PSI PP 2024 User manual

User's Manual

P P 2 0 2 4

5112 991 14564

Acknowledgements

PCL is a Trademark of Hewlett-Packard Corporation.

A Publication of PSi Printer Systems international GmbH

Eiserfelder Straße 316

57080 Siegen @Germany

http://www.psi-si.de

Version: 5112 991 14564 January 2000

Order No.: 8708 294 00010

Great care has been taken to ensure that the information in this handbook is accurate and complete.

However, should any errors or omissions be discovered or should any user wish to make suggestions

for improving this handbook, please feel encouraged to send us the relevant details.

The contents of this manual are subject to change without notice.

Copyright © by PSi Printer Systems international.

All rights strictly reserved. Reproduction or issue to third parties in any form is not permitted without

written authorization from the publisher.

III

Safety Regulations for the Laser Printer PP 2024 Electromagnetic Compatibility

The laser printer PP 2024 fulfils the safety regulations according to IEC and Type: Printer PP 2024

TÜV/GS for computer systems (EN 60950) and laser products (EN 60825-1).

UL 1950 3rd Edition / CAN/CSA C22.2 No 950-95; 21 CFR 1040.10 and corresponds to the law regulations ruling electromagnetic compatibility of

1040.11. appliances (89/336/EWG) and, therefore, fulfils the requirements for conformity

The mains cable must be connected to a ground protected wall-socket. The

selected voltage of the printer needs to be in accordance with the local mains

voltage.

The power plug must be easily accessible at any time so that it can be

disconnected immediately in case of danger or for maintenance purposes.

Before installing the printer, check the surrounding conditions in which the

printer is intended to be used (see next page, Operating Environment).

During thunderstorm you should never attempt to connect or disconnect any

data transfer cable.

The power supply should only be opened and checked by authorized personnel.

Repairs and maintenance beyond the descriptions of chapter 5 may only be

attempted by authorized personnel as well. Repairs done inappropriately may

cause damage to the device and severe danger for the user.

Caution: The use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

During the printing process ozone will be produced. Take care that

the printer is standing in a room with good ventilation. The limt of

ozone concentration should be 0,1 ppm (0,2 mg/m). Note that the

3

specific gravity of ozone is higher than that of air.

We certify that the equipment at issue,

marking with the CE-sign.

Note: This equipment has bee tested and found to comply with the limits for a

CLASS A digital device pursuant to Part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is

likely to cause harmful interference in wich case the user will be required

to correct the interference at his own expense.

To guarantee that the device stays within the limits according to the approval

regulations for conducted and radiated emission (EN 55022, Class B) and

immunity according to EN 50081-1, Generic Standard in any case shielded

interface cables are to be used only.

Changes and modifications not explicitly allowed by the equipment's

manufacturer could void the user's authority to operate the equipment.

Operating Environment

Avoid installing the printer where it is exposed to moisture or heat (eg. direct sun

light).

-Temperature: + 10EC to + 32.5EC (+50EF to +90.5EF)

-Humidity: 20% to 80%

Slots and openings in the printer's housing are provided for ventilation. Always

ensure that these openings are not obstructed.

Also ensure that the cables at the rear of the printer do not interfere with the

output paper path.

III IV

Safety Regulations for the intelligent Paper Stacker iPS 2024

The intelligent Paper Stacker iPS 2024 fulfils the safety regulations according

to IEC and VDE/GS for computer systems (EN 60950);

UL 1950 3rd Edition, CAN/CSA C22.2 No.950-95.

The mains cable must be connected to a ground protected wall-socket. The

selected voltage of the intelligent paper stacker needs to be in accordance with

the local mains voltage.

The power plug must be easily accessible at any time so that it can be

disconnected immediately in case of danger or for maintenance purposes.

Before installing the intelligent paper stacker, check the surrounding conditions

in which the intelligent paper stacker is intended to be used (see next page,

Operating Environment).

During thunderstorm you should never attempt to connect or disconnect any

power cable.

