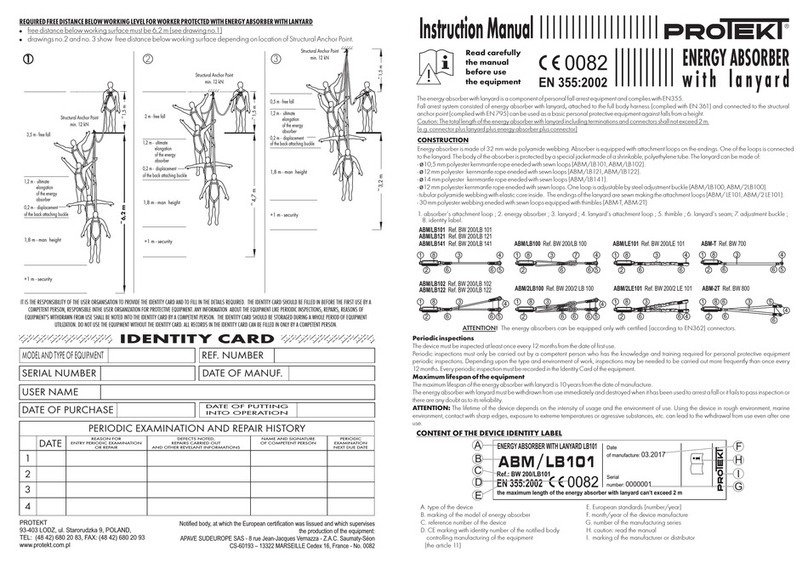

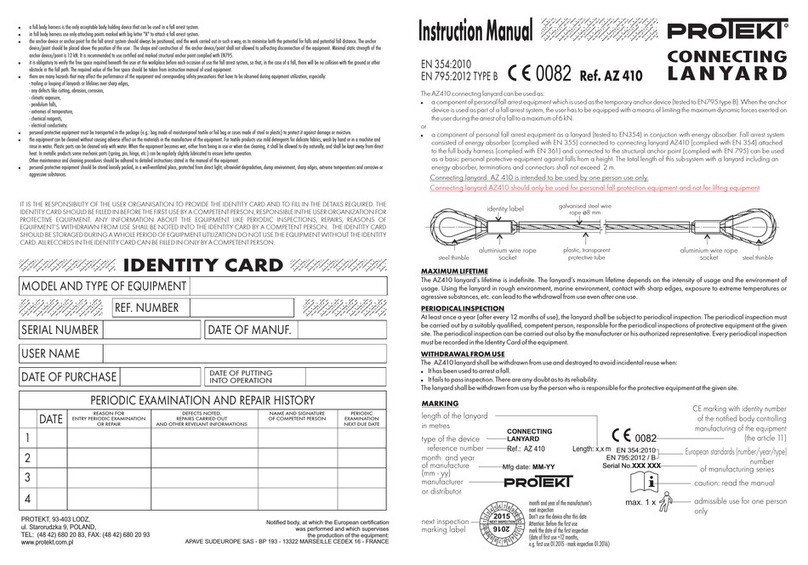

ADMISSIBLE TIME OF USE

There is no limitation of time of use the retractable fall arrester on condition that periodic inspections are regularly carried out.

