Proxess MX Series User manual

To learn more: visit www.proxess.com

or call 303-317-6656

SERVICE MANUAL

Introducing EZ Connect

2

Mortise Service Manual

TABLE OF CONTENTS

INTRODUCTION 3

DOCUMENTATION PACKAGE 3

CERTIFICATIONS AND STANDARDS 3

TECHNICAL SUPPORT 4

FUNCTIONS 4

LOCK FUNCTIONS LETTER CHART 4

LOCK PARTS 5

PARTS BLOWUP 5

PARTS NUMBER CHART 5

CASE AND STRIKE DIMENSIONS 6

CYLINDER/KEYING 6

TRIM PARTS 7

MAINTENANCE 7

TOOLS FOR MAINTENANCE 7

TROUBLESHOOTING HARDWARE 8

INSTALLATION MANUAL 9

MORTISE INSTALLATION DOOR PREP 10

MORTISE INTALLATION INSTRUCTIONS 12

MORTISE INSTALLATION TEMPLATE 21

ADDITIONAL RESOURCES 22

SERVICE EQUIPMENT 22

SOFTWARE SOLUTIONS 23

FCC Staatement 24

3

Mortise Service Manual

COPYRIGHT

Copyright ©2018 Proxess, LLC. All rights reserved. Printed in the United States of America. Information in this document is subject to

change without notice and does not represent a commitment on the part of Proxess, LLC. The software described in this document

are furnished under a license agreement or nondisclosure agreement. This publication is intended to be an accurate description and

set of instructions pertaining to its subject matter. However, as with any publication of this complexity, errors or omissions are

possible. Please call Proxess corporate offices at (303) 317-6656 if you see any errors or have any questions. No part of this manual

and/or databases may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying,

recording, or information storage and retrieval systems, for any purpose, without the express written permission of Proxess, LLC.

This document is distributed as is, without warranty of any kind, either express or implied, respecting the contents of this book,

including but not limited to implied warranties for the publication’s quality, performance, merchantability, or fitness for any

particular purpose. Neither Proxess, LLC nor its dealers or distributors shall be liable to the user or any other person or entity with

respect to any liability, loss, or damage caused or alleged to be caused directly or indirectly by this publication.

INTRODUCTION

The Proxess MX-Series Service Manual contains important information to assist you in maintaining your Proxess Mortise

Lockset.

CERTIFICATIONS AND STANDARD

ANSI/BHMA A156.25 (Indoor/Outdoor)

ANSI/BHMA A156.2 Grade 1

ULC S319 PDR

ULC Canada

UL10C Fire-Rated

UL10B Neutral Pressure Rated

FCC Part 15 ADA Compliant

RoHS Industry Canada (IC)

TECHNICAL SUPPORT

The first source for technical answers is this MX Series Service Manual. All documentation and training materials are also

available on our website: www.proxess.com. If you are not able to find an answer in this manual, contact your local

Proxess Representative. If you do not know your local Proxess Representative, contact the Customer Service

Department at Proxess (303)-317-6656.

4

Mortise Service Manual

Name Similar ANSI

# Mech Description Proxess Electronic Equivalent Function

Entrance F109

Turn/Push button locking. Pushing and turning button on inside locks

outside knob/lever requiring use of a key until button is manually

unlocked. Push button locking. Pushing button locks the outside

knob/lever until unlocked by key or by turning the inside lever/knob.

Inside knob/lever always free.

Enable toggle schedule and double

present credential to outside reader to

lock/unlock door

Storeroom F86 Outside knob/lever always rigid. Key required for entry. Inside always

free.

A valid credential should provide

momentary unlocking and allow entry by

that user, with the latch relocking in an

administrator defined time (usually 5-8

seconds)..

Office F82

Push button locking. Button on inside locks outside knob/lever until

unlocked by key, or by rotating the inside knob/lever. Inside knob/lever

always free. Deadlocking latch bolt.

A valid credential should provide

momentary unlocking and allow entry by

that user, with the latch relocking in an

administrator defined time (usually 5-8

seconds)..

Classroom no Lockdown F84 Classroom/Office or Utility Room. Key locks/unlock outer knob or lever.

Inside always free.

