•Wear hearing protection! Exposure to noise can cause hear-

ing loss! Make sure that the machine and its accessory

parts are in technically perfect condition! Only the above

establishes the optimal conditions for noisereduction. In

particular,make sure that the saw blade is neither dull nor

damaged. Worn or damaged saw blades have anegative

effect on noise generation and also pose asafety risk! You

can minimize noise generation by adjusting the work piece

feed to the requirements of material and saw blade.

•Saw dust from certain materials can be hazardous to your

health if inhaled or if it touches your skin. For that reason,

always wear appropriate protective clothing (e.g. respirator)

and always work with the suction device. Attention: Dust in

certain concentrations can generate an explosive mixture in

the air!

•Make sure your mains plug has aprotective earthing

conductor and is suitable to operate the device!

2.2 Safety guidelines regarding protective covers

a) Leave the protecting covers assembled. Protecting

covers must be functional and assembled correctly.

Loose, damaged or improperly functioning protecting cov-

ers must be repaired or replaced.

b) For separating cuts, always use the saw blade pro-

tecting cover and the splitting wedge. For separating

cuts where the saw blade cuts through the entire work

piece thickness, the protecting cover and other safety

mechanisms reduce the risk of injuries.

c) Once you have completed your operating procedure

(e.g. groove, back-gouge or separating in reversal

method) which requires the removal of protecting cov-

ers, splittingwedge and/or kickback protection, imme-

diately reinstall the protective system. The protecting

cover,the splitting wedge and the kickback protection

reduce the risk of injuries.

d) Before switching on the power tool, make sure the saw

bladedoes not touch the protecting cover,the splitting

wedge or the work piece.Unintentional contact of these

components with the saw blade can lead to adangerous

situation.

