Projecta INTELLI-RV PM200 User manual

P/No. PM200

12V POWER MANAGEMENT SYSTEM

INTELLI-RV

2

IMPORTANT SAFETY INFORMATION

Please read this manual thoroughly before use and store in a safe place for future reference.

WARNINGS

• Explosive gases. Prevent ames and sparks. Provide adequate ventilation during charging

• Before charging, read the instructions

• For indoor use. Do not expose to rain

• For charging Lead Acid and LiFePO4batteries only (of the size & voltage specied in the

specication table)

• Always charge the battery on the correct voltage setting. Never set the charger to a higher

voltage than the battery specications state

• Disconnect the 240V mains supply before making or breaking the connections to the battery

• The battery charger must be plugged into an earthed socket outlet

• Connection to supply mains is to be in accordance with national wiring rules

• Do not attempt to charge non-rechargeable batteries

• Never charge a frozen battery

• If the AC cord is damaged, do not attempt to use. It must be replaced or repaired by a

qualied technician

• Corrosive substances may escape from the battery during charging and damage delicate

surfaces. Store and charge in a suitable area

• Where possible, ensure all vehicle accessories including lights, heaters, appliances etc. are

turned off prior to charging

• This charger is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been

given supervision or instruction concerning the use of the appliance by a person responsible

for their safety

• Young children should be supervised to ensure that they do not play with the appliance

• If the recreational vehicle is to be put in to storage without power, please turn off the

BATTERY MASTER SWITCH. If the recreational vehicle is to be put in to long term storage

without power, disconnect ALL cabling from the battery

3

CONTENTS

1. SYSTEM INTRODUCTION – PM200 ........................................................................................... 4

1.1 Features 5

1.2 LED display 6

1.3 Water tank probes 6

2. KEY FEATURES AND FUNCTIONS ............................................................................................... 6

2.1 Multiple inputs 6

2.2 Battery charger of stationery/service battery 6

2.3 Power supply mode 7

2.4 PWM solar charge controller 7

2.5 Voltage charging relay (VCR) 7

2.6 Categorised outputs 8

2.7 Battery low voltage protection 8

2.8 Manual battery switch 8

2.9 Silent mode 8

3. STRUCTURE AND INSTALLATION ............................................................................................... 9

3.1 PM235 Transformer Unit 9

3.2 LED display 10

3.3 Water tank probes 11

3.3.1 PMWS400 water tank probe 11

3.3.2 PMWS200 water tank probe 11

4. WIRING ....................................................................................................................................... 12

4.1 Material 12

4.2 System schematic 12

4.3 Preparation 13

4.4 Connection 13

5. DISPLAY ...................................................................................................................................... 14

5.1 PM200 master power unit 14

5.2 LED display 15

6. OPERATION ................................................................................................................................. 16

6.1 Conguration on PM200 16

6.1.1 Battery capacity and battery type 16

6.1.2 Select Battery Switch Local / Remote 17

6.2 Maintenance 17

7. TROUBLE SHOOTING .................................................................................................................. 18

7.1 LCD display on PM200 Unit 18

8. SPECIFICATION ........................................................................................................................... 19

8.1 PM200 Basic 19

4

1. SYSTEM INTRODUCTION – PM200

PM200 is designed for use in caravans or motor homes. The unit has integrated functions such as: battery charger, distribution blocks,

PWM solar charge controller, charging relay, battery low voltage protection, water pump controller, water tank indicator and LED Display.

The PM200 is designed for an easy installation and a user-friendly interface.

SYSTEM COMPONENTS:

1. PM235 Master power unit

2. PMSWLED-2 LED display

3. PMWS200 or PMWS400 Water tank sensor (Not supplied)

4. Cables (Refer to Chapter 4.1 or the cable list)

Figure 1 System Components for PM200

P/No. PMSWLED-2

Waste Water Tank Probe

(Optional)

P/No. PMWS200 or PMSW400

Tap Water Tank Probe

(Optional)

P/No. PMWS200 or PMSW400

Fresh Water Tank Probe

(Optional)

P/No. PMWS200 or PMSW400

Battery Temperature

Sensor P/No. PMBS

Solar

Service Battery

Starter Battery

P/No. PM235 Transformer Unit

5

1.1 Features

• Smart battery charger 12V 35A (30A for charging current)