Enable toggle schedule and double

present credential to outside reader to

lock/unlock door.

Classroom w/Lockdown

(Intruder) F110

Deadlocking latch bolt operated by lever from either side. Key either

inside or outside locks or unlocks outside lever. Inside lever always

operates latch bolt.

Enable toggle schedule and double

present credential to outside reader to

lock/unlock door. Lockdown performed by

gesture.

Classroom w/Lockdown

(Intruder) F110

Deadlocking latch bolt operated by lever from either side. Key either

inside or outside locks or unlocks outside lever. Inside lever always

operates latch bolt.

Enable toggle schedule and double

present credential to outside reader to

lock/unlock door. Lockdown performed by

gesture.

Classroom w/Holdback F85

Deadlocking latch bolt by knobs. Outside knob is locked by key in

outside knob. Inside knob is always free. Latch may be held back by

depressing latch and rotating key.

Enable toggle schedule and double

present credential to outside reader to

lock/unlock door. (electronic equivalent to

F84, because unlocked door allows free

entry)

Canadian Function Deadlocking latch bolt by levers except when outside lever is locked by

push button. Outside lever locked by pressing push button only.

Future Use Function

Patio F77

Outside knob/lever locked by push button on inside knob/lever. Rotating

inside knob/lever or closing door releases/unlocks button. Emergency

release in outside knob/lever.

Future Use Function

Secured Privacy

Outside knob/lever locked by pushbutton on inside knob/lever. Rotating

inside knob/lever or closing door releases/unlocks button. Emergency

push button in outside knob unlocks door.

Future Use Function

Hotel Guest Room F93

Outside knob fixed. Entrance by key only. Push button in inside knob

activates visual occupancy indicator, allowing only emergency master

key to operate. Rotation of inside spanner button provides lockout

feature by keeping indicator projected.

A valid credential should provide

momentary unlocking and allow entry by

that user, with the latch relocking in an

administrator defined time (no visual

indicators)

Dormitory F90

Deadlocking latch bolt by levers except when locked by push button in

inside lever. Key in outside lever locks or unlocks outside lever and

releases the button. Closing door releases push button. Inside lever

always free.

Enable toggle schedule and double

present credential to outside reader to

lock/unlock door. (Closing door will NOT

unlock the outside lever)

Service Station F92

Deadlocking latch bolt by lever from either side except when outside

lever is locked by Universal push button in inside lever. Inside lever is

always free. When outside lever is locked, latch bolt may be retracted by

turning key or rotating inside lever. Turning key, rotating inside lever or

closing door releases Universal push button and outside lever, except

when Universal push button has been rotated to a position which keeps

the outside lever locked at all times.

Enable toggle schedule and double

present credential to outside reader to

lock/unlock door.

Exit Latch F89 Deadlocking latch bolt by inside lever. Outside lever inoperable. Mechanical lockset

Privacy F76

Outside knob/lever locked by pushbutton on inside knob/lever. Rotating

inside knob/lever or closing door releases/unlocks button. Emergency

push button in outside knob unlocks door.

