Protector TORNADO T8/SM Manual

A

TORNADO T8/SM and T8/ML

Respiratory Protective Systems

Operating and Maintenance Instructions .........................................1

Betriebs- und Wartungsanleitung......................................................4

Gebruiks- en onderhoudsaanwijzingen............................................8

Instructions d'utilisation et d'entretien ............................................11

Instrucciones de Funcionamiento y Mantenimiento....................15

Instruções Operacionais e de Manutenção....................................19

I Istruzioni d'uso e manutenzione.....................................................22

Operations og vedligeholdelses instruktioner...............................26

Bruksanvisning och skötselinstruktioner.......................................29

Bruks- og vedlikeholdsveiledning....................................................32

Käyttö- ja huolto-ohjeet ......................................................................35

Part No. T/8/LFT Issue A Jan 01

Art No. 2007918

2

T8

4a

5

4b

6

7

1

2

3

8b

8a

4a 5

3

Protector Respiratory

Protector Technologies Ltd

Pimbo Road, West Pimbo,

Skelmersdale,

Lancashire WN8 9RA

United Kingdom

Tel: +44 (0) 1695 711711

Fax: +44 (0) 1695 50819

www.protector-tech.com

Protector Technologies Pty Ltd.

137 McCredie Road,

Guildford,

Australia 2161

Tel: +61 (0) 29722 2333

Fax: +61 (0) 29722 2394

Fig 1

Fig 2

Fig 3

1

TORNADO T8/SM and T8/ML Respiratory Protective Systems

WARNING

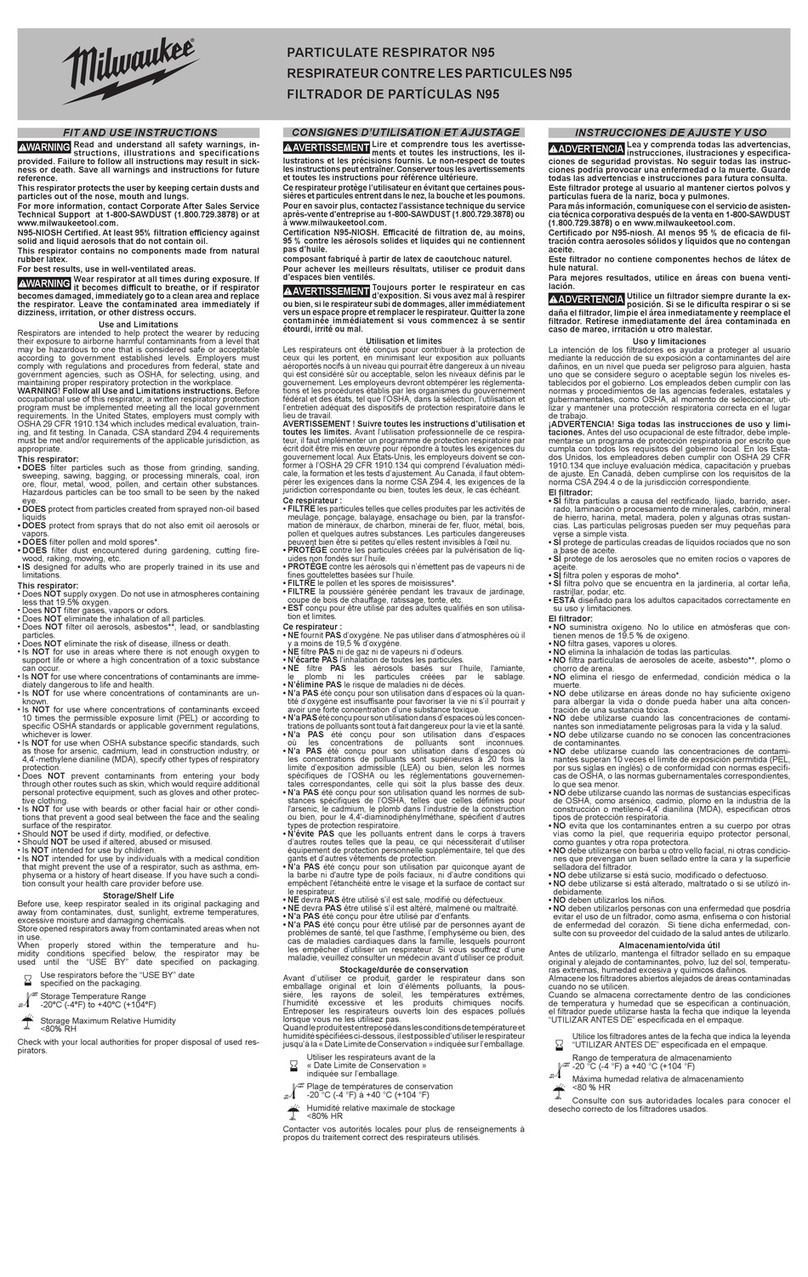

TORNADO powered respirators are designed for use by personnel who

are familiar with workplace hazards.

