S8000 -100 User Manual

iv 97606 Issue 1, June 2021

1 INTRODUCTION ................................................................................................1

1.1 Operating Principle ............................................................................................. 1

2 INSTALLATION ..................................................................................................3

2.1 Safety ................................................................................................................ 3

2.2 Unpacking the Instrument ................................................................................... 3

2.3 Transit Bolts ....................................................................................................... 4

2.4 Operating Requirements ..................................................................................... 5

2.4.1 Environmental Requirements ......................................................................... 5

2.4.2 Electrical Requirements ................................................................................. 5

2.4.2.1 Front Panel ............................................................................................. 6

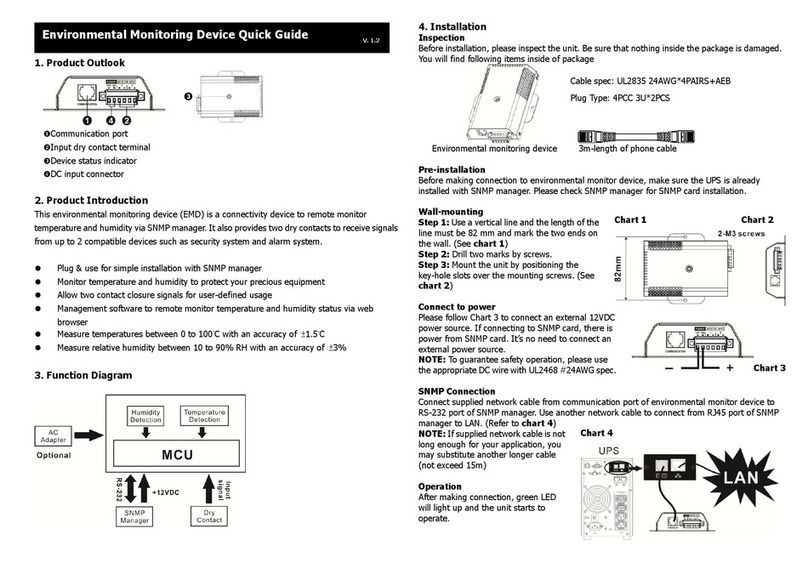

2.4.2.2 Rear Panel Connections ........................................................................... 7

2.4.3 Power Supply Input ....................................................................................... 8

2.4.4 Microscope installation .................................................................................. 9

2.4.5 Analog Output Connections .......................................................................... 10

2.4.6 Alarm Output Connections ........................................................................... 11

2.4.7 Remote Temperature Probe ........................................................................ 11

2.4.8 Remote Pt100 connections ........................................................................... 12

2.4.9 USB Communications Port Connector ............................................................ 12

2.4.10 Ethernet/RS232/RS485 Port (optional) .......................................................... 13

3 OPERATION ....................................................................................................14

3.1 General Operational Information ........................................................................ 14

3.1.1 Sample Flow Adjustment ............................................................................. 14

3.2 Operational Functions ....................................................................................... 15

3.2.1 Operating Cycle .......................................................................................... 15

3.3 Operating Guide ............................................................................................... 16

3.3.1 Automatic Mode .......................................................................................... 16

3.3.1.1 Description ........................................................................................... 16

3.3.1.2 Operating Practice ................................................................................. 17

3.3.1.3 Flood Recovery ..................................................................................... 17

3.4 Manual Mode ................................................................................................... 18

3.4.1 Description ................................................................................................. 18

3.4.1.1 Operating Practice ................................................................................. 18

3.4.2 Shutdown Procedure ................................................................................... 19

3.4.3 DCC – Dynamic Contamination Control ......................................................... 20

3.4.4 MAXCOOL Function ..................................................................................... 20

3.4.5 Pressure Input ............................................................................................ 21

3.4.6 Data Logging .............................................................................................. 21

3.4.7 Frost Assurance Technology (FAST) .............................................................. 21

3.4.8 STANDBY Mode........................................................................................... 21

Contents

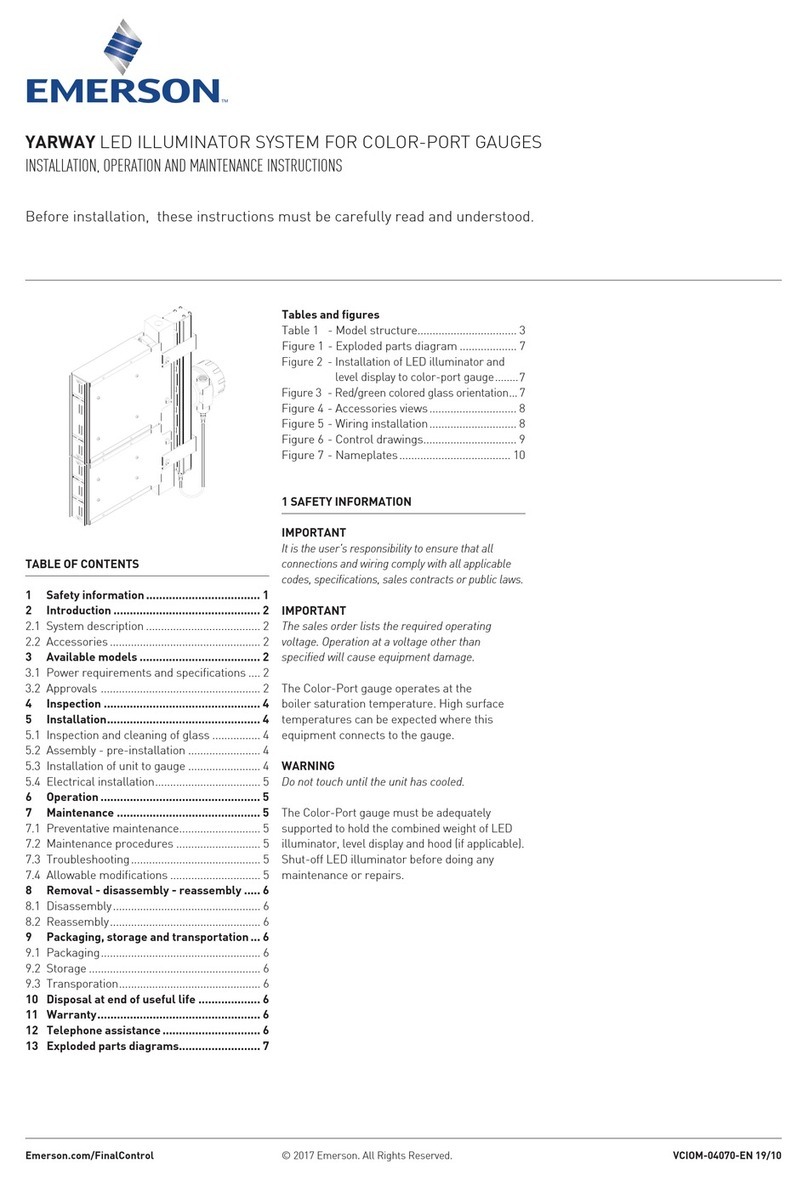

Safety ...............................................................................................................................vii

Electrical Safety ..........................................................................................................vii

Pressure Safety ...........................................................................................................vii

Toxic Materials ............................................................................................................vii

Repair and Maintenance ..............................................................................................vii

Calibration ..................................................................................................................vii

Safety Conformity .......................................................................................................vii

Abbreviations .................................................................................................................... viii

Warnings .......................................................................................................................... viii