Mechanical lockset

Passage F75 Doors that don't require locking. Mechanical lockset

Mortise Lock Functions

LOCK FUNCTIONS

5

Mortise Service Manual

LOCK PARTS

PARTS BLOWUP

DEADBOLT (B) FUNCTIONS

PART NUMBERS AND DESCRIPTIONS

ITEM PART NUMBER DESCRIPTION

1 M00-0031A Cylinder

2 M00-0006A Exterior Trim

3 M00-0018A Exterior Backplate

4 M00-0020A Gasket

5 M00-0013A Spindle

6 M00-0014A Spindle Spring

7 M00-0033A Flat Head Screw (x2)

8 M00-0015A Spring Cage

9 M00-0013A Spindle

10 M00-0035A Set Screw (Long)

11 M00-0037A Counter Sink Screw (x4)

12 M00-0007A Interior Trim

13 M00-0036A Set Screw (Short)

14 M00-0042A Hex Wrench

15 M00-0016A Thumb Turn Spindle

16 M00-0038A Round Hex Screw (x2)

17 M00-0017A Interior Backplate

18 M00-0008A Micro-Switch Flipper

19 Latch Monitor Connector

ITEM PART NUMBER DESCRIPTION

20 M01-0011A Mortise Chassis for

Bolt

Functions

M02-0011A Mortise Chassis for

Latch Only

21 Motor Connector

22 M00-0034A Flat Head Screw (x2)

23 M01-0012A Chassis Faceplate for

Bolt Functions

M02-0012A Chassis Faceplate for

Latch Only

24 M00-0039A Front Panel Screw (x2)

25 M01-0030A Strike Plate for Bolt

Functions

M02-0030A Strike Plate for Latch

Only

26 M00-0040A Strike Plate Screw (x2)

27 M00-0005A Battery Cover

28 M00-0021B 6-Pin Cable

29 M00-0041A Trim Fixing Screw

30 M06-0001A for Angled Return

M08-0001A For Curved Return

8

Mortise Service Manual

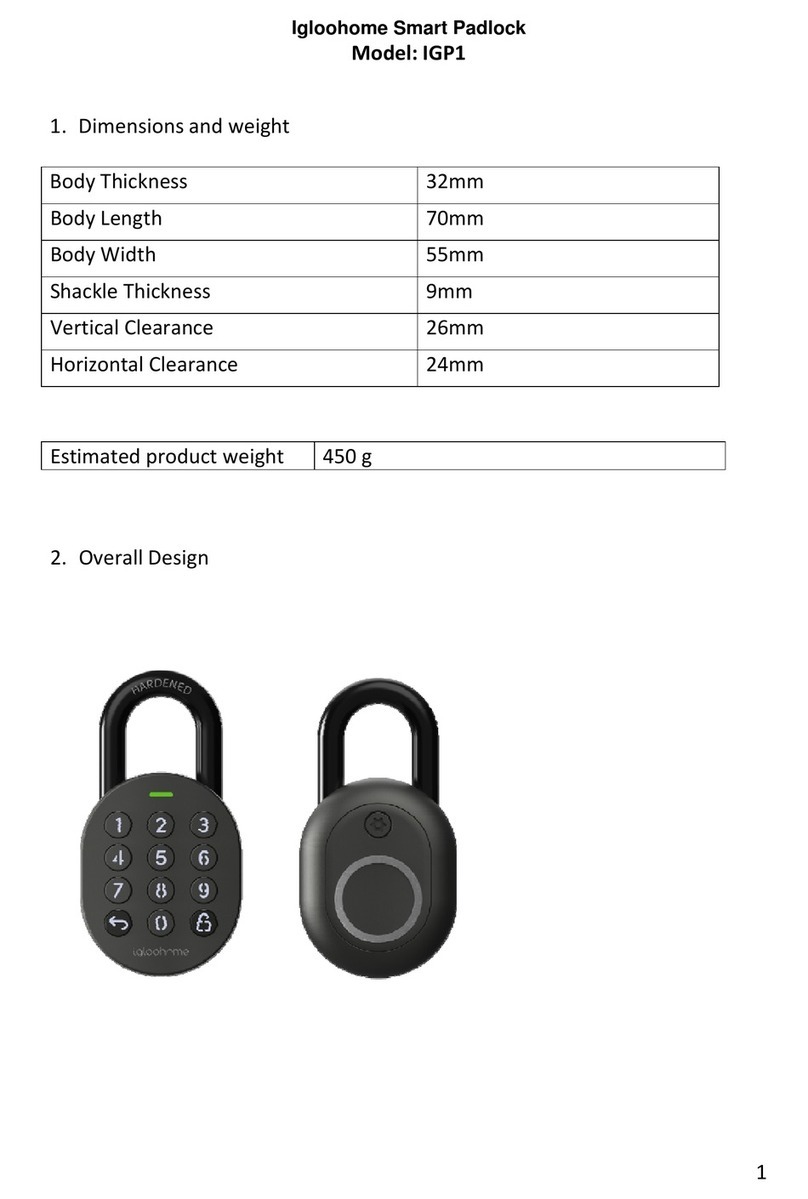

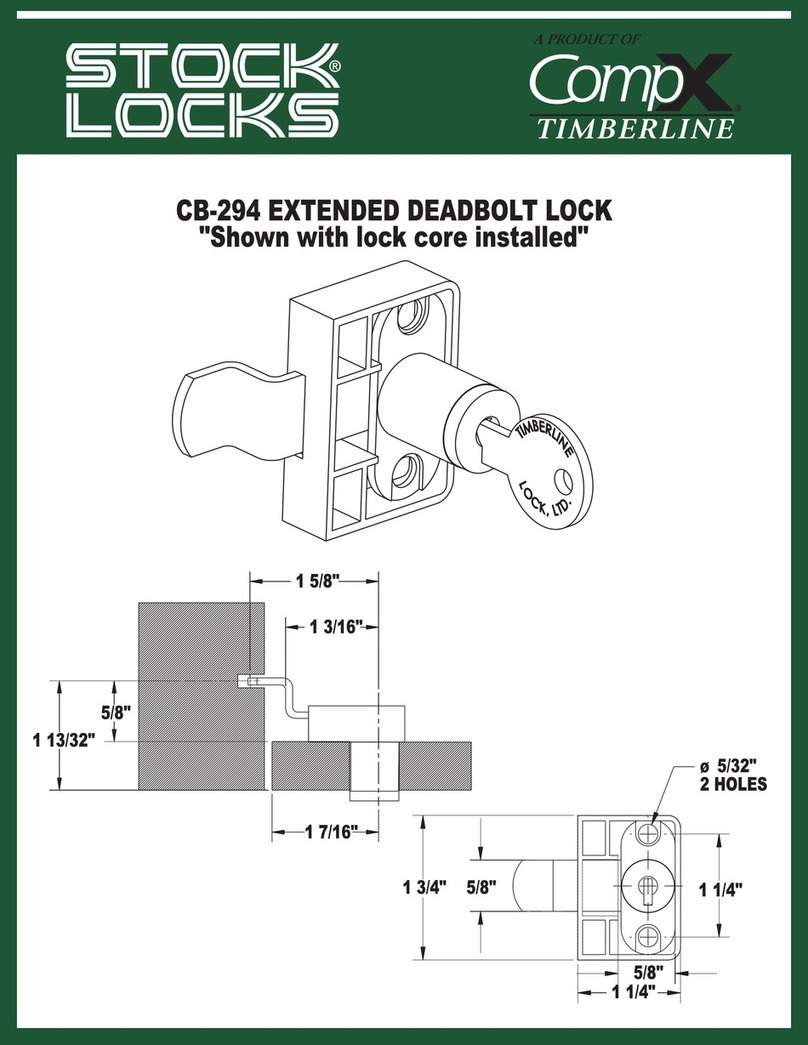

PROXESS MX CASE AND STRIKE DIMENSIONS

CYLINDER/KEYING

