Proxess CX Series User manual

CX- SERIES

SERVICE MANUAL

Introducing EZ Connect

To learn more: visit www.proxess.com or

call 303-317-6656

2

CX-Series Service Manual

CX-SERIES INSTALLATION INSTRUCTIONS

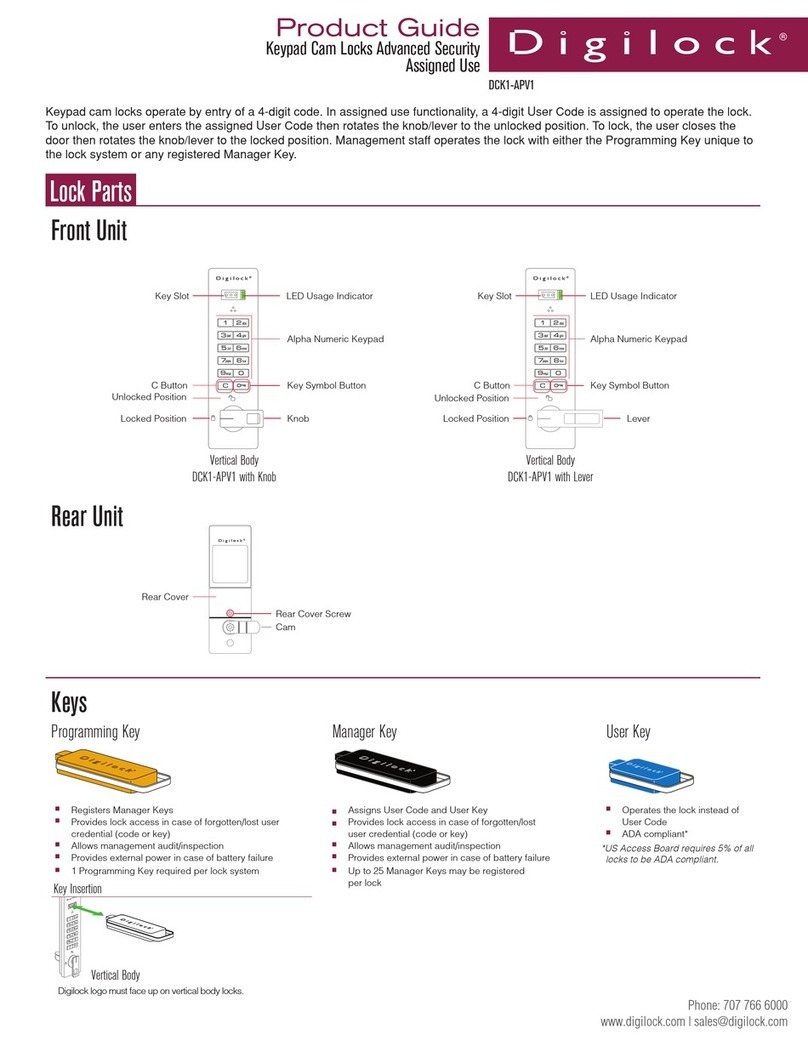

A. CHECKLIST (4 AA Batteries Included)

Parts List: Each Proxess CX-Series lockset includes

•Door Preparation Template

•Cylindrical Lever Lockset with Installation Instructions

•Exterior lock assembly (include housing, lever and cylinder drive unit)

1. Keys

2. Removeable Core

3. Exterior Lever

4. Exterior housing (includes plastics and light pipes)

5. Exterior Rose

6. Chassis plate

7. Chassis

8. Through Bolt Posts

9. Exterior Backplate

10. Ribbon Cable

11. Exterior Assembly Screws

12. Exterior Gasket

•Hardware box includes:

13. Latch

14. ASA Strike Plate

Screw Pack includes:

▪(SP1) Hager mounting screws M5 x 38mm x4pcs

▪(SP2) Flat head tapping screws #8x3/4" x2pcs

▪(SP3) Flat head tapping screws #12-24 x 18mm x2pcs

▪(SP4) Lever release tool

▪(SP5) Hager mounting screws M6 x 10mm x2pcs (optional)

