PSI PP 405 User manual

Eastern European Version

User´s Manual

Acknowledgements

EPSON is a Trademark of Seiko Epson Corporation.

IBM is a Trademark of International Business Machines Corporation.

Proprinter is a Trademark of International Business Machines Corporation.

A Publication of PSi Printer Systems international GmbH

Eiserfelder Straße 316

57080 Siegen @Germany

Pub. No. 5112 991 13254 Juli 1999

Order No.8708 240 00020

Great care has been taken to ensure that the information in this handbook is accurate and complete.

However, should any errors or omissions be discovered or should any user wish to make suggestions

for improving this handbook, please feel encouraged to send us the relevant details.

The contents of this manual are subject to change without notice.

Copyright © by PSi Printer Systems international.

All rights strictly reserved. Reproduction or issue to third parties in any form is not permitted without

written authorization from the publisher.

Safety Regulations

I II

Safety Regulations Electromagnetic Compatibility

The printer PP 405 fulfils the safety regulations according to UL 1950 and

VDE (IEC 950) and CNA/CSA C22.2 / No. 950 for computer systems.

The mains cable must be connected to a ground protected wall-socket. The

selected voltage of the printer needs to agree with the local voltage.

The power plug must be easily accessible at any time so that it can be

disconnected immediately in case of danger or for maintenance purposes..

Comme le câble de secteur sert de dipositif d'arrêt-urgence, sa connexion à

l'imprimante doit être tout le temps accessible.

Before installing the printer, check the surrounding conditions in which the

printer will be placed (see next page, Operating Environment and chapter 1).

During a thunderstorm you should never attempt to connect or disconnect any

data transfer cables.

The power supply should only be opened and checked by authorized personnel.

Repairs and maintenance beyond the descriptions of chapter 4 Maintenance

may only be attempted by authorized personnel as well. Repairs done

inappropriately may cause damage and severe danger for the user.

There is a warning symbol to draw the user's attention to possible injuries:

This symbol is visible when the top cover has been

opened. It indicates that the print head is extremely

hot after long periods of printing.

Ce signal de danger se présente quand le cache

supérieur de l’imprimante soit retiré pour indiquer

que la tête d’impression peut être extrèmement

chaude après imprimer très longtemps.

We certify that the equipment at issue,

Type: Printer PP 405

corresponds to the law regulations ruling electromagnetic compatibility of

appliances (89/336/EWG) and, therefore, fulfils the requirements for conformity

marking with the CE-sign.

This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to Part 15 of the FCC rules. These limits are

designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the in-

struction manual, may cause interference to radio communications.

However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or

television reception, it can be determined by turning the equipment off and on.

The user is encouraged to try to correct the interference by one or more of the

following measures:

SReorient or relocate the receiving antenna.

SIncrease the separation between the equipment and receiver.

SConnect the equipment to an outlet on a circuit different from the circuit

to which the receiver is connected.

SConsult the dealer or an experienced radio/TV technician for help.

Shielded interface cables should be used with this unit to ensure compliance

with Class B limits.

Changes and modifications not explicitly allowed by the equipment's

manufacturer could void the user's authority to operate the equipment.

Changes et modifications pas expressément approuvés par le producteur

peuvent dévaluer l'autorité d'opérer l'équipement.

Safety Regulations

III IV

Operating Environment

Avoid installing the printer where it is exposed to moisture or heat (eg. direct sun

light).

STemperature: + 10EC to + 35EC (+50EF to +95EF)

SHumidity: 20% to 80%

SHumidity with Automatic

Sheet Feeder (ASF): 30% to 70%

Slots and openings in the printer's housing are provided for ventilation. Always

ensure that these openings are not obstructed.

Also ensure that the cables at the rear of the printer do not interfere with the

output paper path.

When processing fanfold paper always place the printer with its front edge

slightly off the edge of the table.

Table of contents

VVI

Table of Contents 2. Printer Operation ...........................................2-1