Due to the extra thick trim that houses RF and battery components, Proxess mortise locks will require special length (1

34

inch) cylinders. When using other manufacturers’ cylinders, ensure that you have the proper 1 34

inch long

cylinder.

Proxess locks are supplied with only small format removable cores and we strongly recommend that these locks are

keyed differently than other cylinders in the existing lock system. Keys for Proxess locks are meant to be used only in

emergency situations that require a mechanical key bypass. Proxess software monitors when a mechanical key is used.

Proxess supplies custom keyed cores to match existing Proxess locks/systems. You will see a core mark on the face of

the core. Simply provide your account name and this core mark in order to receive custom “matching” keying. Most

Proxess cores contain several “spool” segments standard as a safeguard to resist picking. The software will notify the

administrator of entry audits when access was gained by a key or in the unlikely event the lock was picked.

7

Mortise Service Manual

TRIM PARTS

STRIKE PLATES

ITEM

PART NUMBER

DESCRIPTION

SL

M02

-

0030A

Latch only strike plate

SB

M01

-

0030A

Bolt and latch strike plate

LEVERS

ITEM

PART NUMBER

DESCRIPTION

6

M06

-

0001A

Angled Return

8

M08

-

0001A

Curved Return

MAINTENANCE

TOOLS FOR MAINTENANCE

SL

SB

6

8

Philips Screwdriver, #2

Core Turn Knob Tool

Cylinder and Core Testing Wrench

8

Mortise Service Manual

TROUBLESHOOTING HARDWARE

The following table illustrates possible causes and solutions for common problems after installing the lock hardware.

