Dear Customer,

By purchasing your PROXXON MICRO Band Saw

MBS/E, you havechosen agood-quality,high-grade

machine.

In order to operate the MICRO Band Saw safely and

correctly,please read the enclosed safety information

and operating instructions prior to operation.

1. General safety instructions………………………5

2.Additional safety regulations……………………6

3.Additional safety instructions for band saws …6

4. Grounding Instructions…………………………7

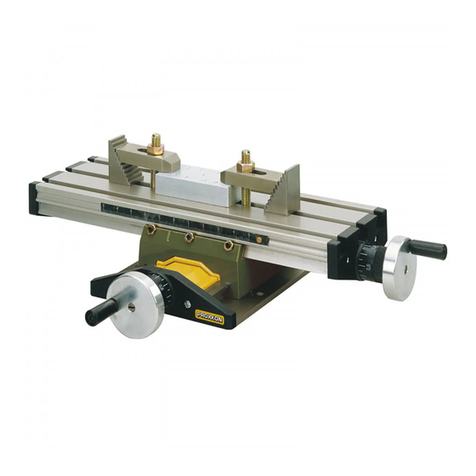

5. Description of machine …………………………7

5.1. Legend (Fig. 1) ……………………………………7

5.2.Introduction ………………………………………7

5.3.Specifications……………………………………8

5.4. Scope of supply…………………………………8

6.Machine set-up……………………………………8

6.1. Attaching the work table to the saw……………8

6.2.Checking and verticaladjusting of the upper

blade guide assembly……………………………8

6.2.1. Verticaladjusting of the upper blade guide……8

6.2.2.Checking and adjusting the blade width………8

6.2.3.Using a vacuumcleaner…………………………8

6.2.4. Adjusting tension of the saw blade ……………9

7.Operating the MICRO Band Saw………………9

7.1. Starting operation…………………………………9

7.1.1. Lockable Switch…………………………………9

7.2.Adjusting blade speed……………………………9

7.3.Sawing ……………………………………………9

7.3.1. Free-hand sawing…………………………………9

7.3.2.Sawing with miter guide …………………………9

7.3.3.Operation with the diamond saw blade………10

8. Careand Maintenance…………………………10

8.1. Checking and adjusting lower blade guide …10

8.2.Changing the saw blade ………………………10

8.3.Changing the rubber rings on the wheels……11

8.4. Careand cleaning of the machine ……………11

9. OptionalAccessories……………………………11

10.Accessory Blades………………………………11

This instruction manualcovers:

• safety regulations

•operation and maintenance

• spare parts list

Please readcarefully!

Using this instruction manual will

•make it easier for youto get used to the machine,

•help preventfaults occurring due to improper useand

•increasethe service life of your machine.

Keep this instruction manualinan easily accessible

place. Only operate this machine if you are qualified to

do soand follow the guidelines in this instruction

manual.

Readand become familiar with this entire instruction

manual,learn the tool`s applications,limitations and

possible hazards.

PROXXON does not accept responsibility for the safe

functioning of the machine,

•if it is handled in amanner whichconstitutes

improper use;

•if it is used for other purposes it is not intended and

designed for;

•if it is used for other purposes whichare not speci-

fied in the instruction manual;

•if the safety regulations are not observed.

•Warranty claims are invalid,if the machine is incor-

rectly operated,or the machine has not been suffi-

ciently maintained.

In the interests of your safety,pleasealways observe

the safety regulations.Failure to follow the instructions

listed below,may result in electric shock,fire, and/or

serious personal injury or property damage. This can

result in serious injury or possibly even death.

Only use genuine PROXXON spare parts.

We reserve the right to make further alterations for the

purpose of technical progress.

We wish you every success with your machine.

Readand understand the entire owners manual

beforeattempting assembly or operation!

1. General safety instructions

1. KEEP GUARDS IN PLACE and in working order.

2.REMOVE ADJUSTING KEYS AND WRENCHES.

Form habit of checking to see that keys and

adjusting wrenches are removed from tool before

turning it on.

3.KEEP WORK AREA CLEAN.Cluttered areas and

benches inviteaccidents.

4. DON'T USE IN DANGEROUS ENVIRONMENT.

Don't use power tools in damp or wet locations,or

expose them to rain. Keep workarea well lighted.

5. KEEP CHILDREN AWAY.All visitors should be kept

safe distance from workarea.

6.MAKE WORKSHOP KID PROOF with padlocks,

master switches,or by removing starter keys.

7.DON'T FORCE TOOL.It will do the job better and

safer at the rate for which it was designed.

8. USE RIGHT TOOL.Don't force tool or attachment

todoajobfor which it was not designed.

9. USE PROPER EXTENSION CORD.Make sure your

extension cord is in good condition. When using an

extension cord, be sure to use one heavy enough

tocarry the current your product will draw.An

undersized cord will causeadrop in line voltage

resulting in loss of power and overheating. Table 1

shows the correct size to use depending on cord

lengthand nameplateampere rating. If in doubt,

use the next heavier gage. The smaller the gage

number, the heavier the cord.

Exception No. 1: The reference to the table and the

table itself may be omitted if a statement indicating

the appropriate gage and length is incorporated

into the instruction.

Exception No. 2: The information regarding exten-

sion cords need not be provided for apermanently

connected tool.

10.WEAR PROPER APPAREL.Do not wear loose

clothing,gloves,neckties, rings, bracelets,or other

-5-