Preface .........................................................XI

About this manual .................................................XI

1.Getting started ................................................1-1

1.1 Unpacking ..................................................1-1

-A First Look at the Printer ....................................1-2

-Site Consierations ..........................................1-3

- Environment Conditions ....................................1-3

- Power Requiremens .......................................1-3

- Transport Lock ...........................................1-4

- Repacking information .....................................1-4

1.2 Installing the Interface Module ..................................1-5

1.3 The Power Supply ............................................1-6

-Main Input Voltage Selection .................................1-6

1.4 Power ON / OFF Switch .......................................1-7

1.5 Installing the Ribbon Cassette ..................................1-8

1.5.1 Changing the Ribbon Cassette ..............................1-12

1.6 Selection of Operator Panel Language ..........................1-13

1.7 Tractor ....................................................1-14

- Inserting Fanfold Paper for the First Time .......................1-14

1.8 Manual Sheet Insertion .......................................1-17

1.9 Selection of The Paper Source .................................1-19

1.10 Test-Prints .................................................1-20

1.11 Connecting to a Computer ....................................1-24

-Parallel/Serial Interface .....................................1-24

1.12 Emulation Selection .........................................1-25

2.1 Control Panel ................................................2-1

2.2 Function Keys ...............................................2-2

2.2.1 Short Description of Keys .................................2-2

- in the printer operation state READY or BUSY ....................2-2

- in the printer operation state LOCAL ............................2-2

2.2.2 Detail Description of Keys .................................2-3

- in the printer operation state READY or BUSY ....................2-3

- Quick Settings ..............................................2-3

- Top Row Keys ..............................................2-4

- Lower Row Keys ............................................2-4

2.2.3 Meaning of the Keys in the LOCAL Mode .....................2-7

- Lower Row Keys ............................................2-7

2.3 Menu Mode .................................................2-8

2.3.1 To Activate the Menu .....................................2-9

2.3.2 To confirm Selection ................................... 2-10

2.3.3 How to Save Settings ................................... 2-11

2.3.4 Quick Settings ........................................ 2-12

2.4 Status and Error Messages ................................... 2-13

Table of Contents Table of contents

VII VIII

3. Configuring the Printer......................................3-1

3.1 What means Configuration.....................................3-1

3.2 Standard Configuration........................................3-3

3.3 Explanation of the Printout.....................................3-4

3.4 Explanation of Individual Menu Items.............................3-5

Main Functions..............................................3-5

-MACRO SELECT..........................................3-5

-CHANGE MACRO.........................................3-5

-INSTALLATION...........................................3-5

-SAVE...................................................3-5

-PRINT OUT..............................................3-6

Main Function CHANGE MACRO...............................3-6

- FONT....................................................3-6

- PRINT QUALITY............................................3-7

- SUB/SUPER FONT.........................................3-7

- PITCH....................................................3-7

- LINE.....................................................3-7

- PAPER LENGTH...........................................3-8

- VERT.POS.ADJ (Vertical Position Adjustment)...................3-9

- LEFT MARGIN.............................................3-8

- RIGHT MARGIN...........................................3-10

- TOP MARGIN.............................................3-10

- BOTTOM MARGIN.........................................3-11

- PERFORATION SKIP......................................3-11

- PAPER SOURCE..........................................3-11

- PAPER EXIT..............................................3-12

- EMULATION..............................................3-12

- CHARACTER SET.........................................3-12

- LINE MODE..............................................3-13

- $$-COMMANDS...........................................3-13

- TEAR OFF MODE.........................................3-13

- PRE-SEPARATION........................................3-13

Main Function INSTALLATION...............................3-14

Sub-Function INTERFACE...................................3-14

- BUFFER................................................3-14

- WORD LENGTH.........................................3-14

- I/F Type.................................................3-14

- BAUD RATE.............................................3-14

- PARITY BIT..............................................3-14

- PROTOCOL.............................................3-14

- CTS MODE ..........................................3-15

Sub-Function ADJUSTMENT.................................3-15

- AGC POSITION..........................................3-15

- PLATEN GAP............................................3-16

- AGC ADJUST............................................3-16

- PAPIER-IN ADJUST.......................................3-16

- CUT V-POS.............................................3-17

- UNI-DIRECT. CMD........................................3-17

- TRACT.FORM FEED MODE................................3-18

Special Menu Items under INSTALLATION......................3-18

- LANGUAGE.............................................3-18

- RESTORE SET UP.......................................3-18

- RECALL FACTORY.......................................3-18

- MENU ACCESS..........................................3-19

- SELF TESTS............................................3-20

- HEX DUMP..............................................3-20

Menu Tree.............................................Menu-1

Table of Contents Table of contents

IX X

4. Maintenance ...............................................4-1

- Preferred Materials ..........................................4-1

4.1 Cleaning the Platen and Surrounding Areas .......................4-1

4.2 Cleaning Procedure ..........................................4-3

4.3 User Replaceable Parts .......................................4-4

- Replacement of the Print Head ................................4-4

- Print Head Removal .......................................4-4

- Print Head Installation ......................................4-6

- Replacement of the Platen ....................................4-8

- To Remove the Platen .....................................4-8

- To Install the Platen .......................................4-9

5. Trouble Shooting and Diagnostics ............................5-1

- How to Use this section ......................................5-1

5.1 Power-related Problems .......................................5-2

5.2 Error Messages ..............................................5-2

5.3 No Printout .................................................5-5

5.4 Operation-related Problems ....................................5-6

5.5 Print-related Problems ........................................5-7

5.6 Ribbon or Carriage-related Problems .............................5-9

5.7 Ribbon Problems ............................................5-9

6. Colour Option ..............................................6-1

6.1 Install the Colour Option .......................................6-1

6.2 Installing the 4-Colour Ribbon ..................................6-5

7. Technical Data .............................................7-1

Appendices

Appendix A System Interface Descriptions ........................... A-1

1Serial Interface RS 232 C ................................... A-2

2Transmission Protocols ..................................... A-3

3Parallel Centronics Interface ................................ A-8

®

4Shared Operation ........................................ A-11

Appendix B Print Samples of Resident Fonts ......................... B-1

Appendix C Character Set Tables ................................... C-1

Appendix D Philips GP Quick Reference - not supported! ................ D-1

Appendix E IBM ProPrinter Quick Reference .......................... E-1

Appendix F EPSON LQ 2550 Quick Reference ........................ F-1

Appendix G Barcode Quick Reference ............................... G-1

Appendix H Information for the System Manager ...................... H-1

Preface

XI XII

Preface 4. Maintenance

About this Manual suggests how to identify and correct simple problems.

This manual covers the printer in combination with an interface module (Perso-

nality Module). 6. Options

The Personality Module (PM) is an integral part of the printer, and the type of the packaging of options may be inserted here.

PM used significantly influences the behaviour or operation of the printer.

The structure of this manual is such that the operator is led step-by-step through All technical details or data about the printer can be found here.

the various procedures. It starts with the unpacking and setting-up, moves on to

detailed instructions for operating the printer and ends with the mounting of Appendix

options. A. Interface Description

The manual is divided into the following chapters: various computer systems and explains particularities depending on the

1. Getting Started illustrated.

This chapter covers the unpacking and setting-up of the printer and the

installation of the PM (Personality Module) and ribbon cassette. By the end B. Print Samples of Resident Fonts

of this chapter the printer should be fully functional and tested in its

primary form. It is not yet connected to the host computer system and no C. Character Set Table

options are mounted. All printer supported character sets are listed in this chapter.

2. Operating the Printer D. Control Codes

This chapter discusses in great detail the operation of the operator panel, Quick reference for Philips General Printer (GP) Emulation

all menu functions, and the general operation of the menu. General status

messages (e.g. COVER OPEN) are also described.

3. Configuring the Printer

This chapter explains how to configure the printer so that it can

communicate with the corresponding system environment. Then this

chapter thoroughly describes the printer's operating controls. In the last

part you will find explanations of individual menu items.

shows how to clean the printer and how to replace the platen and the print

head.

5. Trouble Shooting and Diagnostics

This is a brief description of all available options. Supplements enclosed in

7. Technical Data

This chapter gives hints about possibilities to connect the printer to the

version of the operating system. Additionally, cable connection is

Preface Preface

XIII XIV

E. Control Codes Conventions Used in this Guide

Quick reference for IBM Proprinter and IBM Proprinter AGM (4207, 4208 The following conventions are used:

XL 24) Emulation.

F. Control Codes

Quick reference for EPSOM LQ 2550 Emulation. Note: Contains special advice to facilitate handling.

F. Control Codes Caution: Contains important information to prevent damage

Quick reference for Barcode programming. of the equipment.

G. Verschiedenes / Miscellaneous [ENTER] Key functions are always depicted in brackets or

-Bestellnummern / Ordernumbers you will find the symbol of the key e.g .

-System Manager Information

Bold Headlines and important information.

