Prolitec AirQ AQ1200 User manual

by Prolitec

AQ/PS/RZ 1200 & 1200-SOC

Original Instructions

Rev. 2015-05-15

AQ/PS/RZ 1200 2

Contents

Chapter 1: About AirQ 1200

Chapter 2: Cartridge Life & Room Size Table

Estimating Cartridge Life

Room-Size Table

Chapter 3: IMPORTANT SAFETY

INSTRUCTIONS

Appliance Precautions

Fragrance Precautions

Chapter 4: MOVING AND STORAGE

INSTRUCTIONS

Chapter 5: Appliance and Controls

Chapter 6: USER MAINTENANCE

Changing the Cartridge

O-Ring Replacement

Air Filters and Check Valve

Battery Replacement

Chapter 7: OPERATING INSTRUCTIONS

Unit Programming

Setting Scent Intensity

Scent Control

Chapter 8: INSTALLATION:

Diusion via HVAC system

Installation Kit for Appliance

Installation Kit for HVAC System DIusion

HVAC Pre-installation Checklist

Appliance Positioning

Appliance Installation

Injector Tube Installation

Chapter 9: INSTALLATION:

Diusion via Direct Indoor Fan

Installation Kit for Appliance

Installation Kit for Fan

Pre-installation Checklist

Appliance Positioning

Appliance Installation

Diusion Fan Installation

Chapter 10: Troubleshooting

Chapter 11: General Care and

Customer Support

Chapter 12: Specications

AQ/PS/RZ 1200 3Chapter 1 About AQ/PS/RZ 1200

About AQ/PS/RZ 1200

Welcome to a whole new world of air treatment from Prolitec, the technology leader in air care with scent.

The AQ1200 appliance is the most advanced commercial air-treatment system on the market today. It is the

world’s rst fully adjustable commercial air-treatment system engineered to serve indoor spaces.

AQ1200 is a patented, computer-controlled, always-on system capable of maintaining a constant, uniform

and controlled level of scent or odor neutralizer.

The AQ1200 converts fragrances and odor control formulations (“Agents”) into ultra-ne droplets for

controlled distribution as an aerosol or vapor directly into a room or via the airow of the HVAC system,

either through the central fan unit (CFU) or at suitable locations in the branched ductwork. It is designed for

permanent installation on a wall in the area to be treated or integrated with the CFU.

The AQ1200 is managed by an on-board computer that is fully adjustable, enabling intensity settings to

match space sizes from 1,800 to 150,000 cubic feet (50-4,200 cubic meters) per appliance. The AQ1200 is

programmable, capable of executing 21 distinct start and stop times, repeatable daily or weekly. Utilizing

up to 21 programs and the full range of 50 intensity settings allows you to optimize the fragrance levels

depending on peak and non-peak occupancy in the space. This new feature can save you money on

fragrance AND service visits. Multiple appliances can work together on the same or multiple CFUs to treat

the air in the same spaces served by the HVAC. Multiple appliances can work together in the same space.

Typical AQ1200 applications include air treatment to enhance or improve indoor air quality including

odor cancelling, and ambient scenting in public spaces such as casinos, malls, hotels, theaters, ballrooms,

convention centers, hospitals, retirement and assisted living facilities, schools and restrooms. A single

AQ1200 can do both odor control and ambient scenting at the same time.

The AQ1200 with Prolitec odor control formulations and fragrances will cancel a wide range of oensive

odors and replace them with pleasant scents available from the Prolitec fragrance catalog or custom

developed to meet client requirements.

The AQ1200 works by generating ultra ne, ultra-light droplets approximately 1 micrometer (µm) in

diameter. By comparison, a droplet from a typical pressurized aerosol spray can is 50 microns (50000

nanometers) in diameter or 50 times larger than an AQ1200 droplet. In terms of weight and volume of

liquid, the comparison is even more dramatic. A 50-micron aerosol droplet is 125,000 times heavier than a

1 µm AirQ droplet.1 (See also Table 1 below.) This tiny AirQ droplet oers many performance benets over

a conventional aerosol including: completely uniform distribution of the treatment agent; 50 times more

exposed surface area; and the absence of any liquid deposits on surfaces such as the interior surfaces in an

HVAC system.

AQ1200 is simple to install and program for specic room size, airow conditions, and desired scent

intensity. Minimal maintenance is required beyond the periodic change of the disposable fragrance

cartridge, inspection and annual replacement of three O-rings, and a simple wipe down or dusting of

exterior surfaces. Once installed in the right location, AQ1200 will outperform any other system, providing

completely uniform scent distribution.

