Prolyte H30V Rigging Tower User manual

Prolyte H30V Rigging Tower

Assembly Instructions

Prolyte Products Group © 2001 page 1 of 9

Prolyte has made every effort to ensure the accuracy of this manual, no liability will be accepted for errors.

Prolyte reserves the right to change or alter their products or manuals without prior notice.

No part of this manual may be reproduced in any form or by any means without prior written permission.

Prolyte Products Group · phone: +31-594-851515 · fax: +31-594-851516 · www.prolyte.com

Make sure to read and fully understand this manual, and its specific notes and

warnings, prior to assembly and erection of the structure.

Contents:

1 System Description

2 Limitations of use

3 Scope of use

4 Identification, Parts

5 Dimensions & loading

6 General information

7 Assembly instructions

8 System Dimensions

1. SYSTEM DESCRIPTION

The Prolyte H30V Rigging Tower is a lifting tool where the load is constrained by a horizontal and

vertical V-shaped truss frame. The H30V Rigging Tower has a loading capacity that is limited by the

construction. In general rigging towers are used where the lifting of loads from a building structure is

impossible, very expensive, or when traditional telescopic winch stands do not have a sufficient load

capacity, or when the MPT-Tower does not fit the purposes. This H30V rigging tower is used with a

vertical mast of standardized H30V truss as compression absorbing elements, H30V truss as

outriggers and a 60 mm tube as stabilizer brace.

2. LIMITATIONS OF USE

The H30V Rigging Tower is to be used with Prolyte trusses only. Loads to the trusses and towers shall

be vertical only, no side loading is allowed to the system, with an exception for wind loads. The

system may be used up to wind force 8 maximum.

The H30V Rigging Tower is designed as temporary lifting structure for in- and outdoor use. When

horizontal loading is applied, other than wind forces, appropriate measures, such as placing guy-

wires (cable-stays) and ballast, have to be taken to ensure stability.

The H30V Rigging Tower is to be built by competent and trained persons only. For all other

applications contact your local dealer or Prolyte.

3. SCOPE OF USE

Prolyte H30V Rigging Towers are designed for the lifting of speaker clusters or audience lights over

stages, dance floors, exhibition area’s, public area’s, parking lots, etc. This can either be a single (stand-

alone) Tower, or a Goal post configuration (two towers with a single span).

H30V rigging towers are to be built to a maximum height of 7,5m (7 metre mast length).

Prolyte- H30V Rigging Towers comply with the European Machine Directive and bear the CE-mark.

WARNING

Prolyte H30V Rigging Towers are not designed to lift people!

PROLYTE H30V RIGGING TOWER MANUAL

ASSEMBLY INSTRUCTIONS

Prolyte H30V Rigging Tower

Assembly Instructions

Prolyte Products Group © 2001 page 2 of 9

Prolyte has made every effort to ensure the accuracy of this manual, no liability will be accepted for errors.

Prolyte reserves the right to change or alter their products or manuals without prior notice.

No part of this manual may be reproduced in any form or by any means without prior written permission.

Prolyte Products Group · phone: +31-594-851515 · fax: +31-594-851516 · www.prolyte.com

4. IDENTIFICATION

The H30V Rigging Tower (H30V-RT) is composed of the following parts:

Description Code weight remarks

1, 2 Tower trusses H30V 5.1kg/m1Max. height 7 m

3 Square 30 3-way corner 60° RT-H30V-C002 12.2kg V-shaped corner block

4 Layher spindel attachement ACC-Spin-ATT-30 2 kg Pipe with trussclamps to adapt Screwjacks

5 Layher spindel, 40cm long ACC-Spin-LAY-40 12 kg Hot dip sinc plated screwjack, 20cm adjustable

6 Hinge part square truss CCS6-H 0.58kg

7 Topblock rigging tower H30V RT-009H 12,2kg Top section with removeable 30mm spigot

8 Stabelizer attachment H30V RT-STAB-H30V 2,7kg Frame with clamps to attach bracing to trusses

9 Stabelizer attachment H30V RT-STAB-H30V-TOP 6,4kg Frame with side-entry clamps to attach bracing

10 Stabelizer tube 60 mm RT-T60-CC298CC 8kg Stabelizer tube with conical CCS7 couplers

11 Conical Coupler CCS6-600 0.14kg

12 Spigot CCS6-603 0.04kg

13 Safety R-spring CCS6-605 0.01kg

14 Spigot CCS7-703 0.11kg

15 Safety R-spring CCS7-705 0.01kg

The embossed ring on the ends of the conical coupler receivers, and stickers featuring the Prolyte logo

can clearly identify the MPT towers and truss.

5. DIMENSIONS & LOADING

The maximum allowable height of a complete H30V Rigging Tower shall be no more than 7 m,

including spindles and top-section.

The maximum allowable load to a H30V rigging tower of 7 m is:

Outdoor (max. wind force 8): 550 kg

Indoor (no wind): 700 kg

The max. load relates to the height of the tower. Please consult our engineering department if you

want to deviate from the given values.