PROBLEM CAUSE SOLUTION

No beeps or blinks when

the batteries are installed

Improper plug

connection

Check all wiring and connectors to make sure the

connectors are secure, and the cable is not pinched

Reversed battery or

dead batteries

Check the position of the batteries to make sure they

are seated correctly

Pinched wires or

damaged cabling

Ensure the internal cabling is routed properly and

cables have not been damaged during assembly

LED does not beep or

blink on exterior when

presented

Batteries are dead

and need to be

replaced

Replace the batteries, synchronized the lock with the

MPD and try the credential again

MPD (Mobile phone

device) does not connect

to the lock

Bluetooth is not

enabled on the MPD

Enable Bluetooth in Settings

Red LED When

credential is presented

(Access Denied).

Improper Credential

Permissions

Ensure the credential has appropriate access to the

door.

Lockset is in

Lockdown

Have administrator take the lockset out of lockdown,

or program the necessary credential to have “Pass-

Through” privileges. (See software manual).

MPD does not connect to

the lock

Bluetooth is not

enabled on the MPD

Enable Bluetooth in Settings

The Proxess Mortise lockset will indicate certain conditions with a

series of Beeps and Blinks.

Operation indicators (Usually non-

repeating) Description

3 Red Beep/Blinks The lockset has been set to toggle unlocked.

3 Green Beep/Blinks The lockset has been set to toggle locked.

Warning Indicators (Will continue until

problem resolved)

Description

3 Red Beeps (No Beeping) Battery Low

3 Amber Beep/Blinks Battery Critical

3 Double-Red Beep/Blinks Battery Critical

3 Double-Red Beep/Blinks Lockset Not Synchronized

Start-Up Sequence Beep/Blinks

If a problem with the lockset occurs there may be a sequence of Beep/Blink indicators during start-up

that will help to determine the problem. These will be 3 short Beep/Blinks followed by a series of longer

Beep/Blinks. Please note them and contact a Proxess customer service representative.

9

Mortise Service Manual

INSTALLATION INSTRUCTIONS

The following pages contain the Installation Manual for the MX- Series Mortise Lock

A. CHECKLIST (4 AA BATTERIES INCLUDED)

Parts List: Each Proxess MX-Series lockset includes

Door Preparation Template

Mortise Lever Lockset with Installation Instructions

o Exterior lock assembly (include housing, lever and cylinder drive unit)

o Interior lock assembly

o Cylinder

Hardware box includes:

o ASA Strike Plate (Deadbolt or Latch Only)

o Spindle Pack Includes:

Spindle x4 pcs

Thumb Turn Spindle

Micro Switch CAM

Spindle Spring

Round Head Screw x2 pcs

o Spring Cage Pack Includes:

Spring Cage x2 pcs

Flat Head Screw x4 pcs

o Screw Pack includes:

(SB1) Set Screw (Long)

(SB2) Set Screw (Short)

(SB3) Counter Sink Screw x4 pcs

(SB4) Front Panel Screw x2 pcs

(SB5) Strike Plate Screw x2 pcs

(SB6) Panel Set Screw

(SB7) Hex Wrench

10

Mortise Service Manual

B. Door Preparation

Measure the desired height from the floor to the door handle

.

Use the Mortise Lock Installation Template for prepping the Mortise door holes.

Using the provided template, drill out the proper holes in the door.

o Use a 34

inch hole saw to drill the hole for routing the cables through. If you do not have a hole saw,

use a 12

inch drill bit and drill two holes.

Lock Handing

Note: The lock is right handed by default. To rehand the lock, you will need to change the lock bolt

orientation.

C. Left Hand and Right Hand Reverse Set Up (See D for RH and LHR Set Up)

C.1 Latchbolt Orientation Set up

1.

Remove the front panel set screw (24)

and the front panel (23).

2. Then, unscrew the latch set screw.

3. Pull out the latchbolt, turn it 180, and

replace it in the chassis.

4. Then, screw back in the set screw.

11

Mortise Service Manual

C.2 Remove Free Wheeling Lever Set Screw C.3 Proper Spring Cage Orientation Set Up (For Left

Hand or Right-Hand Reverse)

See below. Note: arrow “B” must point down.

