2

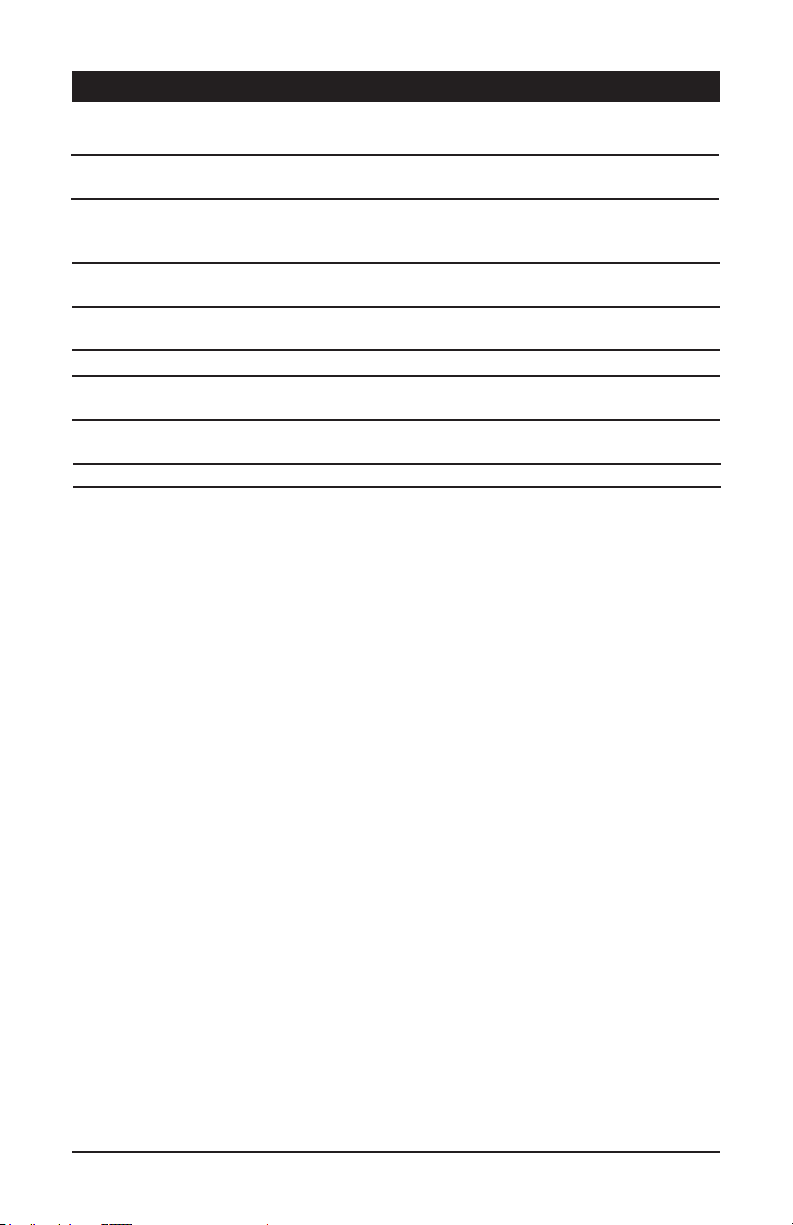

Pressure scale.................................................. 0-1,000 psi (0-7,000 kPa)

Gauge accuracy ...............................................................................+/-2%

Hose size....................................... 15/16 in. I.D. x 35/64 in. OD x 16 in. L

Accessories .............................. 9 Adapter configurations & carrying case

SPECIFICATIONS:

Specifications are subject to change without notice.

1. Do not exceed 1000 psi maximum pressure.

2. Wear ANSI approved safety goggles and protective wear during setup and use.

3. Use tester in well ventilated areas.

4. Before using, set transmission in park (for automatic transmission) or neutral (for

manual transmission) and set parking brake.

5. Keep out of reach of children.

6. Install and remove tester only while engine is stopped.

7. Keep work area clean and well lit.

8. Dress properly. Do not wear loose clothing or jewelry as they can be caught in moving

engine parts. Protective clothes and nonskid footwear are recommended when

working. Wear restrictive hair covering to contain long hair.

9. Do not overreach. Keep proper footing and balance at all times.

10. Maintain test kit with care. Keep clean for better and safer performance. Inspect

hoses periodically, and if

damaged, have them repaired by a qualied technician.

11. Stay alert. Watch what you are doing, use common sense. Do not operate when you

are tired.

12. Check for damaged parts. Before using, any part that appears damaged should

be carefully checked to determine that it will operate properly and perform its

intended function. Check for alignment and binding

of moving parts; any broken parts

or mounting xtures;

and any other condition that may aect proper

operation. Any

part that is damaged should be properly

repaired or replaced by a qualied technician.

13. Do not operate if under the inuence of alcohol or drugs. Read warning labels if

taking prescription medicine to determine if your judgment or reexes are impaired

while taking drugs. If there is any doubt, do not operate.

14. Do not start an engine in an enclosed area (like a garage). A running gasoline engine

generates carbon monoxide; carbon monoxide is a colorless, odorless

gas that can

cause serious injury and death, if inhaled.

15. Keep hands away from the moving parts and hot parts of vehicle’s engine.

16. Read and understand all instructions and safety precautions as outlined in the vehicle

manufacturer’s manual for air condition servicing.

This instruction manual is intended for your benefit. Please read and follow the safety, installation, maintenance and troubleshooting

steps described within to ensure your safety and satisfaction. The contents of this instruction manual are based upon the latest

product information available at the time of publication. The manufacturer reserves the right to make product changes at any time

without notice.

SAFETY GUIDELINES / DEFINITIONS

WARNING: Read and understand this entire instruction manual before attempting to assemble, install, operate or maintain

this product. Failure to comply with the instructions may result in serious personal injury and/or property damage!

The following signal words are used to emphasize safety warnings that must be followed when using this product:

DANGER:

Indicates an imminently hazardous situation

that, if not avoided, WILL result in death or serious injury.

WARNING:

Indicates a potentially hazardous situation that,

if not avoided, COULD result in death or serious injury.

CAUTION:

Indicates a potentially hazardous situation that,

if not avoided, MAY result in minor or moderate injury.

NOTE: Indicates important information, which if not

followed, MAY cause damage to equipment.

IMPORTANT SAFETY INFORMATION