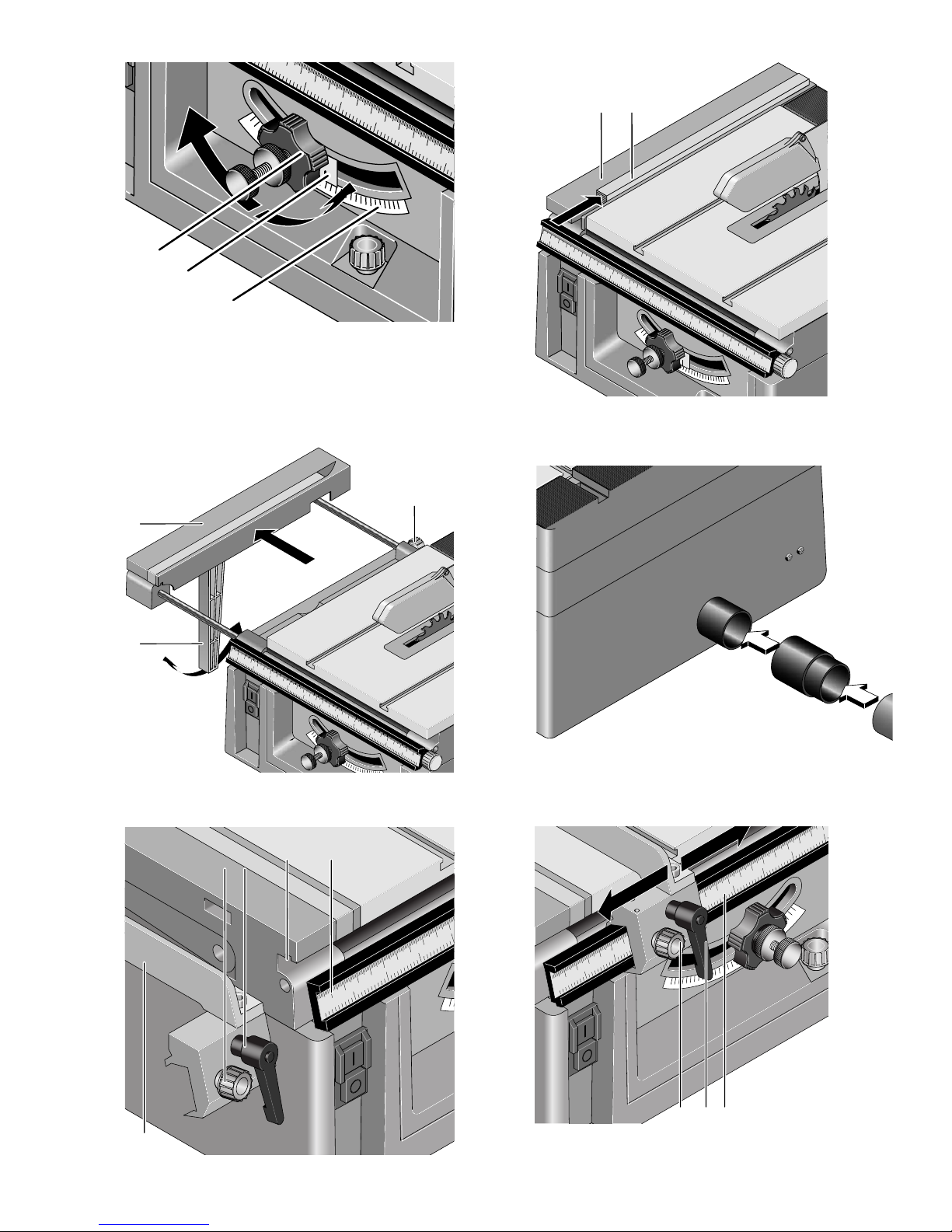

e) Adjust the splitting wedge according to the description

in these operating instructions. Incorrect distances,

position and alignment could be the reason why the split-

ting wedge does not effectively prevent kickback.

f) The splitting wedge and anti-kickback device need to

act on the work piece in order to function. The splitting

wedge and anti-kickback device are ineffective for work

piece sections which are too short for the splitting wedge to

act upon. The splitting wedge and the anti-kickback device

cannot prevent kickback under these conditions.

g) Use the appropriate saw blade for the splitting wedge.

For the splitting wedge to act correctly,the saw blade diam-

eter must match the corresponding splitting wedge, the

steel blade of the saw blade must be thinner than the split-

ting wedge, and the tooth width must be greater than the

splitting wedge thickness.