– Multi stage adaptive charging algorithm

– Active Power Factor Correction (PFC) charging

– Temperature compensation charging

– Voltage compensation charging

• Float charge for starter battery

• Solar charge controller (PWM), 30A

• 14 built in fused outputs

• Built in Voltage Sensing Relay

– 12V 60A Continuous

– 12V 100A Peak for 30mins

• Battery low voltage protection

• Built-in battery switch to isolate the battery when in storage

• Built-in shunt for precise battery measurement

• 1 water pump control with up to 3 connections for water sensors

• Dual control cooling fan

– Temperature Control

– Load Control

• Spring terminal and screw terminal

• RS-485 compatible

Figure 2 System Schematic

10A

K4

F5 L11+

10A F6 L10+

LOAD -

LOAD11 for PUMP

10A F7 L9+

10A F8 L8+

10A F17 L14+

10A F16 L13+

10A F15 L12+

15A F9 L7+

10A F10 L6+

10A F11 L5+

15A F12 L4+

10A F13 L3+

15A F14 L2+

15A F1 L1+

L13-

L12-

L11-

L10-

L9-

L8-

L7-

L6-

L5-

L4-

L3-

L2-

L14-

L1-

K3

D+Input

Remote Switch

Dip Switch Load switch

35A

F4

F3

+

-PWM

MCU

+

-

+

-AC/DC

+

-

+

-

+

-

VCR

Battery switch

35A

K1

Solar In

AC In

Service

Battery

Starter

Battery

Step

Slave charger relay

K2

LOAD4~10 for

Class B Load

LOAD12~14 for

Class B Load

LOAD 2~3 for

Class C Load

LOAD1 for

Class D Load

6

1.2 LED Display

Figure 3 PMSWLED-2 switch panel

Table 1 Front panel of PMSWLED-2

Table 2 LED indication of PM235

1.3 Water Tank Probes

A maximum of up to 3 probes can be monitored by the system.

NOTE: Always check the probe required for the water tank before purchase. If the probe included does not t the water tank,

please contact the seller.

There are 2 probe styles:

PMWS200:

• Side installation

• Suitable for water tank

• Depth >200mm

Figure 5 PMWS400Figure 4 PMWS200

PMWS400:

• Side installation

• Suitable for water tank

• Depth 300-400mm

1

4

2

5 6 7 8

3

NOLABEL DEFINITION DESCRIPTION

1Water Pump DC load control Load control, on/off control

2Night Mode Scene mode Refer to 2.10

3Load DC load control Load control, on/off control. Refer to 2.7

4Fresh Water Tank Sensor Detect the level of fresh water tank

5Tap Water Tank Sensor Detect the level of tap water tank

6Waste Water Tank Sensor Detect the level of waste water tank

7Service Battery SOC Detect the state of the charge of service battery

8Service Battery Voltage Detect the voltage of service battery

NOLABEL COLOUR STATUS DESCRIPTION

1Main Green

ON Battery charged or power supply mode

Flash Battery charging under grid electricity

OFF NO AC input

2PV Green

Solid Battery charged

Flash Battery charging under solar energy

OFF NO solar input / AC charging / Aux charging

3Fault Red

ON Short circuit

1 Flash Service battery voltage low

2 Flash Service battery voltage high

3 Flash Over temp (heat sink)

4 Flash Bulk charge timeout

5 Flash VCR anomaly

6 Flash Over temp (environment)

7

2. KEY FEATURES AND FUNCTIONS

2.1 Multiple Inputs AC MAINS x x

SOLAR x x

STARTER

BATTERY x x

CHARGING

PRIORITY

AC MAINS AC MAINS COMBINED

Table 3 Source priority

2.2 Battery Charger Of Stationery/Service Battery

The charger automatically starts when the appropriate qualied power is connected, either from AC mains, alternator or solar.

With multiple charging stages (soft start – bulk – absorption – oat – recycle), PM200 is designed to fully charge a battery quickly.

To guarantee the optimal charging for batteries of different states, the PM200 features a Microprocessor-controlled charging

algorithm.The Float and Recycle charging programs guarantees that the battery condition does not change despite being

connected for a longer period.

When the charger is at oat Stage, if input a new source (AC Mains or Solar), the charger will return to the BULK stage.

lcc is the rated current

.

