AC040 is a guided-type fall arrester device sliding on a

ø12 mm rope. AC040 is a component of the personal fall

arrest equipment and complies with EN353-2.

The device is a protection for the one person only.

!rope grab is made of stainless steel. It could be used only

with ropes of diameter 12 mm.

!working rope (ø12 mm polyester kernmantle rope).

The endings of the rope are equipped with the loops with

plastic thimble.

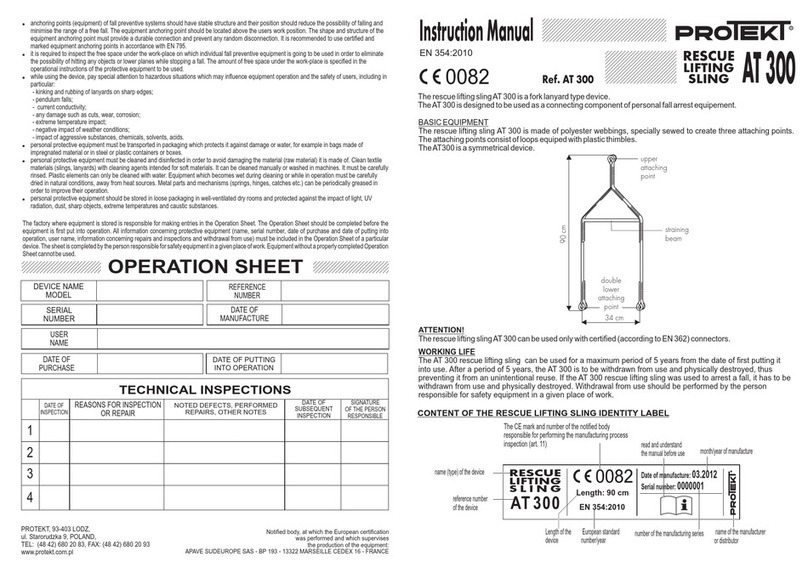

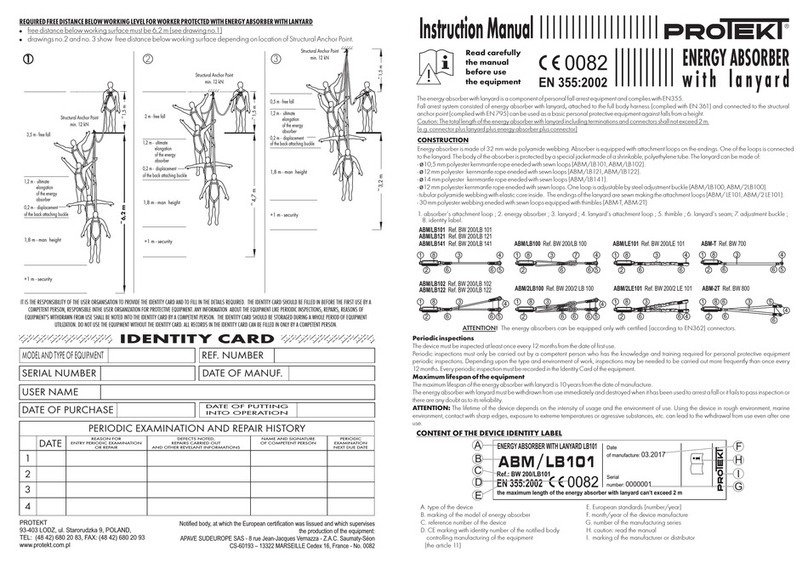

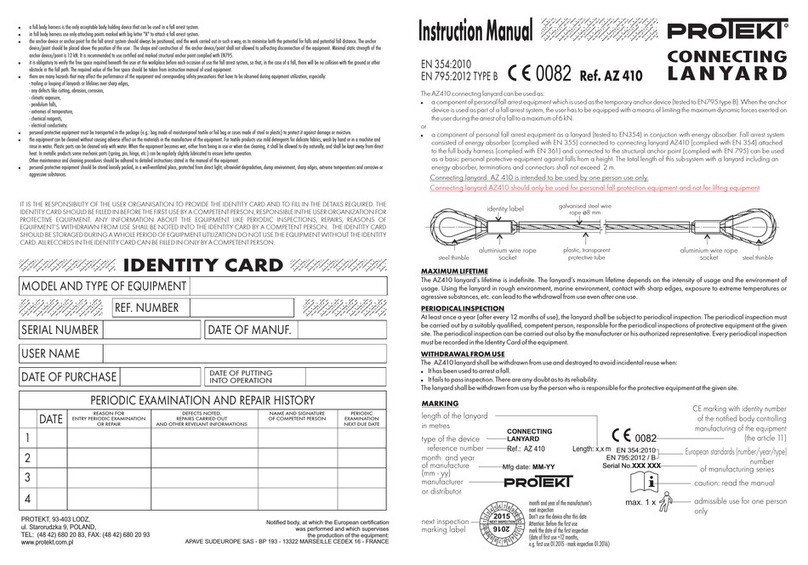

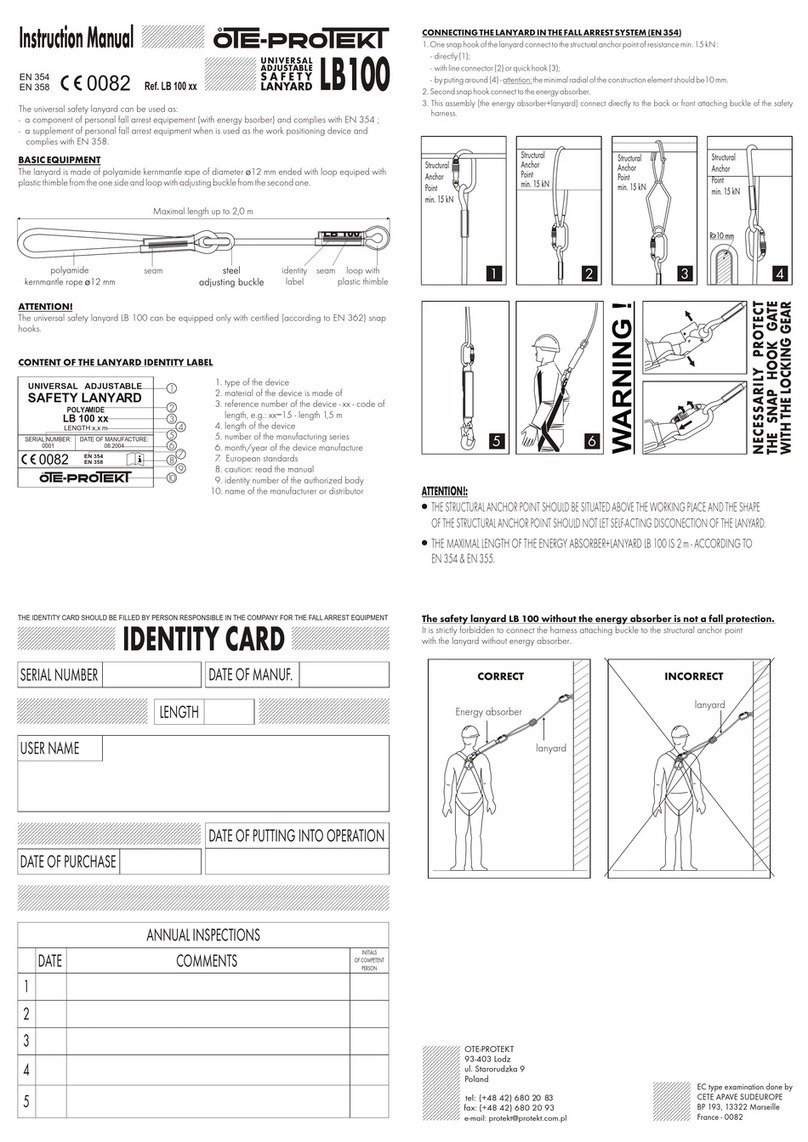

BASIC EQUIPMENT

working rope ø12 mm

working rope identity label

top end

of the working rope

(the loop with the thimble)

rope grab

bottom end

of the working rope

(the loop with the thimble)