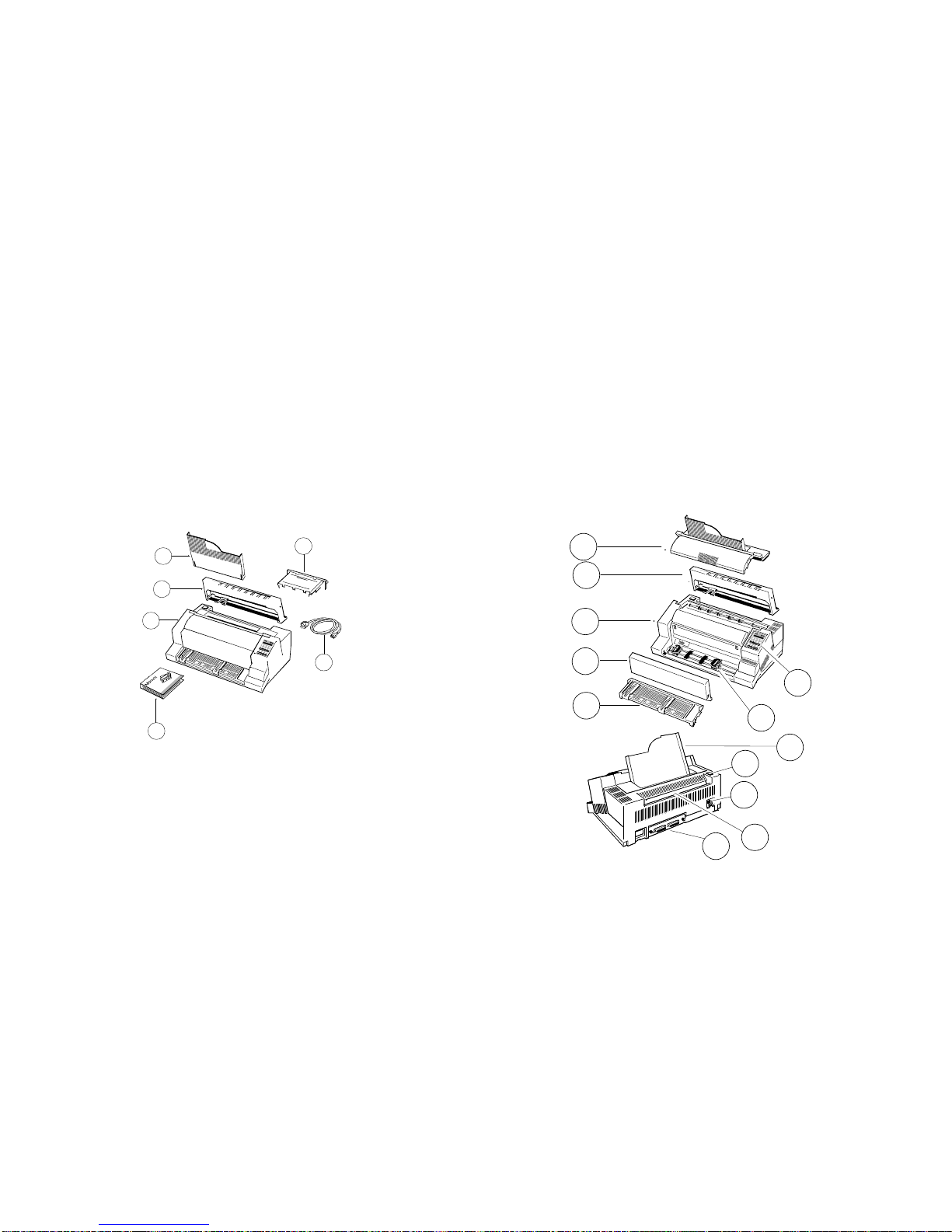

3

6

4

7

2

11

2

3

4

8

12

5

11

10

9

7

6

13703 Getting Started

1-1 1-2

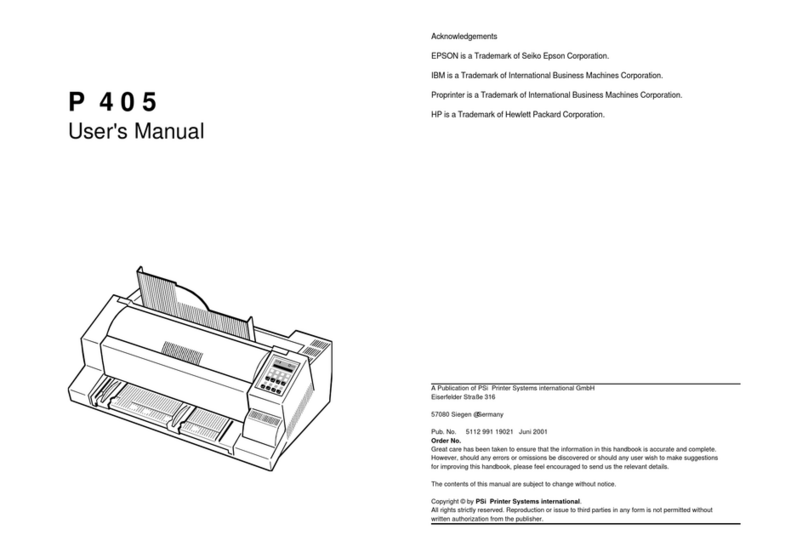

1. Getting Started A First Look at the Printer

1.1 Unpacking

Check each item against the check list detailed below. Contact your delivery

agent immediately if any item is missing or damaged.

The printer package should contain the following:

-Top cover (1) -Printer (3)

-Power cord (7) -Ribbon cassette (2)

-Folder for the User´s Manual (4)

A separate box contains the Personality Module (16) and the chapters 1 - 6 and

Appendix A - G of the User´s Manual. Please file the loosen pages into the

folder.

Caution: Do not connect to the mains until the mains voltage selection has

been checked and the PM is installed.

Note: Save all packing material and boxes for future transportation of the

printer.

The printer drivers for Windows® are available on Internet Address:

http://www.psi-si.de

Before installing the printer, spend some time familiarizing yourself with the

printer.

-Top Cover (1) -Tractor for Continuous Paper (7)

-Ribbon Cassette (2) -Output Stacker (8)

-Printer (3) -Power Switch (9)

-Front Cover (4) -Power Cord Socket (10)

-Manual Front Insertion Guide (5) -Tear Off Edge (11)

-Control Panel (6) -Personality Module (PM) (12)

