ProSoftTechnology, Inc

1560-MBP Modbus Plus SCANport Gateway

Catalog Numbers:

1560-MBP-1 Modbus Plus SCANport Gateway - 115 VAC

1560-MBP-2 Modbus Plus SCANport Gateway - 24VDC

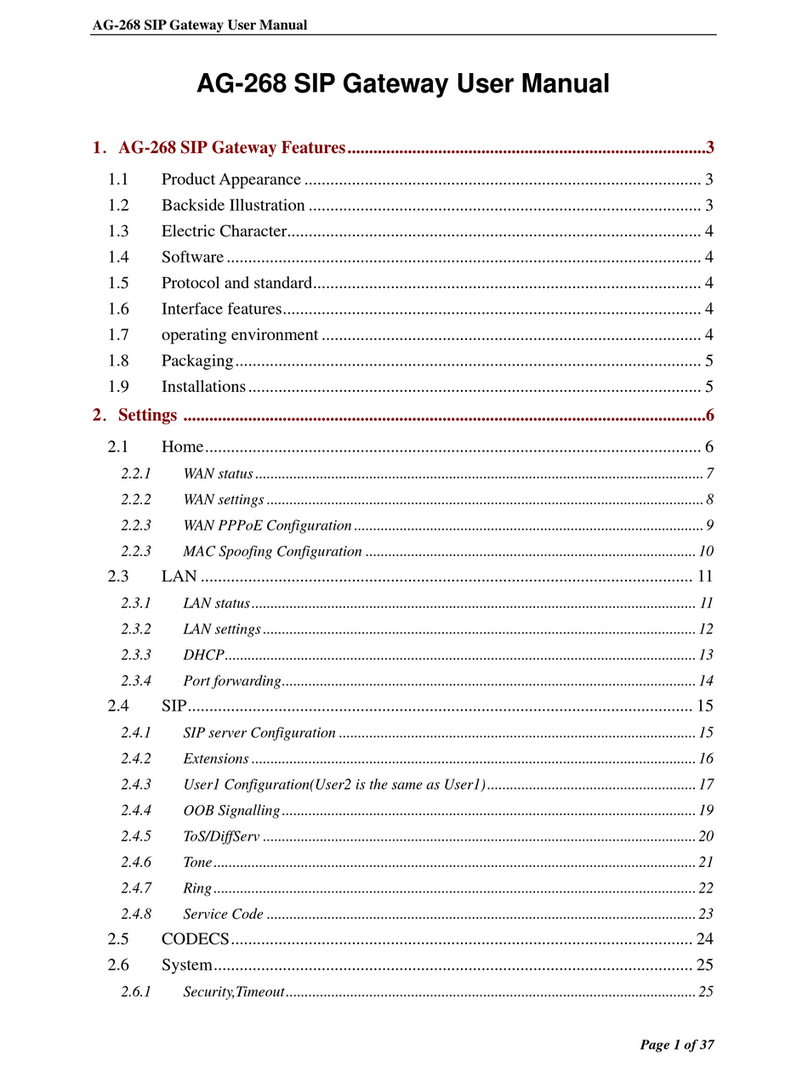

Table of Contents

Quick Start Guide ..................................................................................... 4

Revisions ................................................................................................. 5