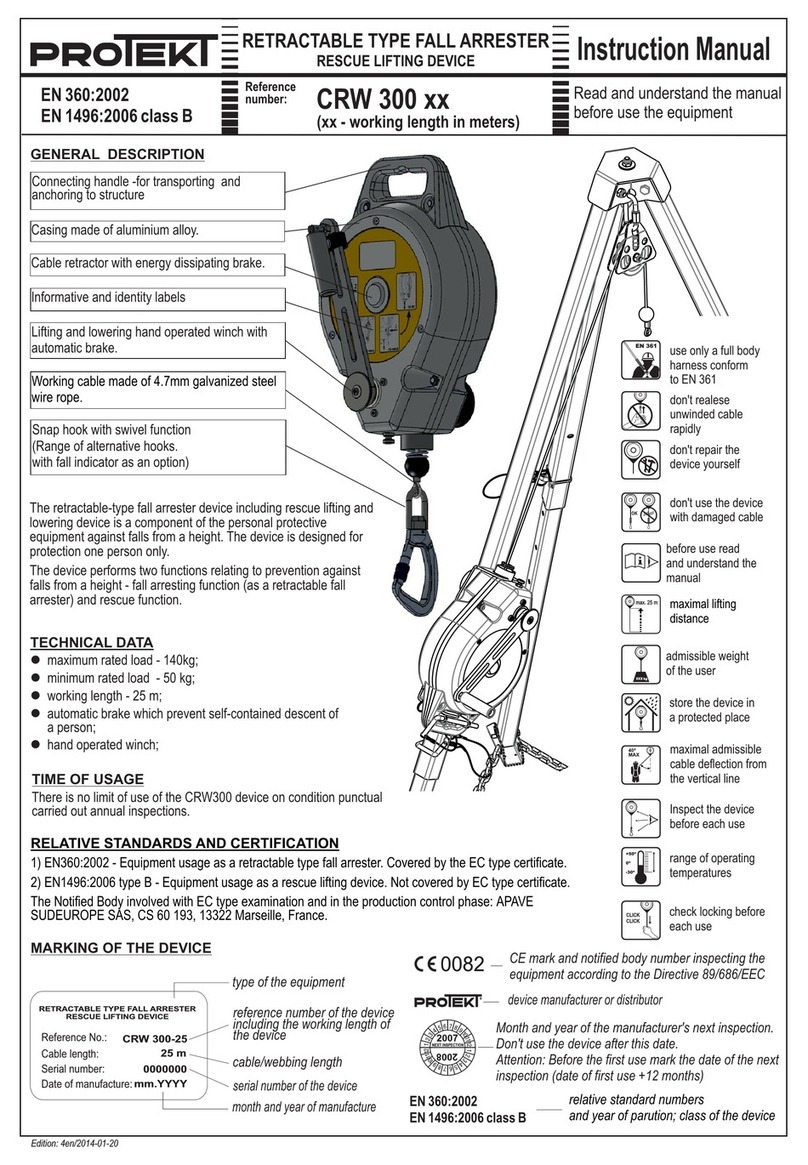

CONNECTING THE FALL ARRESTER TO STRUCTURAL ANCHOR POINT

PRE-USE INSPECTION

Before each use, a person who is going to use the fall arrester, shall a close visual examination of the retractor’s elements:

cover, snap hook, handle, working cable or webbing (entire length), must be carried out in respect of mechanical, chemical

and thermal defects. The user has to check the retractor functioning by dynamic pulling the working cable/webbing.

The cable/webbing should block and stops pulling out. After releasing the cable/webbing, the retractor should pull in the

cable/webbing. The examination must be carried out by . In the case of any defect or doubt of correct condition of the fall

arrester, do not use it.

Using the fall arrester, in connection with fall arrest system, must be compatible with manual instructions of the fall arrest systems

and obligatory standards:

- EN361 - for the safety harness

- EN362 - for the connectors

- EN795 - for anchorages

During use the fall arrester should be protected from a contact with oils, acids, solvents, basics, open fire, hot metal drops and

sharp edges. During working on the lattice constructions we should avoid interleaving the working cable/webbing between the

individual construction elements. We should avoid using the device in the dust laden and greasy environment.

PERIODICINSPECTIONS

Aftereach12monthsof utilization the fall arrester must be withdrawn from use tocarryoutmanufacturer'sdetailedinspection.

Theinspectionmustbecarried out by the fall arrester's manufacturer or his certifiedrepresentativeonly.

During this inspection will be established admissible time of the fall arrester use till next manufacturer's inspection.

The result of inspection must be recorded in Identity Card.

?personal protective equipment shall only be used by a person trained and competent in its safe use.

?personal protective equipment must not be used by a person with medical condition that could affect the

safety of the equipment user in normal and emergency use.

?a rescue plan shall be in place to deal with any emergencies that could arise during the work.

?it is forbidden to make any alterations or additions to the equipment without the manufacturer's prior

written consent.

?any repair shall only be carried out by equipment manufacturer or his certified representative.

?personal protective equipment shall not be used outside its limitations, or for any purpose other than that

for which it is intended.

?personal protective equipment should be a personal issue item.

?before use ensure about the compatibility of items of equipment assembled into a fall arrest system.