▪(SP6) Torx Wrench and Optional Torx Security Screw

•Interior lock assembly

15. Interior Gasket

16. Interior Backplate

17. Interior Backplate Screws

18. Interior Rose

19. Interior Housing

20. Interior Housing Screws

21. Battery Cover

22. Battery Cover Standard Screw

23. Interior Lever

FOR DOOR AND FRAME PREPARATION INSTRUCTIONS, SEE APPENDIX A OR GO TO PROXESS.COM

SP1

SP2

SP3

SP5

SP4

SP6

3

CX-Series Service Manual

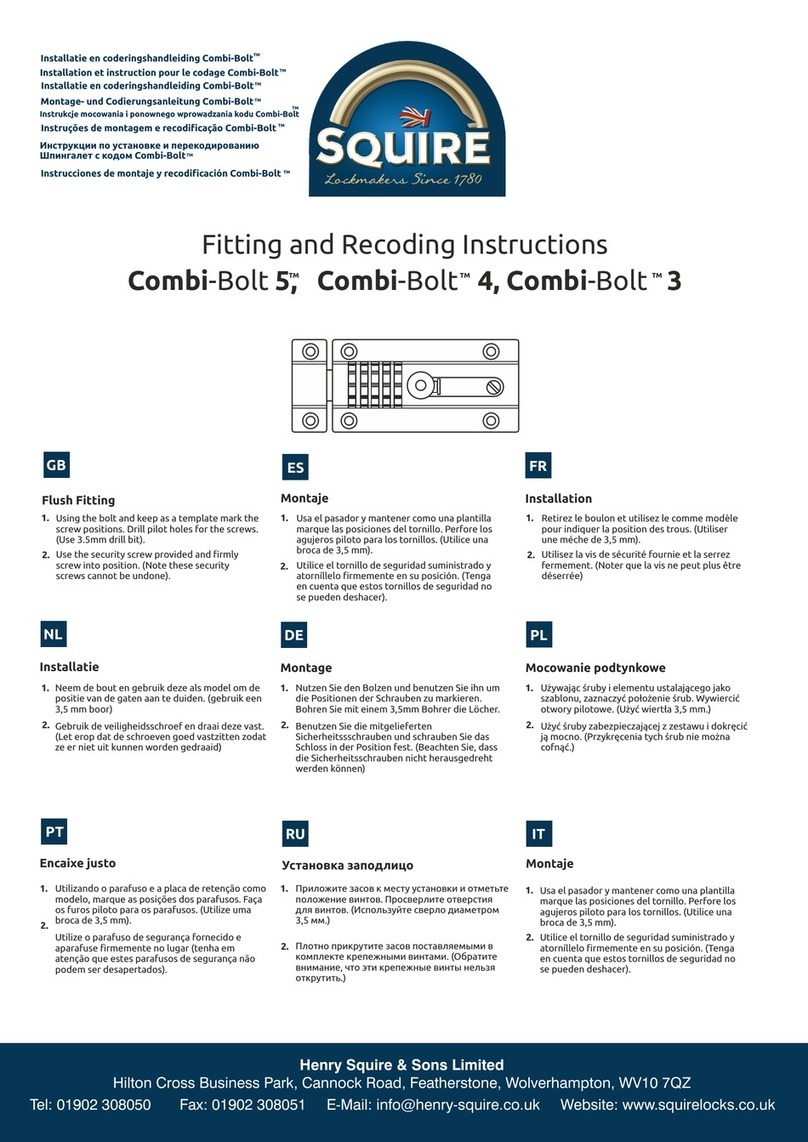

B. ADJUST FOR DOOR THICKNESS

Remove through bolt posts from chassis. Pull chassis and rose mounting plate from exterior lock assembly.

1. Please follow the steps below:

a. Rotate exterior rose mounting plate toward cylindrical chassis.

b. Put the lever release tool into the allocated position of exterior rose mounting plate per the illustration below.

c. Rotate exterior rose mounting plate to door thickness by using the lever release tool.

C. LOCK HANDING AND REHANDING (IF NECESSARY)

Determine the hand of your door. The product is set up for Right Hand by default.

Anti-Rotation Tabs on

the rose mounting plate

PLEASE NOTE THAT THE LOCK BODY COMES

PRE-SET TO ACCOMMODATE A 1¾ INCH DOOR

4

CX-Series Service Manual

D. Hardware Installation Steps

STEP 1

STEP 4 (To Re-hand if Necessary)

Install the latch in the door with the SP2 screws provided. The

latch tube prongs should project into the chassis hole.