The AQ1200’s advanced technology creates a scent eect with a smaller quantity of fragrance ingredients

than any other method. The chemicals employed in making AQ1200 fragrances are fully compliant with

the most restrictive air-quality and inhalation standards. AQ1200 generates no harmful VOCs and uses no

ethanol or propellants. Quite simply, used as directed, AQ1200 is the greenest, most eco- friendly way to

introduce scent into an interior space with no negative impact on indoor air quality. This is not an accident.

1

AQ/PS/RZ 1200 4Chapter 1 About AQ/PS/RZ 1200

The scientists and engineers at Prolitec are committed to the highest ecological and human safety

standards.

This user guide is easy to read. It is also important to read. AQ1200 is a high-performance appliance that,

installed and used correctly, will meet the most demanding requirements.

Table 1. Prolitec AirQ Technology vs. Aerosol Spray Can Technology

Parameter Prolitec AirQ Technology Aerosol Spray Can

Droplet Diameter, µm 1 50

Volume per Droplet, µm3 0.52 65,450

Surface Area per Droplet, µm2 3 7,854

Relative Volume per Droplet 1 125,000

Relative Weight per Droplet 1 125,000

Number of Droplets per Equivalent Volume 125,000 1

Surface Area/Volume, µm-1 6.00 0.12

Relative Surface Area per Volume 50 1

©Prolitec Inc 2009, 2015

1

AQ/PS/RZ 1200 5Chapter 2 Cartridge Life & Room Size Table

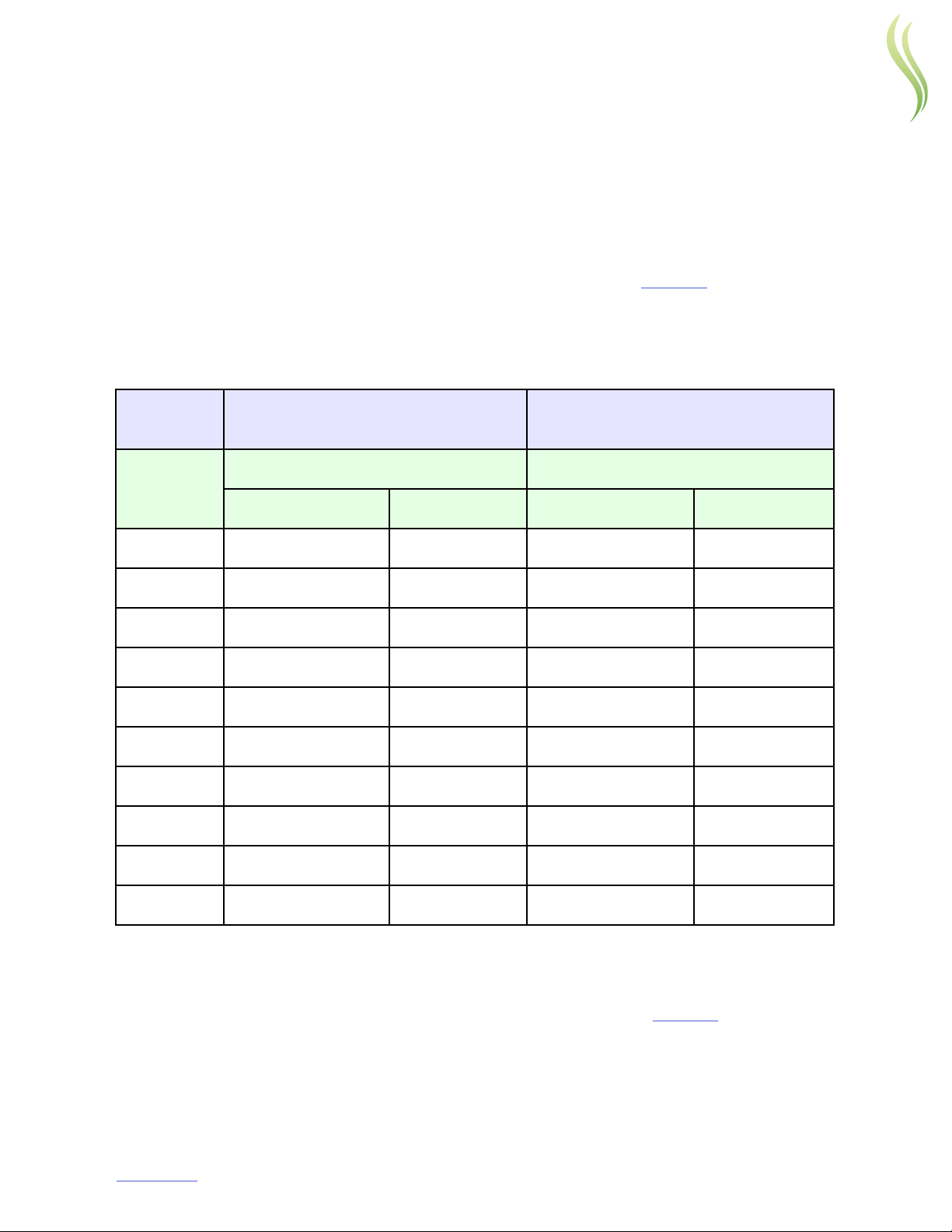

Cartridge Life & Room Size Table

Estimating Cartridge Life

Estimating how long a cartridge will last and the number of days between services is critical to performing

an installation that can be serviced eiciently. This includes determining the number of AQ1200s needed

for a space. Please refer to AirQ’s ‘S3 (Sizing, Service & Success) Tool,’ available at AirQ Tools. The chart

below can be used as a rough guideline for sizing.

Room-Size Table

Normal O-Cycle

(NOC)

Short O-Cycle

(SOC)

Output Level

Range

Room Volume Range Room Volume Range

CFT CM CFT CM

1-5 1800-8100 51-229 6000-25000 170-708

6-10 10000-17400 283-492 30000-47100 849-1333

11-15 19300-27700 546-784 51100-66300 1446-1876

16-20 30000-39700 849-1124 70000-83600 1981-2366

21-25 42300-53400 1197-1511 86800-98900 2456-2799

26-30 56300-68600 1593-1941 101600-112000 2875-3170

31-35 71800-812000 2032-2425 114400-123500 3238-3495

36-40 89400-104800 2530-2966 125600-133600 3554-3781

41-45 108900-126200 3082-3571 135400-142300 3832-4027