Periodically check connecting and adjusting of the equipment components to avoid accidental loosening

or disconnecting of the components.

?it is forbidden to use combinations of items of equipment in which the safe function of any one item is

affected by or interferes with the safe function of another.

?before each use of personal protective equipment it is obligatory to carry out a pre-use check of the

equipment, to ensure that it is in a serviceable condition and operates correctly before it is used.

?during pre-use check it is necessary to inspect all elements of the equipment in respect of any damages,

excessive wear, corrosion, abrasion, cutting or incorrect acting, especially in retractable fall arresters -

cable or webbing, retractor and brake proper acting, casing, energy absorber, connector;

?regular periodic inspections are the essential for equipment maintenance and the safety of the users

which depends upon the continued efficiency and durability of the equipment.

?during periodic inspection it is necessary to check the legibility of the equipment marking.

?it is essential for the safety of the user that if the product is re-sold outside the original country of

destination the reseller shall provide instructions for use, for maintenance, for periodic examination and

for repair in language of the country in which the product is to be used.

?personal protective equipment must be withdrawn from use immediately when any doubt arise about its

condition for safe use and not used again until confirmed in writing by equipment manufacturer or his

representative after carried out the detailed inspection.

,

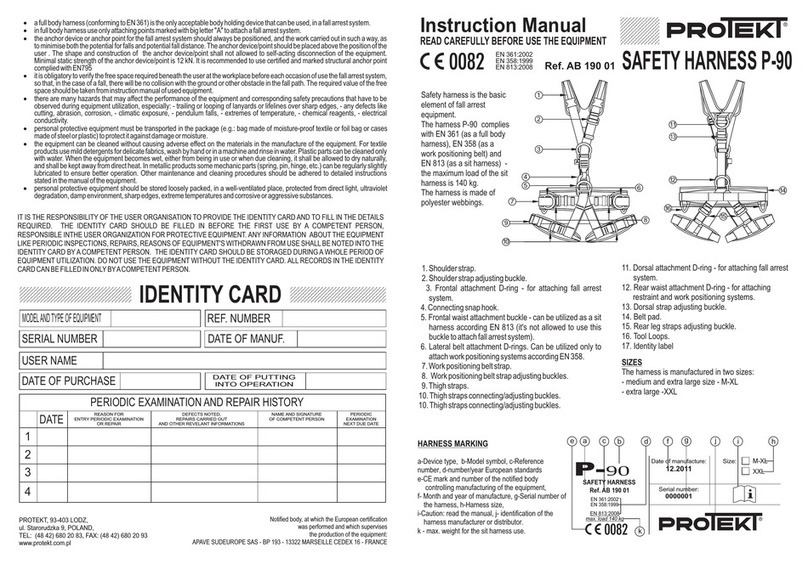

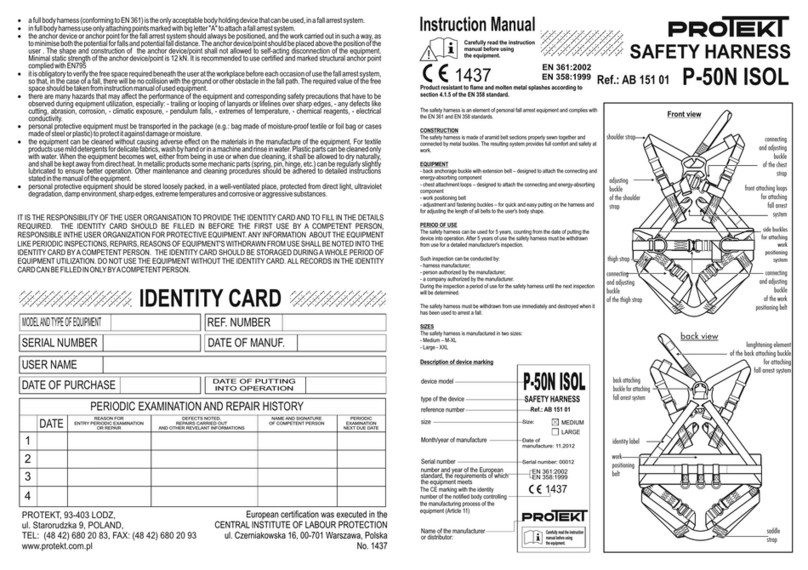

?a full body harness conformed to EN 361 is the only acceptable body holding device that can be used in

a fall arrest system.

