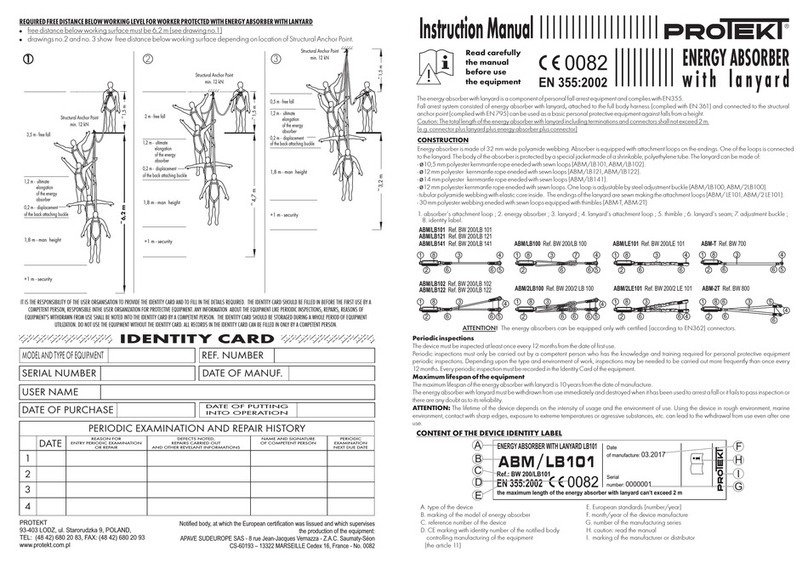

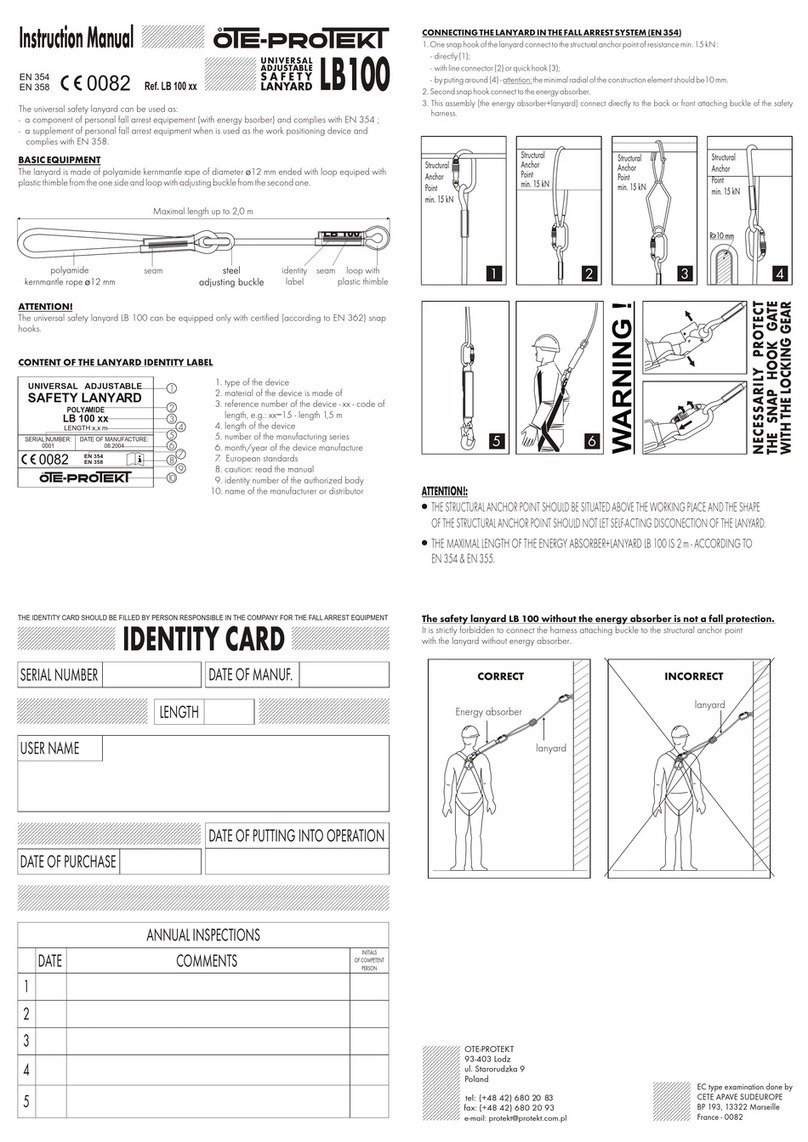

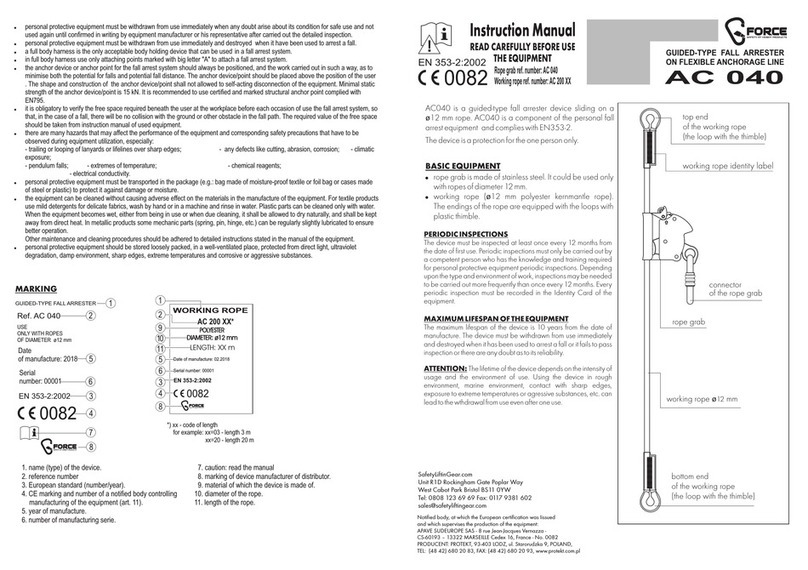

The attachment loop of the roof lanyard (indicated on fig.1) should be connected to the carabineer placed on a

EN360 retractable fall arrester lanyard. The attachment element of the AZ800 must be attached to “A” buckles of

safety harness with the aid of connector compliant with EN 362.

The EN360 retractable type fall arrester must be anchored to structure of building at least 3 m from the edge

along which the user operates (distance “x” - see. fig. 2, fig. 3). The anchor point may be situated at the same

height as the edge at witch a fall might occur or above this level. The user is permitted to move laterally through

distance “y” not greater than “x” (see fig. 2). The clearance distance (distance “h” - see fig.3) between roof level

and ground level must be greater than 3 m + 1/2 lateral distance “y” but not less than 3 m. To minimise fall

distance and pendulum movement the “x” and the “y” distances should be minimized, respecting the minimum

distance “x”=3m. In determining the space under the workplace required to arrest the fall, consider the length of

AZ800 roof lanyard as an additional element that extends the distance for arresting a fall.

