PTI security systems APEX User manual

APEX Access Device

Installation and Operation Manual

www.ptisecurity.com 800.331.6224

114A3863 Rev E - July 2017

Thank you for purchasing the APEX Keypad Access Device. While

every effort has been made to ensure the accuracy of the information

in this document, PTI Security Systems assumes no liability for any

inaccuracies contained herein. We reserve the right to change the

information contained herein at any time and without notice.

NOTE: This equipment has been tested and found to comply

with the limits for a Class A digital device, pursuant to Part 15 of

the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation.

This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance

with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment does

cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user

is encouraged to try to correct the interference by one or more of

the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which

the receiver is connected.

• Consult the dealer or an experienced radio TV technician for help.

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du

Canada.

© 2017 PTI Security Systems

All rights reserved. No part of this publication may be reproduced,

transmitted, transcribed, or translated into any language in any

form, by any means, without written permission of PTI Security

Systems.

APEX Access Device

ii 114A3863.E rev. 7-2017

This equipment generates, uses, and can radiate radio frequency energy

and if not installed and used in accordance with the instruction manual,

may cause interference to radio communications. It has been tested

and found to comply with the limits for a Class A computing device

pursuant to Subpart J of Part 15 of FCC rules, which are designed to

provide reasonable protection against such interference when operated

in a commercial environment. Operation of this equipment in a residential

area is likely to cause interference in which case the user, at his/her own

expense, will be required to take whatever measures may be required to

correct the interference.

With the RS485 communication scheme, a keypad can be located as far

as 4000 feet from the controller, therefore shielded twisted pair cable

with ground wire is required for optimal operation. Additionally, larger

gauge wire must be used the farther the device is from the controller,

The system will not operate properly if the voltage is below

12VDC. Extreme care should be taken when choosing a power supply

voltage and current rating. Long distance runs may require a remote

power supply to be installed in line with an RB5 relay to ensure proper

operation.

Do NOT run low voltage system wires in the same conduit

as high voltage wiring

Incorrect installation of electrical components can result in

damage to electronics as well as personal injury.

Cross-wiring the AC power with the DC power will damage

the electronics.

Cross-Wiring the Power wires with the Data wires will

damage the electronics

Cross-wiring the positive and negative on the DC part of

the system will damage the electronics.

Warning: The User should follow all installation, operation, and

maintenance instructions. The User is strongly advised to conduct

product and systems tests at least once each week. Changes in

environmental conditions, electric or electronic disruptions and

tampering may cause the product to not perform as expected.

PTI Security Systems warrants its Product to the User. The User

is responsible for exercising all due prudence and taking necessary

precautions for the safety and protection of lives and property wherever

PTI Security Systems products are installed. PTI Security Systems does

not authorize the use of its products in applications affecting life safety.

APEX Access Device

iii

rev. 7-2017 114A3863.E

Contents

Technical Specifications............................................................1

Installation ................................................................................2

Placing APEX Devices...................................................2

Mounting Access Devices ............................................3

Installing APEX Access Devices ...................................9

Installation Instructions ............................................... 11

Connecting Additional Features................................. 16

Testing the Keypad..................................................... 23

Operation ............................................................................... 25

Input/Output Descriptions ......................................... 25

Using Extended Door Controls .................................. 30

APEX Access Device Setup Function.......................... 32

Standard Display Messages........................................ 41

Access Codes and Cards ............................................ 42

Access Response Messages ....................................... 46

System Maintenance .............................................................. 48

Troubleshooting ......................................................... 50

Test Power and Communication................................. 51

Test Individual Devices, Card and Code Input ........... 55

Test multiple devices or entire site ............................. 56

Warranty & Disclaimer ........................................................... 58

APEX Access Device

iv 114A3863.E rev. 7-2017

Technical Specifications

Input Power:

Voltage: 12 – 18 VAC or DC

Current Consumption: 300mA Maximum

Relay Specifications:

Maximum Switching Voltage: 30 VAC / 30VDC

Maximum Switching Current: AC: 10A (NO) / 3A (NC)

DC: 5A (NO) / 3 A (NC)

* Resistive load

Environmental:

Ambient Temperature: -40°C to +85°C

(-40°F to 185°F)

Ambient Humidity: 0 to 85% non-condensing

APEX Access Device

1

rev. 7-2017 114A3863.E

Installation

Placing APEX Devices

The APEX Access Device (APEX) controls entry to or exit from a

secured area. It works in conjunction with a controller and control

software. The APEX can be used to control gate access, building

access, room access, elevator access, etc. and is designed for ease

of use and flexibility. Both the keypad and the large LCD are backlit

for easy visibility day and night. Mounting height for devices will

vary with local code regarding handicap access, emergency and

fire access, and other regulations.