?in full body harness use only attaching points marked with big letter "A" to attach a fall arrest system.

?the anchor device or anchor point for the fall arrest system should always be positioned, and the work

carried out in such a way, as to minimise both the potential for falls and potential fall distance. The anchor

device/point should be placed above the user . The shape and construction of the anchor device/point

shall not allowed to self-acting disconnection of the equipment. It is recommended to use certified and

marked structural anchor point complied with EN 795.

THE ESSENTIAL PRINCIPLES OF USE OF PPE AGAINST FALLS FROM A HEIGHT

WITHDRAWN FROM USE

The fall arrester must be withdrawn from use immediately when any doubt arise about its condition for safe use and not used again

until confirmed in writing by device manufacturer or his certified representative after carried out the detailed inspection.

The fall arrester must be withdrawn from use immediately and sent to the device manufacturer of his certified representative to

carry out detailed inspection when it hasbeen used to arrest a fall. Any repair or service operation shall only be carried out by fall

arrester manufacturer or his certified representative.

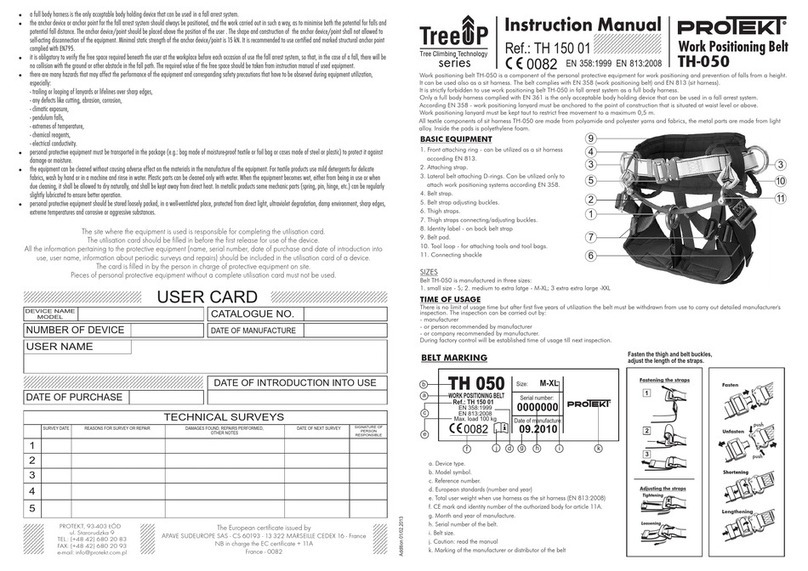

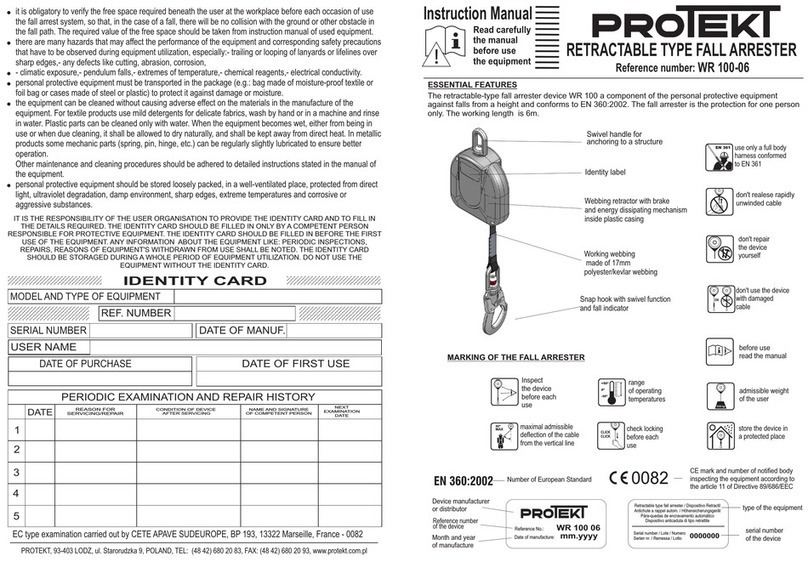

The fall arrester must be connected to structural

anchor point by the top swivel link (CR240) using a

connector [A] or top connector (CR241) [A1] or

sling [B] complying with EN362 or EN795

standards. It is strictly prohibited to attach the

device using its carrying handle [C].

