Warranty & Return Policy

Proluxe warrants all products manufactured by it against defects in workmanship or materials from the date of purchase for a period of

(1) year on parts and labor. This warranty applies to only equipment purchased and used in the United States. Warranty period

shall begin when equipment ships. Warranty travel shall only be covered for 60 miles. Limited lifetime warranty on heating

elements.

ALL WARRANTY SERVICE CALLS MUST BE APPROVED BY PROLUXE. IF THIS PROCEDURE IS NOT FOLLOWED,

WARRANTY SERVICE WILL NOT BE COVERED. WARRANTY SERVICE WILL BE PAID ON STRAIGHT TIME, OVERTIME WILL

NOT BE COVERED.

Exclusions:

1. WOOD / GAS FIRED OVENS: PROLUXE warranty applies to the main body of the oven being steel / refractory and insulation shall

be free from defects in materials and workmanship for a period of four years from the date of purchase. The gas equipment shall be

free from defects in materials and workmanship for a period of one (1) year

from the date of purchase. Lifetime warranty against cracks on oven floor.

2. Air compressors are excluded from this warranty, but PROLUXE may act as a warranty expeditor in certain instances regarding

these compressors. The air compressor manufacturer provides a limited warranty

and a copy of this warranty is furnished with all compressors sold by PROLUXE. For prompt handling of compressor warranty claims

the instructions of the compressor manufacturer must be adhered to.

3. Equipment built to special order as well as accessories cannot be canceled and are not returnable unless defective within the

terms of this warranty.

4. In no event shall PROLUXE be liable for consequential damages arising out of the failure of any of its products if operated

improperly, altered or caused by normal wear or damage by operator abuse.

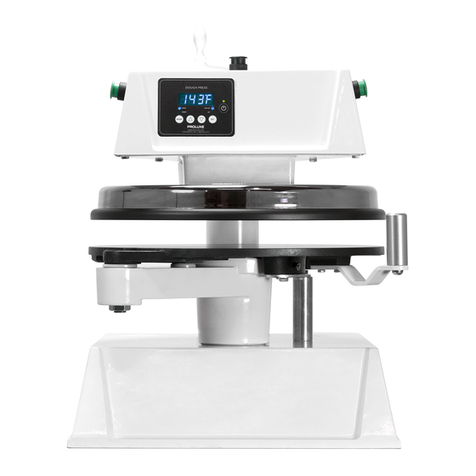

5. BC2325 pedestal warranty disclaimer: Pedestals shall only be covered under warranty if they have been cleaned using the factory

approved cleaning method. Cracked or damaged pedestals must be inspected by the factory before warranty is authorized.

6. Limited lifetime warranty on heating elements: If replacement is needed, Proluxe will send the new part at no charge but labor will

not be covered unless the unit is still under the 1 year manufacture warranty.

Returned Merchandise Policy:

Should it become necessary to return any of the company’s products, the following instructions must be adhered to: First,

contact our customer service department for approval and a return authorization number. Please have the serial number

of your item available at that time. All merchandise must be shipped freight prepaid by customer or service agency.

Subject to the inspection of the product by the company, a restocking charge of 20% of the Net purchased price paid to

PROLUXE will be assessed. Merchandise may not be returned for credit without prior written approval of PROLUXE. Collect shipments

will not be accepted. No returns after 60 days of original shipment date on machines. Purchased parts may not be returned after 30

days.

If upon inspection by PROLUXE or its authorized agent it is determined the equipment has not been used in an appropriate manner,

has been modified, or has not been properly maintained, or has been subject to misuse,

misapplication, neglect, abuse, accident, unauthorized modification, damage during transit, delivery, fire, flood, act or war,

riot or act of God, then this warranty shall be deemed null and void.

Terms & Conditions:

1. Prices indicated in the PRICE LIST are suggested retail prices and are shown in U.S. DOLLARS.

2. Terms of Payment: 1% 10 days, NET 30 days.

3. NEW ACCOUNTS: Satisfactory credit information must be provided before open account status can be extended.

Unless agreed otherwise, all shipments will be made C.O.D., CASH IN ADVANCE.

4. PRICING: Prices, specifications, model numbers, capacities and accessories are subject to change without notice.

5. FREIGHT / ROUTING: Method of shipment will be determined by PROLUXE unless otherwise

advised by PURCHASER.

6. DAMAGED CLAIMS: All merchandise shipped at purchaser’s risk. Inspection must be made by purchaser at time

goods are received. If goods are damaged, the PURCHASER shall request that the agent of the transportation

company make a written notation on the proper shipping documents immediately and then file a claim for damage.

GOODS DAMAGED IN SHIPMENT ARE NOT RETURNABLE.

7. RETURNS: Machines may not be returned after 60 days. Purchased parts may not be returned after 30 days. A

restocking fee of 20% will be assessed on non-warranty returns.

8. TAXES: Prices indicated herein DO NOT include State, Federal, Local or foreign taxes or duties, nor do they include

fees, permits, insurance or other levies, all of which are the responsibility of the purchaser.

9. All orders are subject to acceptance by PROLUXE.

10. Possession of this price list shall not be considered an offer to sell.