46-50 130700-150000 3699-4245 143900-150000 4072-4245

These settings are suggested as a starting point. Start on the lower end of the range and adjust aer one

hour. Fragrance type, room size, number of fresh air changes per hour, temperature, humidity and user

preference will determine the nal setting. Best practice is to use AirQ’s ‘S3 Tool’ at AirQ Tools.

2

AQ/PS/RZ 1200 6Chapter 3 IMPORTANT SAFETY INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS – SAVE THESE INSTRUCTIONS

Appliance Precautions

1. WARNING – When using electric products, basic precautions should always be followed, including the

following:

• Read all the instructions before using the product.

• Children should be supervised not to play with the appliance.

• Do not put ngers or hands into the product.

• The appliance must be operated in an upright or vertical position.

• The appliance should not be used with the door in the open position. The door is opened only to

perform a cartridge or program change.

• Never put your nose to the output of the AQ1200. Within 12 inches of the output, the fragrance is

highly concentrated. The improper inhalation of high concentrations of fragrance may cause irritation

including watery eyes, headache, cough and upper respiratory discomfort.

• This appliance is not intended for use by persons with reduced physical, sensory or mental capabilities,

or lack of experience and knowledge, unless they have been given supervision or instruction

concerning use of the appliance by a person responsible for their safety.

2. INSTRUCTIONS PERTAINING TO A RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS

• The appliance is built to be plugged into an 110VAC or 220VAC power outlet. Must be used only with the

approved and included power supply. The UL and CE compliant power supply converts power to 12V

DC to power the appliance. The appliance must only be supplied at Safety Extra Low Voltage (SELV).

• If the supply cord is damaged, it must be replaced by the manufacturer, its service agent, or similarly

qualied persons in order to avoid a hazard.

• Unplug before cleaning.

• To reduce the risk of electric shock, the appliance should only be plugged into a properly grounded

outlet box. If there is any doubt as to whether an outlet box is properly grounded, a qualied electrician

should be consulted.

3

AQ/PS/RZ 1200 7Chapter 4 MOVING & STORAGE INSTRUCTIONS

Fragrance Cartridge Precautions

• Use only AirQ by Prolitec fragrance cartridges.

