MDM300 User Manual

iv 97122 Issue 16.2 June 2022

Contents

Safety ...............................................................................................................................vii

Electrical Safety .........................................................................................................vii

Pressure Safety ...........................................................................................................vii

Toxic Materials ............................................................................................................vii

Repair and Maintenance ..............................................................................................vii

Calibration ..................................................................................................................vii

Safety Conformity .......................................................................................................vii

Abbreviations .................................................................................................................... viii

Warnings .......................................................................................................................... viii

1 INTRODUCTION ................................................................................................1

1.1 Controls and Indicators ....................................................................................... 3

1.2 Function Keys ..................................................................................................... 5

1.2.1 Enter Key ..................................................................................................... 5

1.2.2 Up () and Down () Keys ........................................................................... 5

1.2.3 Right () Key ............................................................................................... 5

1.2.4 Left () / Escape Key .................................................................................... 5

1.3 Instrument Display ............................................................................................. 6

1.3.1 Display Units................................................................................................. 7

1.3.2 Status Display Indications .............................................................................. 8

2 INSTALLATION ..................................................................................................9

2.1 Safety ................................................................................................................ 9

2.2 Unpacking the Instrument ................................................................................... 9

2.3 MDM300 Accessories ........................................................................................ 10

2.4 Operational Requirements ................................................................................. 12

2.4.1 Environmental Requirements – MDM300 Instrument ...................................... 12

2.4.2 Charger Electrical Requirements ................................................................... 12

2.5 Instrument Gas Connections ............................................................................. 12

2.5.1 Gas Inlet /Outlet Fittings ............................................................................. 13

2.6 Connect External Transmitters ........................................................................... 14

2.6.1 Set-Up Pressure Transmitter Parameters ....................................................... 14

2.6.2 Set-Up External Temperature Transmitter Parameters .................................... 15

2.6.3 Set-Up External Dp (Easidew) Transmitter Parameters ................................... 15

2.6.4 Entering User Pressure ................................................................................ 16

2.6.5 Connecting your own Temperature or Pressure Transmitter ............................ 16

2.7 Battery Charging .............................................................................................. 17

3 OPERATION ....................................................................................................19

3.1 Preparation for Operation .................................................................................. 19

3.2 Instrument Start-Up ........................................................................................ 20

3.3 Overall Menu Structure and Operation................................................................ 21

3.3.1 SET-UP Menu .............................................................................................. 21

3.3.2 Chart Page ................................................................................................. 21

3.4 SET-UP Menu Parameters .................................................................................. 23

3.4.1 SETTINGS .................................................................................................. 23

3.4.2 LOGGING ................................................................................................... 24

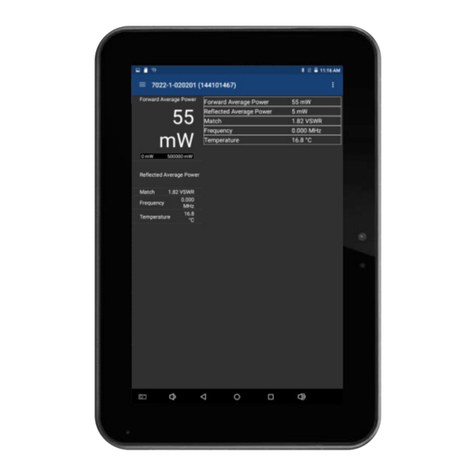

3.4.3 BLUETOOTH ............................................................................................... 25

3.4.3.1 Bluetooth Pairing Procedure ................................................................... 26

3.4.4 EXTERNAL (Sensor Interface) ..................................................................... 27

3.4.5 CLOCK ....................................................................................................... 28

3.4.6 HMI ........................................................................................................... 29

3.4.7 INFO .......................................................................................................... 30

3.4.8 CHART Page ............................................................................................... 30

3.4.9 LOG FILES Page .......................................................................................... 31