5 hours 1 hour5mins

SOFT START

STAGE

CURRE

NT

VOLTAGE

BULK ABSORPTION FLOAT RECYCLE

1 2 3 4 5

1

2

CHARGING

ALGORITHM

SOFT START

Increases battery life by gently starting to

charge the battery at 50% of bulk

BULK

Reduces charging time by delivering

maximum charge to set voltage

ABSORPTION

Ensures a full charge to the battery without overcharging

FLOAT

Float charge maintains the battery at 100% charge

RECYCLE

3

4

5

11.5V

lcc

1/2lcc

Figure 6 Charging Algorithm

PM200 master power unit may have multiple charging

sources at any one time. These sources include AC mains,

solar and starter battery (vehicle).

Charging priorities are listed within the table to the right.

Battery Temperature Sensor

The PMBS (Battery Temperature Sensor) supplied with PM200, measures the temperature of the battery and automatically adjusts, in real time, to

charge the battery properly at compensation rate of – 4mv±10%/°C/cell. In case PMBS is not present, the PM200 will use 25°C as default.

Voltage Compensation Charging

With a voltage sensor PMBS the PM200 can, if required, automatically adjust its output to compensate the voltage drop caused by a cable.

This assures the right voltage is being delivered for optimal charging.

Adjustable Charging Capacity

Users can adjust the charging current by specifying the battery capacity. The charging current is set at threshold rate of 10% the of

the battery capacity (I = 0.1C) by default.

Lithium Battery Charging

The PM200 can be congured to charge lithium batteries. With lithium batteries, the max charging current will automatically be set at

30% of battery capacity (Imax=0.3C).

2.3 Vehicle Battery Charger

Along with a powerful charger for service battery, PM200 offers a oat charge of up to 3A to keep the starter battery charged, whether

connected to the AC main or PV.When starter battery is less than 12.4V, the PM200 starts charging after 30 minutes delay and stops

charging when voltage reaches 12.8V.

2.4 Power Supply Mode

If no battery is attached to PM200 unit, it will work as a power supply automatically with a 12.8VDC output.

8

Battery Switch Load Switch

Step

Fuse 15A Fuse 10A

Fuse 10A

Load of Class D Load of Class C

Load of Class B

Load of Pump

Fuse 10A

Fuse 10A

Fuse 10A

Fuse 10A

Fuse 10A

Fuse 10A

Fuse 10A

Fuse 10A

Fuse 10A

Fuse 15A

Fuse 15A

2.8 Battery Low Voltage Protection (BLVP or commonly known as an LVD)

The PM200 transformer unit has a built-in low voltage protection relay. It will disconnect the load once the battery voltage drops below

the threshold voltage.The default setting is 10.5VDC.

NOTE: Class C and Class D loads remain active.

2.9 Manual Battery Switch

The PM200 unit offers a convenient way to switch off the output of the on-board service battery. It protects the service battery from

being drained by the electronics on board, completely isolating the battery. PM200 unit also supports a remote manual battery switch.

Before using the remote switch, ensure the ‘switch selector’ is set to ‘Remote’.The switch is only effective when the system has no

other energy resource for the load except the battery.

2.10 Silent Mode

In Silent Mode, the backlight of the LED Display and the fan will be turned off or decreased in speed.

Table 4 Categorised outputs denition

CATEGORY QTY DESCRIPTION POSSIBLE LOAD SUITABLE

Class A1 1Relay controlled output with fuse, protected by main master switch relay Water pump

Class B 10 Fused outputs, protected by master switch relay Ventilation fan etc

Class C 2Live load Fridge, security alarm etc

Class D 1Permanent on load Auto step

2.5 PWM Solar Charge Controller

PM200 has a built-in PWM charger for the service battery.

• Max input voltage 30VDC

• Max charging current 30A

• Max supply current 30A

2.6 Voltage Charging Relay (VCR or commonly known as a VSR)

PM200 Master Power Unit has a built-in voltage charging relay (VCR), which offers a convenient source to charge the service battery by

alternator whilst the engine is running.

LEAD ACID BATTERY – When the start battery reaches 13.4VDC with threshold time delay, the VCR will charge the service battery from

the alternator.VCR will continue charging until the starter battery voltage drops under 12.8VDC.

