2

LIMITATIONS: Consider the following

limitations when using the Reble SRL:

IT IS NOT PERMISSIBLE to1. make additions or alterations

to this equipment.

Follow manufacturer’s instructions2. for the correct use of the SRL

and associated accessories.

NEVER attach clips, etc., as a3. positioning device to the lifeline

which will prevent the lifeline

from retracting automatically. This

practice is dangerous as it leaves

excessive slack in the lifeline which,

in the event of a fall, will increase

the fall distance and the shock load

on the body to unacceptable levels.

Avoid allowing the lifeline to pass4. between your arms or legs while

moving about or working.

Avoid allowing the lifeline to contact5. paints, concrete, bitumen, oils,

etc. which will adversely affect the

SRL if it enters the mechanism.

Always keep the lifeline clean and6. free of dry mud, cement, etc. Failure

to do so could result in premature

locking and rewinding failure.

When detaching from the SRL7. do not quick-release the lifeline

allowing uncontrolled rewind

back into the device. This can

be dangerous and there is a

probability that the lifeline will

rewind unevenly. Uneven rewind of

lifeline can prevent full retraction.

Do not leave lifeline extended8. for long periods of time.

DO NOT repair equipment in9. the field. Only Capital Safety is

equipped to repair Protecta devices.

DO NOT combine SRLs with other10. components such as lanyards

to extend their length.

DO NOT OPEN the SRL as the11. spring is under tension.

CHEMICAL HAZARDS: Solutions12. containing acid or caustic

chemicals, particularly at elevated

temperatures, may damage Protecta

SRLs. When working with such

chemicals, frequent inspection of

the entire SRL must be completed.

If chemical damage is detected the

SRL must be removed from service.

Exercise caution when using13. this equipment around moving

machinery or electrical hazards.

RESCUE: When using this equipment,

the employer must have a rescue plan

and the means at hand to implement

and communicate that plan to users,

authorized persons, and rescuers.

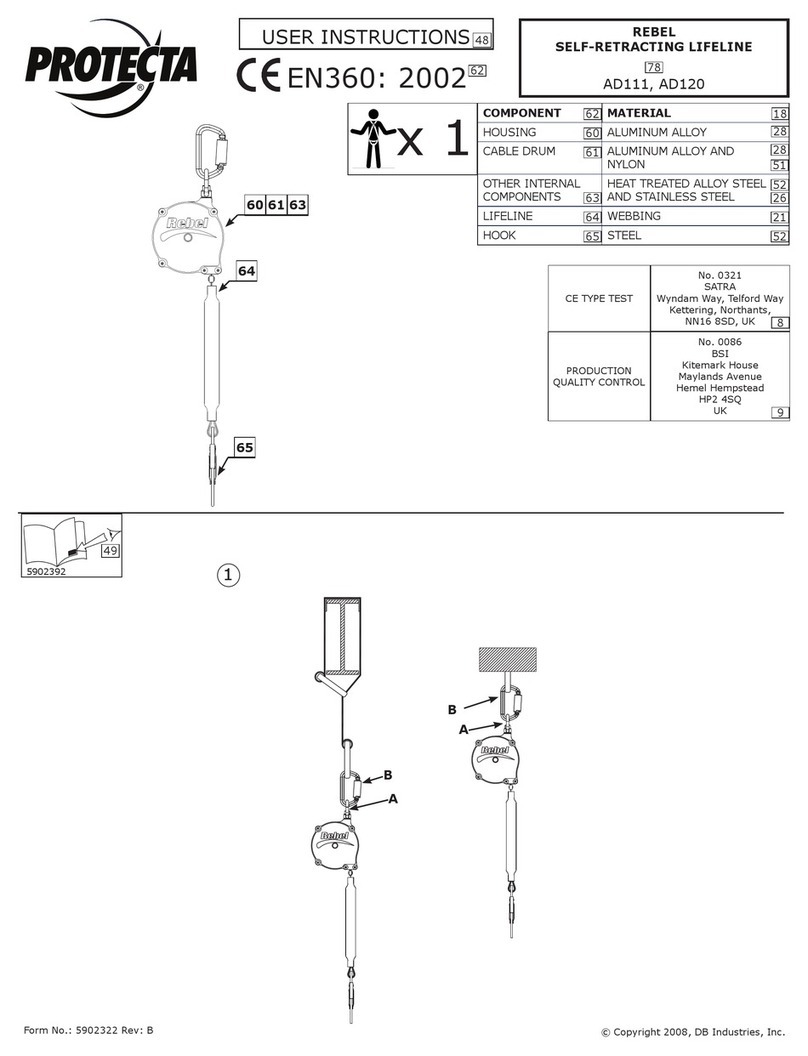

OPERATION AND USE

WARNING: Read and understand all

instructions and warnings on the labels attached

to the device before using. These instructions

and warnings are placed on the device for your

protection. Be sure that you understand and follow

these directions carefully.