This leaflet must be read together with the user leaflets for T/POWER and

T/FILTER.

DO NOT use in oxygen deficient atmospheres (<19.5%), confined spaces,

stills, tanks, or areas immediately dangerous to life or health.

DO NOT use equipment that is damaged.

Check that the type of filter(s) used with T/POWER are suitable for the

workplace hazard.

DO NOT use if there is no airflow from the T/POWER or if the airflow

output is low (see the Flow test detailed in T/POWER).

DO NOT confuse the markings on a filter relating to any European

Standard other than EN12942 with the classification of this device when

used with this filter.

DO NOT use T8 with T/POWER switched off. In the unlikely event that

T/POWER fails to supply air while in a hazardous area, continue to breath

from the half mask and go immediately to a safe area. The halfmask will

continue to provide a degree of respiratory protection.

T8 is not suitable for use with T/A/LINE.

T8 must not be used where contaminant concentration exceeds 20 times

its Occupational Exposure Limit, or 1000 ppm by volume.

T8 must only be used with the T8 breathing hose. DO NOT use other

TORNADO breathing hoses.

It is unlikely that the requirements for leakage will be achieved if hair,

spectacle side arms or clothing intrude into the faceseal.

T8/SM and T8/ML SPECIFICATION

Facepiece T8/SM and T8/ML

Description Halfmask

Classification: EN 12942 TM2

Minimum design flow rate 110 L/min

Nominal protection factor 200

Assigned* protection factor 20

Operating temperature range -10oC to 40°C

Maximum operating humidity 95%

Material Silicone elastomer

*According to BS4275 : 1997

2

INTRODUCTION

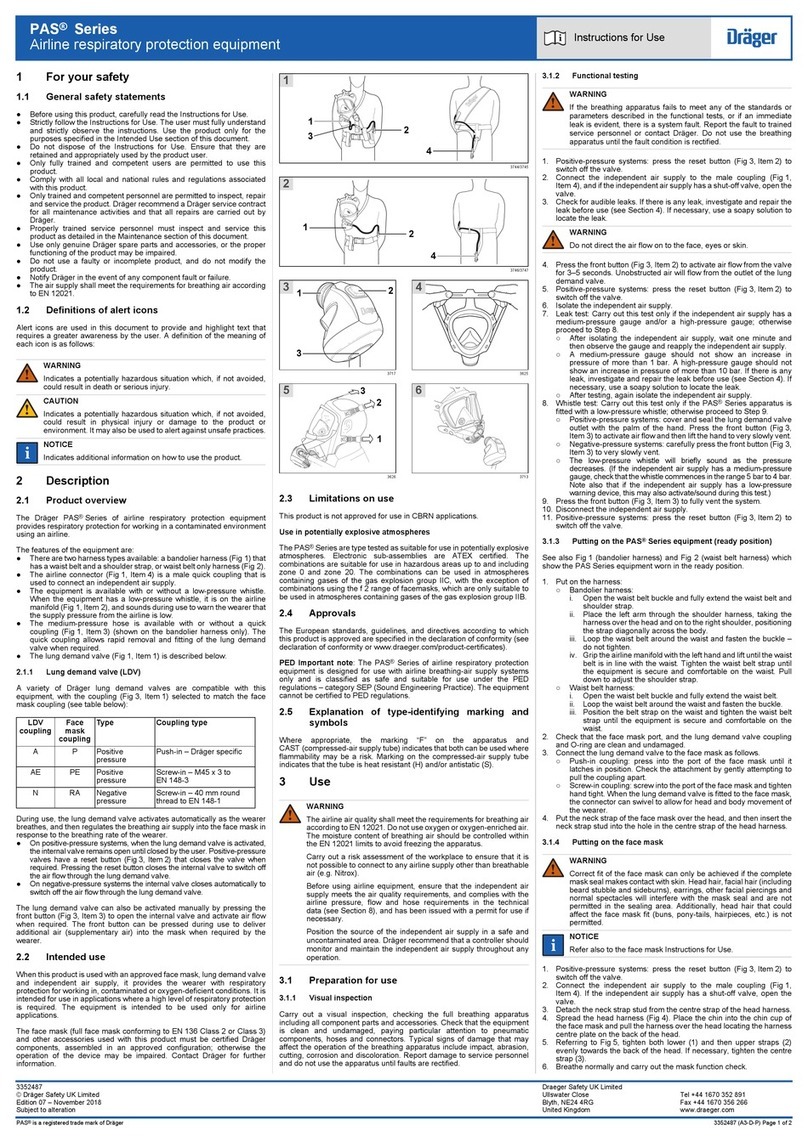

To aid component identification in the following procedures, bracketed numbers after a

component show component's location in the T8 diagram inside the front cover.

