically revert back to

the service display.

POWER FAILURE

In the event of a power failure, the program will remain

stored in the NOVRAM®duringan undefined period, while an

incorporated SuperCap will maintain the correct time of day

during a period of several hours; consequently, in case of

prolonged power failure, the time of day might not be

maintained; if this happens, the time of day will be reset to

8:00 when the power supply is re-established, while the

indication will flash, indicating that the time of day needs to

be set.

When the power failure occurs during the execution of an

automatic regeneration, the control valve will remain in its

last position; when the power supply is re-established, the

control valve will return to the service position, stay there for

60 sec. and restart a complete regeneration from the

beginning.

TIMER FAILURE

In the event of a timer failure, the display will show the

message:

If powering off/on the appliance doesn’t solve this problem,

professional service is required.

SERVICE MODE

In service mode the display shows the time of day and the

number of days remaining until the next regeneration:

REGENERATION MODE

In regeneration mode the display shows the remaining

regeneration time and the remaining cycle time:

The control valve can be reset to service modeat any timeby

pressing the scroll button, as such manually advancing it

through the regeneration cycles.

MANUAL REGENERATION

It is possible to manually initiate a regeneration.

1. Press the scroll button repeatedly until the display

shows:

If the control valve is left in this position, the count-

down timer will count down to 0 sec and start a

regeneration.

To cancel this mode, press the scrollbuttonbefore

the countdown timer has reached 0 sec; the control

valve will return to the service mode.

2. Press the scroll button again if you want to manually

advance the control valve to the next regeneration cycle.

DRIVE MOTOR SPEED

(only for PF-OXY1 & PF-OXY+1)

The drive motor of the control valve, that drives the valve

body to its different regeneration positions, will start-up at

low speed to reduce its noise level. To increase the speed of

the drive motor, simply press the scroll button as soon as

the drive motoris activated.

Service Required

Regen in 10 sec

8:01 4 DAY REM

Rgn:123 CycY:456

ELECTRONIC CONTROL PANEL

Page 11

PROGRAMMING INSTRUCTIONS -

BASIC SETTINGS

Beforeenteringtheprogrammingmode,makesurethat

the appliance is in the service mode.

1. Press the scroll button; the display will show:

Press the up or down button to set the

language.

2. Press the scroll button again; the display will show:

Press the up button or down button to set the

time of day.

3. Press the scroll button again; the display will show:

Press the up ordown button to set the number

of days between regenerations.

The filtration capacity of the appliance mainly depends

on the daily water usage and the Iron/Manganese content

in the water; many otherfactors mayalso have a significant

impact on the filtration capacity. Therefore it is

recommendedtoregeneratetheapplianceona regulartime

basis. In most applications a regeneration every 4 days

should besufficient.

In case of extreme iron/manganese content and/or

water consumption, it is recommended to lower the

regeneration interval to 1 or max. 2 days.

Language:English

Set time: 8:01

Interval:4 Days

ELECTRONIC CONTROL PANEL

Page 12

PROGRAMMING INSTRUCTIONS -

CONFIGURATION PARAMETERS

Beforeenteringtheprogrammingmode,makesurethat

the appliance is in the service mode.

All configuration parameters on this appliance have

been pre-programmed in the factory, to offer optimal

performance in a wide range of applications and situations.

Neverthelessitmaybenecessaryordesirableto changeany

of these parameters, to further optimize the appliances

performance or to adapt it to the specific requirements of

the installation.

1. Press the scroll button and hold it for 5 sec until the

displayshows:

2. Within 10 sec, press the up button; the display will

show:

Press the up or down button to set the length

of the regeneration cycle.

Pressthescrollbuttonagaintoadvancetothenext

regeneration cycle.

Cycle 1

Backwash

Cycle 2

Air intake

Cycle 3

Fast rinse

Cycle 4

No function

(PF

-

OXY

1,5

& PF

-

OXY1,5

+

)

3. Press the scroll button again; the display will show:

Press the up or down button to set the time of

regeneration.

4. Press the scroll button again; the display will show:

Press the up or down button to save the

program into the NOVRAM® and exit the

programming level.

Cycle 1: XX min

System Check

Regen @ 0:00

Exit

MAINTENANCE

Page 13

ROUTINE CHECKS

Regularlytheusershouldperformabasicchecktoverifyifthe

appliance is functioning correctly, on the basis of the

following control points:

1. Check settings of electronic control panel.

2. Check water composition before/after appliance.

3. Check drain line from control valve; there shouldn’t be

any water flow(unless appliance is in regeneration).

4. Checkapplianceandsurroundingarea;thereshouldn’tbe

any water leakages.

BYPASSING THE APPLIANCE

Occasionally it may be necessary to put the appliance

hydraulically in bypass, i.e. to isolate it from the water

distribution system; f.e.:

in case of an urgent technical problem;

when it is not necessary to supply treated water to the

application.