Before installing the APEX determine where and how the device

will be installed, since the mounting location is determined by how

the device will be used. For drive up access, install the device where

it can be reached from a vehicle’s driver door. If the APEX is used for

walk up access, install it where it can be accessed by a person on foot.

Drawing 1: Drive up accessability

Inside of propertyInside of property

BOLLARD

EXIT KEYPAD

DETECTOR

LOOP

DETECTOR

LOOPS

BARRIER

OR PAD

BARRIER

OR PAD

ENTRY KEYPAD

ENTRY KEYPAD

Outside of property Outside of property

SLIDE GATE

OR PAD

APEX Access Device

2114A3863.E rev. 7-2017

Drive Up Accessibility

When the APEX will be positioned for drive up accessibility, the

device must be mounted within easy reach of the driver of an

automobile or light truck. Most of these locations use gooseneck

stands on an island between the entry and exit gates (or to the

left side of the gate if a single gate is used). “Drawing 1: Drive up

accessability” on page 2 shows different entry layouts.

Local building codes may set a minimum and maximum height for

devices that are accessible by vehicle. shows suitable mounting

locations when used for vehicle access.

Walk Up Accessibility

When the APEX is used for walk up access, it can be mounted on a

stand or attached to a wall. It can also be surface mounted so that

it protrudes from the wall.

Mounting Access Devices

The proper mounting height for the APEX varies with the application

and it can be installed at an entrance on a gooseneck/bollard or

attached to a wall.

Once the keypad location is determined, note , the location and

purpose of the device on a site security wiring plan. Keep the plan

in a safe location for future maintenance and service purposes.

Surface Mount

Surface mounted keypads are often used in conjunction with door

strikes and elevators.

Mounting height is usually 48” – 58” from the floor to the center of

the ‘5’ button on the touchpad. However, the final location of the

keypad may be affected by local building codes.

The choice of fasteners depends on the construction material of

the wall.

APEX Access Device

3

rev. 7-2017 114A3863.E

Note: If the APEX is installed on an exterior wall, seal the contact

point between the housing and the wall with a silicone sealant

rated for outdoor use. This prevents moisture and insects from

getting into the housing.

Flush Mount

A flush mount box allows the keypad to be

set into hollow walls and is used in interior

installations.

The flush mount box must be ordered

separately. Mounting height is generally

48” – 58” from the finished floor to the

center of the ‘5’ button on the touchpad.

A gasket is needed for the face plate if the

flush mount kit is used outdoors.Refer to

“Drawing 3: Flush mount exploded view”

on page 5 for the mounting details of

the flush mount adapter.

The actual placement of the APEX device and its wiring methods

may be affected by local building codes.

An elevator flush mount is available made of brushed stainless steel

for mounting inside elevator cars; this model does not include an

intercom.

Drawing 2: Flush mount

keypad

APEX Access Device

4114A3863.E rev. 7-2017

Box Mount

A box mount with no shaded overhang

is available for locations that require the

keypad to be mounted lower than standard

height, such as for handicap access. This

box mount must be ordered separately.

With a normal APEX mount, a standing

person may not be able to see the display.

Mounting height varies from 42” – 58”

from the finished floor to the center of the

‘5’ button on the touchpad.

Most standard keypad installations place the ‘5’ button on the

touchpad at approximately 50 inches from the finished floor for

walk up keypads, and 45 inches from the finished driveway for

standard vehicle access.

6 - 32 x /”

F.H MACHINE SCREWS

ADAPTOR/

COVER PLATE

JUNCTION BOX

GASKET

MATERIAL

SHEETROCK

TOP

ADJUSTABLE BRACKET.

BRACKET CAN BE POSITIONED

FLUSH TO EDGE OF J-BOX

⁄”FROM EDGE AND /” FROM

EDGE (LEFT AND RIGHT

6 - 32 x /” P.H MACHINE SCREWS

(FASTENS J-BOX MOUNTING

BRACKETS TO J-BOX)

7.800”

2.800”

8.440”

Drawing 3: Flush mount

exploded view

Drawing 4: Box mount

for keypad

APEX Access Device

5

rev. 7-2017 114A3863.E

Gooseneck Stand Mount

A gooseneck is commonly used for driveways for vehicle access.

