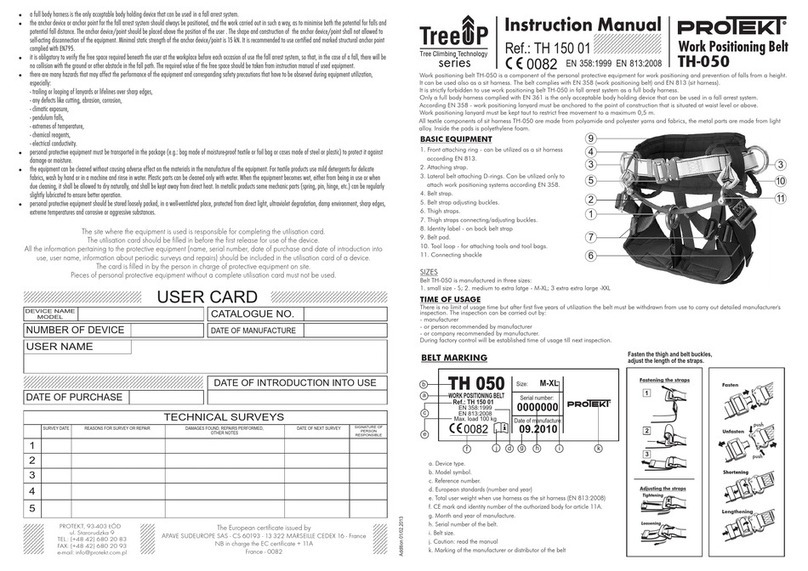

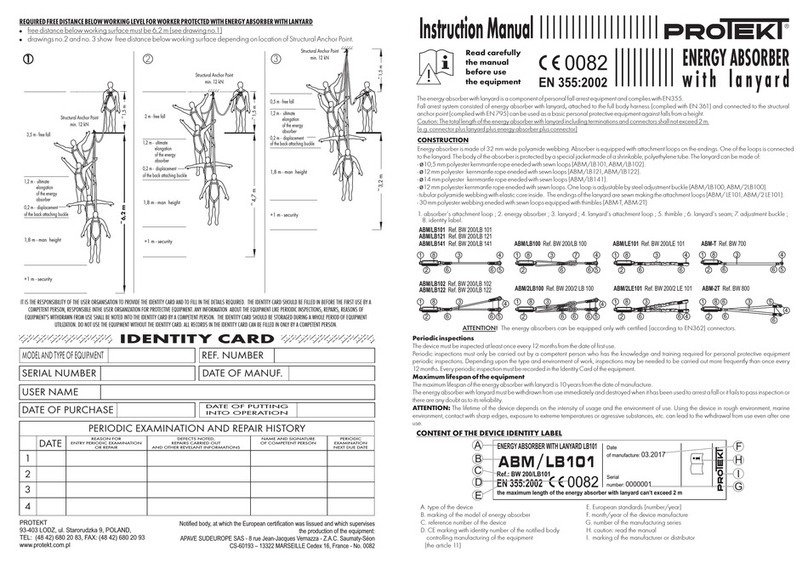

USAGE THE LANYARD AS THE WORK POSITIONING LANYARD (EN 358)

1. Connect one of the lanyard snap hooks to the selected attaching buckle of the work positioning belt (1).

2. Put the lanyard around the construction element (2).

3. Connect second snap hook to the another buckle of work positioning belt. Adjust lanyard length with

regulating buckle. The tension of the lanyard should assure a stable work position and restrict the free fall

of the worker. The distance of the free fallshould not exceed 0,5 m (3).