Only remove the screw from the reader/ external side of

the Mortise assembly.

1.

For Exterior Panel Spring Cag

e

-

Place the

spring

cage on the exterior side of the trim. Arrow should

point clockwise or in the direction you want the

handle to engage the latch.

2. Then, screw in the two set screws.

For Interior Panel Spring Cage – Arrow should point

counterclockwise.

D. Right Hand and Left-Hand Reverse Setup

D.1 Default factory assembly is set for both RH and

LHR

D.2 Remove Free Wheeling Lever Set Screw

Do not

remove

the latchbolt

.

1. Remove the front panel set screw (24) and the

front panel (23).

See below. Note: Arrow B must point down.

Only remove the screw from the reader/ external side of

the Mortise assembly.

Set Screw

Set Screw

12

Mortise Service Manual

D.3 Proper Spring Cage Orientation Set Up (For Right Hand or Left Hand Reverse)

The factory default setting will work with LHR and RH.

The arrow should point in the direction you want the handle to

engage with the latch.

For Exterior Panel Spring Cage – Arrow should point counterclockwise.

For Interior Panel Spring Cage – Arrow should point clockwise.

Hardware Installation

E. Mortise Chassis Installation

1.

Route the cables through the door hole. Use pliers if necessary.

2. Slide Latch Monitoring Cable (19) and Motor Cable (20) through the door hole as shown.

3. Then, slide Mortise Lock chassis (20) into the door and screws (22) as shown (Do not fasten screws at this

point). It may be easiest with a second person to hold the chassis.

.

F. External Panel Installation

Insert Hex Bolts (9) onto the

Exterior Trim

(2)

.

13

Mortise Service Manual

F.1 External Panel Installation

1. Ensure Ribbon Cable is secure in Exterior Trim first. Note that cable cannot be folded.

2. Then install Exterior Backplate and Gasket onto the Exterior Trim.

F.2 Insert Spindle F.3 Insert Ribbon Cable

1.

Insert the spindle (5) and spindle spring (6) into

the spring cage.

Ensure the lever rotates smoothly and drives the spindle

properly.

Having a hard time installing the spindle? Make sure the

handle is 90 perpendicular to the trim in the desired

orientation. Shifting the handle slightly may help

particularly troublesome spindles.

NOTE: Pay close attention to the spring. The small spring

is not attached to anything and can be easily misplaced.

1.

Insert the

ribbon cable into the oval opening on

the side of the door.

2. Pull the ribbon cable through the other side of the

door.

If necessary, use pliers to route the cable. Make sure the

cable is not bent or pinched.

F.4 Insert the Exterior Panel Assembly into the door F.5 Install Interior Backplate

(Ensure the

handle moves freely

)

1.

Insert the ribbon cable into the Interior Gasket (4)

and Interior Backplate (17).

2. Fasten the two set screws (16).

14

Mortise Service Manual

F.6 Install Cylinder F.7 Tighten Cylinder and Backplate

1. Loosen the cylinder set screw in the mortise

chassis to insert the cylinder.

2. Insert the cylinder (1) into the front panel and

ensure it sits flush with the front plate.

1.

Insert the screwdriver into the side of the lock and

tighten the cylinder.

2. Then, tighten the mortise lock set screw (22).

3. )Tighten interior backplate (17).

Step F Completed

G. Interior Assembly Preparation

G.1 Remove Battery Cover

Use Hex Wrench (14) to

loosen

long (10) and short set

screws (13). Next remove the battery cover (27).

15

Mortise Service Manual

G.2 Inserting Micro Switch CAM

1.

Insert the Micro Switch Cam (18) on the spring cage as shown. Make sure the switch is engaged.

2. Then, move (18) to the right and align it with the spindle slot as shown.

G.3 Inserting Spindles G.4 Engaging the Micro Switch

Insert spindle (5) and spring (6) into the spring cage as

shown.

Note: The spring is not attached to anything and

can be easily misplaced. Use caution when

installing the spring.

Turn the lever to make sure (18) is properly engaged with

the Micro Switch.

Step G Completed

16

Mortise Service Manual

EZ Connect Wiring

H. Interior Panel Installation

H.1 Installing Thumb Turn Spindle and Connectors

Insert Thumb Turn Spindle (15).