OTHER METHODS OF USING THE AZ800 ROOF LANYARD CONTRARY TO OPERATING INSTRUCTIONS ARE

PROHIBITED

UTILIZATION FOR ROOF WORK

Fig. 2Fig. 2

EN360 retractable

type fall arrester

EN360 retractable

type fall arrester

roof edgeroof edge

y

AZ800AZ800

anchor pointanchor point

x 3mł

x 3mł

EN 360 retractable

type fall arrester

EN 360 retractable

type fall arrester

AZ800AZ800

anchor pointanchor point

h 3mł

Fig. 3Fig. 3

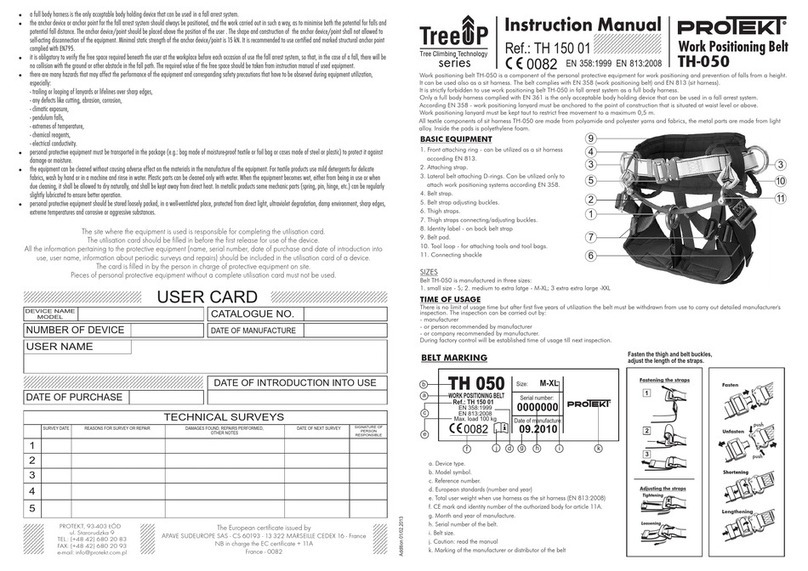

GENERAL RULES FOR USING THE AZ800 AS A PERSONAL PROTECTIVE EQUIPMENT

Personal protective equipment should be used only by people trained in operating it.

Personal protective equipment cannot be used by people whose health condition may influence their safety

during everyday use or emergency procedures.

There must be a rescue operation plan which can be used whenever needed.

It is forbidden to perform any modifications of the equipment without the written consent of the manufacturer.

Any repairs of the equipment may be performed only by its manufacturer or an authorised representative of the

manufacturer.

Personal protective equipment must be used in conformity with its operational purpose.

Personal protective equipment is considered personal equipment and should be used by a single person only.

Make sure that all elements of the equipment that constitute the fall protection system are properly mated prior

to use. Perform periodical inspections of connections and mating of equipment in order to avoid unintentional

loosening or disconnecting.

All parts of the fall protective equipment must be in accordance with appropriate regulations and equipment

operational instructions and binding standards: EN 361 (for full body harnesses); EN 353-1, EN 353-2, EN 354,

EN 355, EN 360, EN 362 (for fall arrest systems); EN 795 (for anchor points); EN 358 (for work positioning

systems).

đ

đ

đ

đ

đ

đ

đ

đ

đ

đ

The amount of slack of the lanyard should be minimised near a fall hazard.

GENERAL RULES -cont.

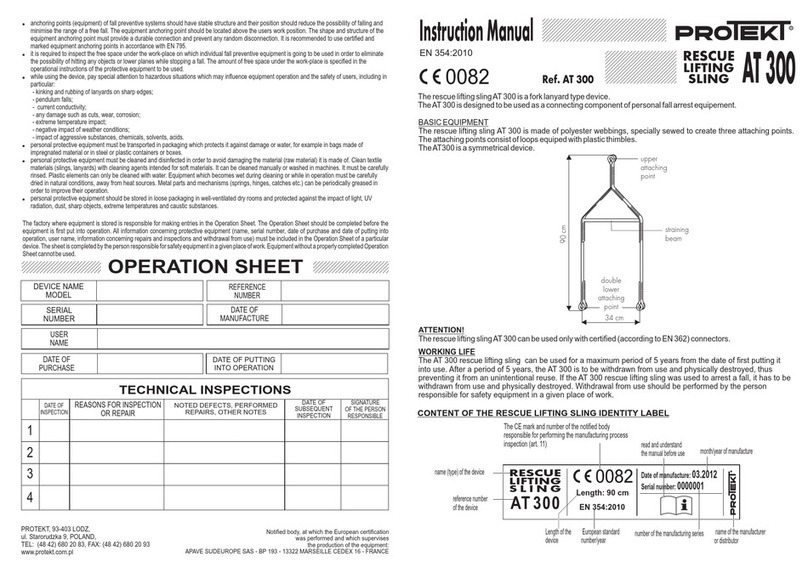

Carry out a careful inspection of the product prior to each separate use in order to check its condition and