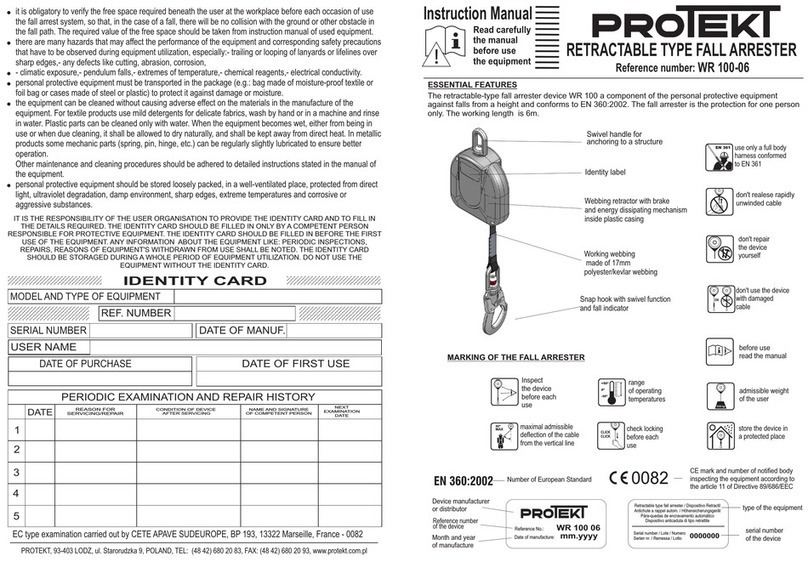

BASIC RULES OF USING THE UNIVERSAL SAFETY LANYARD

!the lanyard must be used by a person previously trained for working of heights.

!the lanyard should be a personal equipment and should be used by one worker.

!before each use, a close visual examination of the rope, splices, thimbles and snap hooks

must be carried out in respect of mechanical, chemical and thermal defects.

The examination must be done by a person who is going to use the lanyard. In case of any

defect or doubt of correct condition of the lanyard do not use it.

!during using, the of oils, acids, solvents, basics,

open fire, hot metal drops and sharp edges.

!the total length of energy absorber in connection with lanyard shall not exceed 2 m.

!the structural anchor point to which is connected the lanyard with energy absorber should

have static resistance min. 15 kN.

!free distance below working surface must be compatible with instruction manuals of the

lanyards and the energy absorbers.

!

!using the

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!before and during use, consideration should be given as to how any rescue should be

safely and efficient carried out.

lanyard must be protected from a contact

The shape of the structural anchor point should not let self-

acting disconnection of fall arrest system.

It is recommended to use certified and marked structural anchor point complied

with EN795.

lanyard in connection with fall arrest system must be compatible with use

instructions of the fall arrest systems and obligatory standards:

- EN 361 - for safety harness;

- EN 355 - for energy absorbers;

- EN 362 - for connectors;

- EN 795 - for anchorages;

- EN 358 - for work positioning systems.

the lanyard must be taken out of service and destroyed by a competent person after being

used to arrest of fall.

it is allowed to use the safety lanyard only with the energy absorbers, safety harness and

horizontal lifelines.

it is strictly forbidden to make any modifications to the lanyard yourself.

all elements of fall arrest system must work together without any disturbance.