1. To re-hand the lock chassis, begin by removing both

the through bolt posts. See arrows below.

2. Remove the lock chassis and rotate both the internal

mechanics and the chassis 180 degrees to

accommodate the hand of the door. You will not need

to remove the exterior gasket or backplate.

3. Replace through bolt posts.

STEP 2

Install the strike plate with the SP3 screws provided, checking

to make sure that the position of the deadlocking plunger is

aligned against the strike plate. See Appendix A for additional

Door Preparation instructions.

STEP 3

STEP 5

Ensure the cable from the exterior board is properly routed

through the cylindrical lock chassis by first inserting one edge,

then pressing the other into the cable slot.

Slide the lock chassis through the chassis hole in the door,

ensuring that the chassis engages the latch.

Re-handed lock chassis to

accommodate left-handed door

5

CX-Series Service Manual

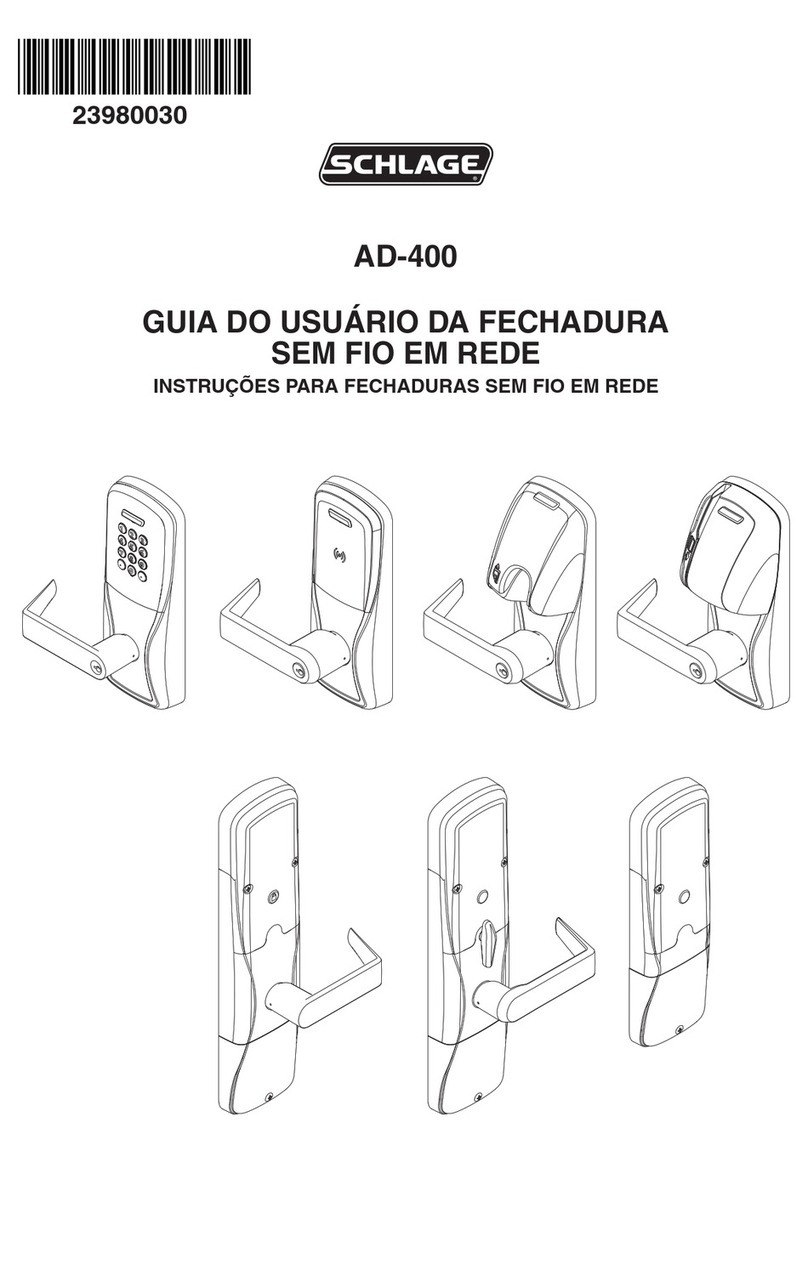

STEP 6

STEP 8

Place the back plate on the interior of the door with the upper

and lower screws near the chassis. Route the chassis cable

through the square hole, and the exterior cable through the

upper oval hole.