2

9

Getting Started Getting Started

1-3 1-4

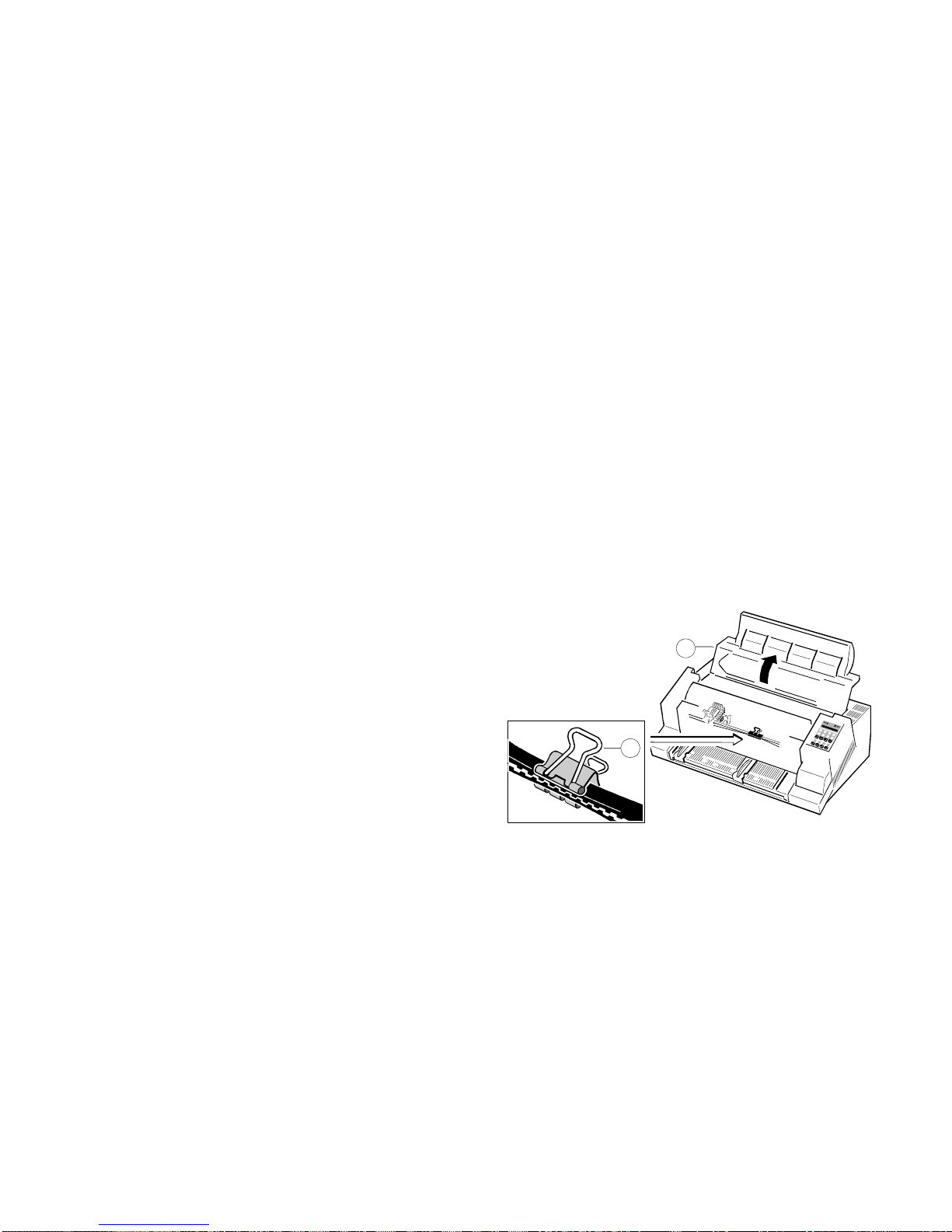

Site Considerations Transport Lock

Environment Conditions You will find a red shipping tab under the top cover (2).

-Install the printer in an area away from any heat source, air conditioner or

strong drafts. Grasp the top cover (2) on the left and right, lift it and remove the transport

-Avoid installing the printer in a dusty or humid environment.

Work Location To ensure maximum protection when transporting the printer, always

-Place the printer on the stand or a flat, solid level area such as a desk.

-Slots and openings in the printer's housing are provided for ventilation; -Remove the output stacker and the mains cable.

always ensure that these openings are not obstructed. -Remove the ribbon cassette.

-When processing fanfold paper always place the printer with its front edge -Pack the printer in its original packing material and ship in its original box.

slightly off the edge of the table.

-Also ensure that the cables at the rear of the printer do not interfere with the

output paper path.

Power Requirements

-No special wiring is required. A typical office wall outlet is sufficient.

-Do not plug into the same wall outlet other equipment besides the printer

such as coffee machines, copy machines or air conditioners.

locking clip (12) from the print head drive belt.

Re-packing Information

-Remove any installed paper handling option.

-Reposition the transport locking clip.

613 11

6

Getting Started Getting Started

1-5 1-6

1.2 Installing the Personality Module 1.3 The Power Supply

The printer functions only in combination with an installed interface module, Mains Voltage Selection

called a Personality Module (PM). In general, the mains voltage selection is determined at factory site.

The illustration below shows the standard PM with a serial and parallel interface. Since an incorrect voltage selection can seriously damage the printer, please

For detailed information about your PM, see Chapter 2. pay special attention to the following:

Note -To avoid damage due to electrostatic discharge, do not touch the pins Make sure that the specified voltage on the voltage selector (11) corresponds to

or components of the PM. your mains voltage:

-Never attempt to install or remove a PM while the printer is switched

ON. -either 230 V for 180 to 264 V alternating current

1. Remove the PM (6) from its packaging.

2. Insert the Personality Module (6) with the component side upwards until the If it is necessary to change the voltage, slide the selector button to the required

connector fully engages. Hand tighten the two lock screws (13). voltage selection.

-or 115 V for 90 to 140 V alternating current.