• Read the Consumer Product Safety Information Sheet and the Material Safety Data Sheet provided

with each shipment of Cartridges. Insure that these information sheets are available for review by

employees.

• Use latex gloves to handle a Cartridge to avoid the liquid getting on hands. The AirQ fragrances

are formulated so as to not be harmful in contact with the skin, but the concentrated nature of the

fragrances may make the scent diicult to remove from hands and skin.

• Wash your hands aer all contact with Cartridges or fragrance.

• While AirQ Air Treatment Agents do not contain ingredients deemed harmful to the skin, if there is skin

contact, wash with soap and water. If there is contact with the eyes, irrigate the eye with fresh water for

5 minutes. If there is any eye irritation, consult a physician immediately.

MOVING AND STORAGE INSTRUCTIONS

1. Remove the cartridge.

2. Unscrew and remove the long round-head screws in the lower corners.

3. Li the appliance upward, o the mounting posts.

4. Unplug the appliance.

5. Unscrew the mounting plate.

6. Store at -4°F (-20°C) to 158°F (70°C), 5% to 95% humidity

3& 4

AQ/PS/RZ 1200 9Chapter 6 USER MAINTENANCE

USER MAINTENANCE

Changing the Cartridge

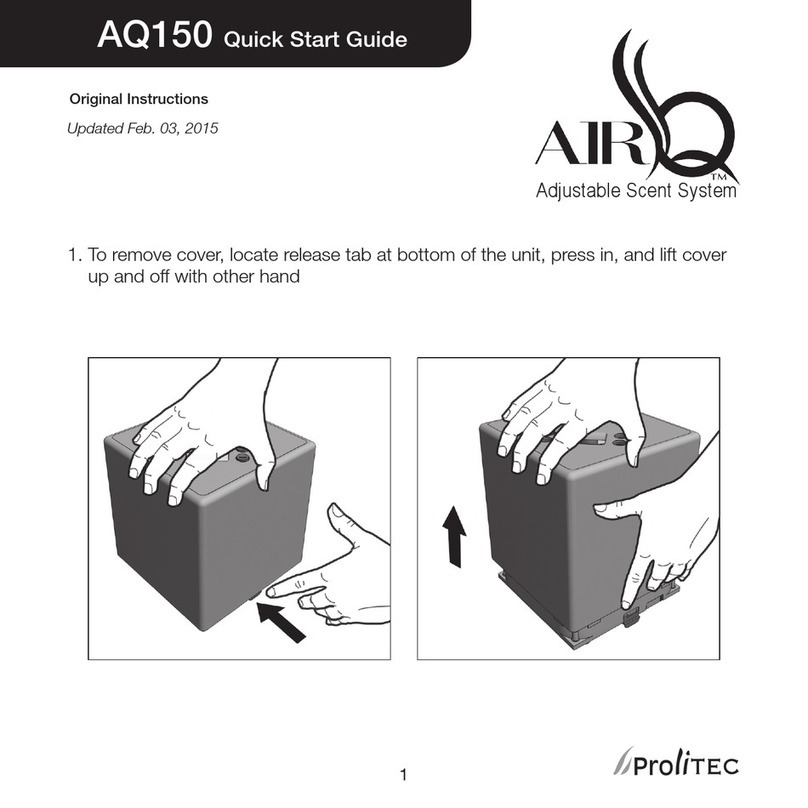

1. Unlatch and open the door to access the cartridge: The door should be opened only to perform a

cartridge or programming change. When in use, the door must be closed.

2. Press POWER button to turn appliance OFF.

3. Remove air nozzle (located on the side of the cartridge head) by rotating 90 degrees and pulling

towards you. (See Fig. 1)

4. Detach injector hose and hose connector from the cartridge output port (located on the top of the

cartridge head). This is done by unscrewing the hose connector from the cartridge output port and

pulling out.

5. Remove cartridge from appliance enclosure.

6. Install new cartridge, place and tighten hose connector rmly on cartridge output port.

7. Insert air nozzle and rotate the handle 90 degrees until secured (by stem retaining tab on cartridge

head). (See Fig. 2)

8. Turn appliance ON. Verify that the plume is not escaping inside the appliance and that all connections

are tight. Close the door when complete.

Fig. 1 Fig. 2

O-Ring Replacement (each year or as needed)

1. Replace the air nozzle’s three O-rings (PN 8212) if worn or damaged. Replace as needed and/or each

year for preventative maintenance.