The power supply should only be opened and checked by authorized personnel.

Repairs may only be attempted by authorized personnel as well. Repairs done

inappropriately may cause damage to the device and severe danger for the

user.

Caution, the chain of the motor to move the paper exit tray

up and down will start automatically or after pushing the

key at the left side of the table.

Electromagnetic Compatibility

We certify that the equipment at issue,

Type: intelligent Paper Stacker iPS 2024

corresponds to the law regulations ruling electromagnetic compatibility of

appliances (89/336/EWG) and, therefore, fulfils the requirements for conformity

marking with the CE-sign.

Note: This equipment has been tested and found to comply with the limits for a

CLASS A digital device pursuant to Part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is

likely to cause harmful interference in wich case the user will be required

to correct the interference at his own expense.

To guarantee that the device stays within the limits according to the approval

regulations for conducted and radiated emission (EN 55022, Class B) and

immunity according to EN 50081-1, Generic Standard in any case shielded

interface cables are to be used only.

Changes and modifications not explicitly allowed by the equipment's

manufacturer could void the user's authority to operate the equipment.

The intelligent Paper Stacker can only be used in conjunction with the printer

PP 2024.

Operating Environment

Avoid installing the intelligent paper stacker where it is exposed to moisture or

heat (e.g. direct sun light).

-Temperature: + 10EC to + 32.5EC (+50EF to +90.5EF)

-Humidity: 20% to 80%

Also ensure that the cables at the rear of the printer do not interfere with the

output paper path. The feet of the laser printer PP 2024 should be positioned

over the four screws on the stacker's table.

Table of Contents

VVI

Table of Contents 2. Printer Operation .............................................2-1