The gooseneck can also be used near doors for wheelchair access

or when sidewalks and landscaping require a freestanding keypad

mount away from the building.

• The base plate of a gooseneck has a hole that accepts conduit

(¾” maximum) for electrical wiring. Ensure the conduit is

placed properly and the wiring runs through the conduit before

mounting the gooseneck stand to the concrete base. The final

location of the gooseneck and the mounting techniques may

be affected by local building codes.

• As a precaution, the gooseneck should be protected with

concrete bollards to prevent vehicles from damaging the

electronics.

• There are several different styles of gooseneck stands available.

See for the dimensions of two common styles in “Drawing 6:

Gooseneck stand mount” on page 7.

Both single and double bollards are mounted on a Schedule 40

10 3/4” diameter pipe with a .365” wall. This pipe is footed in

concrete and filled 3/4 of the way with concrete to create a solid

barrier. The entire pipe and bollard are then painted to match the

facility. Contact PTI Security Systems for full

measured installation plans and instructions.

Wall Mount Gooseneck

A wall mount gooseneck allows the keypad

to be mounted on a wall. It may be used

for door strikes or for gates in driveways

ajacent to a building wall, as shown in

“Drawing 5: Wall mount Gooseneck” on

page 6. Drawing 5: Wall mount

Gooseneck

APEX Access Device

6114A3863.E rev. 7-2017

This gooseneck also gives wheelchair users access to a device.

Mounting height is generally 48” – 58” from finished floor to the

‘5’ button on the touchpad for walk-up access and 45 inches from

driveway level to the ‘5’ button on the touchpad for vehicular

access.

If the APEX is installed on an exterior wall, seal the contact point

between the housing and the wall with a silicone sealant rated for

outdoor use. This prevents moisture and insects from getting into

the housing.

46.00”

46.00”

Drawing 6: Gooseneck stand mount

APEX Access Device

7

rev. 7-2017 114A3863.E

Keypad Adapter Plate

• A keypad adapter plate is an aluminum plate used to mount

keypads to stands, bollards, and goosenecks manufactured by

other companies.

• The installer measures, marks, and drills holes in the adapter

plate to match the stand configuration. To prevent tampering,

ensure the holes are countersunk on the same side as the

installed screws so that the keypad covers the mounting screws.

• The screws and screwholes provided on the aluminum plate

match up with the APEX keyhole mounting pattern.

Single Bollard

A bollard is an attractive and functional stand for

keypads. It helps protect the keypad from vehicle

damage. It can be used in driveways for vehicle

access or near doors as a keypad stand. Height is

determined by the length of the pipe on which it is

mounted.

Bollards can be filled with concrete and used as

barriers to protect keypads, walls, or gates.

Drawing 7: single

bollard

APEX Access Device

8114A3863.E rev. 7-2017

Installing APEX Access Devices

Power and data-communication wiring are the most important

wiring component for APEX devices. The APEX requires power and

communication lines to be supplied from the controller.

PTI recommends that power and data communication be run

through a single 18 AWG, 4-conductor shielded cable. Some

installations will require larger gauge wire. See for details on

connecting the wiring

Additional cables may be needed for the intercom, gate operator,

door strike, presence detector, or other device.

• Use a different cable for each device.

• Use approved electrical conduit to supply the wiring to the

APEX.

• Local building codes determine the actual installation

techniques and wiring methods.

• Only licensed contractors should install APEX devices.

• Correct installation methods are critical for a trouble-free

keypad. Most of the problems that emerge during use can be

traced back to poor installation techniques or improper wiring

• All installations must conform to local building and electrical

codes. When there are discrepancies between local code and

this manual, local code takes precedence.

Never install any other devices in the same wire run as the

APEX.

The system will not operate properly if the voltage is below

12VDC.Extreme care should be taken when choosing a power

supply voltage and current rating. Long distance runs may

require installing a remote power supply.