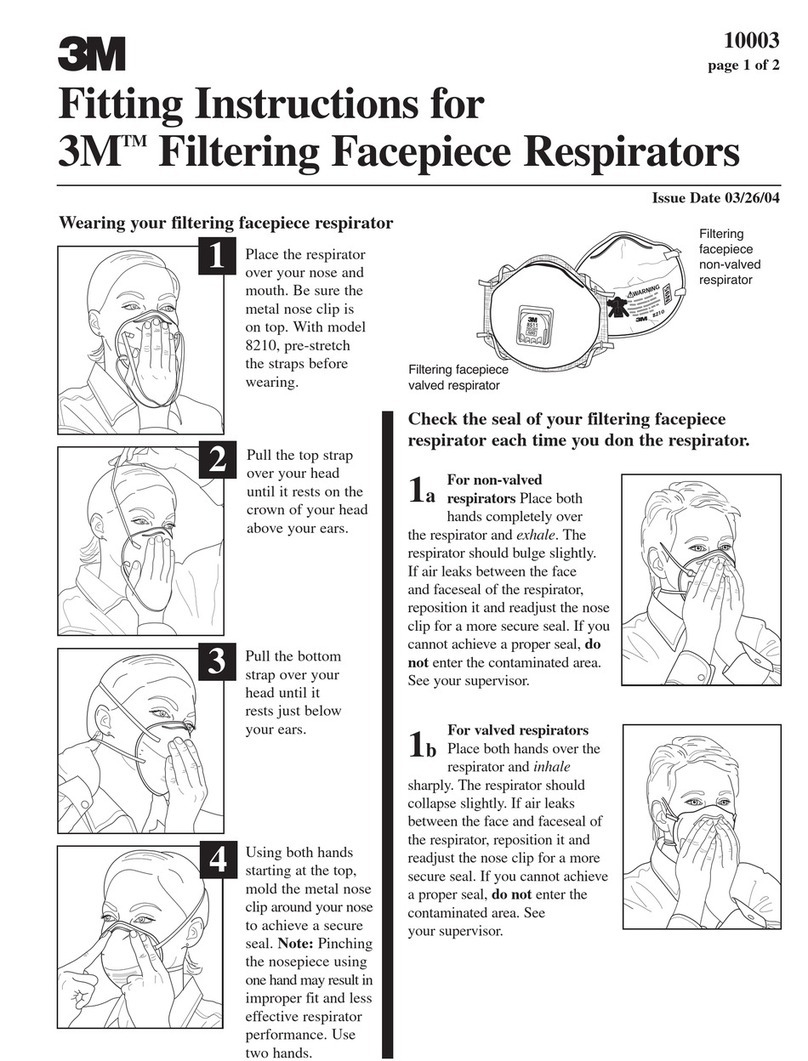

DONNING

Note: Initial donning procedures should be supervised by a competent person. Select the

appropriate size of mask: S/M or M/L.

1. Check that all parts of T8 are clean and in good condition.

2. Check that the breathing hose seal (8b) is in place and in good condition and screw the

breathing hose (8a) firmly, hand-tight, onto the halfmask (Fig 1). Do not over-tighten.

3. Adjust the harness (1) so that the buckle is away from the mask and the head pad rests on

top of the mask. Place the strap around the neck (Fig 2).

Note: Once a comfortable fit has been achieved for a given wearer, there should be no need to

alter the head-strap length when donning in the future.

4. Place the halfmask on the face and adjust until the faceseal (2) fits smoothly against the

face.

5. Pull the head pad onto the crown of the head (Fig 3) and adjust the harness, feeding the

harness through the anchors to equalise the pull on the anchors.

6. The mask should feel firm against the face with no undue movement. If it does not fit, or is

uncomfortable, adjust the harness (1) length using the nape buckle (It may be easier to do this

prior to donning the mask). Excessive tightening causes discomfort and may distort the face

seal.