WITH FACTORY BYPASS (optional) (only for PF-OXY1 & PF-

OXY+1)

Picture 11.a

SERVICE POSITION

= inlet valve to appliance is OPEN

= outlet valve from appliance is OPEN

Picture 11.b

BYPASSPOSITION

= inlet valve to appliance is CLOSED

= outlet valve from appliance is CLOSED

Picture 11.c

MAINTENANCE POSITION

= inlet valve to appliance is OPEN

= outlet valve from appliance is CLOSED

SANITIZING THE APPLIANCE

This appliance is manufactured from premium quality

material and assembled in safeconditions to assureit is clean

and sanitary. If installed andserviced correctly, this appliance

willnotinfectorcontaminateyourwatersupply.However,as

in any 'device' plumbed-in in your water distribution system,

a proliferation of bacteria is possible, especially in case of

'stagnant water'. Therefore this appliance will automatically

rinse the filter media periodically.

If the power supply to the appliance is disconnected for a

longer period of time, we recommend, when the power

supply is re-established, to manually initiate a complete

regeneration.

TROUBLESHOOTING

Page 14

PROBLEM

C

AUSE

S

OLUTION

U

ntreated

water to

service

Open or defective bypass

C

lose

orreplace

bypass

A

ppliance

in regeneration

Wait until regeneration finishes or

manually

advance regeneration to end

Excessive water usage

Initiate regeneration manually

Change in raw water

composition

Verify

composition

of

i

ncoming

untreated

water

and adjust regeneration frequency accordingly

Appliance

fails to

start a

regenerat

ion

Refer to problem “Appliance fails to start a

regeneration”

Appliance

fails to backwash properly

Refer to problem “

Appliance

fails to

backwash

properly”

PF

-

OXY

1

&PF

-

OXY

+

1

only

: valve body andtimer

out of synchronisation

Synchronize valve body and timer

Decreasing

filter

capacityof

filter media

Clean or replace filter media

Loss of

filtermedia

Refer to problem “Loss of

filtermedia

”

Leak between riser tube and

control valve body

Verify that riser tube is seated correctly and is not

cracked

Low levels of

contaminant in treated

water

Bypass not completely closed

Close bypass

Excessive service flow rate

Lower service flow rate

Increasefiltercapacitybyincreasingvolumeoffilter

media

Leak between riser tube and

control valve body

Verify that riser tube is seated correctly and is not

cracked

Air from compressed

air chamber rapidly

escapes to outlet

Leak between riser tube and

control valve

body

Verify that riser tube is sea

ling off correctly inside

control valve body

Bypass between inlet and outlet of system

PF

-

OXY1 only

: check that mixing valve on factory

bypass is completely closed

Checkthat bypass valveon 3-valve bypasssystemis

closed

Valve body and timer out of synchronisation

Synchronise valve body and timer

Treated water is

slightly non-

transparent and/or

effervescent

Passage through

compressed air

chamber

causes water to become highly oxygenated

T

otallyharmlessforqualityofthetreatedwaterand

will disappear rapidly if water is left standing for a

moment

Appliance

fails to

start

a regeneration

Faulty electrical supply

Verify electrical service

(fuse, transformer,...)

Defective PCB

Replace PCB

Defective

drive motor

Replace

drive motor

Regeneration frequency not programmed

Program regeneration frequency

Loss of water pressure

B

uild

-

up

of impurities

in

pressure

tank

Clean

filter media

and control valve; increase

regeneration frequency

Plugged lowerand/or upperdistributor

Verify that distributors are free of debris

Drain line from control

valve flows

continuously

Appliance

in regeneration

Wait until regeneration finishes or

manually

advance regeneration to end

Faulty electrical supply

Verify electrical service (fuse, transformer,...)

Defective drive motor

Replace drive motor

PF

-

OXY

1

& PF

-

OXY

+

1

only

: defective micro

switch

Replace micro switches

PF

-

OXY

1

,5 & PF

-

OXY

+

1,5

only

:defective optical

switch

Replace optical switch

Defective PCB

Replace PCB

PF

-

OXY

1

&PF

-

OXY

+

1

only

: valve body andtimer

out of synchronisation

Synchronise valve body and timer

Loss of

filter media

Lower and/or upper distributor damaged

Replace

distributor(s)

Leak between riser tube and upper distributor

Verify that riser tube is seated correctly and is not

cracked

TROUBLESHOOTING

Page 15

PROBLEM

C

AUSE

S

OLUTION

Appliance fails to

backwash properly

Low operating pressure

Check

operating pressure; must

be

higher than

2,5

bar

Insufficient water supply

Check water supply(flow rate/dynamicpressure)

Restricted drain line

Verify drain linefor kinks or restrictions

Excessiveb

uild

-

up

ofimpurities

in

pressure

tank

Clean

or replace

filter media

and control valve;

increase regeneration frequency

Plugged backwash flow control

Clean

or replace backwash flow control

Plugged top or bottom distributor

Verifythattopandbottomdistributorarecleanand

slots are not clogged by iron or other impurities

Filter media is completely ‘caked’ (solid block)

