Easidew Advanced Online Hygrometer Manual

iv 97621 Issue 1, March 2022

Contents

Safety ................................................................................................................................vi

Electrical Safety ..........................................................................................................vii

Pressure Safety ...........................................................................................................vii

Hazardous Materials (WEEE, RoHS3 & REACH) ..............................................................vii

Repair and Maintenance ..............................................................................................vii

Calibration ..................................................................................................................vii

Safety Conformity .......................................................................................................vii

Abbreviations .................................................................................................................... viii

1 INTRODUCTION ................................................................................................1

1.1 Features ............................................................................................................ 1

2 INSTALLATION ..................................................................................................2

2.1 Unpacking the Instrument ................................................................................... 2

2.1.1 Unpacking the Easidew Advanced Online Sensor ............................................. 3

2.1.2 Unpacking the Process Monitor ...................................................................... 3

2.2 Easidew Advanced Online Components ................................................................ 4

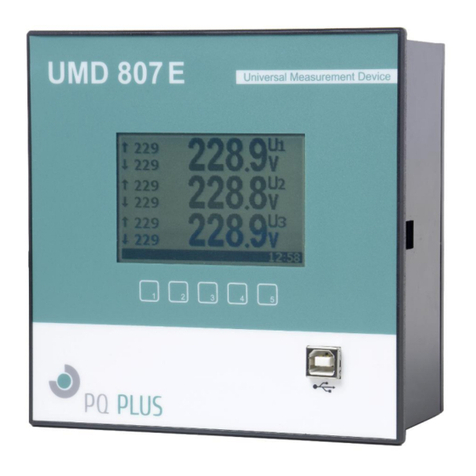

2.3 Process Monitor Display ...................................................................................... 5

2.3.1 Process Monitor Display Layout ...................................................................... 5

2.3.2 Electrical Connections .................................................................................... 6

2.3.2.1 High-Voltage Power Supply Input ................................................................... 6

2.3.2.2 Low-Voltage Power Supply Input (Alternative) ................................................. 7

2.3.2.3 Dew-Point Sensor Modbus RTU over RS485 Digital Input (Required) ................ 7

2.3.2.4 Pressure Sensor Input (Optional) ................................................................... 8

2.3.2.5 Analog Outputs ............................................................................................. 8

2.3.2.6 Modbus RTU Output ...................................................................................... 8

2.3.2.7 Relay Outputs ............................................................................................... 9

2.3.2.8 Transmitter Connections ................................................................................ 9

2.4 Mounting the Process Monitor ........................................................................... 10

2.5 Easidew Transmitter ......................................................................................... 11

2.5.1 Easidew M12 Connector Version ................................................................... 11

2.5.1.1 Electrical Connections .................................................................................. 12

2.5.1.2 Easidew M12 Cables .................................................................................... 13

2.5.2 Cable Selection for Self-Assembled Cables ..................................................... 13

2.6 Transmitter Mounting ........................................................................................ 14

2.6.1 5/8” 18 UNF Version .................................................................................... 14

2.6.2 3/4” - 16 UNF Version ................................................................................. 14

2.6.3 G1/2” BSPP Version ..................................................................................... 14

2.6.4 Transmitter Mounting – Sample Block .......................................................... 15

2.6.5 Transmitter Mounting – Direct Pipeline Connection ........................................ 16

2.6.6 Transmitter Mounting – With Additional Process Connection Adapter .............. 17

2.7 Mounting the Sample Block and Transmitter ....................................................... 18

2.7.1 Sample Block Gas Connections ..................................................................... 18

3 OPERATION ....................................................................................................20

3.1 Process Monitor Conguration ........................................................................... 20

3.2 Front Panel Conguration Menu Access .............................................................. 20

3.3 Conguration Menu Explained ........................................................................... 22

3.4 Setting Up the Process Monitor Conguration ..................................................... 23

3.4.1 Alarms Conguration ................................................................................... 23

3.4.2 Analog Outputs Conguration ...................................................................... 26

3.4.3 Display Conguration .................................................................................. 28

3.4.4 Input Conguration ..................................................................................... 29