Preface ....................................................... XIV

About this Manual ............................................... XIV

Conventions used in this guide ..................................... XVI

1. Getting Started ...............................................1-1

1.1 Unpacking ................................................1-1

-Printer Package .........................................1-1

-Contents of Starter Kit Box .................................1-2

-Transportation Hints ......................................1-4

1.2 Installing the Consumables ...................................1-5

-Installing the Developer Unit ................................1-6

-Filling in Starter Toner ....................................1-8

-Inserting the Ozone Filter .................................1-10

-Installing the Waste Toner Container ........................1-11

-Inserting the Cleaner Felt .................................1-12

-Installing the OPC Drum ..................................1-13

1.3 The Power Supply .........................................1-14

1.4 Power ON/OFF Switch .....................................1-15

1.5 Inserting Fanfold Paper .....................................1-17

1.6 Connection to the Computer .................................1-21

1.7 Connecting the Stacker System ..............................1-22

2.1 Control Panel ..............................................2-1

2.1.1 Description of the Four Indicators ...........................2-1

2.1.2 description of the LCD Display ..............................2-2

2.1.3 Function Keys ...........................................2-3

2.2 Menu Mode ................................................2-4

2.2.1 Activate the Menu ........................................2-5

2.2.2 Confirm a new Selection ...................................2-6

2.3 Status and Error Messages ...................................2-7

3. Configuring the Printer ........................................3-1

3.1 What is Configuring .........................................3-1

3.1.1 Profiles ................................................3-1

SProfiler .................................................3-2

3.1.2 Basic Printer Settings .....................................3-2

3.1.3 Test Mode ..............................................3-2

3.2 Printout of Standard Configuration ..............................3-3

3.2.1 How to Start a SELF TEST ................................3-4

SSELF TEST Sample ......................................3-5

3.3 Printout of the 10 Profiles .....................................3-6

3.4 Menu Structure .............................................3-7

3.5 Menu Item Description .......................................3-9

SSELECT PROFILE ..........................................3-9

SPAPER MENU ........................................... 3-10

SPCL MENU .............................................. 3-11

SHEXDUMP MENU ........................................ 3-12

SGENERAL MENU ........................................ 3-13

SCONFIG MENU .......................................... 3-14

STEST MENU ............................................. 3-15

SINFO MENU ............................................. 3-16

Table of Contents

VII VIII

3.6 Configuration Programs .....................................3-17

SProfiler ...................................................3-17

SProfile Selector ............................................3-17

3.6.1 Installation .............................................3-17

3.6.2 Profiler ................................................3-18

3.6.3 Selector ...............................................3-23

4Explanation of Individual Menu Items ...........................4-1

4.1 Menu Mode SELECT PROFILE ...............................4-2

4.2 Menu Mode CHANGE PROFILE ..............................4-2

4.2.1 PAPER MENU ..........................................4-2

SPAPER .............................................4-2

SPAPER LENGTH .....................................4-3

SLENGTH FACTOR ....................................4-3

SIMAGE WIDTH .......................................4-4

SORIENTATION .......................................4-4

SLANDSCAPE MODE ..................................4-5

SORIENT. MODE ......................................4-6

SPAPER EXTENDED ..................................4-7

SPAPER SELECTION ..................................4-7

SFUSER TEMP. .......................................4-7

SVER SHIFT ..........................................4-7

SHOR SHIFT .........................................4-7

4.2.2 PCL MENU .............................................4-8

SFONT NUMBER ......................................4-8

SPITCH ..............................................4-8

SPOINT SIZE .........................................4-8

SSYMBOL SET .......................................4-9

SLINE SPACING .....................................4-10

STOP MARGIN .......................................4-10

SLEFT MARGIN ......................................4-10

SRIGHT MARGIN .....................................4-10

STEXT LENGTH .....................................4-10

SPERF. SKIP ........................................4-10

4.2.3 HEXDUMP MENU ..................................... 4-11

SUEL COMMAND .................................... 4-11

4.2.4 GENERAL MENU ..................................... 4-12

SEMULATION ....................................... 4-12

SAUTO FORM FEED ................................. 4-12

SPAPER RETRACT .................................. 4-12

4.3 Menu Mode BASIC SETTINGS .............................. 4-13

4.3.1 CONFIG. MENU ....................................... 4-13

SPOWER SAVE ..................................... 4-13

SALARM BELL ...................................... 4-13

SLANGUAGE ....................................... 4-13