Connect the chassis, exterior, and handle switch cables to the EZ

connect board, leaving the exterior connection (6 pin rightmost

connection) for the last connection. Ensure all cables are

neatly tucked into the retaining clips on the rose plate.

*RS-485 Option boards will have a 4th cable to connect to the

EZ Connect board located on the left side of the board.

STEP 6B Deadbolt Configuration

For information about installing the Proxess Cylindrical Lockset

with a deadbolt, see “Door Preparation and Installation” in the

CX-Series Service Manual available at proxess.com.

STEP 7

STEP 9

Place the interior rose liner on the interior back plate and screw

in. Route the chassis cable through the square hole in the rose

liner, and the exterior and handle switch cables through the

upper oval hole (the handle switch will route through the lower

oval hole for other than default handing).

Install the interior trim onto the back plate. The boards will plug

into one another when placed correctly. Screw the interior trim

onto the back plate using the two screws on the right and left of

the battery compartment.

Exterior

connector

Handle switch

connector

Chassis

connectors

6

CX-Series Service Manual

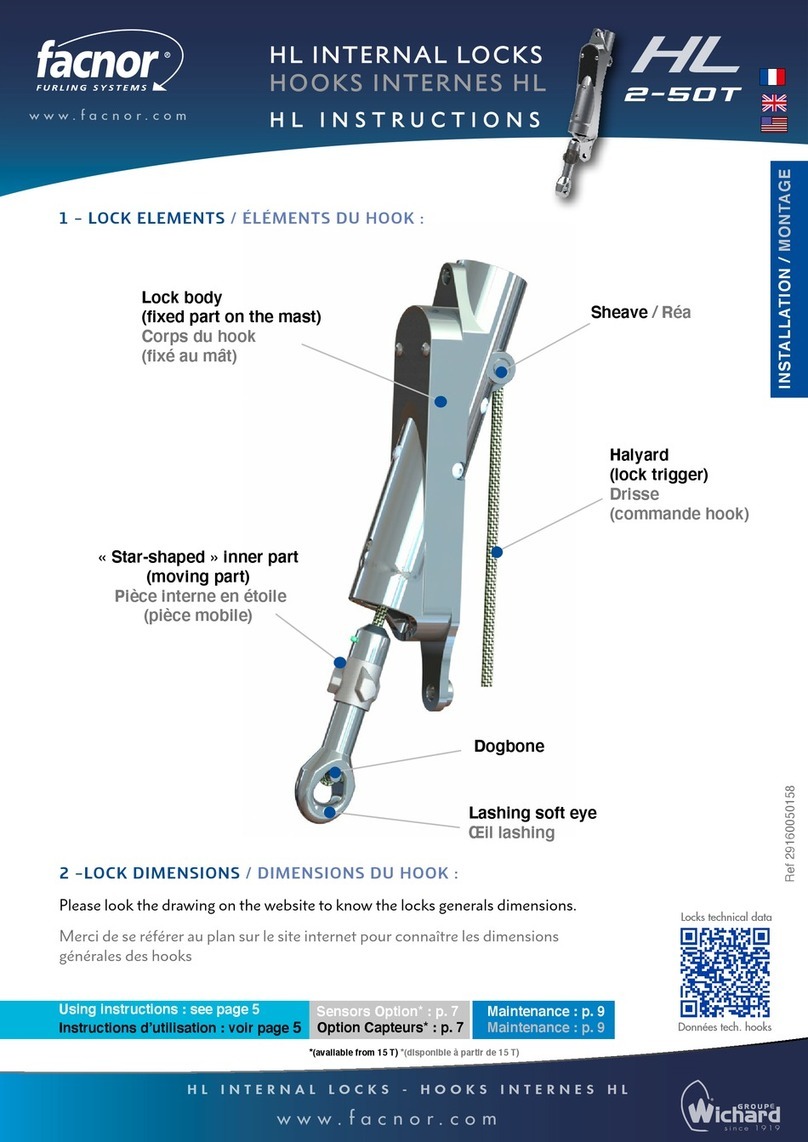

STEP 10

STEP 12

Install the four AA batteries, beginning with the outer two.

After the batteries are properly installed, the lock should beep

once and the motor will run. The lock is then in the locked

position.