GUIDED-TYPE FALL ARRESTER

ON FLEXIBLE ANCHORAGE LINE

Rope grab ref. number: AC 040

Instruction Manual

READ CAREFULLY BEFORE USE

THE EQUIPMENT

AC 040

Working rope ref. number: AC 200 XX

EN 353-2:2002

AC 200 XX*

WORKING ROPE

EN 353-2:2002

Date of manufacture: 02.2018

Serial number: 00001

LENGTH: XX m

POLYESTER

DIAMETER: ø12 mm

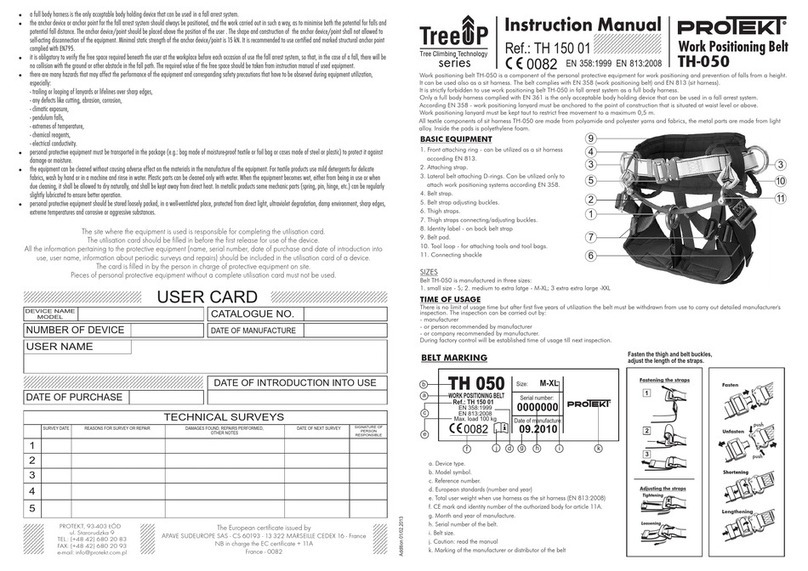

1.

2. reference number

3. European standard (number/year).

4. CE marking and number of a notified body controlling

manufacturing of the equipment (art. 11).

5. year of manufacture.

6. number of manufacturing serie.

name (type) of the device. 7. caution: read the manual

8. marking of device manufacturer of distributor.

9. material of which the device is made of.

10. diameter of the rope.

11. length of the rope.