Replace filter media and reduce regeneration

interval

Control valve cycles

continuously

PF

-

OXY

1

& PF

-

OXY

+

1

only

: defective micro

switch

PF-OXY1,5 & PF-OXY+1,5only: defective optical

switch

Replace micro switches

Replace optical switch

ELECTRICAL WIRING DIAGRAMS

Page 16

PF-OXY1 & PF-OXY+1

= position switches

= powerlead

= drive motor

= service valve NO (optional)

= key pad

PF-OXY1,5 & PF-OXY+1,5

= optical switch

= powerlead

= drive motor

= service valve NO (optional)

= key pad

DEFAULT CONFIGURATION PARAMETER SETTINGS

Page 17

Model PF-OXY1 & PF-OXY+1

Filter media (cuft) 1 2 3

Interval (days) 4 4 4

Cycle 1:BACKWASH (min) 10 10 10

Cycle 2:AIRINTAKE(min) 10 10 10

Cycle 3:PURGE (min) 1 1 1

Regen@ 0:00 0:00 0:00

Model PF-OXY1,5 & PF-OXY+1,5

Filter media (cuft) 3 4 5 7 10

Interval(days) 4 4 4 4 4

Cycle 1:BACKWASH (min) 10 10 10 10 10

Cycle 2:AIRINTAKE(min) 9 12 15 21 30

Cycle 3:PURGE(min) 1 1 1 1 1

Cycle 4:nofunction 0 0 0 0 0

Regen@ 0:00 0:00 0:00 0:00 0:00

COMPOSITION OVERVIEW

Page 18

Model Media

volume PN Control valve, incl. transformer,

1” male BSP connections Pressure tank,

incl. distributor assy Underbedding Filter media

(1 cuft bag)

cuft model # model # type ltr type #

PF-OXY1

1 35669 2400TF/J5N/SV/AIR 1 10x40 1 Gravel 2-4 mm 4 Birm 1

2 35670 2400TF/J5Q/SV/AIR 1 12x52 1 Gravel 2-4 mm 6 Birm 2

3 35708 2400TF/J5S/SV/AIR 1 14x65 1 Gravel 2-4 mm 8 Birm 3

PF-OXY+1

1 35781 2400TF/J5N/SV/AIR 1 10x40 1 Gravel 2-4 mm 4 Katalox-Light 1

2 35782 2400TF/J5Q/SV/AIR 1 12x52 1 Gravel 2-4 mm 6 Katalox-Light 2

3 35783 2400TF/J5S/SV/AIR 1 14x65 1 Gravel 2-4 mm 8 Katalox-Light 3

Model Media

volume PN Control valve, incl. transformer,

1,5” male BSP connections Pressure tank,

incl. distributor assy Underbedding Filter media

(1 cuft bag)

cuft model # model # type ltr type #

PF-OXY1,5

3 35862 EV1.5TF/J/100/AIR 1 14x65 1 Gravel 2-4 mm 12 Birm 3

4 35863 EV1.5TF/J/150/AIR 1 16x65 1 Gravel 2-4 mm 15 Birm 4

5 35864 EV1.5TF/J/200/AIR 1 18x65 1 Gravel 2-4 mm 18 Birm 5

7 35865 EV1.5TF/J/250/AIR 1 21x62 1 Gravel 2-4 mm 22 Birm 7

10 35866 EV1.5TF/J/350/AIR 1 24x72 1 Gravel 2-4 mm 26 Birm 10

PF-OXY+1,5

3 35874 EV1.5TF/J/100/AIR 1 14x65 1 Gravel 2-4 mm 12 Katalox-Light 3

4 35875 EV1.5TF/J/150/AIR 1 16x65 1 Gravel 2-4 mm 15 Katalox-Light 4

5 35876 EV1.5TF/J/200/AIR 1 18x65 1 Gravel 2-4 mm 18 Katalox-Light 5

7 35877 EV1.5TF/J/250/AIR 1 21x62 1 Gravel 2-4 mm 22 Katalox-Light 7

10 35878 EV1.5TF/J/350/AIR 1 24x72 1 Gravel 2-4 mm 26 Katalox-Light 10

Page 19

EXPLODED VIEW - PF-OXY1 & PF-OXY+1 - SYSTEM

Page 20

Other manuals for PF-OXY1

1

This manual suits for next models

2

Table of contents

Other ProFlow Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Schaffner

Schaffner FN5420 User and installation manual

MAUNAWAI

MAUNAWAI PI CONNECT PiTec 2in1 manual

Riello

Riello BAG2 MIX CLIMA INSTRUCTIONS FOR THE INSTALLER AND THE TECHNICAL ASSISTANCE SERVICE

KOGANEI CORPORATION

KOGANEI CORPORATION FRZ Series instruction manual

Unilever

Unilever pureit UR5640 instruction manual

Thermo Scientific

Thermo Scientific 1403 Series operating manual