not want to do without the more accurate guiding of the blades with flat

ends (unlike those with pin ends) but do not want their disadvantages.

There is no lateral twisting in the attachment yet the blades can still fol-

low the up and down movements of the saw arms freely without being

exposed to bending forces.

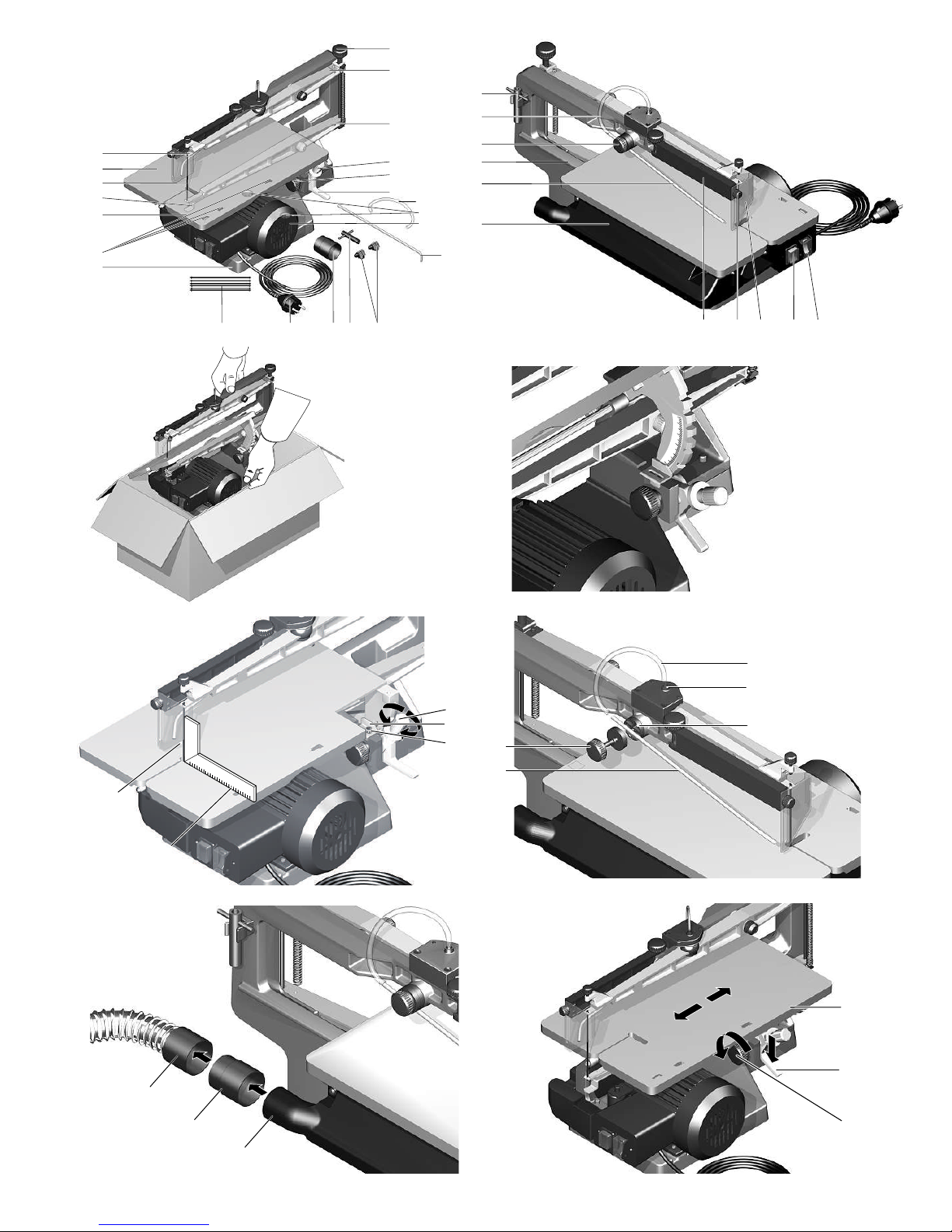

1. Place the sliding blocks 1 (fig. 7a) in the openings provided in the

saw table 2. The right clamping length is defined immediately. Cau-

tion: The clamping nuts 3 must be loosened and facing upwards!

The sliding blocks must be inserted so that the pointed ends are

facing each other, i.e. inwards.

2. Insert the saw blade in the centre of the clamping slit and tighten

the clamping nuts with the Allen key 5 provided. Caution: The saw

blade must be inserted the same distance into the clamping slit on

both sliding blocks.

3. Push back the saw table 2 as described above and fold away the

saw blade guard 6 if necessary.

4. Turn the knob 7 to the left to loosen the tension on the saw blade.

5. Remove the saw blade if necessary and insert a new saw blade 4

with the sliding blocks into the saw blade holders as shown in fig.

7b. Slight pressure can be applied to the top arm as required or the

blade tension can be loosened further on the knob 7 if necessary.

Caution: The teeth of the blade must face downwards!