SMENU ACCESSS ................................... 4-14

SRECALL FACTORY ................................. 4-14

4.4 Menu Mode TEST MODE .................................. 4-15

4.4.1 TEST MENU .......................................... 4-15

SPANEL TEST ...................................... 4-15

SSELF TEST ........................................ 4-15

SCONT SELF TEST .................................. 4-15

SCONFIG. PRINT .................................... 4-15

SPCL TYPEFACE LIST ............................... 4-16

4.4.2 INFO MENU .......................................... 4-18

SMACHINE COUNT .................................. 4-18

SENGINE ID ........................................ 4-18

SFIRMWARE VERSION .............................. 4-18

SSTACKER VERSION ................................ 4-18

Table of Contents

IX X

5Maintenance .................................................5-1

5.1 Installing the Parts of the Toner Kit .............................5-1

-Filling in Toner ..........................................5-2

-Replacing the Waste Toner Container .......................5-4

-Changing the Cleaner Felt .................................5-6

5.2 Replacement of the OPC Drum ................................5-7

5.3 Replacement of the Developer Unit .............................5-9

-Filling in Starter Toner ...................................5-11

-Inserting the Ozone Filter .................................5-13

5.4 Replacement of the Fuser Unit ...............................5-14

5.5 Exchanging the Control Unit .................................5-15

6. Trouble Shooting and Diagnostics ..............................6-1

-How to Use this Section ......................................6-1

6.1 Power-related Problems ......................................6-2

6.2 Error Messages ............................................6-2

7. Intelligent Paper Stacker iPS 2024 ..............................7-1

7.1. Assembling the Intelligent Paper Stacker ........................7-1

7.1.1 Unpacking .............................................7-1

-Delivery Contents ........................................7-1

7.1.2 To Mount the Tear Off Bar .................................7-2

7.1.3 Paper Exit Tray Assembly .................................7-3

7.1.4 The Pendulum ..........................................7-4

7.1.5 Put the Printer onto the Table ..............................7-5

7.1.6 The Power Supply .......................................7-6

7.2. Operating the intelligent Paper Stacker ..........................7-7

7.2.1 Inserting Paper ..........................................7-7

7.2.2 Adjusting the Paper Length ................................7-8

7.2.3 Power On the intelligent Paper Stacker .......................7-9

7.2.4 Tear Off and Remove Paper ............................. 7-10

7.3. Troubleshooting and Diagnostics ............................. 7-11

7.3.1 Printer stops because of wrong page length selection ......... 7-11

7.3.2 Printer stops when the paper exit tray is full .................. 7-11

7.3.3 Paper not stacked in Right Order .......................... 7-11

7.3.4 Proceeding after Power Down or Inadvertently Power Off ...... 7-12

8. Technical Data ...............................................8-1

8.1 Printer Specification .........................................8-1

8.2 Paper Specification ..........................................8-3

8.3 Connectivity ................................................8-4

8.4 Consumables ..............................................8-5

8.5 Specification of Intelligent Paper Stacker .........................8-6

8.6 Paper Specification for Intelligent Paper Stacker iPS 2024 ...........8-7

Table of Contents

XI XII

9Paper Specification ...........................................9-1

9.1 Basic Theory of Operation ..................................9-1

9.2 Storing Media .............................................9-1

9.3 Environmental Considerations ..............................9-2

9.4 Guidelines and Specification for Selected Fanfold Paper ........9-2

9.4.1 General Guidelines .......................................9-3

SQuality .................................................9-3

SBasic weight ............................................9-3

STransport holes ..........................................9-4

SPerforation .............................................9-5

9.4.2 Typical Paper Properties for Laser Printer .....................9-6

9.4.3 Paper / Form Properties ...................................9-7

9.4.4 Label Carrier Properties ...................................9-9

9.4.5 Label Properties ........................................9-10

10 Maintenance / Logbook ......................................10-1

10.1 Toner Kit .................................................10-1

10.2 OPC Drum ...............................................10-3

10.3 Developer Unit ............................................10-4

10.4 Fuser Unit ................................................10-5

10.5 Inspection Report ..........................................10-6

10.6 Customer Remarks ........................................10.7

Appendix A Programming Guide .................................A-1

A-1 Support of Printer Specific Features and Functions ................A-2

A-1.1 Profiles ................................................A-2

A-1.2 Paper Size Select ........................................A-2

A-1.3 Semigraphics Support under SAP R/3 .......................A-3

A-1.4 EURO Symbol Support ...................................A-3

A-1.5 Support of Logical and Physical Pages ........................A-4

A-1.7 Conventions ............................................A-5

A-2 List of Supported PJL Control Function ......................... A-6

A-2.1 Basic Rules for PJL Programming .......................... A-6

