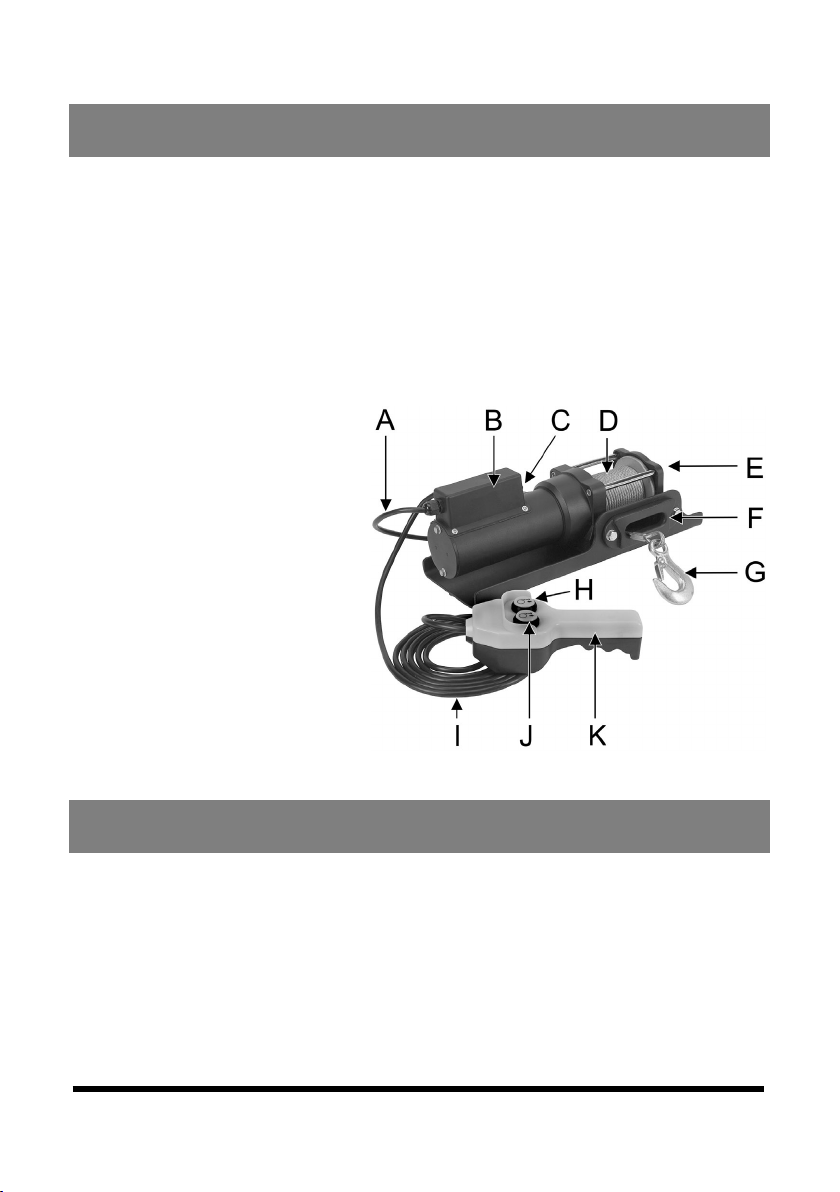

8880429 1,500 LB 120V AC ELECTRIC WINCH V1.0

6 For technical questions call 1-800-665-8685

12. Stay well away from the winch, steel cable and load when under

tension. A cable that breaks under tension can whiplash and

inflict death or a serious injury.

12.1 Use a winch rope dampener to absorb the cable’s energy

should it break.

13. Secure the load after moving it with the winch. Do not rely on the

winch to hold a load in position for an extended period of time.

Never leave the load unattended.

14. Apply blocks to a vehicle while connecting and disconnecting

the winch cable.

15. Observe the spooling of the cable onto the drum. Side pulls can

cause the cable to pileup at one end of the drum. To correct

uneven stacking, spool out that section of cable and move it to

the other end of the drum and continue winching. Uneven

spooling causing cable pileup can interfere with the winch tie

rods causing damage to the winch.

16. Do not use the winch to transport animals or people.

ELECTRICAL SAFETY

WARNING! Do not touch or handle a live tool with any part of your

body that is wet or damp. Wet skin reduces resistance to electrical

current, increasing the danger of a serious or fatal shock.

WARNING! To reduce risk of electric shock, be certain that the plug

is connected to a properly grounded receptacle.

1. Disconnect tool from power source before cleaning, servicing,

changing parts/accessories or when not in use.

2. Protect yourself against electric shocks when working on

electrical equipment. Avoid body contact with grounded

surfaces. There is an increased chance of electrical shock if your

body is grounded.

3. Do not expose the tool to rain or wet conditions. Water entering

a tool will increase the risk of electric shock.

4. Do not disconnect the power cord in place of using the ON/OFF

switch on the tool. This will prevent an accidental start-up when

the power cord is plugged into the power supply.