2.3 Safety guidelines for sawing process

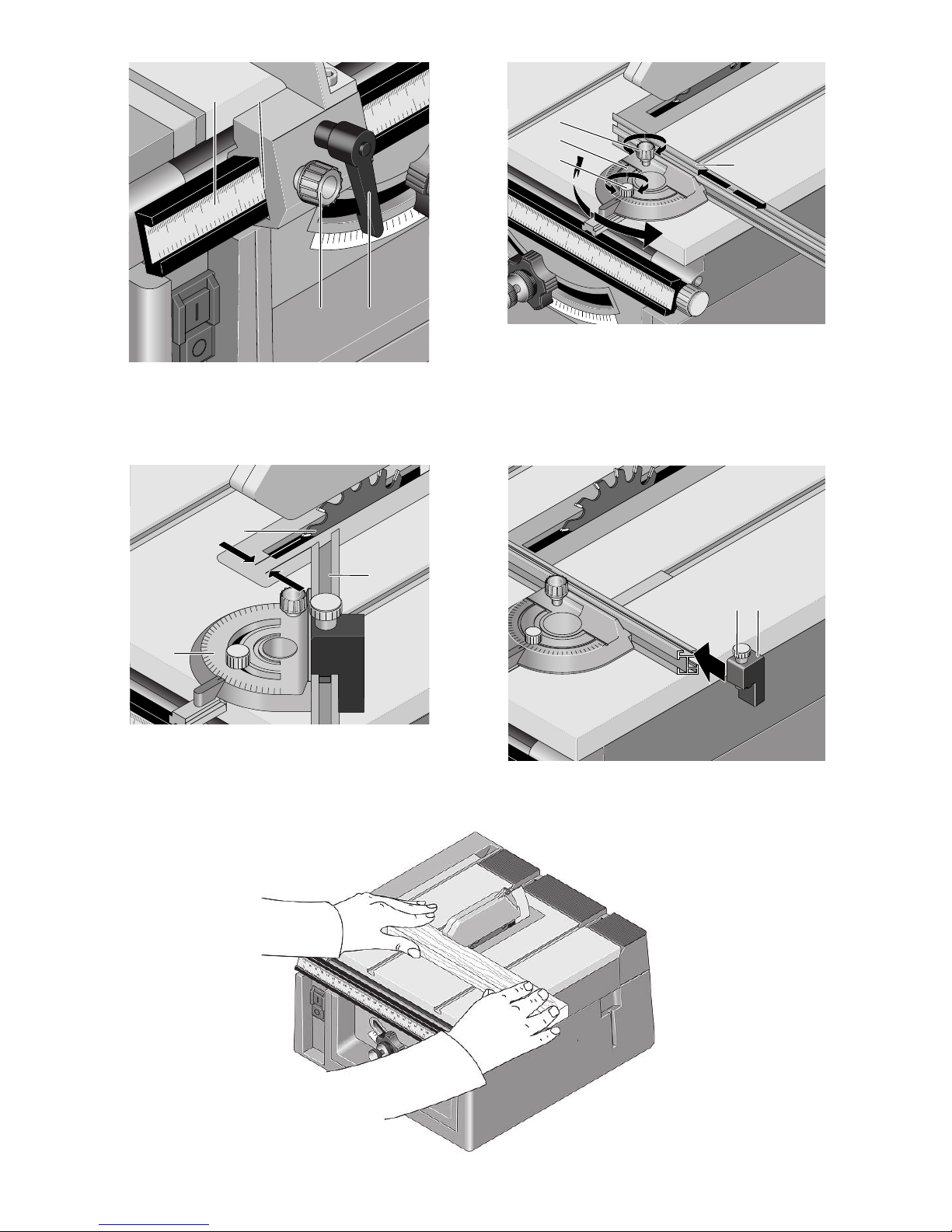

a) DANGER: Your fingers and hands should not come

near the saw blade or within the sawing range. A

moment of carelessness or slipping could direct your hand

towards the saw blade and result in serious injuries.

b) Always guide the work piece against the direction of

rotation of the saw blade. Feeding the work piece in the

same direction as the direction of rotation of the saw blade

above the table can cause the work piece and your hand to

be drawn into the saw blade.

c) Never use the mitre stop to feed the work piece for

long sections, and for cross sections with the mitre

stop, never use the parallel limit stop additionally to

the longitudinal adjustment. Guiding the work piece

simultaneously with the parallel limit stop and the mitre

stop increases the probability that the saw blade will jam

and kickback.

d) For long sections, always exert the feeding force on

the work piece between stop rail and saw blade. Use a

push rod when the distancebetween stop rail and saw

blade is less than 150 mm; use apush block when the

distance is less than 50 mm. Such working aids ensure

that your hand remains at asafe distance to the saw blade.

e) Use only the supplied push rod of the manufacturer,or

one that has been manufactured according to instruc-

tion. The push rod ensures asufficient distance between

hand and saw blade.

f) Never use adamaged or partially cut pushing rod. A

damaged pushing rod can break and cause your hand to

come against the saw blade.

g) Do not work “freehand”. Always use the parallel limit

stop or the mitre stop to position and guide the work

piece. “Freehand” means supporting or guiding the work

piece with the hands instead of with the parallel limit stop

or the mitre stop. Freehand sawing leads to misalignment,

jamming and kickback.

h) Never reach around or over arotating saw blade.

Reaching for awork piece can result in unintentionally

touching the rotating saw blade.

i) Support long and/or wide work pieces behind and/or to

the side of the saw table so they stay horizontal. Long

and/or wide work pieces tend to tilt down at the end of the

saw table; this leads to loss of control, jamming of the saw

blade and kickback.

j)

Guide the work piece evenly.Donot bend or twist the

work piece. If the saw blade jams, immediately shut off

the power tool, disconnect the mains plug and eliminate

the cause of jamming. Awork piece which has jammed the

saw blade can lead to kickback or to blocking of the motor.

k)

Do not remove sawn off material whilst the saw is still

operating. Sawn offmaterial can become fixed between saw

blade and stop rail or in the protecting cover and will pull your

fingersinto the saw blade if you attempt to remove the mate-

rial.Switch offthe saw and wait until the saw blade has come

to acomplete standstill before you remove the material.

18