A-2.1.1 PJL Syntax Rules ................................. A-6

A-2.1.2 PJL Environments ................................. A-7

A-2.1.3 List of Supported PJL Commands .................... A-8

A-2.1.4 List of Supported PJL Variables and Values ........... A-10

A-2.1.5 List of Supported PJL Variables and Values for PCL

Personality ...................................... A-13

A-3 List of Supported PCL5 Control Functions ..................... A-14

A-3.1 Job Control Commands ................................. A-14

A-3.2 Page Control Commands ................................ A-15

A-3.3 Cursor Positioning Commands ........................... A-17

A-3.4 Font Selection Commands ............................... A-19

A-3.5 Font Management Commands ........................... A-20

A-3.6 Macro Control Commands ............................... A-21

A-3.7 Graphic Commands .................................... A-22

A-4 Support of Semigraphics for SAP/R3 ......................... A-23

A-5 Barcode Programming ..................................... A-24

A-5.1 Resident Barcode Font Code 39 HP Compatible ............. A-24

A-5.2 Resident Barcode Controlled by Private Command Sequence ... A-25

A-5.2.1 Programming ................................... A-26

SBarcode Print Position ............................... A-26

SBarcode Print Orientation ............................. A-26

SBarcode Type ...................................... A-27

SBarcode Height ..................................... A-28

SBarcode Data ...................................... A-28

SBarcode Text Control ................................ A-29

SBarcode Module Width ............................... A-29

SBarcode Ratio ...................................... A-30

SStart and Stop Characters ............................ A-31

SError Checking Characters ............................ A-31

SUnprinted Areas .................................... A-31

A-5.3 Barcode Programming Examples .......................... A-32

Table of Contents

XIII XIV

Appendix B Symbol Sets ........................................B-1

Appendix C Miscellaneous ...................................... C-1

C-1 Order Numbers ......................................... C-1

C-2 Printer Drivers .......................................... C-1

Preface

About this Manual

This manual covers the printer including the Control Unit. The Control Unit is an

integral part of the printer which determines the functionality of the printer

especially regarding the user and system interface. Due to the variety of Control

Units different printer models are defined which, with respect to the user

interface however, all behave the same.

The structure of this manual is such that the operator is led step-by-step through

the various procedures. Starting with unpacking and installation of the

consumables it moves on to setting-up configuration parameters and ends with

the mounting of options.

The manual is divided into the following chapters:

1. Getting Started

This chapter covers the unpacking and setting-up of the printer and the

installation of the consumables. By the end of this chapter the printer should

be fully functional and tested in its primary form. It is not yet connected to

the host computer system and no options are mounted.

2. Operating the Printer

This chapter discusses in great detail the operation of the operator panel, all

menu functions, and the general operation of the menu. General status

messages are also described.

3. Configuring the Printer

This chapter explains how to use the Profiles and to configure the printer so

that it can communicate with the corresponding system environment.

Furtheron this chapter includes a view of the Menu Structure and thoroughly

describes in a short form the printer's operating controls. Finally you will find

a description of the Configuration Programs Profiler and Profile Selector .

The Profiler is a menu controlled program and supports the printer

configuration via PC. Different configurations can be downloaded into the

printer.

Profile Selector is a program for quick access to a profile.

Preface Preface

XV XVI

4. Explanation of Individual Menu Items Appendix A Programming Guide

In this chapter are the individual menu items are explained in detail. This appendix describes command extension of PCL5 and PJL in section

5Maintenance

This chapter explains how to replace the consumables. Appendix B Symbol Sets

6. Trouble Shooting and Diagnostics

suggests how to identify and correct simple problems. Appendix C Miscellaneous

7. Intelligent Paper Stacker iPS 2024 SPrinter Driver

Description of assembling and operating the printer PP2024 in combination

with the Intelligent Paper Stacker iPS 2024

8. Technical Data

All technical details or data about the printer and the Intelligent Paper Conventions Used in this Guide

Stacker can be found here. The following conventions are used:

9. Paper Specification Bold Headlines and important information.

Guidelines, Specification, Paper and Label properties are defined in this

chapter. Note: Contains special advice to facilitate handling.

10. Maintenance / Logbook Caution: Contains important information to prevent damage

All activities of maintenance should be written down here. of the equipment.

A-1, A-2, and A-3. Bar Code Programming is decribed in section A-5.

All supported Symbol Sets are listed.

SOrder Numbers

[ENTER] Key functions are always depicted in brackets or

indicated by the corresponding symbol.

Getting started

1-1 1-2

1. Getting Started Contents of Starter Kit Box

1.1 Unpacking Sone spout (9)

The Laser Printer is delivered in two boxes, the larger one contains the printer Sone Cleaning Kit (10)

itself, the smaller one contains the Starter Kit. Check each box contents against

the list below. Contact your delivery agent immediately if any item is missing or

damaged.