LiFePO4LITHIUM BATTERY – When the starter battery reaches 14.0VDC with threshold time delay, the VCR will charge the service battery

from the alternator.The VCR will continue charging until the starter battery voltage drops below 13.5VDC with less than 2A charge to the

service battery with threshold time delay.

NOTE: The PM200, when charging from the starter battery, does not provide 5 stage charging.

It simply takes whatever power and charging is available from the alternator.

NOTE: If your vehicle is tted with a smart charging system (Variable Voltage or Temperature Compensating),

the VCR charge system may not function correctly and the PMDCS range of DC-DC chargers are recommended.

Please consult your local dealer or installer for further information.

2.7 Categorised Outputs

The 14 outputs are categorised into groups and controls as per below:

Figure 7 Categorised output

9

Figure 8 Front panel of PM235

Table 5 Categorised outputs

NOLABEL DEFINITION DESCRIPTION

1 AC Mains AC input port

2 Ambient Temp Sensor Comm port Connect to switch panel

3 LCD Display Comm port Connect to Monitor

(Monitor is not available in PM200)

4 Power Switch Service battery switch Manual battery switch

5Fresh Water Tank 1 Connect to fresh water tank 1

6Fresh Water Tank 2 Fresh water tank 2 is not available in PM200

7 Tap Water Tank Connect to tap water tank

8 Waste Water Tank Connect to waste water tank

9 Battery Sensor For voltage and

temperature compensation

Connect to service battery+

10 PV+ Solar input Connect to PV+ terminal

11 PV- Solar input Connect to PV- terminal

12 Starter Bat+ Starter battery+ Connect to starter battery+ (<16Vdc)

13 Service Bat+ Service battery+ Connect to service battery+ (<16Vdc)

14 Starter Bat- Starter battery- Connect to starter battery-

15 Service Bat- Service battery- Connect to service battery-

16 L1+ Step Connect to load of class D

17 L2+ ~ L3+ Connect to load of class C

18 L4+ ~L10+ Connect to load of class B

19 L11+ Water pump Connect to water pump+

20 L12+ ~ L14+ Connect to load of class B

21 L1- ~ L14- Connect to DC load -

22 D+ Point D+ input Connect to D+

23 Remote Switch Terminal block Connect to remote switch

24 Select Switch Dip switch Select local switch or remote switch

(NOTE: open the upper cover board to operate)

25 Setting Dip switch Set the battery type and capacity

(NOTE: open the upper cover board to operate)

26 Fuse Fuse and fuse failure indication

3. STRUCTURE AND INSTALLATION

3.1 PM200 Master Power Unit

1

3 4

2

26

5

6

7

8

9

10 11 12 13 14 15 16 17 19 20 2118

25

22 2324

10

3.2 LED Display

Figure 11 Dimension of PMSWELD (Unit: mm)

Installation:

PM235 can be installed on a horizontal surface or vertically on a wall. Please see following instructions:

Figure 10 Installation of PM235 (Unit: mm)

Ensure clearance on both sides of PM235 unit

upon installation. A recommended clearance of

5cm on each side.

Figure 9 Dimension of PM235 (Unit: mm)

164

264

300

128 55

35 M4

7.97

150

90

23.62

11

Figure 12 Installation of PMSWELD (Unit:mm)

3.3 Water Tank Probe

3.3.1 PMWS400 Water Tank Probe

Figure 13 Dimension of PMWS400 (Unit:mm) Figure 14 Installation of PMWS400

3.3.2 PMWS200 Water Tank Probe

Installation

Figure 15 Dimension of PMWS200 (Unit:mm) Figure 16 Installation of PMWS200

Installation

Installation:

138

60

4-M3* 12mm

7860

28.1

HOLE SIZE

12

1

4 6 7

3

PMAC

PMSWLEDC PMBS

PMWS200/

PMWS400

PMWS200/

PMWS400

PMWS200/

PMWS400

9

PM235

Switch

Panel

Solar

Battery Temperature

Sensor and Terminal

Voltage

AC in

240V / 50Hz

~

L

N

A

Service Battery –

Service Battery +

Service Battery

(12VDC)

Starter Battery –

Starter Battery +

Starter Battery

(12VDC)