6. Pull the table forward again as described above.

7. Regulate the saw blade tension as described in the section “Fine

Setting of the Correct Saw Tension”.

6.6.2 Swa Blades with Pin Ends (Fig. 8):

Saw blades with pin ends are very suitable for working with many

closed inside cuts. Here, the saw blade can be taken quickly and con-

veniently out of the top holder, looped through the workpiece and reat-

tached. Details can be found in the “Inside Cuts” section. But be

carefully: The precision of the guiding with pin end blades is inferior to

that of saw blades with flat ends and sliding blocks. Absolute precision

in the guiding of the cut can only be achieved with these.

1. Push back the saw table 1 as described above and fold away the

saw blade guard 2 if necessary.

2. Turn the knob 3 to the left to loosen the tension on the saw blade.

3. Remove a saw blade already in the holder and fit the saw blade 4

with the teeth facing downwards into the bottom holder 5.

4. Press the top arm 6 lightly if necessary and attach a new saw blade

to the top holder 7. Loosen the saw blade tension further with the

knob 3 if necessary.

5. Release the arm after attaching the blade and set the blade tension

with the knob 3.

6. Regulate the saw blade tension as described in the section “Fine

Setting of the Correct Saw Tension”.

6.6.3 Fine Setting of the Correct Saw Tension (Fig. 9):

The right saw tension is decisive for a good work result. It must there-

fore be set carefully. The saw blade can also break if it is too tight or

too slack.

Please turn the knob 1 (fig. 9) to set the tension. The saw blade is

tightened by turning the knob to the right (clockwise) and loosened by

turning it to the left (anticlockwise).

A correctly tensioned blade emits a high tone when “plucked”.

7Working with the Saw:

7.1 General Information for Working with the Scroll Saw

The scroll saw is primarily a machine for sawing curves and precise

cut-outs. A typical application is shown in fig. 10. The operator must

move the workpiece carefully for this. N.B.: Scroll saws are usually

operated without a longitudinal stop because the saw blade “wanders”

when it is guided “by force” against a stop, especially in the grain of

wood.

Please note that the saw blade only saws in the downward movement

in the direction in which the teeth are facing.

For good results, please note the following points:

•Press the workpiece against the worktop when sawing; guide gently

with little force; more pressure on the worktop, less pressure on the

saw blade.

•Make sure that the workpiece is lying firmly on the saw table (no burr

or chips).

•Adapt the movement to the requirements of the saw blade, speed

and material of the workpiece.

•Move the workpiece into the saw blade slowly especially if the blade

is very thin and the teeth very fine or the workpiece is very thick.

N.B.: The teeth only saw in the downward movement!

•Only use perfect saw blades!

•Do not leave the device unattended!

•Draw/mark the guide line carefully.

•Provide good lighting conditions!

•Always work with connected dust exhaust and align the air nozzle

carefully (see also “Assembling the Air Nozzle”).

•The best results are achieved with a wood thickness of less than 25

mm.

•For wood thicknesses greater than 25 mm, you have to guide the

workpiece very carefully to avoid jamming, bending, twisting and

snapping of the saw blade.

•For exact cuts in wood please bear in mind that the saw blade will

always try to follow the grain (applies especially for thin saw blades).

•When sawing round materials, please bear in mind that these could

turn with the movement of the saw band and therefore must be held

particularly tightly! Please use a suitable holding device for the work-

piece if necessary!

7.1.1 Choice of Saw Blade

As already mentioned, the right choice of blade for the material has a

great influence on the quality of the result. The table below serves for

orientation. Of course, a wide experience with many different types of

materials and saw blades is always helpful, too. It is worth experiment-

ing a little!

A tip: The saw blades are usually only heavily worn in the place where

the teeth are most stressed and therefore get blunt quickly. To “use up”

the teeth which are not worn and thus prolong the life of the saw

blades, the contact surface for the workpiece can be “raised” slightly

artificially.

Simply fix a smooth underlay of the appropriate thickness and same

size of the table to the saw table with double-sided adhesive tape for

example. The parts of the saw blade which are not worn now saw into

the workpiece.

This is particularly useful when sawing very hard and therefore very

wearing materials frequently with fine blades.

The figures for characterising the “fineness” of the teeth refer to the

number of teeth per inch of the saw blade length:

Round saw blades (with flat ends) are ideal for use with plastic, hard

and soft wood. They cut on all sides so there is no need to turn the

workpiece when sawing.

Our full range of suitable saw blades for your DS 460 can be found in

our Micromot catalogue or on the Internet under www.proxxon.com.

Teeth/inch Material:

approx. 10-14 soft and hard wood (approx. 6- 50 mm),

plastics, softer materials, thicker work-

pieces

approx. 17-18 finer sawing work, wood (up to approx.

6 mm), plastics, softer materials, thinner

workpieces

approx. 25-28 plastic, GRP, non-ferrous metal, plexiglass,

iron, FR-2 with restrictions

approx. 41 iron, FR-2

15