Printer Package

SLaser Printer (1)

SControl Unit (already mounted)

Sthis User's Manual (2)

another small box contains:

Sone (plastic) front paper guide (3)

Sone (plastic) exit paper guide (4)

Sone power cord (5)

Note: Printer Driver for Windows® are available - (see Appendix C)

Sone Developer Kit consisting of:

Sone Developer Unit (6)

Sone Ozone Filter (7)

Sone bottle with Starter Toner (8)

Sone OPC Drum (11)

Getting started Getting started

1-3 1-4

Sone Toner Kit consisting of: Transportation Hints

Stwo Toner bottles (12) Save all packing material and boxes for future transportation of the printer.

Sone spout (13)

Stwo Waste Toner Containers (14) To ensure maximum protection when transporting the printer, please pay

Stwo Cleaner Felts (15) attention to the following:

Note: Do not connect the printer to the mains until the mains voltage selection

has been checked and the consumables have been installed (see the

following pages).

1. always remove the plastic paper guides and the power cord

2. remove the Developer Unit

3. empty the Toner box

4. remove the OPC Drum

5. remove the Waste Toner Container and lock it with the green cap

6. put the printer into its original packing material and ship it in its original box

7. put the Developer Unit into its original packing box.

8. Wrap the OPC Drum with stuffed antistatic and lightproof foil and pack it into

its orginal packing box.

Getting started Getting started

1-5 1-6

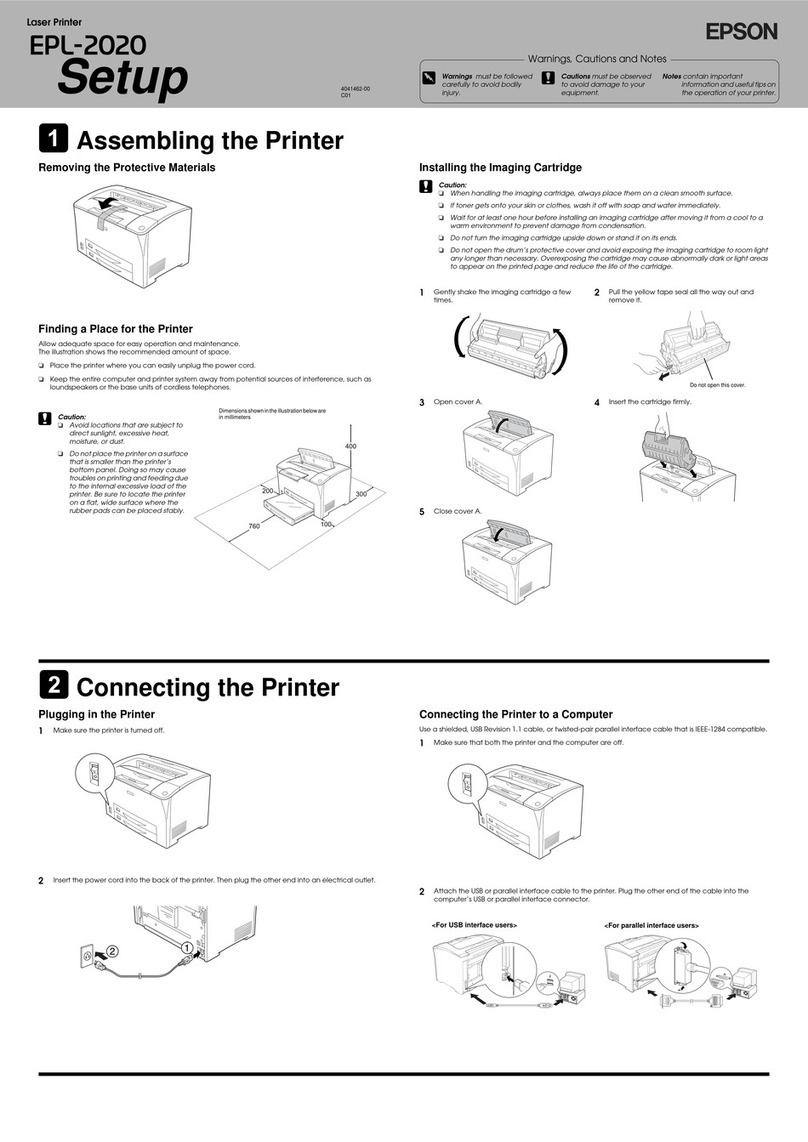

1.2 Installing the Consumables Installing the Developer Unit

Open the cover (20) by firmly pressing the button (21) at the left top corner of Gently lift the plastic tabs (24) inside the printer, at the left and at the right side