1 Product Specifications .................................................................... 6

1.1 Mobus Plus Specifications ........................................... 6

1.2 General Specifications ................................................. 6

2 Modbus Plus Functionality .............................................................. 8

2.1 Modbus Plus Communications ..................................... 8

2.1.1 Supported MSTR Programming Commands ................. 8

2.1.2 Modbus Register Map .................................................. 9

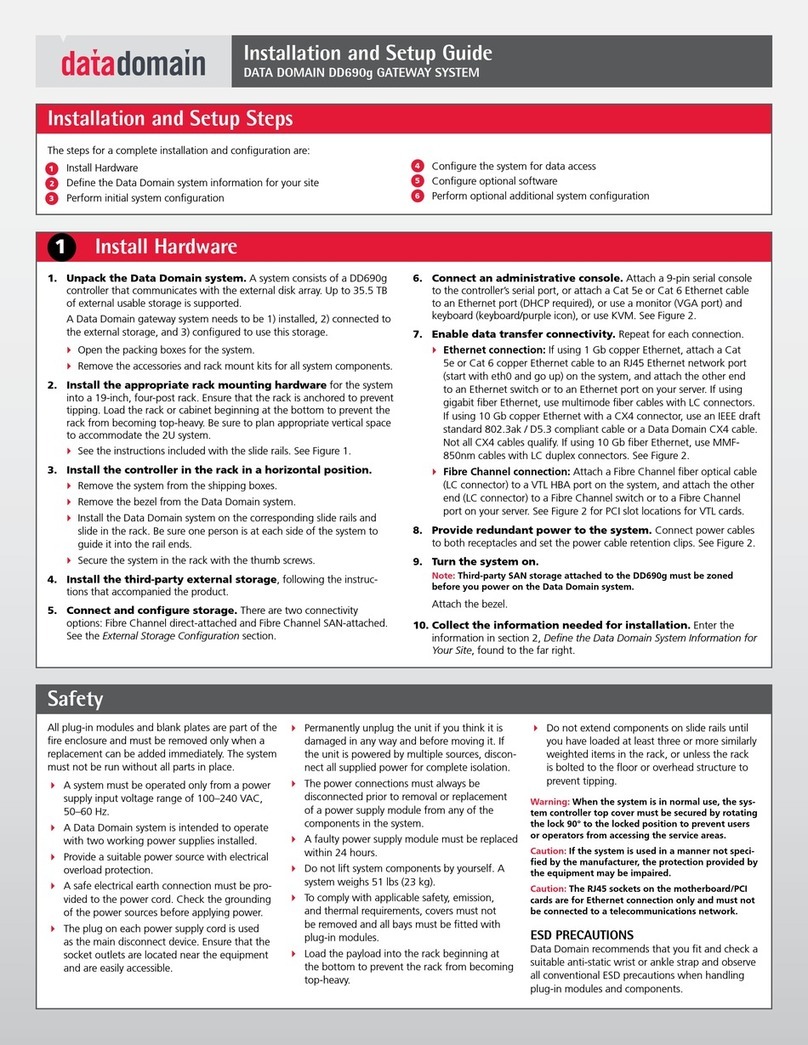

3 Hardware Setup ............................................................................... 10

3.1 1560-MBP Card Setup................................................. 10

3.1.1 Connecting Power to the 1560-MBP Card...................... 10

3.1.2 Dip Switch Configuration .............................................. 10

4. Programming Considerationations ................................................. 15

4.1 Writing to the 1560-MBP .............................................. 15

4.1.1 Global Data Enabled - MSTRType 5 ............................. 15

4.1.2 Host IssuedWrite Commands - MSTRType 1 ............... 18

4.2 Reading from the 1560-MBP ........................................ 19

4.2.1 Global Data - MSTRType 6 .......................................... 19

4.2.2 Host Issued Read Commands - MSTRType 2 ............... 20

4.3 The MBP Status Registers (40021 to 40100) ................. 22

5.Troubleshooting .............................................................................. 25

5.1 LED Locations............................................................. 25

5.1.1 LEDTroubleshootingTable ........................................... 25

5.2 MBPSTAT Diagnostics ................................................. 27

6. Cable Diagram ................................................................................ 28

7.Technical Support ........................................................................... 29

7.1 Technical Support Contacts .......................................... 29

Appendix A ........................................................................................ 30

1560-MBP Modbus Register Map............................................... 30

Appendix B ........................................................................................ 31

Device Specific Hints ................................................................. 31

Appendix C ........................................................................................ 33

Single Drive Peer COP Application Example ............................... 33

Appendix D ........................................................................................ 39

Mounting and SCANport Cabling Instructions .............................. 39

Appendix E......................................................................................... 41

Repair andWarranty ........................................................................... 42