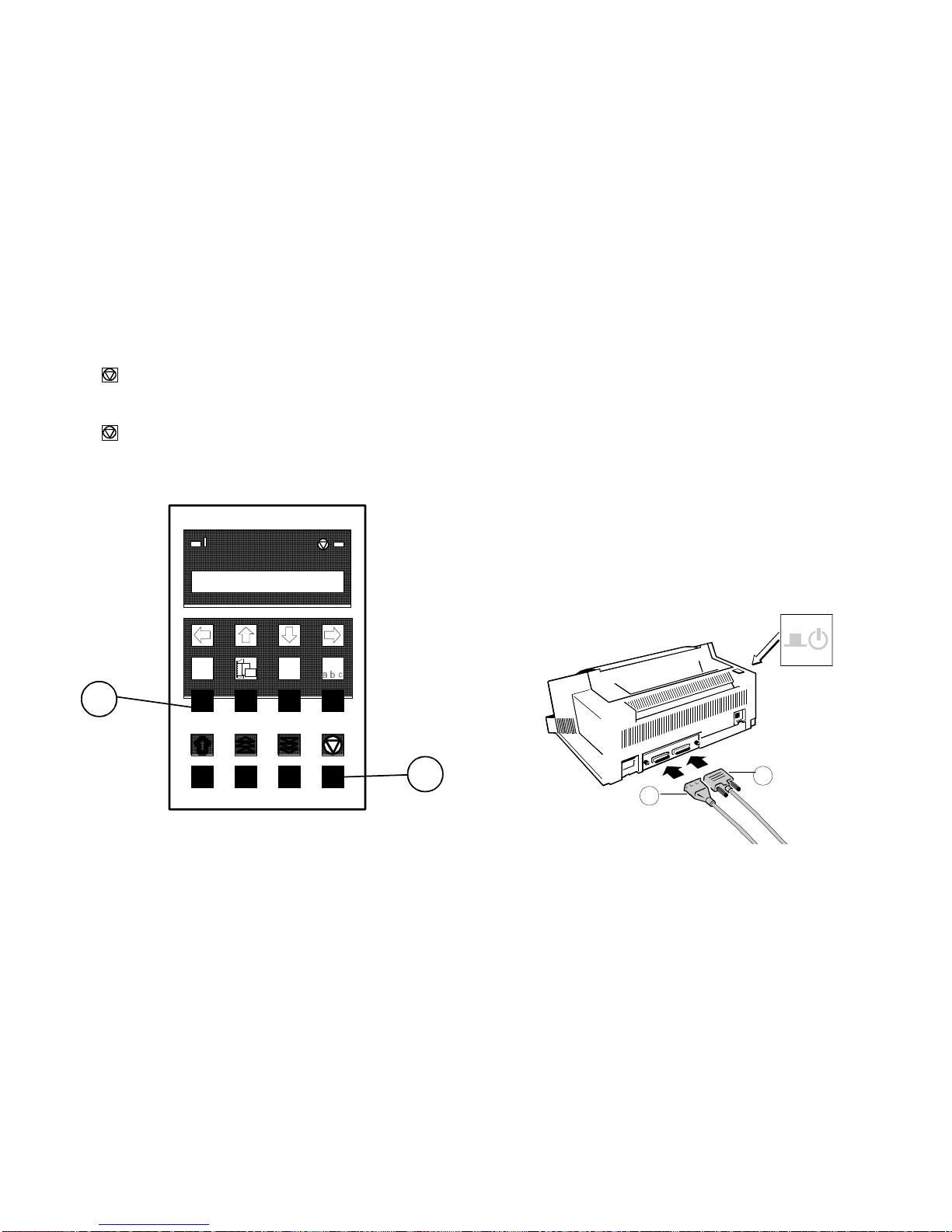

Connect the printer to the mains using the power cord (6). First connect the

cable to the power cord socket and then to the mains.

Note: As the power cord serves as a safety cut-off, its connection to the printer

must be accessible any time.

1

Getting Started Getting Started

1-7 1-8

1.4 Power ON/OFF Switch

The power ON/OFF switch (1) turns the printer's power supply ON or OFF.

When switched ON the printer performs an internal self-test which checks the

electronics, the print head carriage movement and the interface. Power ON is

indicated by a green LED on the operator panel and shows TEST.... .

If the message INSTALL RIBBON is shown, follow the steps in chapter 1.5

Installing the Black Ribbon Cassette.

After inserting the ribbon press to continue. When the internal test has been

completed successfully the display shows READY 4 ELQ or BUSY 4 ELQ in

case data has already been transmitted.

Note: If the display shows anything different please refer to chapter 5

Troubleshooting and Diagnostics.

1.5 Installing the Black Ribbon Cassette

Note: Information about installing the 4-colour-ribbon cassette you will find in

chapter 6 Colour option.

It is recommended to use only original ribbon cassettes (part numbers in

Appendix H) put out by our company. Using other ribbons will void your war-

ranty.

Caution: Never manually move the print head fully to the right hand stop (you

could change the way of the paper output).

Note: If the printer is busy (message BUSY 4 ELQ) always press

before opening the top cover.

1. Switch the printer ON at the power switch; Power LED is lit and wait for the

message READY 4 ELQ or INSTALL RIBBON.

2. If the printer is busy (message BUSY 4 ELQ) press .

3. Lift the top cover to gain access to the ribbon cassette mountings. The print

head will move to the correct position, aligned with the cut-out in the paper

guide plate to facilitate the installation of the ribbon cassette.

4. Remove any excess slack by turning the green knob on the ribbon cassette

clockwise. Move the ribbon feed guide to the position indicated on the plastic

cover of the cassette.

Getting Started Getting Started

1-9 1-10

5. Position the lower mounting pin (a) on the guide to the right. Slide the

cassette downward. In this position, the green ribbon feed guide touches the

green plastic clip.

6. Move the cassette toward you until you hear a click on both sides. Swing the

ribbon underneath the print head for the final click. The audible clicks

indicate that the mounting pins have engaged properly.

click ! click !

1.

2.

Getting Started Getting Started

1-11 1-12

Note When installed correctly the ribbon cassette has a sloping position. 1.5.1 Replacing the Ribbon Cassette

7. Move the print head back and forth to settle the ribbon in the correct position.

8. If necessary remove excess ribbon slack by turning the green knob

clockwise.

9. Close the top cover and press [START/STOP] .

Caution: The print head may be very hot immediately after printing!

-Close the top cover and switch the printer ON. Lift the top cover after the

display shows the message READY 4 ELQ to gain access to the ribbon

cassette mountings. The print head will move to the correct position, aligned

with the cut-out in the paper guide plate to facilitate the installation of the

ribbon cassette.

-Now swing the lower part of the ribbon to the back.

In this way the mounting pins loosen from the lower position.

-Then press the upper part of the ribbon to the back. Die upper mounting pins

get free and the ribbon can be taken out.

-To install a new ribbon cassette please see 1.5 Installing the ribbon

cassette (see pages before).