2. If there is any fragrance that leaks during the cartridge installation, clean it carefully with a paper towel

and some ethanol or another alcohol.

6

AQ/PS/RZ 1200 10Chapter 6 USER MAINTENANCE

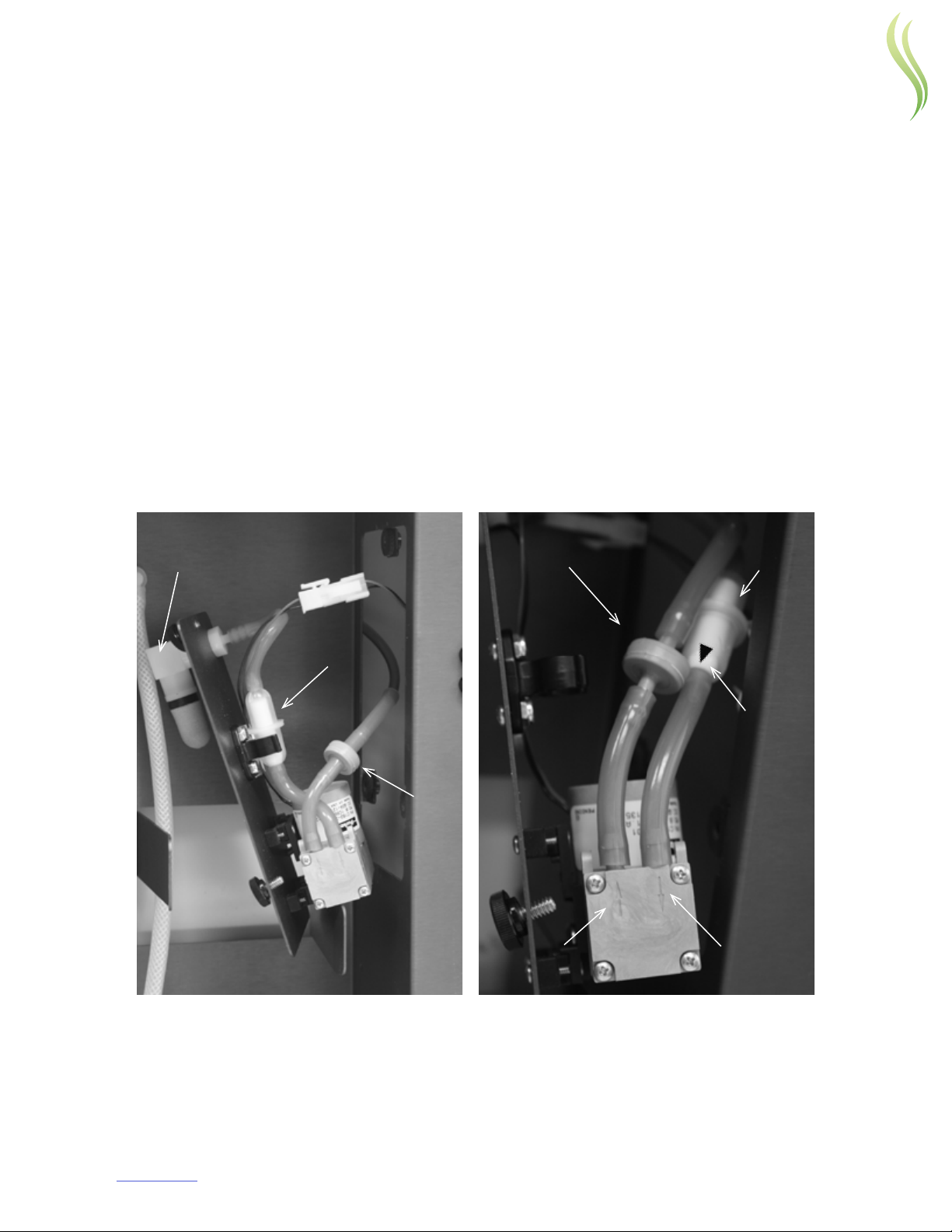

Air Filters and check valve

(every 6 months or sooner depending on use)

AQ1200 is equipped with two stages of air ltration and a check valve system.

The rst stage is a sintered lter (PN 10417). It is can be unscrewed and washed with clean water as

needed. Replace every six months.