7. Test the faceseal by blocking the breathing hose inlet with the palm of the hand and

inhaling. Check that the mask pulls onto the face until the wearer exhales. If there is a leak,

check the faceseal, breathing hose seal (8b) and the exhalation valves (4a). It may be

necessary to try the alternative size of mask. Do not use the mask if a good fit cannot be

achieved.

8. Arrange the breathing hose so that it trails freely down the back and is not kinked, likely to

snag, or be crushed.

9. Follow the instructions in the T/POWER leaflet to: Attach the breathing hose to

T/POWER, Perform the airflow test, and Check the filters.

AFTER USE

WARNING: DO NOT remove the halfmask until well clear of the hazard area.

1. Take off the halfmask and undo the breathing hose.

2. Clean the mask and the outside of the breathing hose with a synthetic sponge moistened

in a mild solution of soap and warm water, or TriGene solution.

Note: Water MUST NOT enter the breathing hose.

3. Rinse the mask thoroughly under clean running water and hang it by the harness until

thoroughly dry. DO NOT use radiant heat or sunlight to speed drying.

4. Use TriGene wipes to sanitise the faceseal.

5. After cleaning, check that all components are in good condition. Worn or damaged items

must renewed prior to further use.

MAINTENANCE

Important: Check the valve flaps (4a) and (4b) visually every 3 months to ensure that they are

clean and undamaged. Check that the faceseal (2) and valve flaps are flexible. Valve flaps

must be replaced annually.

Important: The breathing hose elbow is glued to the halfmask shell (3) and must not be

removed. If an elbow is removed or damaged, the shell assembly must be renewed.

3

Important: Exhalation valve flaps should be as new with no damage. They are marked with a

code indicating the year of manufacture. The letter ‘Y' corresponds to 1994 and a dot is added

each year thereafter, so ‘Y...' is 1997. Discard valve flaps that are more than 6-years old.

Storage Note: Plastic and rubber components must be stored in clean dry conditions, away

from direct sunlight and heat, within a temperature range 10oC to 30oC and in humidity not

exceeding 65%.

Replacing the Harness - Push the harness anchors from the shell (3) to free the harness.

Push the replacement harness anchors into the slots in the shell assembly. Check that they

click into place and are securely attached.

Replacing the Exhalation Valve Flap and Valve Cover - There are two exhalation valves.

To replace an exhale valve flap, or valve cover: grasp the lower edge of the green valve cover

(5) and pull off the covers. Grasp the valve flap (4a) and pull from the faceseal (2). Check that

the replacement flaps are in good condition, and carefully pull the stem of each flap through the

centre of the valve frame, until the flap lies flat against the frame.

Replacing an Inhale Valve Flap - Pull the valve flap (4b) from the locking ring (6). Check that

the replacement flap is in good condition and carefully attach the flap over the tab on the locking

ring. Check that the flap is flat against the frame.

Replacing the Shell Assembly, Locking Ring and Thrust Washer - Unclip and remove

both exhale valve covers (5). Turn the inhale valve locking ring (6) anti-clockwise and remove it.

Align the notches on the thrust washer with the tabs on the elbow, and remove the thrust

washer (7). Remove the shell. Fit the replacement shell (3) over the faceseal and ensure that

the exhale valve apertures engage in the groove in the rim of the valve frames. Fit the

replacement thrust washer (7) and locking ring (6), taking care to align the notches on both with

the tabs on the elbow. Clip both exhale valve covers (5) into place. Push the harness anchors

into the notches on the shell.

Breathing Hose and Seal - Unscrew the breathing hose and discard the seal if it is 6-years

old, if it is damaged or cannot form a good seal.

MAINTENANCE RECORD

Record details of all items replaced during maintenance in the table at the end of this book.

SPARE PARTS

Item, See T8 DESCRIPTION Part No.

1Harness kit KIT94/2

3Elbow / Shell Assembly KIT/T8SHELL

4Valve kit (2 exhale (4a), 4 inhale valves (4b)) KIT94/1

5Valve cover (green) RXHM7034/Y

6Locking ring (Pack of 2) 071.788.00

7Thrust washer for locking ring (Pack of 2) 071.790.00

8T8 Breathing hose (8a) with seal (8b) (Pack of 3) T8/HOSE

8b T8 Breathing hose seal (Pack of 3) T8/H/SEALS

Notified Body INSPEC CERTIFICATION LTD (NUMBER 0194),

Upper Wingbury Courtyard, Wingrave, Aylesbury,

Buckinghamshire, HP22 SLO, UK

This manual suits for next models

1

Table of contents

Other Protector Respiratory Product manuals