MENU a a

aaabc

94

93

MENU

4

Getting Started Getting Started

1-13 1-14

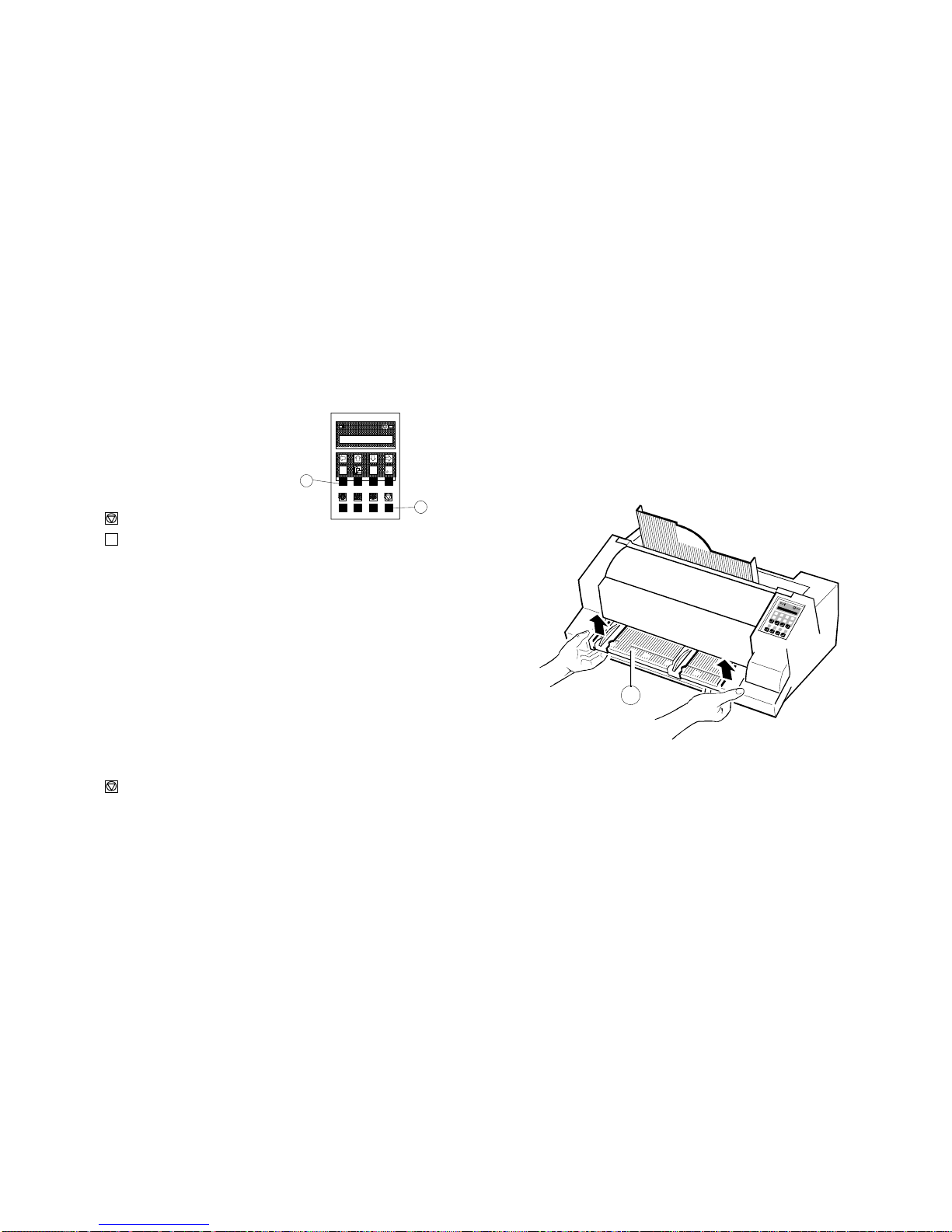

1.6 Selection of Operator Panel Language 1.7 Tractor

The printer control panel and LCD display menu is used for the next steps. It is Inserting Fanfold Paper for the First Time

possible to change the language in the printer menu from English to French or -Ensure that the printer is placed in the depression on the top of the stand

German. The following example shows how to change from English to German: (option). If the printer is used without a stand, align the printer with the front

Key Display against the resistance and remove by pulling forward.

1. Switch the printer on

2. (93) LOCAL

3. (94) MACRO SELECT 6

4. [\] -- [\]INSTALLATION 6

5. [Y]7INTERFACE 6

6. [\] -- [\]7LANGUAGE 6

7. [Y]7ENGLISH *

8. [\]7DEUTSCH

9. [Y]7DEUTSCH *

10. [Z]7SPRACHE 6

11. [Z]INSTALLATION 6

12. [\]MENÜ SICHERN 6

13. [Y]7SICHERT 6

MENÜ SICHERN 6

14. (93) BEREIT 4 ELQ

Note: In chapter 2 Printer Operating you will find a description of the function

keys.

edge of the table. The cables at the back of the printer should be tucked into

the cable clips in order not to block the paper path.

-Hold the front of the manual insertion guide (4) on both sides, pull upwards

12

14

13

14

Getting Started Getting Started

1-15 1-16

-Pull the green tractor lock levers (12) toward you to release the tractors. -Open the tractor covers (16) and insert the paper.

-Lock both green tractor levels -Close the tractor covers.

-Roughly adjust the tractors (13) to the paper width, and space out the paper -Tighten the upper edge of the fanfold paper by slightly pushing the right

supports (14) evenly. tractor to the right. Make sure not to stress the paper too much.

-Lock the tractors by pushing back the green lock lever again.

-Reapply the manual front insertion guide

Note: If you do not refit the manual front insertion guide, there is no

guarantee for a proper paper transport and accurate printing.

2

522

Getting Started Getting Started

1-17 1-18

-Select the paper source TRACTOR using either the menu selection of the -Move the left hand paper guide into the position indicated by ±•(22) on the

printer or your software (chapter 1.9). insertion guide. In this setting the margin has the smallest value possible.

-Initiate a printout (chapter 1.10), to check the margins. Readjust the tractors -Adjust the right hand paper guide to the width of the paper to be used.

until the printout appears within the desired margins.

