Promega Corporation · 2800 Woods Hollow Road ·Madison, WI 53711-5399 USA ·Toll Free in USA 800-356-9526 ·Phone 608-274-4330 ·Fax 608-277-2516 · www.promega.com

Printed in USA. Part# TM274

Revised 6/08 Page 7

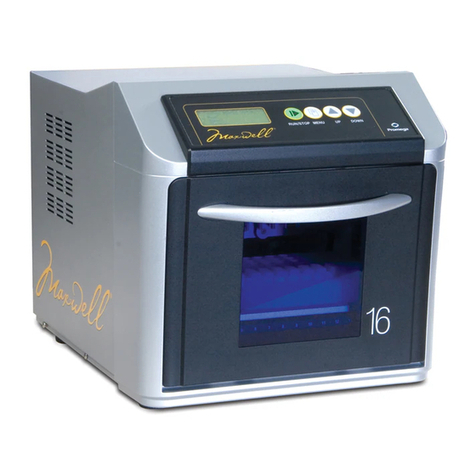

I.D. Precautions (continued)

IMPORTANT SAFETY INSTRUCTIONS. SAVE THESE INSTRUCTIONS.

Safety Precautions Mesures de Sécurité

Do not use this instrument for anything other than

its intended use.

Ne pas utiliser cet instrument à d'autres fins que celle

pour laquelle il a été conçu.

Always disconnect the power before cleaning or

performing routine maintenance.

Toujours débrancher le cordon d'alimentation avant

d'effectuer le nettoyage ou l'entretien de routine.

Do not disassemble unit. Ne pas démonter l'unité.

Do not override the door sensor. Moving parts may

cause personal injury.

Ne pas neutraliser le capteur de la porte. Les pièces

mobiles risquent d'entraîner un préjudice corporel.

Ensure cartridges, elution tubes and plungers have

been securely inserted in their correct positions and

orientation. Failure to do so may result in damage

to the instrument.

S'assurer que les cartouches, les tubes à élution et les

pistons ont bien été insérés dans la position et

l'orientation correcte. Tout manquement à ces directives

risque d'entraîner des dommages de l'instrument.

After each run, verify that the plungers have been

completely removed from the magnet rods before

pressing “OK” to extend the platform.

Après chaque cycle, vérifier que les pistons ont été

complètement retirés des tiges magnétiques avant

d'appuyer sur "OK" pour étendre la plate-forme.

Use only Promega Maxwell®16 cartridges and

plungers designed for use with the instrument.

Utiliser uniquement des cartouches et pistons Promega

Maxwell®16 conçus pour une utilisation avec

l'instrument.

Do not reuse cartridges or plungers. Ne pas réutiliser les cartouches ou pistons.

If the equipment is used in a manner other than that

specified by Promega, the protection provided by

the equipment may be impaired.

Si l'instrument est utilisé d'une autre manière que celle

mentionnée par Promega, la protection apportée par

l'equipement pourrait être endommagée.

Keep hands clear of instrument platform as it

moves in and out of the instrument.

Éloigner les mains de la plate-forme de l'instrument

pendant qu'elle effectue son mouvement de va-et-vient

dans et hors de l'instrument.

During elution, the heated elution block at the front

of the platform becomes very hot. Do not touch.

Lors de l'élution, le bloc d'élution chauffé à l'avant de la

plate-forme devient très chaud. Ne pas le toucher.

To avoid muscle strain or back injury, use lifting

aids and proper lifting techniques when removing

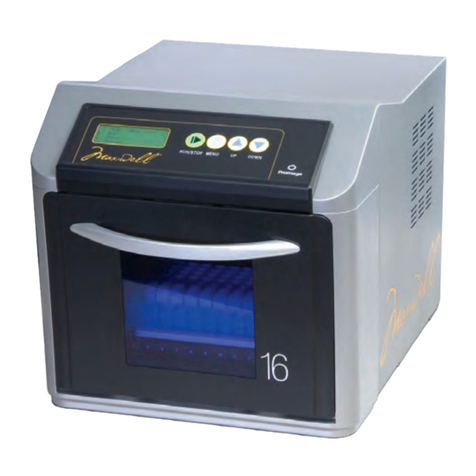

or replacing the instrument. The Maxwell®16

Instrument weighs 40lb (18kg) and should be

handled by two people.

Pour éviter des claquages musculaires ou de se faire mal

au dos, utiliser du matériel permettant de soulever et des

techniques de soulèvement correctes lors du retrait ou du

repositionnement de l'instrument. L'appareil Maxwell®16

pèse environ 18kg (40 lb) et doit être manipulé par deux

personnes.

Equipment can be hazardous due to the use of

chemical and biohazardous substances.

L'équipement peut être dangereux du fait de

l'utilisation de subtances chimiques et biologiques

dangereuses.

tm274.0608.qxp 6/4/2008 9:47 AM Page 7