1

2

9

10

11

5

6

3

4

8

*) xx - code of length

for example: xx=03 - length 3 m

xx=20 - length 20 m

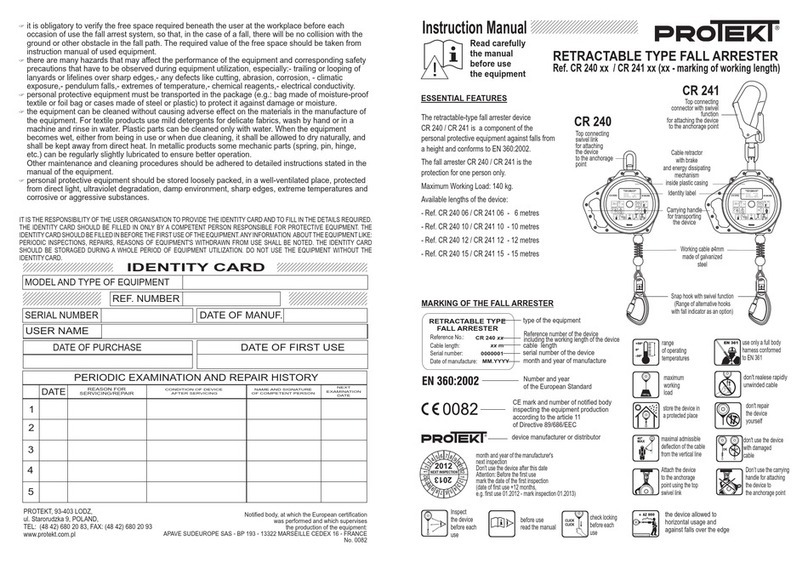

EN 353-2:2002

Date

of manufacture: 2018

USE

ONLY WITH ROPES

OF DIAMETER ø12 mm

Serial

number: 00001

GUIDED-TYPE FALL ARRESTER

Ref. AC 040

MARKING

1

2

5

6

3

4

8

7

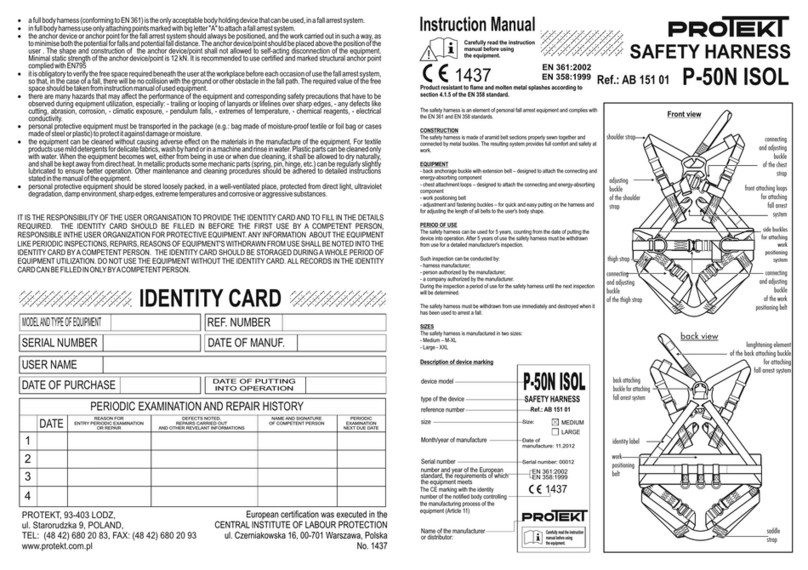

!personal protective equipment must be withdrawn from use immediately when

used again until confirmed in writing by equipment manufacturer or his representative after carried out the detailed inspection.

!personal protective equipment must be withdrawn from use immediately and destroyed when it have been used to arrest a fall.

,

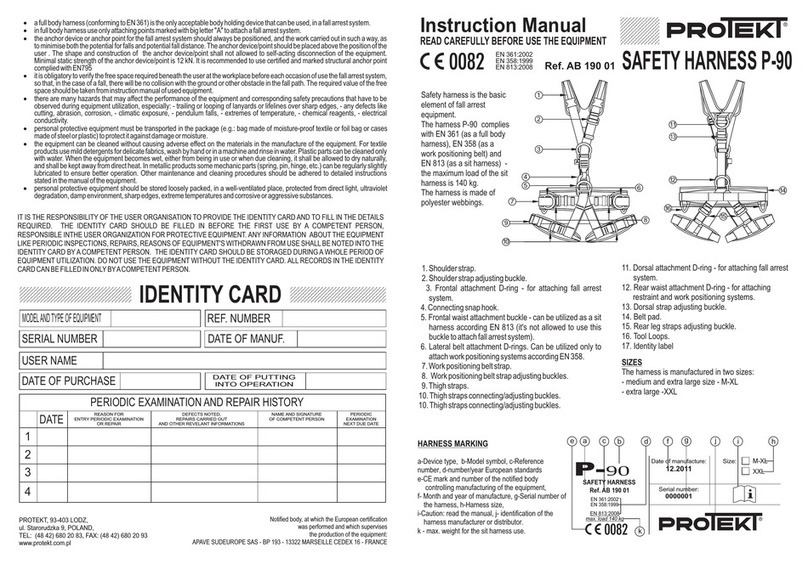

!a full body harness is the only acceptable body holding device that can be used in a fall arrest system.

