PROLEC Liftwatch 5 User manual

Part Number 560361-020 Issue 1.0 November 2012.

Liftwatch 5 Rated Capacity Indicator

Operator Manual

This guide describes operation of the

PROLEC LIFTWATCH 5 RATED CAPACITY INDICATOR HYDRAULIC EXCAVATORS

Model covered : MODEL Ref LW5 Mk1 Material Handling option

PART No. ?

Prolec supports a nationwide network of fully trained service engineers. Warranty claims, service work, technical information and spare

parts are available by contacting :

Prolec Ltd Telephone +44 (0) 1202 681190

25 Benson Road Fax +44 (0) 1202 677909

Poole Dorset BH17 0GB

DURING NORMAL OPERATION THE SWL OF A CRANE SHOULD NOT BE EXCEEDED. THEREFORE THE WARNING OF

OVERLOAD SHOULD NOT BE USED AS A NORMAL OPERATING FACILITY. IT SHOULD BE NOTED THAT CERTAIN

STATUTORY REQUIREMENTS DO NOT PERMIT THE SAFE WORKING LOAD TO BE EXCEEDED EXCEPT FOR THE PURPOSE

OF TESTING.

THIS RCI IS NOT SUITABLE FOR USE IN EXPLOSIVE ATMOSPHERES. ADJUSTMENT BY UNAUTHORISED PERSONS WILL

INVALIDATE ANY WARRANTY OR CERTIFICATION SUPPLIED. IF A PROBLEM ARISES WHICH CANNOT BE RECTIFIED

USING THIS GUIDE, AUTHORISED SERVICE SHOULD BE SOUGHT.

THIS DEVICE IS CERTIFIED TO MEET CURRENT UK & EC SAFETY REGULATIONS FOR EXCAVATORS USED AS CRANES.

Any alterations or modifications to machine components which affect this system and any system component failure must be reported to

Prolec Ltd or via the machine convertor/service agreement holder. This manual must be kept with the product and be passed on to any

subsequent user of the product.

Manufacturers original instructions.

1 Power up 5

2 Operation - general 7

Operation - overload 8

Operation - motion control 9

Operation - override 10

Operation - low pressure 10

3 System test 11

4 Load charts 13

Contents

Part Number 560361-020 Issue 1.0 November 2012.

5 of 13

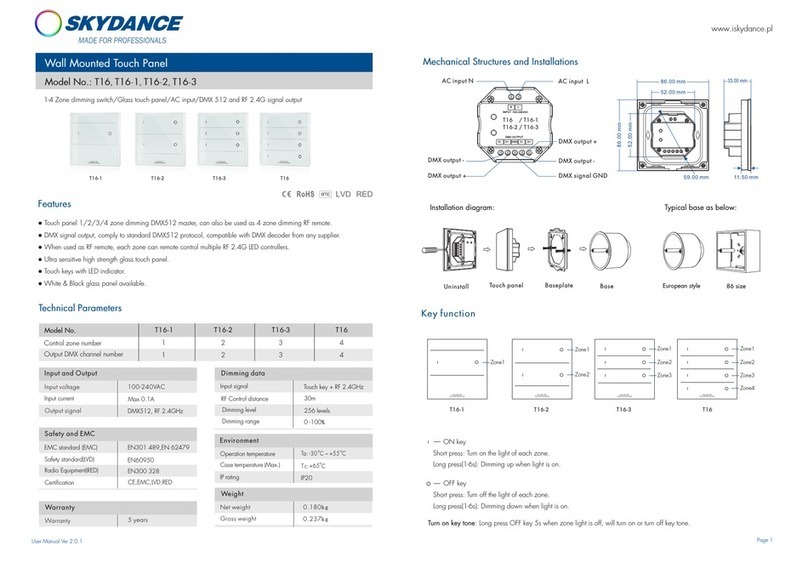

The Liftwatch 5 Rated Capacity Indicator can be configured during installation to operate in one of two ways.

Automatic

If the auto-on link has been fitted to the display PCB, Liftwatch 5 will automatically power up when the machine ignition is switched on.

Manual

If the LCD display remains blank after the machine ignition is switched on, press the ON/OFF button once (circled in red below).

1 Power up

Once powered, Liftwatch 5 will perform an initialising process and system self test. If these processes are successful, normal operation

will commence. If a problem is detected, the system will fail to safe and all machine hydraulics will be disabled. The following page

describes possible failure states.

Part Number 560361-020 Issue 1.0 November 2012.