the printer and swinging the cover up. of the cover, and pull the front cover (23) in forward direction. The front cover

Remove the polyfoam transport lock (22) inside the printer underneath the degree angle.

Fuser Unit.

will only open to a 45 degree angle. Please do not force this cover beyond a 45

Now the rail guides inside the cabinet are free to accept the Developer Unit.

Remove the Developer Unit (6) from its foil package and turn it so that the

sleeve roller (26) is toward the back of the printer.

Slide the Developer Unit fully into the printer along the plastic rails on the left

and right. To lock push down the two green plastic tabs.

Getting started Getting started

1-7 1-8

Filling in Starter Toner

Before using the Developer Unit for the first time, you have to fill it with Starter

Toner. One bottle of Starter Toner (8) with a spout (9) is in the box of the

Developer Unit. Shake the bottle several times to mix the carrier and the toner.

Carefully open the seal underneath the cap of the toner bottle and attach the

spout to the bottle. Open the top cover (28) of the Developer Unit. Spread the

toner evenly across the opening.

Note: Do not squeeze the toner bottle since the toner could be blown out of the

hopper and contaminate the printer. If the toner bottle does not completely

empty, gently tap the end of the bottle while holding it upside down over

the hopper.

This first filling only allows Starter Toner to be used. Refilling any other toner is

not allowed before the message "Toner Low" appears on the display.

Getting started Getting started

1-9 1-10

Close the top cover (28) of the Developer Unit. If you hear a "click" the shutter is

closed completely.

Inserting the Ozone Filter

The box of the Developer Unit also contains an Ozone Filter (7), a black

rectangular block. On one of the narrow sides there is a small tab to hold the

filter. Insert the Ozone Filter into the slot immediately behind the operator panel

and besides the Developer Unit.

Firmly close the front cover (23).

Getting started Getting started

1-11 1-12

Installing the Waste Toner Container Inserting the Cleaner Felt

The toner box contains two Waste Toner Containers (14). Take one of them and The toner box also contains two Cleaner Felts (15). Take one of them and put it

insert it into its opening at the inner left side of the printer immediately behind under the top cover of the Fuser Unit in the back of the printer. After inserting

the Developer Unit. Be sure the green cap is on the cap hoder and not blocking the felt the top cover does not lock completely. Don't worry about this, the

the filling hole of the container. printer top cover will provide the necessary pressure to keep the cleaner felt

cover tight.

Getting started Getting started

1-13 1-14

Installing the OPC Drum 1.3 The Power Supply

The OPC Drum (11) is packed seperately in the Starter Kit. The OPC Drum is Since an incorrect voltage selection can seriously damage the printer, please

very light-sensitive, so it is wrapped up in lightproof foil. Carefully remove the pay special attention to the following:

drum from its foil container.

Note: Do not touch the green part of the OPC Drum with your fingers. Oil and mains voltage:

dirt degrade print quality. 230 V for 220 to 240 V alternating current

Do not expose the light-sensitive OPC Drum to room lighting or sunlight

any longer than necessary.

Insert the OPC Drum into the printer behind the Developer Unit. Gently press

the top of the OPC unit to make sure it is fully down. The opening for toner

waste is now just over the Waste Toner Container (14).

SMake sure that the specified voltage on the type plate corresponds to your

SConnect the printer to the mains using the power cord (34). First connect the

cable to the power cord socket and then to the mains.

Note: As the power cord serves as a safety cut-off, its connection to the

printer must be accessible any time.