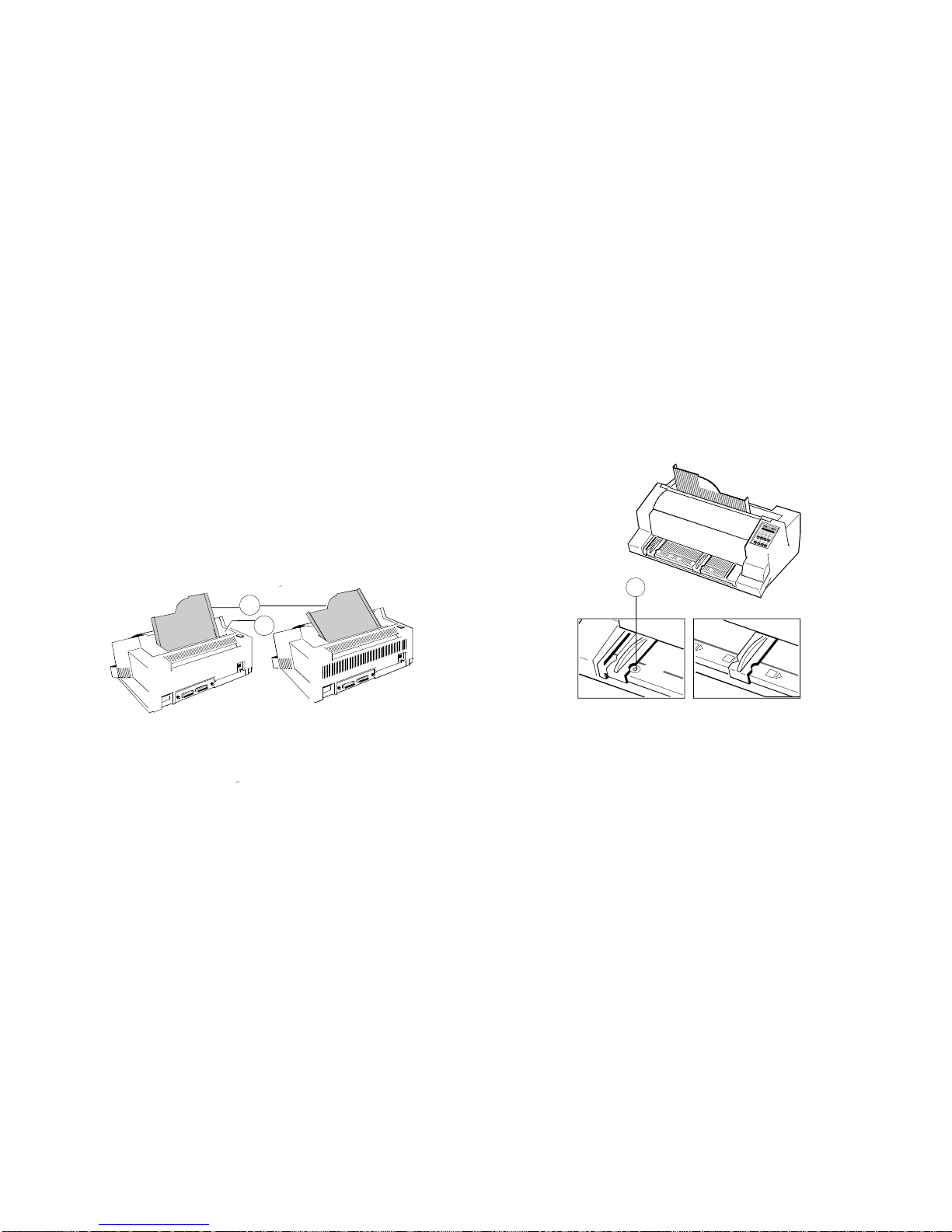

1.8 Manual Sheet Insertion

Install the output stacker (5) into one of the two rails in the top cover (2).

The meaning of the two Positions:

-for paper with 80 g/m² or thicker use the steeper position (left picture);

-for thinner paper use the less inclined position (right picture).

-Check, if the manual sheet insertion is installed. Note: If continuous form paper is in print position on the platen and has not been

-Select MANUAL as the paper source using either the menu settings or your

software (see also chapter 1.9 Paper Source Selection).

teared off, it will be moved forward and TEAR OFF PAPER will be

displayed.

MENU aa

aaabc

95

93

Getting Started Getting Started

1-19 1-20

1.9 Paper Source Selection 1.10 Test Printouts

The basic selections for PAPER SOURCE are: There are three test printouts available.

-TRACTOR (Default, indicated by ’)

-MANUAL -PRINT TEST 1 shows a pattern of all printable characters. Use this to check

Select 'MANUAL' as paper source on the operator panel -PRINT TEST 2 produces a standard letter (ECMA-132) which can be used for

The following diagram shows which keys to press and what is displayed on the measuring the printer's throughput.

operator panel. -PRINT TEST 3 lists all available fonts, contains the page count to identify the

Key Display

1. Switch the printer ON and wait for the message READY 4 ELQ.

2. (93) LOCAL

3. (95) 7TRACTOR ’

Note: Starting now the top row keys function as arrow keys.

4. [\]7MANUAL

5. [Y]7MANUAL ’

6. (93) READY 4 ELQ

-After that LOAD MANUAL is displayed. Insert a single sheet evenly. After a

short delay, the printer draws in the sheet.

if the printer operates correctly.

actual number of printed pages, and gives information on technical releases

which are intended for service purposes.

The print tests are printed using the parameters set in the menu, e.g. font, pitch

etc. Refer to section "Menu Mode" for details.

ABCDEFGHIJKLMNOPQRSTUVWXYZabcdefghijklmnopqrstuvwxyz0123456789!§

§ABCDEFGHIJKLMNOPQRSTUVWXYZabcdefghijklmnopqrstuvwxyz0123456789!