PV+

PV-

PV in

Vmp: 15 – 25V

Fresh Water

Tank 1

Level Sensor

Fresh Water

Tank 2

Level Sensor

Waste Water

Tank

Level Sensor

N L

AC IN

Monitor Switch

Panel

Battery

Sensor

Waste

Water

Tank

Tap

Water

Tank

Fresh

Water

Tank 2

Fresh

Water

Tank 1

•

L12

•

L13

•

L14 L14

•

L13

•

L12

•

L11

•

L10

•

L9

•

L8

•

L7

•

L6

•

L5

•

L4

•

L3

•

L2

•

L1

•

PV

• •

D+ Input

Remote

Switch

Service

Batt -

Service

Batt +

Starter

Batt -

Starter

Batt +

L11L10 L9 L8 L7 L6 L5 L4 L3 L2 L1

• • • • • • • • • • •

Load of class B

Load of class B

Load of class B

Step

Load of class C

Load of class C

Load of class B

Load of class B

Load of class B

Load of class B

Load of class B

Load of class B

Load of class B

Load of class B

D+ Input

4. WIRING

4.1 Material

CODE NAME MODEL/

LENGTH

QTY P/No. ON

DRAWING

1Caravan Master Power PM235J 1 1

2Membrane Switch Panel PMLCD-BTJ 1 3

3Fresh Water Tank Level Sensor Not included

and to be

ordered

separately

0 4

4Tap Water Tank Level Sensor 0 6

5Waste Water Tank Level Sensor 0 7

6PV 0 9

Table 6 Component list of PM200

4.2 System Schematic

Figure 17 System diagram

CODE NAME MODEL/

LENGTH

QTY P/No. ON

DRAWING

7Switch Panel Line 5m 1PMSWLED-

2C

8Battery Sensor Line 3m 1PMBS

9Water Tank Probe Line 4m 0PMWS200 /

PMWS400

10 Water Tank Probe Line 4m 0

11 Water Tank Probe Line 4m 0

12 Power Cable 1.5m 1PMAC

13

4.3 Preparation

PM200 system is designed with the concept of ‘Plug in and Play’ in mind. To complete the easy installation, a screw driver and DC cables

are required. Follow Table 5 recommendation for minimum wiring size.

4.4 Connection

PM200 unit is designed with a spring and screw terminal. Please refer to following illustration below.

Each type of terminal is designed to t a different range of cables.

CURRENT MINIMUM CABLE SIZE

0–5A 1.0mm2or 18 AWG

5–10A 2.0mm2or 14 AWG

10–15A 3.0mm2or 13 AWG

15–20A 4.0mm2or 11 AWG

20–25A 5.0mm2or 10 AWG

25–30A 6.0mm2or 9 AWG

Table 7 Minimum cable size

Table 8 Recommended terminal and cable gauge Figure 18 PM235 Terminal

TYPE TERMINAL MODEL

NUMBER

SUITABLE CABLE

GAUGE

Type 1 ERTB10-10.16 0.5mm2– 10mm2

Type 2 Wago804-114 0.25mm2– 2.5mm2

Figure 19 Connection of Terminal Type 1

When running cables, if they pass through panels or wall, ensure the

cables are protected from damage by sharp edges. In such cases, it is

recommended to use cable glands.

Recommendation is to install the PM200 as close to the service battery as

possible to minimize voltage drop and ensure accurate charging.

TYPE 1

TYPE 2

Figure 20 Connection of Terminal Type 2

Type 1 Type 2

14

No. LED COLOUR STATUS DESCRIPTION

1Mains GREEN

ON AC input OK

OFF AC disconnected

Quick ashing (ash twice every second) AC input abnormal

2Starter Bat GREEN

ON Starter battery charging the battery

Slow ashing (ash once every second) The input of the Aux is normal but it is charged by the

AC

Quick ashing (ash twice every second) Starter battery input error

OFF Starter battery disconnected.