The second stage lter (PN 5251) collects ne dust. Replace every 6 months or sooner depending on use. It

is accessible behind the air pump panel. A layer of black dust on top of the ltering media is a sign that the

lter should be replaced. To replace it, unscrew the 3 knobs to open the panel and exchange the lter aer

pulling o the rubber tubing from both sides of the lter. Note the small triangle showing the normal air

ow direction and position lter accordingly as shown below.

The check valve (PN 10200) should be replaced every six months. It is also located behind the panel. Note

the position of the check valve. Replace check valve accordingly as shown below.

Reinstall the panel and screw the three knobs back in place being careful not to strip the threads. The

screws should align and go in easily.

Check

Valve

Second Stage

Filter

Triangle

Pointing Down

Arrow

Pointing

Down

Arrow

Pointing

Up

First Stage

Filter

Second Stage

Filter

Check

Valve

6

AQ/PS/RZ 1200 11Chapter 6 USER MAINTENANCE

Battery Replacement (approximately every two years)

(Requires 3 Volt CR2032 Lithium Battery, PN 8111)

1. Unlatch and open the door to access the enclosure.

2. Using a pair of tweezers or needle-nose pliers, remove battery from the center opening of the battery

grommet. The battery is located on the lower front corner of the silver bracket.

3. Insert the new CR2032 battery. The positive side of the battery should face your right while looking at

the front of the appliance. The battery will have a + or – marking on a side.

NOTE: The battery is necessary to safeguard your program and to

ensure operation will resume automatically even aer several days of

a power interruption. The battery should be replaced at least every 2

years for proper reliable system operation.

6

AQ/PS/RZ 1200 12Chapter 7 OPERATING INSTRUCTIONS

OPERATING INSTRUCTIONS

Unit Programming

1. Unlock and open the door

2. Turn on the power by pressing ON/OFF button in the upper le corner of the control panel.

3. Set the Clock

• Turn the dial to Set Clock. The day-of-week icon will blink.

• Adjust the day forward or backwards using the +/- buttons on the right side of the control panel.

• Press the Set button on the lower le corner of the LCD display. The time will blink.

• Adjust the time forward or backwards using the +/- buttons. AM or PM is indicated on the right side

of the time digits.

4. 24/7 Mode

• If you want the AQ1200 to run continuously -7 days a week, 24 hours a day 7 Days a week turn the

dial to Run 24/7. If not, skip to Step 5.

• You can adjust the fragrance intensity level (1 to 50) using the +/- buttons. Refer to Setting Scent

Intensity for the intensity level to set.

5. Set multi-program timer

• Turn the dial to Set Program. The Program icon comes on.

• The day-of-week icons will all blink, indicating you are selecting all days with the same program. If

you want to program a specic day, use the +/- buttons to select the day. You can set maximum of

3 on/o programs same for every day or individually for each day. Aer selecting the day, press the

Set button to advance.

• Now the “1” icon is turned on to indicate you are setting program 1. The Rate digits blink to prompt

you to set the rate. You may set to any value between 1 to 50, or set to 0 to disable the program.

Press the Set button to advance.

• If you set the rate to 0, then the current and subsequent programs are all disabled. For example, if

the rate for program 2 is 0, then program 2 and 3 are disabled.

• If you set a non-zero rate, then the rate digit changes to “S” to indicate start time. The hour digit

should blink to prompt you to set the start hour. Use the +/- buttons to set the hour. Then press the

Set button to advance and set the minute. Press the Set button to advance.

• The rate digit now changes to “E” to indicate you are setting the end time. Use the +/- buttons to

set the end time. Press the Set button to advance to the next program.

• Program icon 2 should now turn on. Use the +/- and Set buttons to set the start and end times

for program 2 and then for program 3. Note that if you need only 1 or 2 programs for the day, you

simply disable the subsequent programs by setting its rate to 0.

• Aer setting the programs, turn the dial to Run Program.

7

AQ/PS/RZ 1200 13Chapter 7 OPERATING INSTRUCTIONS

HINT:To set same programs for Monday to Friday, you may set the

programs for every day rst and then disable Saturday and Sunday. You

may review the programs by doing the same as in programming. Just

beware not to accidentally set the every day programs as this will also

set and change the programs of all the days.

Setting Scent Intensity

1. Consult the Room Size Table, which provides a setting for the size in cubic feet (length x width x ceiling

height) of the space you are treating. Use the indicated intensity setting as a starting point from which

you can increase or decrease to taste. Number of fresh air changes per hour and user preference will

aect settings.

2. Press the power button on. Turn the dial to Program and set the intensity level with the +/– keys. You

will see the level numbers (1 to 50) on the right side of the screen.