Install the levers onto the outside and inside of the door. See

tips for installing and removing exterior handle in the CX-Series

Service Manual prior to installation.

STEP 11

STEP 13 (If Necessary)

Screw the battery cover onto the trim.

Install the removable core.

Once the removable core is aligned with the forked pin in the

lock, insert the control key and turn clockwise 15 degrees to

retract the locking lug, then insert the core into the lever. Turn

the control key back counterclockwise 15 degrees to engage the

core and remove the key.

E. Now that the hardware is installed, see “Software Solutions” in this manual to locate your

software resources and begin programming.

Insert first

Insert last

Align with prongs

of forked pin

7

CX-Series Service Manual

APPENDIX A: INSTRUCTIONS FOR DOOR AND FRAME PREPARATION OF CYLINDRICAL LOCK

A. CHECKLIST

Tools for Door Preparation

•Drill

•Drill Bits: 1” (31/32” for drive in latch), 5/16”

•Hole Saw: 2-1/8”

•Phillips Screwdriver, #2

•Hammer

•Chisel

B. DOOR PREPARATION

1. Doors: Steel or Wood

2. Door thickness range: 1-3⁄8" (35mm) ~ 2" (51mm).

3. Match the Backset of your Proxess CX-Series lockset to the corresponding installation (either 2-3⁄8" [60 mm] or 2-3⁄4" [70

mm] Backset).

4. Place the installation template onto the door and mark holes. Drill the 2 1⁄8" (54 mm) first, then drill the two 5/16" (8mm)

holes for lock chassis mounting. Drill the 1" (25 mm) cross bore hole for the latch last.

5. Insert latch into 1" hole and hold it parallel to door face, mark outline and remove latch. Chisel 11⁄64" (4.3mm) deep or

until faceplate is flush with the edge of the door. Insert latch into the 1" hole again, making certain that the latch bolt bevel

faces direction of closing door (see section E for Lock Handing).

6. Secure the latch to the door using two #8x3/4" screws (SP2).

NOTE: Removing the through bolt posts from the chassis will decrease the security of the lock, voiding ANSI

Grade 1 rating of the lock.

C. FRAME PREPARATION

1. Close the door and mark the horizontal line aligned to the strike.

2. Measure one half of door thickness from door stop to mark vertical center line of strike. Drill 1" (25 mm) hole, 1/2" (12.7

mm) deep at intersection of horizontal and vertical center lines.

3. Chisel out the jamb 3/32" (2.4mm) deep or until strike is flushed with jamb and then secure the strike to the jamb using two

#12-24 x 1” screws (SP3).

Backset thickness –note

that lock is preset to

standard 1¾ inch door

8

CX-Series Service Manual

ADDITIONAL RESOURCES

SERVICE EQUIPMENT

ENR™

Enrollment Reader and Programmer

MPD Mobile Programming Device

Android Mobile Phone with no Sim Card

OTG On-the-Go Converter

(included with MPD)

SOFTWARE SOLUTIONS FOR LOCKSET PROGRAMMING

For data sheets and user manuals, please visit our website under the “Support Documents & Data Sheets” and Solutions tabs.

LoxIQ™ : A simple, yet powerful, system that requires only the locks and a phone. It is typically implemented in smaller systems of 50

doors/users or less…Expandable to full server system software.

ProxessIQ™ : The robust scalable access control software supporting Proxess Wireless Locksets and Controllers.

Proxess Sync™:Mobile phone app synchronizes changes from the ProxessIQ™ software to locksets across the country.

FCC STATEMENT

This equipment has been tested and found to comply with the limits for a Class A and Class B digital device, pursuant to part 15 of the FCC Rules.

Please see our full CX-Series Service Manual posted on our website for most recent FCC Statements and compliance information.

FCC Caution:

Any changes or modifications not expressly approved by the party responsible for compliance could void the user’s authority to operate this

equipment.

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause harmful

interference, and (2) this device must accept any interference received, including interference that may cause undesired operation.