!§ABCDEFGHIJKLMNOPQRSTUVWXYZabcdefghijklmnopqrstuvwxyz0123456789

9!§ABCDEFGHIJKLMNOPQRSTUVWXYZabcdefghijklmnopqrstuvwxyz012345678

89!§ABCDEFGHIJKLMNOPQRSTUVWXYZabcdefghijklmnopqrstuvwxyz01234567

789!§ABCDEFGHIJKLMNOPQRSTUVWXYZabcdefghijklmnopqrstuvwxyz0123456

6789!§ABCDEFGHIJKLMNOPQRSTUVWXYZabcdefghijklmnopqrstuvwxyz012345

56789!§ABCDEFGHIJKLMNOPQRSTUVWXYZabcdefghijklmnopqrstuvwxyz01234

456789!§ABCDEFGHIJKLMNOPQRSTUVWXYZabcdefghijklmnopqrstuvwxyz0123

3456789!§ABCDEFGHIJKLMNOPQRSTUVWXYZabcdefghijklmnopqrstuvwxyz012

23456789!§ABCDEFGHIJKLMNOPQRSTUVWXYZabcdefghijklmnopqrstuvwxyz01

123456789!§ABCDEFGHIJKLMNOPQRSTUVWXYZabcdefghijklmnopqrstuvwxyz0

0123456789!§ABCDEFGHIJKLMNOPQRSTUVWXYZabcdefghijklmnopqrstuvwxyz

z0123456789!§ABCDEFGHIJKLMNOPQRSTUVWXYZabcdefghijklmnopqrstuvwxy

yz0123456789!§ABCDEFGHIJKLMNOPQRSTUVWXYZabcdefghijklmnopqrstuvwx

xyz0123456789!§ABCDEFGHIJKLMNOPQRSTUVWXYZabcdefghijklmnopqrstuvw

wxyz0123456789!§ABCDEFGHIJKLMNOPQRSTUVWXYZabcdefghijklmnopqrstuv

vwxyz0123456789!§ABCDEFGHIJKLMNOPQRSTUVWXYZabcdefghijklmnopqrstu

uvwxyz0123456789!§ABCDEFGHIJKLMNOPQRSTUVWXYZabcdefghijklmnopqrst

tuvwxyz0123456789!§ABCDEFGHIJKLMNOPQRSTUVWXYZabcdefghijklmnopqrs

stuvwxyz0123456789!§ABCDEFGHIJKLMNOPQRSTUVWXYZabcdefghijklmnopqr

rstuvwxyz0123456789!§ABCDEFGHIJKLMNOPQRSTUVWXYZabcdefghijklmnopq

qrstuvwxyz0123456789!§ABCDEFGHIJKLMNOPQRSTUVWXYZabcdefghijklmnop

pqrstuvwxyz0123456789!§ABCDEFGHIJKLMNOPQRSTUVWXYZabcdefghijklmno

opqrstuvwxyz0123456789!§ABCDEFGHIJKLMNOPQRSTUVWXYZabcdefghijklmn

nopqrstuvwxyz0123456789!§ABCDEFGHIJKLMNOPQRSTUVWXYZabcdefghijklm

mnopqrstuvwxyz0123456789!§ABCDEFGHIJKLMNOPQRSTUVWXYZabcdefghijkl

lmnopqrstuvwxyz0123456789!§ABCDEFGHIJKLMNOPQRSTUVWXYZabcdefghijk

klmnopqrstuvwxyz0123456789!§ABCDEFGHIJKLMNOPQRSTUVWXYZabcdefghij

jklmnopqrstuvwxyz0123456789!§ABCDEFGHIJKLMNOPQRSTUVWXYZabcdefghi

ijklmnopqrstuvwxyz0123456789!§ABCDEFGHIJKLMNOPQRSTUVWXYZabcdefgh

hijklmnopqrstuvwxyz0123456789!§ABCDEFGHIJKLMNOPQRSTUVWXYZabcdefg

ghijklmnopqrstuvwxyz0123456789!§ABCDEFGHIJKLMNOPQRSTUVWXYZabcdef

fghijklmnopqrstuvwxyz0123456789!§ABCDEFGHIJKLMNOPQRSTUVWXYZabcde

efghijklmnopqrstuvwxyz0123456789!§ABCDEFGHIJKLMNOPQRSTUVWXYZabcd

defghijklmnopqrstuvwxyz0123456789!§ABCDEFGHIJKLMNOPQRSTUVWXYZabc

cdefghijklmnopqrstuvwxyz0123456789!§ABCDEFGHIJKLMNOPQRSTUVWXYZab

bcdefghijklmnopqrstuvwxyz0123456789!§ABCDEFGHIJKLMNOPQRSTUVWXYZa

abcdefghijklmnopqrstuvwxyz0123456789!§ABCDEFGHIJKLMNOPQRSTUVWXYZ

Zabcdefghijklmnopqrstuvwxyz0123456789!§ABCDEFGHIJKLMNOPQRSTUVWXY

YZabcdefghijklmnopqrstuvwxyz0123456789!§ABCDEFGHIJKLMNOPQRSTUVWX

XYZabcdefghijklmnopqrstuvwxyz0123456789!§ABCDEFGHIJKLMNOPQRSTUVW

PRINT TEST 1

MENU

Getting Started Getting Started

1-21 1-22

Eilzustellung

Norddeutsche Farbwerke KG

Herrn Dr. Grauert

Große Elbstraße 64

2000 Hamburg 4

Org. III 5/37 H-A 4 34 22.04.75

17.04.75 Volkmann

Vordruckgestaltung für den allgemeinen Schrift-

verkehr, für das Bestell- und Rechnungswesen E i l t

Sehr geehrter Herr Dr. Grauert,

Sie können das Schreiben der Briefe, Bestellungen, Rechnungen usw.

sowie das Bearbeiten des Schriftguts rationalisieren, wenn die

Vordrucke Ihres Unternehmens den folgenden Normen entsprechen:

DIN 676 Geschäftsbrief; Vordrucke A4

DIN 677 -; Vordruck A5

DIN 679 Geschäftspostkarte; Vordrucke A6

DIN 4991 Vordrucke im Lieferantenverkehr; Rechnung

DIN 4992 -; Bestellung (Auftrag)

DIN 4993 -; Bestellungsannahme (Auftragsbestätigung)

DIN 4994 -; Lieferschein/Lieferanzeige

DIN 4998 Entwurfsblätter für Vordrucke

Diese Normen enthalten alle Einzelheiten für den sinnvollen und

zweckmäßigen Aufdruck. Wenn dazu bei der Beschriftung genormter

Vordrucke DIN 5008 'Regel für Maschinenschreiben' beachtet wird,

entstehen übersichtliche und werbewirksame Schriftstücke.

Die beifgefügten 6 Mustervordrucke zeigen, daß das Beachten der

Normen die künstlerische und werbewirksame Gestaltung der Vor-

drucke nicht ausschließt.

Da wir uns auf die Herstellung genormter Vordrucke spezialisiert

haben, können wir besonders billig liefern. Eine Probestellung

wird Sie und Ihre Geschäftsfreunde von den Vorteilen überzeugen.

Mit bester Empfehlung

NORAG

Druckerei und Verlagshaus KG

Herrmann

Anlagen

6 Mustervordrucke

PRINT TEST 2

To start a print test:

1. Switch the printer ON (display shows READY 4 ELQ).

The following identifies the keys to press and the corresponding operator panel

displays.

KEY Display

2. (93) LOCAL

3. (94) MACRO SELECT 6

4. [\] -- [\]INSTALLATION 6

5. [Y]7INTERFACE 6

6. [[] -- [[]7SELF TEST 6

7. [Y]7PRINT TEST 1

Use [\] to select PRINT TEST 2 or 3.

8. [Y]7PRINT TEST 1 *

9. (93) PRINT TEST 1 *

The printer starts to print using paper from the defined paper source.

Note: A number of VALUE settings is summarized in a "Macro". It is possible to

have a total of four macros, each with a different summary of VALUE

settings.

MENU aa

aaabc

94

93 17

18

Getting Started Getting Started

1-23 1-24

To stop the print test: 1.11 Connection to a Computer

1. (93) 7PRINT TEST 1 *Parallel/Serial Interface

2. [Z]7SELF TEST 6-Connect the interface cable coming from the computer to the printer's parallel

3. (93) READY 4 ELQ -The printer is set by default to SHARED interface with the following parame-

-Switch the printer and computer OFF.

(17) or serial port (18).

ters:

-8 Kbyte buffer,

-8 bit,

-even parity,

-9600 baud and

-DTR protocol.

SHARED means that, after Power-ON, both the serial and the parallel interfaces

are available for data transfer. The port to which data is sent becomes active

automatically. If the parallel or serial parameters need to be changed, see

Chapter 2, Menu Mode, and Appendix A, Interface Description.

Table of contents

Other PSI Printer manuals