The amount of Ballast that should be applied is:

Outdoor (max. wind force 8): 100 kg per leg

Indoor (no wind): no ballast needed

The necessary amount of ballast relates to the height of the tower, applied load and load surface.

Please consult our engineering department if you want to deviate from the given values.

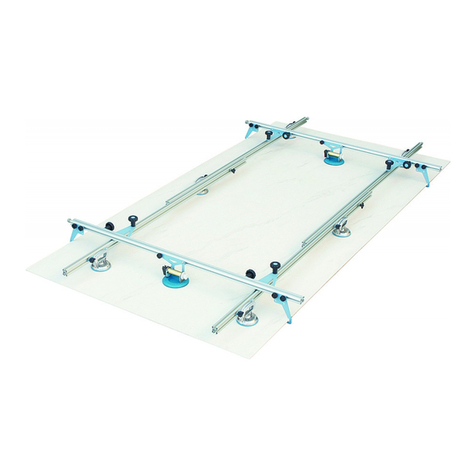

Loading dimensions:

The total surface of the load may not exceed 2,5 square meters at the front, and max. 1,25 square

meters at the sides.

The surface area per H30V rigging tower base is approximate 3.80x 3.20m

NOTE

Make sure the system is built only of genuine Prolyte components, which are clearly and positively

identified as Prolyte products. Copies do exist, and even though they may appear to fit to Prolyte trusses,

the

y

do not have identical stren

g

th and safet

y

characteristics.

WARNING

Payloads are to be vertical only at all times. Side loads are NOT permitted.

Prolyte H30V Rigging Tower

Assembly Instructions

Prolyte Products Group © 2001 page 3 of 9

Prolyte has made every effort to ensure the accuracy of this manual, no liability will be accepted for errors.

Prolyte reserves the right to change or alter their products or manuals without prior notice.

No part of this manual may be reproduced in any form or by any means without prior written permission.

Prolyte Products Group · phone: +31-594-851515 · fax: +31-594-851516 · www.prolyte.com

6. GENERAL INFORMATION

1) First identify all separate components and types of Prolyte truss to be used, ensure that you are

fully conversant with this manual before you start using any of these parts, components and

trusses!

2) Never use trusses parts or vital components such as wire ropes (or chains), that show visual

damage, deformation wear or have any other reason to doubt the safe functioning within the

system. Make sure to check each item before each time of use.

3) Make sure that the system is built on solid ground. In situations where it has to be built on grass,

sand or any unstable subsoil, under fill the screw jacks with plywood pads of 300x300x20mm

(minimum size for each screw jack).

4) Check the building site for obvious hazardous objects such as power lines. Keep a safe distance of

at least 8m from those in any possible direction of sway in the wind, or the distance as specified in

the national or local codes or regulations for safe operation of mobile cranes. Always check the

planned tower-building activity with the power-company.

5) Check the building site for obstacles such as lamp-posts, trees or tree-tops, overhead piping, in

house constructions, or any other higher objects that might hamper erection of the towers or

might endanger it when swaying in the wind or so.

6) Check local authorities for possible risks in subsoil, such as low stability peat or bog fillings, sewer

or large drainage pipes, waterlogged soils in slopes etc.

7) Measure the area where the tower needs to be and make sure there is enough room for all

components including the outriggers with the plywood padding (the free and cleared building

site for each tower, needs to be app. 3.5m wide, 7.5m deep and 8m high).(1)

8) The complete tower should be totally level when built. If the tower is not exactly level this may

result in constructive weakness of the system.

9) Avoid dynamic loads. Do not turn the hoist on and off when hoisting the load in place. Lift the

load as steady as possible.

10) Make sure the load can not turn once hoisted in place. Use tag-lines if needed.

11) Make sure the screw jack bracing attachments are placed correctly in alignment to the geometry of

the truss sections.

1Except in the situations of hazardous objects or obstacles as mentioned above.

NOTE

Make sure only one competent person is chosen to be responsible for and in charge of all coordinating

actions and supervising the entire building, erecting and dismantling process.

WARNING

Even if local legislation might be lacking any demands on personal safety, it is strongly advised to use fall

protection-equipment when climbing the system during building, particularly at over 2m high from

ground level, when falling hazards are prominent.

NOTE

The ground pressure on the screw jacks underneath a tower can easily be more than 0,95 ton with dead

load, live load, wind load and full ballast imposed!

Never erect the tower when any doubt remains on the safety of the underlying ground.

Prolyte H30V Rigging Tower

Assembly Instructions

Prolyte Products Group © 2001 page 4 of 9

Prolyte has made every effort to ensure the accuracy of this manual, no liability will be accepted for errors.

Prolyte reserves the right to change or alter their products or manuals without prior notice.

No part of this manual may be reproduced in any form or by any means without prior written permission.

Prolyte Products Group · phone: +31-594-851515 · fax: +31-594-851516 · www.prolyte.com

7. ASSEMBLY INSTRUCTIONS

Assembly of a H30V Rigging Tower

5

3

2

4

1

1. Mast

2. Legs/outriggers

3. Top section

4. Stabilizers

5. Spindles

6. Stabilizer attachment

6

Prolyte H30V Rigging Tower

Assembly Instructions

Prolyte Products Group © 2001 page 5 of 9

Prolyte has made every effort to ensure the accuracy of this manual, no liability will be accepted for errors.