Hint: There are many variables to nding the scent level that works:

size, airow, number of fresh air changes per hour, number of

people in the space and, most of all, user preferences. Experiment

with dierent levels until you are satised. Utilize the S3 Tool.

Scent Control

If you followed the Room-Size Table or S3 Tool, you have set AQ1200 to the low end of the range for your

room size. If aer one hour you feel the scent is not detectable, increase the setting by about 10%. For

example, if your start setting was 20, increase it by 10%, or to setting 22. Keep increasing until you and

others in the space can detect a slight scent throughout the space.

The Last Step

1. Set the appliance to either 24/7 or Run Program.

2. Make sure the power is on. The blue light will show through the button.

3. Close and lock the door, storing the key in a known place.

7

AQ/PS/RZ 1200 14Chapter 8 INSTALLATION: Diusion via HVAC System

INSTALLATION: Diusion via HVAC System

Installation Kits

Installation Kit for Appliance (included)

1. One (1) AQ1200 appliance (not pictured) with:

2. Four (4) drywall anchors for mounting in drywall

3. Four (4) lead anchors for mounting in concrete

4. Four (4) screws and (4) washers for mounting in drywall and concrete

5. Four (4) #10 self-tapping sheet metal screws for mounting in sheet metal

6. Plume connector: A: (1) Tubing assembly; B: (1) Connector; C: (2) Washers; D: (1) Nut; E: (1) Cable Tie

2

6

543

E

E

C

B

A

8

AQ/PS/RZ 1200 15Chapter 8 INSTALLATION: Diusion via HVAC System

Installation Kit for HVAC System Diusion (included)

1. One (1) Prolitec injector tube for diusion into HVAC system

2. Three (3) #10 self-tapping sheet-metal screws for mounting the injector tube in sheet metal

3. Five (5) feet of injector hose

1

2

3

HVAC Pre-installation Checklist

This checklist should be completed before the install date.

1. Conrm the area to be targeted for air treatment.

2. Determine the Air Handling Unit or duct that serves the target area.

3. Make sure the AHU does not use an open gas ame.

4. Find and mark the optimal insertion point for the Injector Tube. (See “Appliance Positioning” below)

5. Find and mark the exact location for placement of the appliance. (See “Appliance Positioning” below)

6. Note the distance between the insertion point and the proposed appliance location. (NEVER MORE

THAN 5 FEET and there should NEVER be a LOW POINT in the hose run.)

7. Determine and mark the location for the 110 or 220V AC power outlet (NEVER DIRECTLY BELOW THE

appliance).

8

AQ/PS/RZ 1200 16Chapter 8 INSTALLATION: Diusion via HVAC System

Appliance Positioning

It is important to nd an insertion point where the plume output will be smoothly drawn into and mixed

with the airow. This usually means those parts of the AHU where the static pressure is negative. Ideal

locations include:

• Before the supply fan with injection through the wall of the AHU. Positioning immediately before the

fan and aer the coils if possible or in the mixed air chamber.

• Behind the blower with the whole appliance mounted inside the AHU in the mixed air chamber.

• Outside the AHU in the Supply air duct.

Best practice when installing in an AHU is to place the injector tube aer the heating and cooling coils. If

this is not possible, the Plume output can pass over hot water, steam, chilled water, and DX coils.

Open gas ames should absolutely be avoided. If installation must be over gas heated coils or open

gas ames, contact Prolitec Technical Support.

The best location for the Appliance is below the injector tube (Fig. 15). The injector hose should be run

upward as short a distance as possible and NEVER MORE THAN 3 FEET. If an upward injector hose run is

not possible, care should be taken support the hose to prevent sagging or any low spot in the run to avoid

any possibility of condensation and liquid collection which will block the plume output. The injector hose

is prone to stretching, so support points should be placed every 6 inches on horizontal runs. Give the hose

a slight upward slant along its run (See Fig. 16). The hose must not be run horizontally. A strong tape (such

as Venture tape) may be used to support short runs. The hose may be run through PVC pipe for longer

distances.

Injector Tube

AQ1200

Injector Hose

Power

Junction Box

Fig. 15

8

AQ/PS/RZ 1200 17Chapter 8 INSTALLATION: Diusion via HVAC System

Fig. 16

CORRECT INCORRECT

Appliance Installation

1. The appliance is wall-mounted. Place the appliance onto the desired location on the wall or AHU and

ensure that it is level.