Structural anchorage point should be situated

above the job place and have static resistance

min. 12kN.

The shape of the structural anchorage point should

not let self-acting disconnection of the device. It is

recommended to use certified and marked

structural anchorage point complied with EN 795.

The retractable fall arrester shall be installed above

the operator. When the device is installed in the

vertical line above the user the minimal clearence

distance below working level shall be 1,5 m.

When the cable of the retractable fall arrester is

deflected from vertical line a pendulum effect occurs

during fall arresting. In order to minimise the

pendulum effect the cable deviation angle from

vertical shall never exceed 40°. For this purpose

the user is permitted to move laterally through

distance “l” not greater than 1/2 “v” .

The clearance distance bellow working level must

be greater than 1,5 m+ lateral distance “l”.

STRUCTURAL ANCHOR POINT REQUIRMENTS

v

retractable type

fall arrester

retractable type

fall arrester

anchor pointanchor point

l

z

working

level

pendulum

effect

ground

level

o

max 40

CONNECTING THE FALL ARRESTER TO FULL BODY HARNESS

A

B C

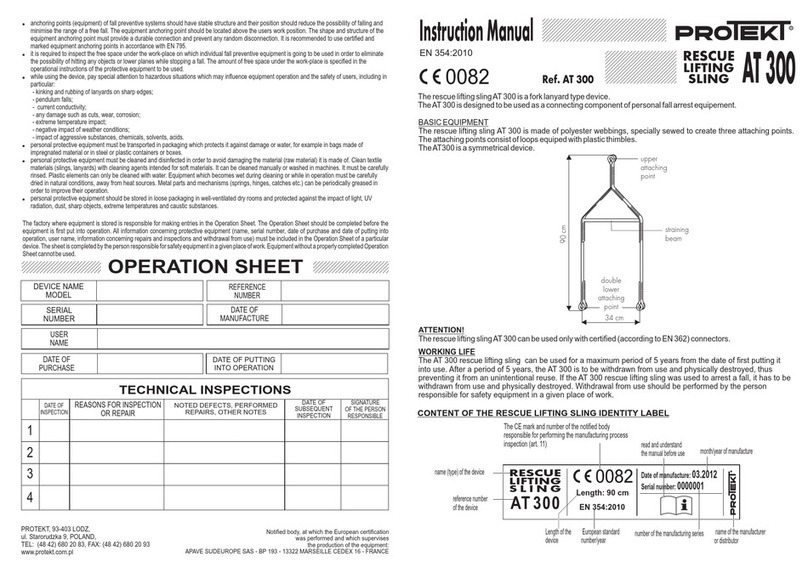