Prolyte reserves the right to change or alter their products or manuals without prior notice.

No part of this manual may be reproduced in any form or by any means without prior written permission.

Prolyte Products Group · phone: +31-594-851515 · fax: +31-594-851516 · www.prolyte.com

Assemble and connect the corner

and the legs of the base.

2

Then level the complete base by

adjusting the screwjacks at the end

of the legs. Work from front to rear

side.

4

Unscrew the intermediate screw

j

acks

until their footplates rest on the

ground.

Place the hinge-parts as shown on

the drawin

g

, to facilitate the erection

of the mast. Mount the other hinge-

parts in a simular way to the bottom

end of the mast.

Level the V-shaped base, starting

with the corner. Adjust the

screwjacks as far as necessary, work

from left to right.

3

Inspect all components before using them on visual wear & tear, deformation, damage or any other

shortcomings. NEVER use parts or component that are not visually correct or you suspect have been subject

to other damage.

1

Prolyte H30V Rigging Tower

Assembly Instructions

Prolyte Products Group © 2001 page 6 of 9

Prolyte has made every effort to ensure the accuracy of this manual, no liability will be accepted for errors.

Prolyte reserves the right to change or alter their products or manuals without prior notice.

No part of this manual may be reproduced in any form or by any means without prior written permission.

Prolyte Products Group · phone: +31-594-851515 · fax: +31-594-851516 · www.prolyte.com

Build the mast from the parts as shown on

the drawing. Other lenghts may be used.

Make sure the stabilizer adapter is placed at

the connection of two trusses.

6

Mount the stabilizer attachment to the

trusses.

7

Attach the stabilizer tubes.

8

Prolyte H30V Rigging Tower

Assembly Instructions

Prolyte Products Group © 2001 page 7 of 9

Prolyte has made every effort to ensure the accuracy of this manual, no liability will be accepted for errors.

Prolyte reserves the right to change or alter their products or manuals without prior notice.

No part of this manual may be reproduced in any form or by any means without prior written permission.

Prolyte Products Group · phone: +31-594-851515 · fax: +31-594-851516 · www.prolyte.com

Attach the top hook of the hoist chain that

will hoist the load in place.

Note: The rigging tower is not

desi

g

ned to accommodate double

reeved chains.

9

Use two people to lift the mast in place. A

third person should be ready to mount the

hinge spigot from the back once the mast is

completly erect.

10

Mount the stabilizer tubes, by means of the

stabilizer attachments to the trusses in the

legs.

All bolts of the clamps should be tightened

with the aid of a torque wrench, the used

torque should be no more or less then

50N/m.

11

Prolyte H30V Rigging Tower

Assembly Instructions

Prolyte Products Group © 2001 page 8 of 9

Prolyte has made every effort to ensure the accuracy of this manual, no liability will be accepted for errors.

Prolyte reserves the right to change or alter their products or manuals without prior notice.

No part of this manual may be reproduced in any form or by any means without prior written permission.

Prolyte Products Group · phone: +31-594-851515 · fax: +31-594-851516 · www.prolyte.com

Always make sure that the floor or subsoil is

sufficiently capable of carrying the load of the tower

as it is transferred through the screw jack dishes. Use

plywood panels or similar material to increase

bearing capacity if needed. When in doubt check with

a competent person.

14

WARNING

Neglecting the addition of the appropriate amount of ballast and/or not applying part of the guy

wires is dangerous. Under influence of wind this can result in failure of the complete structure.

WARNING:

NOT FOLLOWING THE GUIDELINES IN THIS

MANUAL MAY CAUSE DANGER, PROPERTY

DAMAGE, INJURIES OR EVEN DEATH.

Before the load is raised check the vertical position of

the tower and proper surface contact of the screw jack

dishes. Adjust the screw jacks if necessary.

Determine the weight of the load before lifting.

Run the system up to trim height, and secure it in this

position by means of a secondary independent

support such as a clutch chain or wire rope.

Check if the tower is in an exact vertical position,

using a level with a plumb-position-eye. Correct any

angles in tightening or releasing the screw jacks of the

base outriggers

Apply the prescribed amount of ballast to the legs of

the tower.

12

Make sure that the hook of the hoist chain is

slinged excactly in the middle of the shaft of the

top section, in such way that an even

distribution of the load to both sides of the top

section is acchieved. To provide the hook from

sliding along the shaft, the best slinging method

would be a choke hitch.

13

Prolyte H30V Rigging Tower

Assembly Instructions

Prolyte Products Group © 2001 page 9 of 9

Prolyte has made every effort to ensure the accuracy of this manual, no liability will be accepted for errors.

Prolyte reserves the right to change or alter their products or manuals without prior notice.

No part of this manual may be reproduced in any form or by any means without prior written permission.

Prolyte Products Group · phone: +31-594-851515 · fax: +31-594-851516 · www.prolyte.com

8. SYSTEM DIMENSIONS

This manual suits for next models

1

Other Prolyte Lifting System manuals