Liquidew I.S. User Manual

iv 97092 Issue 5.3, September 2021

Contents

Safety .............................................................................................................................................vii

Electrical Safety ........................................................................................................................vii

Pressure Safety ........................................................................................................................vii

Toxic Materials .........................................................................................................................vii

Repair and Maintenance............................................................................................................vii

Calibration ...............................................................................................................................vii

Safety Conformity .....................................................................................................................vii

Abbreviations .................................................................................................................................. viii

Warnings ........................................................................................................................................ viii

1 INTRODUCTION .......................................................................................................... 1

1.1 Performance Features ..................................................................................................... 2

1.2 Applications .................................................................................................................... 2

1.3 Theory of Operation ........................................................................................................ 3

1.4 System Components ....................................................................................................... 4

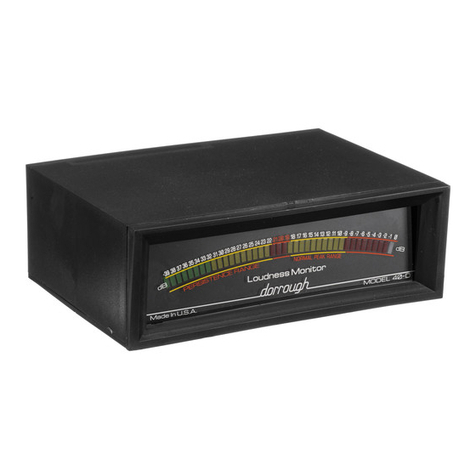

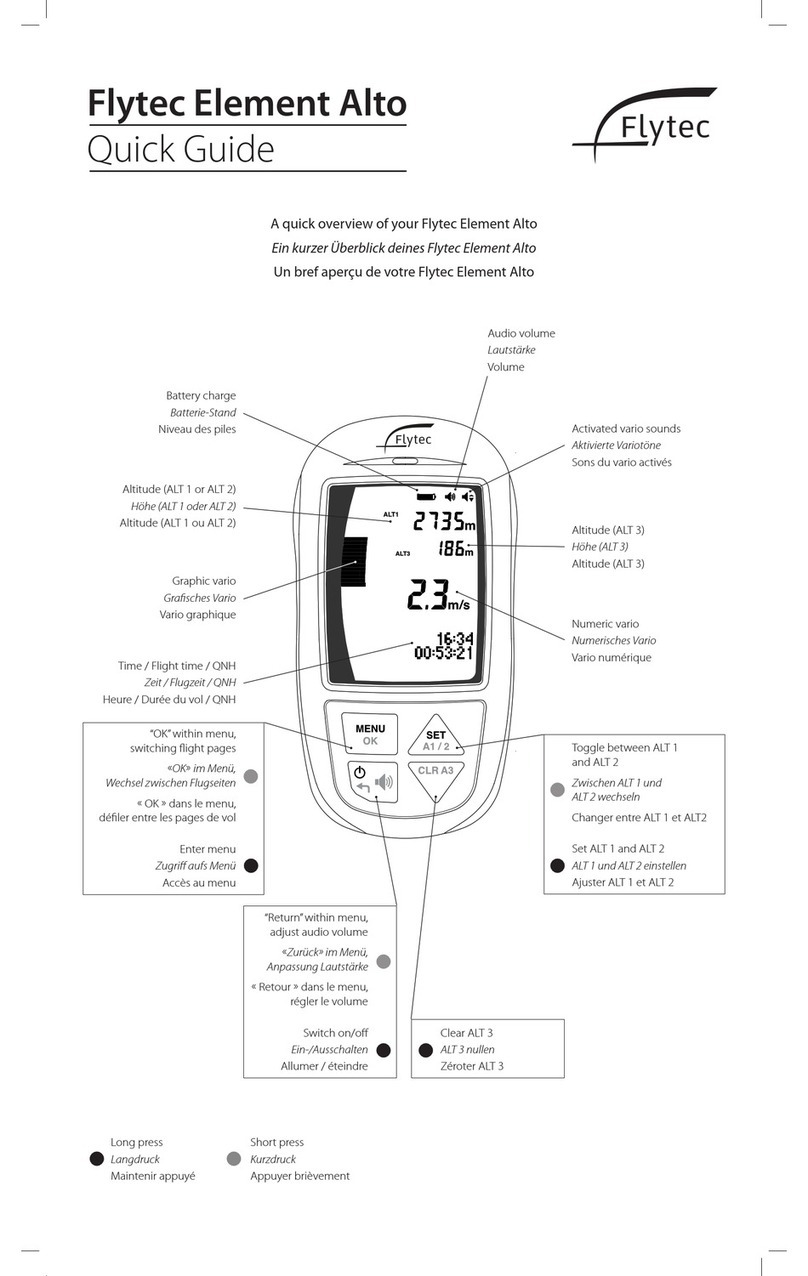

1.4.1 User Interface .......................................................................................................... 5

1.4.2 Power Supply and Input/Output Signal ....................................................................... 7

1.5 Sampling System ............................................................................................................ 8

2 INSTALLATION ............................................................................................................. 9

2.1 Unpacking the Analyzer ................................................................................................... 9

2.2 Operating Requirements .................................................................................................10

2.2.1 Environmental Requirements ....................................................................................10

2.2.2 Power Requirement ..................................................................................................10

2.3 Mounting ......................................................................................................................10

2.3.1 Control Unit Installation ............................................................................................10

2.3.2 Mounting the Liquidew I.S. Sensor Assembly into the Sampling System .......................12

2.3.3 Sampling System Installation ....................................................................................14