Industrie Canada l’énoncé

L’émetteur/récepteur exempt de licence contenu dans le présent appareil est conforme aux CNR d’Innovation, Sciences et Développement

économique Canada applicables aux appareils radio exempts de licence. L’exploitation est autorisée aux deux conditions suivantes :

1. L’appareil ne doit pas produire de brouillage;

2. L’appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage est susceptible d’en compromettre le fonctionnement.

FCCID: 2AKUZPXH01

Product Marketing Name: CX- Series Cylindrical Lockset

IC ID: 22335-PXH01

Contains: SH6MDBT50Q

Models (HVINS): PXHO1-CX03-B (Proxess CX-Series Wireless Cylindrical Lockset), PXH01-CX03-DC (Proxess CX-Series DC Powered Lockset), PXH01-

MX02-B (Proxess MX-Series Wireless Mortise Lockset), PXH01-MX02-DF (Proxess MX-Series DC Powered Mortise Lockset)

UL STATEMENT (Pending)

Other manuals for CX Series

1

Table of contents

Other Proxess Lock manuals

Popular Lock manuals by other brands

Mottura

Mottura POWER 541 Instruction and maintenance manual

Creche Innovations

Creche Innovations MicroCool Station mode instructions

Kaba Mas

Kaba Mas Auditcon 52R installation instructions

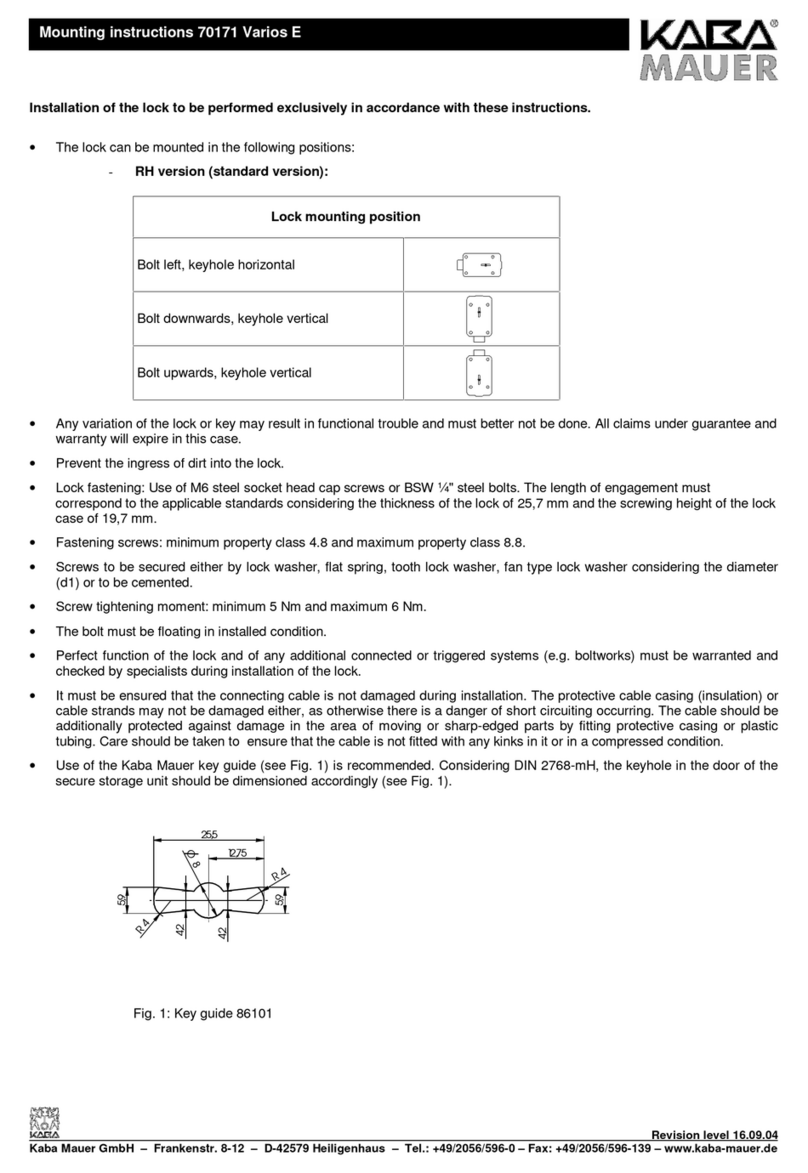

Kaba Mauer

Kaba Mauer Varios E 70171 Mounting instructions

IKEA

IKEA ROTHULT manual

AmazonBasics

AmazonBasics Travel Sentry AB-TL100 quick start guide