!in full body harness use only attaching points marked with big letter "A" to attach a fall arrest system.

!the anchor device or anchor point for the fall arrest system should always be positioned, and the work carried out in such a way, as to

minimise both the potential for falls and potential fall distance. The anchor device/point should be placed above the position of the user

. The shape and construction of the anchor device/point shall not allowed to self-acting disconnection of the equipment. Minimal static

strength of the anchor device/point is 15 kN. It is recommended to use certified and marked structural anchor point complied with

EN795.

!it is obligatory to verify the free space required beneath the user at the workplace before each occasion of use the fall arrest system, so

that, in the case of a fall, there will be no collision with the ground or other obstacle in the fall path. The required value of the free space

should be taken from instruction manual of used equipment.

!there are many hazards that may affect the performance of the equipment and corresponding safety precautions that have to be

observed during equipment utilization, especially:

- trailing or looping of lanyards or lifelines over sharp edges; - any defects like cutting, abrasion, corrosion; - climatic

exposure;

- pendulum falls; - extremes of temperature; - chemical reagents;

- electrical conductivity.

!personal protective equipment must be transported in the package (e.g.: bag made of moisture-proof textile or foil bag or cases made

of steel or plastic) to protect it against damage or moisture.

!the equipment can be cleaned without causing adverse effect on the materials in the manufacture of the equipment. For textile products

use mild detergents for delicate fabrics, wash by hand or in a machine and rinse in water. Plastic parts can be cleaned only with water.

When the equipment becomes wet, either from being in use or when due cleaning, it shall be allowed to dry naturally, and shall be kept

away from direct heat. In metallic products some mechanic parts (spring, pin, hinge, etc.) can be regularly slightly lubricated to ensure

better operation.

Other maintenance and cleaning procedures should be adhered to detailed instructions stated in the manual of the equipment.

!personal protective equipment should be stored loosely packed, in a well-ventilated place, protected from direct light, ultraviolet

degradation, damp environment, sharp edges, extreme temperatures and corrosive or aggressive substances.

any doubt arise about its condition for safe use and not

connector

of the rope grab

SafetyLiftinGear.com

Unit R1D Rockingham Gate Poplar Way

West Cabot Park Bristol BS11 0YW

Tel: 0808 123 69 69 Fax: 0117 9381 602

sales@safetyliftingear.com

Notified body, at which the European certification was Iissued

and which supervises the production of the equipment:

APAVE SUDEUROPE SAS - 8 rue Jean-Jacques Vernazza -

CS-60193 – 13322 MARSEILLE Cedex 16, France - No. 0082

PRODUCENT: PROTEKT, 93-403 LODZ, ul. Starorudzka 9, POLAND,

TEL: (48 42) 680 20 83, FAX: (48 42) 680 20 93, www.protekt.com.pl

PERIODIC INSPECTIONS

The device must be inspected at least once every 12 months from

the date of first use. Periodic inspections must only be carried out by

a competent person who has the knowledge and training required

for personal protective equipment periodic inspections. Depending

upon the type and environment of work, inspections may be needed

to be carried out more frequently than once every 12 months. Every

periodic inspection must be recorded in the Identity Card of the

equipment.

MAXIMUM LIFESPAN OF THE EQUIPMENT

The maximum lifespan of the device is 10 years from the date of

manufacture. The device must be withdrawn from use immediately

and destroyed when it has been used to arrest a fall or it fails to pass

inspection or there are any doubt as to its reliability.

ATTENTION: The lifetime of the device depends on the intensity of

usage and the environment of use. Using the device in rough

environment, marine environment, contact with sharp edges,

exposure to extreme temperatures or agressive substances, etc. can

lead to the wthdrawal from use even after one use.