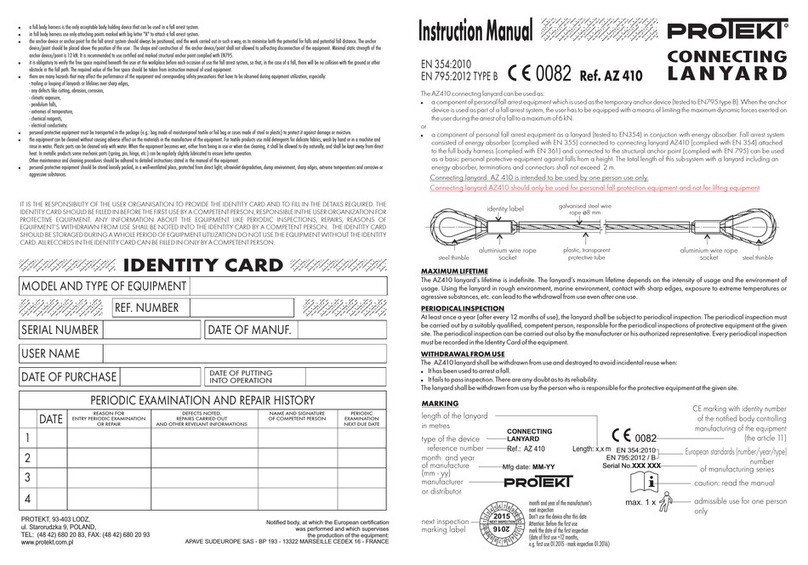

GENERAL CONDITIONS OF THE UNIVERSAL SAFETY LANYARD UTILIZATION

11

22

55

66

77

88

99

33

44

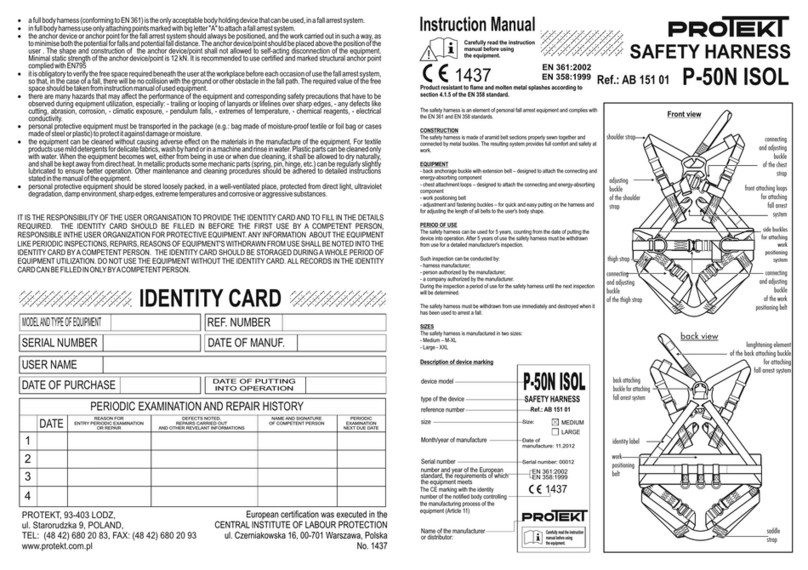

IDENTITY CARD - should be filled in by competent person and kept during whole period of

the lanyard using.

FIRST USE - fill in the Identity Card.

PERIOD INSPECTIONS - annual inspection of the lanyard must be carried out by a

competent person. Whole parts of the lanyard: rope, splices, thimbles, adjusting buckle

and snap hooks must be controlled in respect of mechanical, chemical and thermal defects.

The result of inspection must be recorded in Identity Card by a competent person.

OUT OF SERVICE - the lanyard must be taken out of service and destroyed when:

!is used more than 5 years from the date ofputting it into operation.

!was used to arrest a fall.

!any mechanical, chemical or thermal defects have appeared.

TIME OF USAGE - the lanyard can be used five years, counting from the date of putting the

device into operation. After five years of usage the lanyard must be out of service and

destroyed.

STORAGE - the lanyard must be stored in a dry, ventilated, room temperature and free of sun

places.

CLEANING - clean the lanyard in a warm water and household soap. Do not use any acid

or basic solvents.

After cleaning the lanyard must be natural dry far away from any fire and heat.

REPAIRS - it is strictly forbidden to make any repairs and modifications to the lanyard by

yourself.

TRANSPORT- the lanyard must be transported in the package (for example: impregnated

textile, foil bag or plastic, steel box) avoid moisture mechanical and chemical or others

defects .

1

3

2

WARNING !

NECESSARILY PROTECT

THE SNAP HOOK GATE

WITH THE LOCKING GEAR

CORRECTCORRECT

ATTENTION!

The universal safety lanyard used as the work positioning lanyard (according to EN 358)

is not the fall protection. In that case, necessarily use independent fall arrest system paying

attention to working of both systems without distrubance.

ATTENTION!

is not the fall protection

INCORRECTINCORRECT

INCORRECTINCORRECTINCORRECTINCORRECT

INCORRECTINCORRECTCORRECTCORRECT

!using the lanyard as a work positioning lanyard each snap hook must be connected to the

different side buckle of the work positioning belt.

it is strictly forbidden:

- to connect both snap hooks to the same, single belt buckle;

- to connect one snap hook to the belt buckle and the second one to the structural

anchor point;

- to connect one snap hook to the belt buckle and the second one connect on the

rope.