6 of 13

1 Power up (continued)

ANG1 no response :

This message indicates the combined

boom angle and dual pressure

transducer CAN bus sensor is not

operating correctly. The error message

and ‘press [any] key’ message will

alternate. Press any key to continue.

ANG2 no response :

This message indicates the arm angle

CAN bus sensor is not operating

correctly. .

COMB no response :

This message indicates the combined

input/output CAN bus controller is not

operating correctly. .

The unit will now display one or more of the messages shown below. Both the internal and external alarms will operate and the red LED

will illuminate.

Part Number 560361-020 Issue 1.0 November 2012.

7 of 13

2 Operation - general

Radius

Distance in metres from the slew

centre line to the lifting point.

SWL*

Maximum safe working load in tonnes for the active lifting duty. The

load is assumed to be suspended vertically below the lifting point.

The preceding Hindicates that the maximum safe load is limited by

hydraulic capacity, not stability.

Lifting duty

Active lifting duty. Most

machine will have a

single lifting duty—

normally 360° operation.

Duty switching, when

available, can be either

manually controlled or

sensed automatically.

Bar Graph

This indicates the lifting

capacity currently being

utilised.

LOH

Load on hook. This is the weight of

the currently suspended load in

tonnes.

Status LED’s

These indicate system

states and are discussed

in the following pages.

*Any non-permanent attachment (e.g. grab, spreader beam etc) and all lifting accessories (slings & chains etc) are deemed to be part

of the suspended load.

Part Number 560361-020 Issue 1.0 November 2012.

8 of 13

2 Operation - overload

Approach to maximum safe working load

When the suspended load constitutes more than 95% of the maximum permissible safe working load the amber LED will illuminate and

the internal alarm will sound.

When the suspended load exceeds the maximum permissible safe working load by more than 5% the red LED will illuminate, the

internal and external alarms will sound, and all equipment motions that would decrease the SWL further will be disabled. Dangerous

equipment motions are those that either raise the load further, or increase the load radius. Examples for a monoboom machine are

shown on the following page.

Part Number 560361-020 Issue 1.0 November 2012.

9 of 13

A green arrow indicates that the SWL will be increased if that section of the equipment is moved in the direction of the arrow

An amber arrow indicates that the SWL will decrease (as the radius increases) if the equipment is moved in that direction.

A red arrow indicates that the load will be RAISED if the equipment is moved in that direction.

2 Operation - motion control

Part Number 560361-020 Issue 1.0 November 2012.

10 of 13

2 Operation - override

When the system is in a overload condition certain equipment motions will be disabled. Condition No 4 shown on the previous page has

all motions disabled. To allow the machine to be moved to a safe position the motion control can be cancelled. To override the system

press the MODE button. The red LED and the internal and external alarms will still operate, but hydraulic control will be released. The

system will automatically cancel the override function when the machine reaches a safe position.

2 Operation - low pressure The measurement of hydraulic oil pressure

in the boom lift cylinder is crucial to the

operation of the RCI. In the event of low

pressure being detected the message

shown here will appear, the amber LED will

illuminate, and the internal alarm will sound.

This condition can be ignored it the

equipment is resting on the ground as low

pressure under this circumstance is normal.

Part Number 560361-020 Issue 1.0 November 2012.

11 of 13

3 System test

If there is a suspected fault with the

Liftwatch 5 system, basic diagnostics are

available via the TEST button. The test

function can be accessed at any time

other than when in an overload condition.

Press TEST to access this feature. Press

TEST again to scroll through the available

displays. Press MODE at any time to exit

back to normal operation.

A brief description of each display is given

on the right.

Software version number (1.08). This number

should be quoted in any communication with Prolec

or their appointed agents.

Programmed boom length. This is the boom pivot

pin to arm pivot pin straight line distance in metres.

Equipment lengths can only be altered by Prolec or

their appointed agents.

Programmed arm length. This is the arm pivot pin to

lifting tool pin straight line distance in metres.

Equipment lengths can only be altered by Prolec or

their appointed agents.

When this display is shown the cab roof mounted

rotating beacon should operate (if fitted).

When this display is shown the external alarm

should operate.

When this display is shown the internal alarm should

operate.

When this display is shown the display amber LED

should operate.

Part Number 560361-020 Issue 1.0 November 2012.

12 of 13

3 System test (continued)

When this display is shown the display red LED

should operate.

Pressure is shown in bars. The pressure should

increase with additional load, or increased load

radius. Pressure should fall to zero when the

equipment rests on the ground.