operation. Inspections must be performed by the user. Such inspection should check all equipment elements

with particular attention paid to: any defects (like broken wires), excessive wear, corrosion, points of tearing, cuts

and improper operation. Particular attention must also be paid to: wirerope, clamps, loops, thimbles.

The product must be withdrawn from use and undergo a complete periodical inspection at least once a year

(after 12 months of use). Periodical inspection must be carried out by a qualified person responsible for

periodical inspections of safety equipment in a given place of work. Periodical inspections may be also carried

out by the equipment manufacturer or an authorised representative of the manufacturer. Such an inspection

should check all equipment elements with particular attention paid to: any

defects, excessive wear, corrosion, points of tearing, cuts and improper operation (see the previous point). The

date of the subsequent inspection shall be specified after the periodical inspection has been completed. Regular

periodical inspections are essential in terms of equipment condition and safety of users only fully operational

equipment is able to provide safety.

All information concerning protective equipment (name, serial number, date of purchase and date of first

operation, user name, information concerning repairs and inspections and withdrawal from use) must be

included in the Identity Card for a particular device. The factory where equipment is stored is responsible for

making entries in the Identity Card. The Identity Card should be completed by the person responsible for safety

equipment in a given place of work. Equipment without a properly completed Identity Card cannot be used.

If equipment is exported to other countries, the provider must equip it with operational and maintenance

instructions as well as information concerning periodical inspections and repairs in the language of the country

where the equipment is going to be used.

The product must be immediately withdrawn from use if there are any doubts concerning its condition or

operational correctness. Equipment can be reused after it has undergone a complete inspection carried out by

the manufacturer and written authorisation for reuse has been issued.

If the product was used to prevent a fall, it must be withdrawn from use and physically destroyed.

A full body harness in accordance with EN 361 is the only accepted device for keeping a body in a fall arrest

system utilizing the AZ800 roof lanyard.

It is required to inspect the free space under the work-place on which individual fall preventive equipment is

going to be used in order to eliminate the possibility of hitting any objects or lower planes while stopping a fall.

The amount of free space under the work-place is specified in the operational instructions of the protective

equipment to be used.

While using the device, pay special attention to hazardous situations which may influence equipment operation

and the safety of users, including in particular: - pendulum falls; - current conductivity; - any damage such as

cuts, wear, corrosion; - extreme temperature impact; - negative impact of weather conditions; - impact of

aggressive substances, chemicals, solvents, acids.

Personal protective equipment must be transported in packaging which protects it against damage or water, for

example in bags made of impregnated material or in steel or plastic containers or boxes.

Personal protective equipment must be cleaned and disinfected in order to avoid damaging the material (raw

material) it is made of. Clean textile materials (slings, lanyards) with cleaning agents intended for soft materials.

It can be cleaned manually or washed in machines. It must be carefully rinsed. Plastic elements can only be

cleaned with water. Equipment which becomes wet during cleaning or while in operation must be carefully dried

in natural conditions, away from heat sources. Metal parts and mechanisms (springs, hinges, catches etc.) can

be periodically greased in order to improve their operation.

Personal protective equipment should be stored in loose packaging in well-ventilated dry rooms and protected

against the impact of light, UV radiation, dust, sharp objects, extreme temperatures and caustic substances.

_

_

_

_

_

_

_

_

_

_

_

_

_

legibility of the product marking,

It is forbidden to use a combinations of the protective equpment items in which the safe function of any one item

is affected by or interferes with the safe function of another.