2. Fasten the appliance to the wall or AHU using necessary screws.

3. Connect the power cord to a junction box or attach an AC plug to the cord and connect to a nearby

outlet. Open the enclosure door and unscrew the aluminum cap of the waterproof collar located on top

of the appliance enclosure. Remove and set aside the grommet (Fig. 1).

4. Assemble the Plume Connector:

• Insert washer and insert assembly, threaded side rst, through hole on top of the appliance (Fig. 17).

• Insert another washer and secure with nut. Use pliers to ensure a watertight seal (Fig. 18).

• Push the tubing assembly over the barbed tting (Fig. 19).

• Important: Secure with cable tie (Fig. 20).

Thread

Fig. 17 Fig. 18 Fig. 19 Fig. 20

8

AQ/PS/RZ 1200 18Chapter 8 INSTALLATION: Diusion via HVAC System

Injector Tube Installation

The injector tube is installed directly into the AHU or ductwork. Its orientation can be adjusted relative to

airow.

• For installations into the negative/suction side of the AHU fan, orient the tube with the elbow pointed

upwards, so that any plume condensation will drip back down the tube.

• For installations aer the supply fan, such as in a supply duct, it is necessary to congure and orient

the Injector Tube to obtain a good aspiration of the output into the air stream. The injector tube

should be pointed in the direction of the airow and inclined approximately 45o upward. Turbulence

in the airow can prevent even aspiration of the plume. It is best to place the tube in a straight

section of duct, and far away from any turns, branches, or cross-section changes as practical, and not

immediately aer the supply fan.

1. At the insertion point, drill a hole using a ½” drill bit.

2. Insert the Injector Tube through the hole.

3. Find an orientation of the injector Tube that appears to produce a good draw of air into the end of the

barb.

4. Fasten the ange using the three #10 sheet metal screws.

5. Turn the appliance on and verify that a plume is produced.

6. Before attaching the Injector hose to the injector, verify that the plume can ow easily through the

injector. This can be done by placing the end of the hose ½ inch away from the injector and verifying

that the plume is being drawn in (a ashlight will make the plume easier to see). If the plume does not

rise into the hose, adjust the orientation of the Injector Tube until aspiration is achieved.

7. Attach the Injector hose onto the hose barb of the Injector Tube.

For Cartridge Installation – See “Changing the Cartridge”

8

AQ/PS/RZ 1200 19Chapter 9 INSTALLATION: DIusion via Direct Indoor Fan

INSTALLATION: Diusion via Direct Indoor Fan

(Product# AQ1200-FAN)

Installation Kits

Installation Kit for Appliance (included)

1. One (1) AQ1200 appliance (not pictured) with:

2. Four (4) dry wall anchors for mounting in drywall

3. Four (4) lead anchors for mounting in concrete

4. Four (4) screws and (4) washers for mounting in drywall and concrete

5. Four (4) self-tapping sheet metal screws for mounting in sheet metal

6. Plume connector: A: (1) Tubing assembly; B: (1) Connector; C: (2) Washers; D: (1) Nut; E: (1) Cable Tie

2

6

543

E

E

C

B

A

9

AQ/PS/RZ 1200 20Chapter 9 INSTALLATION: DIusion via Direct Indoor Fan

Installation Kit for Fan (accessory sold separately)

1. One (1) Prolitec Diusion fan and cable for direct indoor diusion

2. Three (3) drywall anchors for mounting fan onto dry wall

3. Three (3) lead anchors for mounting in concrete

4. Three (3) screws for mounting in drywall and concrete

5. Five (5) feet of small cable raceway for fan cable

6. Five (5) feet of OD injector hose

1

4

5

6

3

2

9

This manual suits for next models

5

Table of contents

Other Prolitec Accessories manuals

Prolitec

Prolitec AIRQ AQ 570 CM User manual

Prolitec

Prolitec AirQ 270 TT User manual

Prolitec

Prolitec AirQ 380 User manual

Prolitec

Prolitec AirQ AQ550 User manual

Prolitec

Prolitec AQ1570 User manual

Prolitec

Prolitec AIRQ AQ160 User manual

Prolitec

Prolitec AirQ 1570 User manual

Prolitec

Prolitec AirQ AQ150 User manual

Prolitec

Prolitec AirQ AQ 1270 TT User manual

Prolitec

Prolitec AirQ AQ1200WHTTT-SS User manual