Boom angle is shown in degrees. When a line

between the boom pivot pin and the arm pivot pin is

horizontal, this should show 0°. The angle will

increase as the boom is raised.

Arm angle is shown in degrees. When a line

between the arm pivot pin and the lifting tool pin is

vertical, this should show 90°. The angle will

decrease as the arm is moved outwards.

This display shows the time and date when the

system was initially commissioned.

Part Number 560361-020 Issue 1.0 November 2012.

13 of 13

4 Load charts

Each Liftwatch 5 system will have one or more load charts similar to the EXAMPLE above. Maximum safe working loads are given in

tonnes at suitable height and radius increments. Radius is given in metres and is the distance from the slew centre line to the lifting tool

pin. Height is given in metres and is from ground level to the lifting tool pin. If a particular load is limited by hydraulic capacity rather than

stability, it will have a letter appended. b = limited by boom cylinder hydraulics, a= limited by arm cylinder hydraulics.

The machine is assumed to be positioned on firm and level ground.

Part Number 560361-020 Issue 1.0 November 2012.

Prolec Ltd

25 Benson Road

Nuffield Industrial Estate

Poole

England

BH17 0GB

Tel: +44 (0)1202 681190

Table of contents

Popular Touch Panel manuals by other brands

Emerson

Emerson RXi quick start guide

Beijer Electronics

Beijer Electronics X2 extreme 15 HP web installation manual

Acnodes

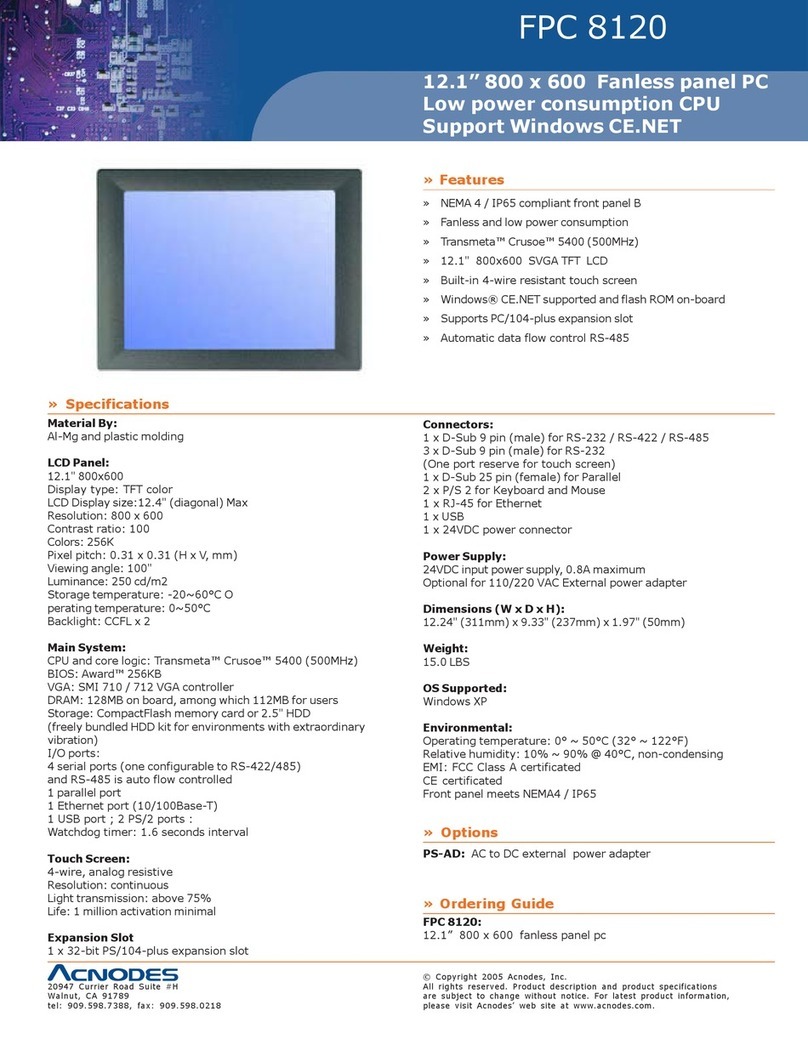

Acnodes FPC 8120 Specifications

Displays2go

Displays2go DGSNKTCH43BK user manual

Maple Systems

Maple Systems OMI6800 Series Operation manual

ExpertDAQ

ExpertDAQ EX-919 V Series user manual