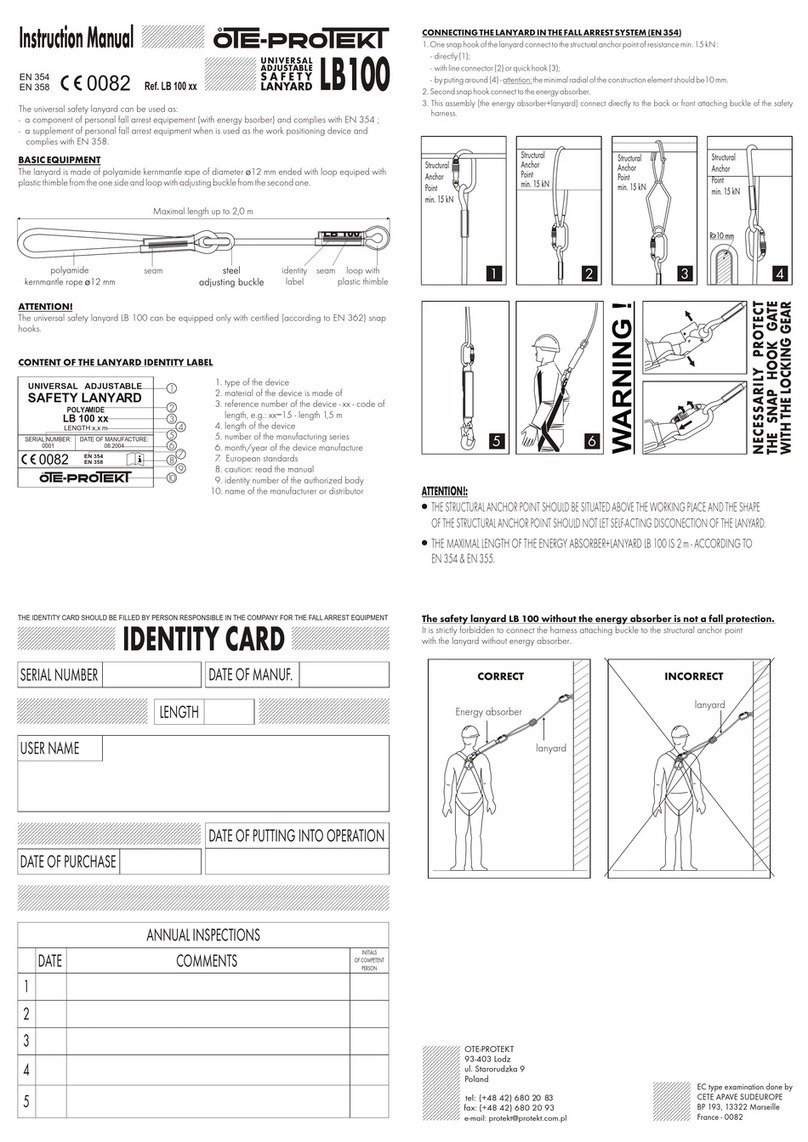

?the working cable/webbing snap hook must be connected only to frontal or

dorsal attachment point of full body harness. Full body harness must

conform to EN 361.

?always protect the gate of the snap hook against accidental opening with

locking gear.

PROHIBITED !!!

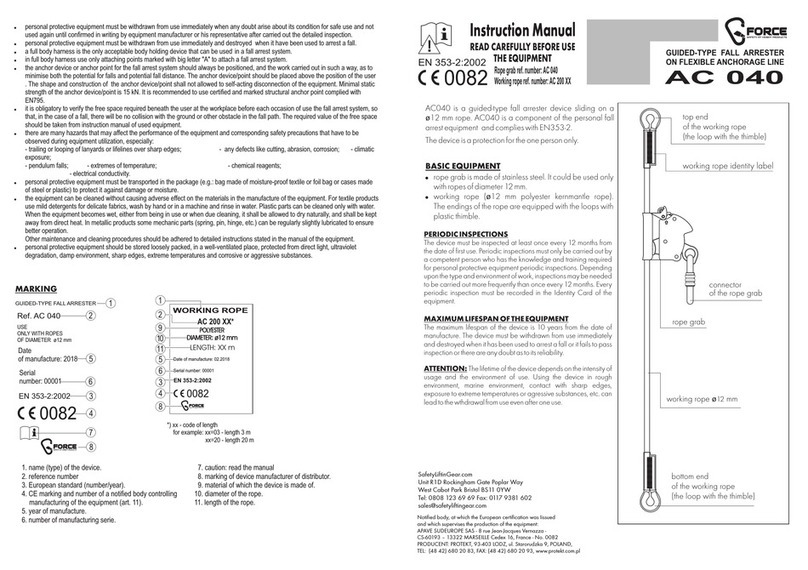

The retractable fall arresters is allowed to horizontal usage and to protection against falls over an edge are specially marked

- see pictogram description. The arresters were successfully tested according to new PPE -Directve 89/686/EEC regulation

(Document CNB/P/11.054). For roof works the retractable device shall be associated with roof lanyard AZ 800. The

equipment may be used over all kind of sharp edges for example: trapezoidal sheet metal, rolled steel profiles and other

metal constructions, wooden beams or clad, roof parapet and similar concrete edges. However in case of „very cutting” or

“not free of burrs” type edge relevant risk assessment should be carried out or the manufacturer should be contacted.

The exact method of use the equipment is described in Instruction Manual of the roof lanyard AZ800.

UTILIZATION THE FALL ARRESTER FOR ROOF WORK

A1