3PV GREEN

ON PV charging the battery

Slow ashing (ash once every second) The input voltage of the PV is normal but it is charged

by the AC or Starter battery

Quick ashing (ash twice every second) PV input error

OFF PV disconnected

4CHG GREEN

ON Battery charged

Flashing (ash once every second) Battery charging

Slow ashing (1 second on 2 seconds off) Battery discharge

OFF Battery disconnect

5FAULT RED

ON Short circuit

1 ash Service battery voltage low

2 ash Service battery voltage high

3 ash Over temperature (heat sink)

4 ash Bulk charge timeout

5 ash VCR anomaly

6 ash Over temperature (ambient)

8 ash BMS Over-Voltage Protection

Table 9 LED indicator description of PM235

Figure 21 An overview of PM235

5. DISPLAY

5.1 PM235 Master Power Unit

15

5.2 LED Display

Figure 22 An overview of PMSWLED-2

Table 10 Front panel of PMSWLED-2

NoLABEL TYPE DESCRIPTION

1Water Pump DC Load Control Load control, on/off control

2Night Mode Scene Mode Refer to 2.10

3Load DC Load Control Load control, on/off control. Refer to 2.7

4Fresh Water Tank Sensor Detect the level of fresh water tank

5Tap Water Tank Sensor Detect the level of tap water tank

6Waste Water Tank Sensor Detect the level of waste water tank

7Service Battery SOC Detect the state of the charge of service battery

8Service Battery Voltage Detect the voltage of service battery

NoLABEL COLOUR STATUS DESCRIPTION

1Mains Green

ON Battery charged or power supply mode

Flash Battery charging under grid electricity

OFF NO AC input

2PV Green

Solid Battery charged

Flash Battery charging under solar energy

OFF NO solar input / AC charging / Str Bat Charging

3Fault Red

Voltage Detect the voltage of starter battery

ON Short circuit

1 Flash Service battery voltage low

2 Flash Service battery voltage high

3 Flash Over temp (heat sink)

4 Flash Bulk charge timeout

5 Flash VCR anomaly

6 Flash Over temp (environment)

8 Flash BMS Over-Voltage Protection

Table 11 LED indication description of PMSWLED-2

1

4

2

5 6 7 8

3

Note: SOC may not be accurate if system run a inverter or other device direct to the battery.

If you want an accurate SOC, please replace the display with PMLCD-BT and install PMSHUNT.

16

Congure the max charging current of PM235:

Figure 23 Dip Switch of PM200

6. OPERATION

6.1 Conguration on PM200

Battery type and capacity are congured via PM235 master power unit.

6.1.1 Battery Capacity and Battery Type

There is a dip switch for you to set battery capacity and battery type.

Dip switch denitions:

When choosing max charging

current, please take into

consideration the

consumption of the DC load

connected with the system.

Congure the battery type connected: Factory default setting:

Table 12 Dip Switch denition

Table 13 Battery Capacity setting by dip switch

Table 14 Battery Type setting by dip switch

Table 15 Factory default setting

1 2 3 4

ON

OFF

DIP

SWITCH

1 2 3 4

Charging Current Battery Type

DIP SWITCH 1 2 3 4

STATUS OFF OFF OFF OFF

LEAD ACID LITHIUM

DS1 DS2 AC CHARGE SOLAR CHARGE LITHIUM

ON ON 10A 20A 30A

ON OFF 15A 30A 30A

OFF ON 20A 30A 30A

OFF OFF 30A 30A 30A

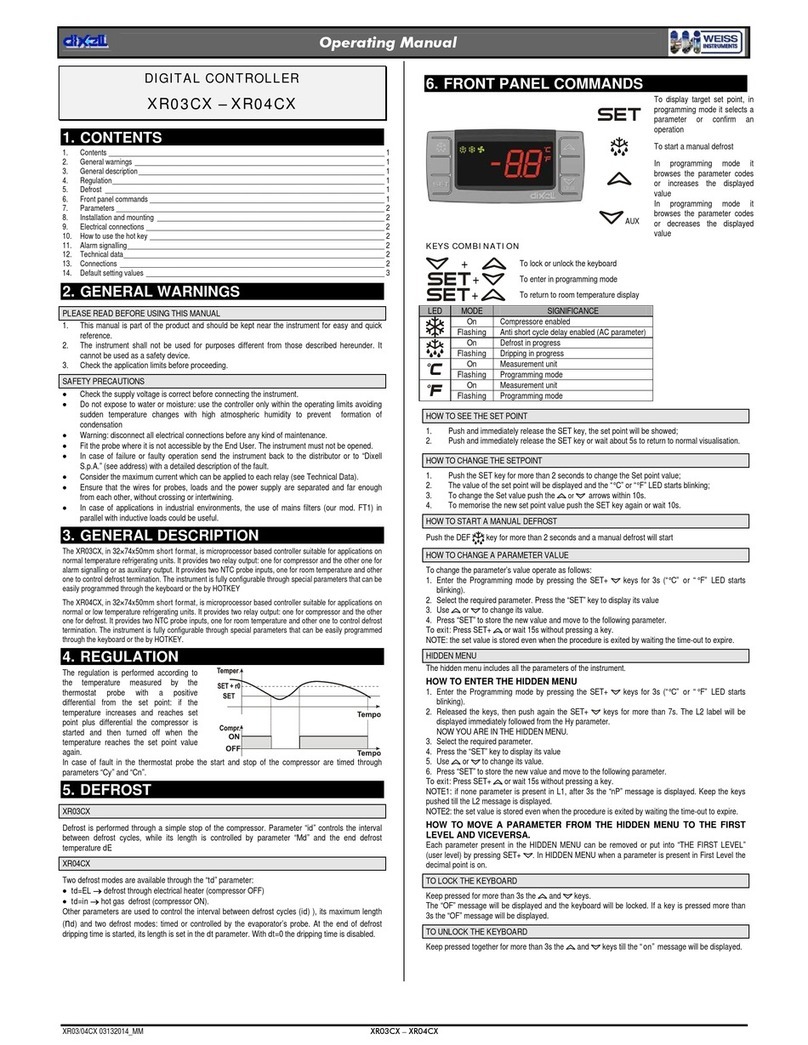

DS3 DS4 BATTERY

TYPE

ABSORPTION FLOAT

OFF OFF AGM 14.4V 13.5V

OFF ON GEL 14.1V 13.5V

ON OFF LiFePO414.2V 13.5V

ON ON WET 14.7V 13.7V

17

6.1.2 Select Battery Switch Local/Remote

This function offers a possibility for user to use a remote battery switch to power on/off the service battery output

DIP SWITCH DESCRIPTION

Local The switch on PM235 unit works

Remote The remote switch works and local one is disabled

6.2 Daily Maintenance

• Conrm the Battery Switch is switched on when you want to charge the battery with the AC grid.

• Check the nominal battery voltage is 12Vdc.

• Ensure the space (5cm each side) beside the PM235 unit for the good ventilation.

• When replacing and existing battery, please fully charge via AC grid to ensure SOC% is

accurately calibrated.

It is recommended to switch off the local Battery Switch on main panel of PM200 master power

unit or remote switch to cut off the consumption of the service battery.

Figure 24 Local/Remote Select Switch Table 16 Local/Remote Setting

Local

Remote

18

7. TROUBLE SHOOTING

7.1 L.E.D Display on PM235 Unit

Table 17 Error LED indicator of PM235

No. LED COLOUR STATUS DESCRIPTION

1Mains GREEN Quick Flashing

(ash twice every second)

AC input abnormal

2Str Bat GREEN Quick Flashing

(ash twice every second)

The Starter Battery is 2~13.4V or >16.0V, while AC

power is connected.

3PV GREEN Quick Flashing

(ash twice every second)

Solar input voltage error – Solar input >30Vdc

4Fuse L.E.D RED OFF Fuse blown, need to check load and replace fuse

5FAULT RED

ON Short circuit

1 Flash Service battery voltage low

2 Flash Service battery voltage height

3 Flash Over temp (heat sink)

4 Flash Bulk charge timeout

5 Flash VCR anomaly

6 Flash Over temp (environment)

8 Flash BMS Over-Voltage Protection

19

8. SPECIFICATIONS

Table 18 Specication of PM235

MODEL PM235

ELECTRICAL SPECIFICATIONS

Grid Nominal input voltage

(V)

240±10%VAC

50/60Hz

Power factor 0.95

Input current at full

load

2.5A

Battery Starter battery 12VDC

Starter battery voltage

range

12.8 – 16VDC

Service battery 12VDC

Service battery

voltage range

10.5 – 16VDC

PV Charger type PWM

Open circuit voltage 30VDC

Max charging current 30A

Maximum solar input 800W

Charging

Relay

Relay specication 12VDC 60A

continuous,

peak current

100A, 30mins

Connect voltage

Lead Acid - 13.4VDC

LiFePO4- 14.0VDC

Connect delay time 10sec

Disconnect voltage

Lead Acid - 12.8VDC

LiFePO4- 13.5VDC<2A

Disconnect delay time 60sec

High voltage limit 16.0VDC

Charger

Mode

Charge Algorithms 5 Stage

Battery type AGM/GEL/LFP

(LiFePO4)//WET

Start voltage

Lead Acid – 2VDC

Lithium – 0VDG

Bulk current 30A (Max)