H.2-3 Completed

H.2 Then align the spindles with the chassis and

place it onto the interior backplate.

Ensure that the thumbturn is horizontal when the

deadbolt is in, and vertical when the deadbolt is

out/thrown.

H.4 Turn the lever to ensure proper latch

engagement. The latchbolt should retract.

H.5 Insert the 4 battery compartment screws and bottom set screws to finish installing the interior trim.

17

Mortise Service Manual

I. Operation Test

I.1 Insert AA Alkaline batteries (x4) into the battery

compartment

I.2 Green light will turn on and you will hear a beep,

indication that the power is on

I.3 Turn the lever and make sure the lever is free to

rotate

I.4 Testing the Lock

1.

Take the credential, place it in front of the panel and wait for one second. The green light will flash and you

should hear a beep.

2. Turn the handle to actuate the latch and the door can be opened. After about 5-6 seconds, the door will

automatically lock again.

I.5 If the latch cannot be actuated, go back to I.1.

I.6 Thumb turn lever function test (F15 only). I.7 Fasten mortise chassis plate on with the chassis

plate screws after all function tests work properly.

Turn thumb turn lever, deadbolt latch will extend;

deadbolt latch will work with Cylinder Emergency Key.

I.8 Insert Battery Cover (27) onto the Exterior Trim.

I.9 Tighten the Battery Cover into place.

18

Mortise Service Manual

J. Strike Plate Installation

J.1 Use the template provided to create the strike plate mounting hole on the door frame.

J.2 Insert the strike plate set screws (25) and (26).

J.3 Repeat Section I.4 and Complete Installation.

21

Mortise Service Manual

INSTALLATION TEMPLATE – FOR REFERENCE ONLY:

(USE THE TEMPLATE FROM MX INSTALLATION MANUAL FOR ACURATE DIMENSIONS)

22

Mortise Service Manual

ADDITIONAL RESOURCES

SERVICE EQUIPMENT

ENR™

Enrollment Reader and Programmer

Proxess’ ENR™ makes the credential enrollment process intuitive and simple. Just

place a credential on the desktop reader and a pop-up window automatically

appears. From here you can create a new user, assign this card to an existing user,

or view the details of an existing cardholder.

NX™ Smart Credentials

Network on Card Smart Credentials

Proxess systems utilize the most advanced and flexible credential technology in

the industry, DESFire EV2, and add six layers of protection, encryption and mutual

authentication, providing the most secure credentials in the industry.

MPD Mobile Programming Device

Android Mobile Phone with no Sim Card

The Mobile Programming Device is used with the Proxess LoxIQ™ software to build

door groups, access profiles, time schedules, and so much more. It can also be used

to assign high security Network on Card credentials to personalized profiles with

the Proxess Enrollment Reader and On-the-Go Converter. Proxess software is

currently compatible with only Android devices. However, we are excited to

develop software with IOS capabilities. Please check our website for the latest

capabilities for Proxess products.

OTG On-the-Go Converter

The On-the-Go Converter is provided with the Mobile Programming Device and

Enrollment Reader to assign credentials. Proxess offers OTG converters for both

Micro USB and Type C devices.

For additional information about service equipment and Proxess products, please visit our website:

www.proxess.com

Other manuals for MX Series

2

Table of contents

Other Proxess Lock manuals

Popular Lock manuals by other brands

Nerival

Nerival Ner 5000LR user manual

BASETech

BASETech 1833947 operating instructions

Trilogy

Trilogy DL2700DB installation instructions

KFV

KFV SIEGENIA A-opener 2.2 operating instructions

R.E Williams Contractor

R.E Williams Contractor CODELOCK CL4210 installation guide

Mul-t-lock

Mul-t-lock Entr user manual

hune

hune 6000RL-M user manual

VIZpin

VIZpin Grade 1 Cylindrical Smartlock installation instructions

Gantner

Gantner GAT ECO.Side Lock 7000 BA Installation, commissioning & operation

keylezz

keylezz Turn BasicPlus Customer's operating and assembly instructions

ENFORCER

ENFORCER SD-72081-6MQ manual

M-LOCKS

M-LOCKS EuroLine Modular Series user manual