Getting started Getting started

1-15 1-16

1.4 Power ON/OFF Switch

The power ON/OFF switch (35), at the right side at the rear of the printer, turns The display signals the message:

the printer's power supply ON or OFF.

When switched ON shortly the revision level of the Bootstrap software that is

installed in the printer appears on the display:

PP2 0 2 4 BOOTSTRA P

REVISION2.0 0

MEMORYTE S T

PLEASE WAIT...

After successful completion the following message appears:

INITIALTE S TOK

STARTINGP P OS. . .

Further tests are performed now. The indicators READY, DATA, and ONLINE

are switched off; all fields of the display shortly show black squares and a short

beep sounds.

On the display two messages pop up shortly after each other:

ONLINE(1)

PCL

After WARMING UP the display changes into:

ONLINE(1)

Now the printer is ready for operation, the indicators READY und ONLINE light

up.

right

wrong

Getting started Getting started

1-17 1-18

1.5 Inserting Fanfold Paper Insert the smaller Exit Paper Guide (4) at the rear of the printer so that the

The printer has a tractor which can handle fanfold paper of a minimum width of edge of this paper guide also serves as tear-off edge.

4inch and a maximum width of 10 inch.

Ensure that the printer is placed on its printer stand (option) to guarantee an

optimal paper run. If you do not use the printer stand align the printer with the

front edge of the table.

Depending on paper property it would be helpful to use the printer together with

the Stacker System (option).

The cables at the rear of the printer should not block the paper path.

Installation of Paper Guides

Use the delivered paper guides to ensure a straight paper path. The paper

guides are in the same box as the power cord. Note: A correct paper operation of the printer together with the intelligent Paper

Insert the larger Entry Paper Guide (3) into the front of the printer so that the the fold points to the operator. If the fold is negative (it points to the printer)

plastic hooks fit just inside the right and left edges of the paper entry slot. the first page must be torn off (see also chapter 7.2.1 Inserting Paper).

plastic hooks fit just inside the right and left edges of the paper exit slot. The

Stacker (iPS) is only assured if the fold behind the first page is positive i.e.

Getting started Getting started

1-19 1-20

Inserting paper for the first time or changing to another paper width: 3. Unlock the tractors (40) by moving the two green locking levers (42) to their

1. Power on the printer and open the top cover 4. Roughly adjust the tractors (40) to the paper width, and space out the paper

2. Insert the paper into the slot at the front of the printer. Press and hold the supports (43) evenly.

button (36) on the center front of the printer. The button releases the paper 5. Open the tractor covers (41) and place the paper evenly on the pins. Close

rollers for paper insertion. Shift the paper into the slot until it appears behind the tractor covers (41). Be sure the top edge of the paper does not extend the

the OPC unit near to the tractors. If you now release the button the paper is tractors.

kept by the rollers and your hands are free to adjust the tractor. 6. Adjust the width of the tractors that the paper is taut between the tractors and

upright position.

secure the tractors using the locking levers (42).

Note: The pins of the tractor (40) must be centered into the transport punches of

the paper.

Getting started Getting started

1-21 1-22

1.6 Connection to the Computer 1.7 Connecting the Stacker System

Parallel/serial Interface As an option to the printer there is also an active Stacker System available.

-Switch the printer and the computer OFF.

-Connect the interface cable coming from the computer to the printer's parallel For installation please follow the instructions in chapter 7 . These instructions

port (32) . also explain how to connect the stacker and the printer to the mains.

Note: The serial interface is not supported in the Firmware rev. 1.20 or higher. left side of the Control Unit's cover at the rear.

The datatransmission rate of the serial interface is not fast enough to

ensure continuous printing in typical PCL applications. Connect the stacker to the printer by means of the cable that comes with the

The Control Unit of the printer has a stacker interface. This is a 9-pin plug at the

stacker. The printer now takes care that the motors of the stacker are only

activated in case of paper movement.

Table of contents

Other PSI Printer manuals