Absorption voltage (14.4/14.1

/14.2/14.7)

±0.15VDC

Float voltage (13.5/13.5

/13.5/13.7)

±0.13VDC

Power

Supply

Mode

Nominal output

voltage

12.8±0.2 VDC

Rated output current 35A

(Continuous)

Efciency 88%

Working Temperature -40°C~+65°C

(50°C:full load;

60°C:20A; 65°C:

shutdown the

output)

MODEL PM235

ELECTRICAL SPECIFICATIONS

Battery

Disconnect

(LVD)

Disconnect voltage AGM/GEL/WET 10.5VDC

(default)

LFP (LiFePO4)11.2 VDC

(Default)

Delay off time 60 sec

Reconnect voltage AGM/GEL/WET 11.5VDC

(default)

LiFePO412.2 VDC

(Default)

Current Draw

on Battery

240VAC is off, no

vehicle charging

405mA

LVD battery <10.5V

current draw on

battery

110mA

LVD battery <10V

current draw on

battery

0mA

Fused Outputs Numbers 14

Rated Current 15A x 4, 10A x 10

Protection Short circuit on output Fuse blown

Reverse polarity Diode reverse isolation

Overload protection Derate the output until overload

is removed

Battery charger over

temperature

Shut down PM235

Ambient over

temperature

Alarm

Battery over voltage

limits

Battery charger disconnect,

loads disconnect

PHYSICAL SPECIFICATIONS

Dimensions

(L*W*H)

264 × 164 × 128mm

Weight 3kgs

Enclosure Steel Case

Battery

Connector

M4 Screw (16mm2)

Load Connector Wago804-114 (2.5mm2)

Cooling Forced cooling

Protection

Category

IP20

Approvals

Electrical AS/NZS 60335.2.29

EMC CISPR14

20

WARRANTY STATEMENT

Applicable only to product sold in Australia

Brown & Watson International Pty Ltd of 1500 Ferntree Gully Road, Knoxeld, Vic.,telephone (03) 9730 6000,

fax (03) 9730 6050, warrants that all products described in its current catalogue (save and except for all

bulbs and lenses whether made of glass or some other substance) will under normal use and service be free

of failures in material and workmanship for a period of two (2) years (unless this period has been extended

as indicated elsewhere) from the date of the original purchase by the consumer as marked on the invoice.

This warranty does not cover ordinary wear and tear, abuse, alteration of products or damage caused by the

consumer.

To make a warranty claim the consumer must deliver the product at their cost to the original place of

purchase or to any other place which may be nominated by either BWI or the retailer from where the

product was bought in order that a warranty assessment may be performed.The consumer must also deliver

the original invoice evidencing the date and place of purchase together with an explanation in writing as to

the nature of the claim.

In the event that the claim is determined to be for a minor failure of the product then BWI reserves the right

to repair or replace it at its discretion. In the event that a major failure is determined the consumer will be

entitled to a replacement or a refund as well as compensation for any other reasonably foreseeable loss or

damage.This warranty is in addition to any other rights or remedies that the consumer may have under State

or Federal legislation.

IMPORTANT NOTE

Our goods come with guarantees that cannot be excluded under the Australian Consumer Law. You

are entitled to a replacement or refund for a major failure and compensation for any other reasonably

foreseeable loss or damage.You are also entitled to have the goods repaired or replaced if the goods fail to

be of acceptable quality and the failure does not amount to a major failure.

IS402

Issue No. 3 30.10.23

Distributed by

AUSTRALIA

Brown & Watson International Pty Ltd

Knoxeld Victoria 3180

Phone: (03) 9730 6000

Fax: (03) 9730 6050

National Toll Free: 1800 113 443

NEW ZEALAND OFFICE

Grifths Equipment Ltd.

19 Bell Avenue,

Mount Wellington,

Auckland 1060, New Zealand

Phone: (09) 525 4575

Other manuals for INTELLI-RV PM200

1

Table of contents

Other Projecta Controllers manuals