Before using this equipment,

make a visual inspection to ensure

serviceable condition of the device (see

Inspection). Under no circumstances

should the SRL be used if the lifeline

has any defect (i.e., cut fibers or is

not retracting correctly). To check

for proper lifeline operation:

Pull the entire length of lifeline1. out and allow it to retract

slowly through your hand.

Test the locking mechanism several2. times by jerking down on the lifeline

and ensuring the system locks.

SRLs with suspected faults should be

immediately withdrawn from service.

IMPORTANT: Always hold on to the lifeline

while it is rewinding into the SRL. Do not leave the

lifeline extended for long durations.

WARNING: The Rebel SRL should always

be used with a Capital Safety approved Full Body

Harness. Never use a waist or chest belt of any

type for fall arrest hazards.

After connecting the Fall Arrest Device to

a safe anchorage point attach the snap

hook at the end of the lifeline to the

dorsal D-ring of the harness, ensuring

that the snap hook closes fully and locks.

In situations where it is necessary to use

a front D-ring as a point of attachment

such as working on a fixed ladder a

harness with chest D-rings must be

used. Refer to OSHA requirements.

Capital Safety highly recommends

the exclusive use of DBI-SALA or

Protecta full body harnesses with all

its individual fall prevention systems.

Make every effort to keep the

lifeline clean and free from dry

mud, cement, etc. Failure to do

so can result in premature locking

and rewind failure of the device.

Never allow the lifeline to contact sharp

abrasive edges, i.e. girders, roofing

panels, etc. which could damage

and ultimately weaken the lifeline.

The SRL permits complete freedom

of movement; however, ensure

that you move normally as sudden

or quick movements will activate

the locking mechanism.

While using, always ensure that there

is constant tension on the lifeline.

Slack in the lifeline could result in an

increase in fall distance. Move normally,

sudden jerky movements will activate

the locking mechanism. In the event

of a fall, the fall arrest device must

not be used until it has been visually

checked by a competent person.

INSPECTION

Before Each Use:• OSHA 1910.66,

OSHA 1926.502 and ANSI

Z359.1 requires an inspection

of equipment before each use

(see Inspection Steps).

Annually:• ANSI Z359.1 requires

a formal inspection of the SRL

be completed by a competent

person other than the user at least

annually. More frequent inspections

by a competent person may be

required based on the nature and

severity of workplace conditions

affecting the equipment and the

modes of use and exposure time

of the equipment (see Inspection

Steps). Record the results of

each formal inspection in the

Inspection and Maintenance log

at the end of this manual.

After a Fall Arrest:• Rebel SRLs are

not repairable and must be removed

from service after a fall arrest.

WARNING: If the self retracting lifeline has

been subjected to fall arrest or impact forces, it

must be removed from service.

IMPORTANT: Extreme working conditions

(harsh environment, prolonged use, etc.) may

require increasing the frequency of inspections.

INSPECTION STEPS:

Inspect for loose screws and1. bent or damaged parts.

Inspect housing for distortion,2. cracks or other damage. Ensure

the swivel eye is not damaged

or distorted in any way. Ensure

the swivel eye turns freely.

The lifeline must fully extend3. and retract without hesitation or

creating a slack line condition.

Ensure the device locks up when4. lifeline is jerked sharply. Lock-up

must be positive, with no slipping.

The labels must be present and5. fully legible (see Labels).

Look for signs of corrosion6. on the entire unit.

Inspect the web lifeline for7. concentrated wear, frayed strands,

broken yarn, burns, cuts, and

abrasions. The lifeline must be

free of knots throughout its length.

Inspect for excessive soiling, paint

build-up, and rust staining. Inspect

for chemical or heat damage

indicated by brown, discolored, or

brittle areas. Inspect for ultraviolet

damage indicated by discoloration

and the presence of splinters and

slivers on the lifeline surface.

Inspect connecting hooks or8. carabiners for signs of damage,

corrosion, and working condition.