2.4 Wiring ...........................................................................................................................15

2.4.1 Overall Wiring Arrangement ......................................................................................15

2.4.2 Control Unit Wiring ..................................................................................................16

2.4.2.1 Power Supply Input Connection ..........................................................................18

2.4.2.2 Sensor Signal Input Connection ..........................................................................20

2.4.2.3 Analog Output Connection .................................................................................21

2.4.2.4 Alarm Output Connection ...................................................................................22

2.4.2.5 RS485 Port Connection ......................................................................................23

2.4.3 Sensor Assembly Wiring ...........................................................................................24

2.4.3.1 Dew-point Transmitter Wiring .............................................................................24

2.4.3.2 Temperature Transmitter Wiring .........................................................................27

3 OPERATION ............................................................................................................... 29

3.1 Preparation ...................................................................................................................29

3.2 Start-Up ........................................................................................................................29

3.2.1 Function Keys Activation ...........................................................................................29

3.2.2 Powering-up the Analyzer .........................................................................................30

3.2.3 Sample Flow Start-Up...............................................................................................31

3.3 Menu Structure ..............................................................................................................32

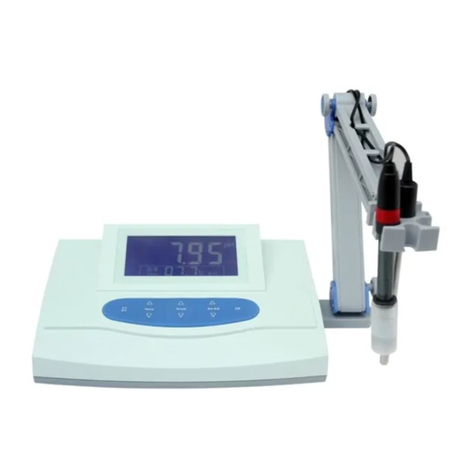

3.4 Main Reading Page ........................................................................................................34

3.5 Liquid Set-Up .................................................................................................................34

3.5.1 Liquid Selection .......................................................................................................34

3.5.2 User-Dened Liquid ..................................................................................................35

3.5.3 Liquid Mixing ...........................................................................................................36

3.6 Analog Output 1 (Moisture Content or Dew Point - User-Selectable) ..................................38

3.6.1 Output Source Selection ...........................................................................................38

3.6.2 Output Range ZERO Value Settings ...........................................................................39

3.6.3 Output Range SPAN Value Settings ...........................................................................39

3.7 Analog Output 2 (Sample Temperature - Only) .................................................................39