APEX Access Device

9

rev. 7-2017 114A3863.E

NOTE: IF 2 GATES

ARM = RELAY1

SLIDE = RELAY2

RELAY2 CAN BE TIMED

FROM POWER

SUPPLY AND

CONTROLLER

TO GATE OR

DOOR STRIKE

TO REMOTES

CAMERA

AC/+

AC/−

ERTH

DAT+

SHLD

DAT−

1

2

P1 P4

NO1

C1

NC1

NO2

C2

NC2

K1 K2

RELAY 1 RELAY 2

AC

DC

+ −

DATA

FROM

CTRLR

RED

BLK

WHT

SHD

GRN

Drawing 8: Wiring for

APEX keypad

APEX Access Device

10 114A3863.E rev. 7-2017

Installation Instructions

1

Open the device by removing the four stainless steel button

head machine screws on the front of the keypad faceplate

using the security hex key provided with the unit. The front

and back half will separate.

2

Mount the back plate to the desired keypad location using the

three-keyed holes. Seal around the back of each screwhole

and around the back of the wire hole with an outdoor silicone

sealant as shown in”Drawing 9: silicone seal for goosneck” on

page 11

• If the keypad is being mounted

on a gooseneck or bollard, run

a bead of silicone in a triangle

around the three screwholes as

shown in Drawing 9 on page

11:

• If the keypad is being mounted

on a wall, before mounting, run

a bead of silicone in a square

around the back of the keypad

about ½ inch from the edge.

3

Pull the necessary wires through the wire hole on the back

of the housing. Allow an extra 1 foot of wire to remain inside

the housing. After the wire connections are complete, excess

wire can be pushed back into the gooseneck or wall or it can

be carefully positioned inside the keypad housing for future

maintenance and service. Each keypad should have the

following wires as shown in “Drawing 10: KP wiring for the

APEX keypad” on page 12:

Drawing 9: silicone seal for

goosneck

APEX Access Device

11

rev. 7-2017 114A3863.E

-One of 18 AWG, 4-conductor, shielded cable coming in

from the controller or from the previous AI device in line.

-One of 18 AWG, 4-conductor, shielded cable going out to

the next AI device in line (if there is another AI device down

the line).

-One of earth ground wire

-One or two of 18 AWG, 2-conductor cable(s) coming from

the gate operator or door strike.

A cable for the door strike or gate operator will only be

present if the relay inside the specific keypad is used to

trigger the door or gate. The controller can be configured

to trigger a gate or door using relays on the circuit board,

a separate relay board, or any other AI device.

For security reasons, the relay in the keypad nearest

a door or gate should not be the one used to directly

trigger the door or gate.

8-32 x 3/8" Screws

(qty 3)

Cover hole

with silicone

RG 59U Camera Cable

(If optional camera is part

of this device)

18GA, 2-Conductor Unshielded Cable

(only if relay in this device used to

trigger Gate/Door Strike)

18GA, 2-Conductor Shielded Cable

(for Intercom)

18GA, 4-Conductor Shielded Cable

(RS485, may have more than one

cable to daisy-chain to other

Access interface devices

Earth Ground

(connect to Chassis Ground

with wire nut and tape)

Chassis Ground

(connect to Earth Ground

with wire nut and tape)

Chassis Ground

(connected to keypad)

Drawing 10: KP wiring

for the APEX keypad

APEX Access Device

12 114A3863.E rev. 7-2017

-One of 18 AWG, 2-conductor, shielded cable coming from

the intercom base station if intercoms are being used.

-1 of RG59U video cable if a pinhole camera is being used.

-One of 18 AWG, 2-conductor cable for the presence sensor

if it is being used.

4

Strip back the outer insulation and shield foil from both of

the 18 AWG, 4-conductor, shielded cables (coming from the

controller or previous AI device in line and going out to the next

AI device in line), being careful not to cut the bare shield wire.

Strip ¼ inch of insulation off the end of each of the individual

colored conductor wires.

5

Remove the terminal blocks from the keypad circuit board by

sliding them up and off.

6

For Terminal Block P1 “Drawing 11: Terminal block

P1 wiring” on page 13 Insert both red wires (coming in

from the controller and going out to the next AI device) into

terminal slot 1 on the first terminal block (P1).

Terminal Block P1 (Left)

1. Red DC + *

2. Black DC – (see footnote)

3. Earth Ground (if applicable)

4. White Data +

5. Shield**

6. Green Data –

* If using AC power, place the AC

wires in slots 1 and 2. We recommend

12-18VAC or DC can be used.

** Shield wire should be insulated with

heat shrink or electrical tape.

Drawing 11: Terminal block P1 wiring

APEX Access Device

13

rev. 7-2017 114A3863.E

7

Ensure that both wires are seated all the way inside the slot.

Use a flathead precision screwdriver to tighten down the

terminal screw.

8

Verify that the terminal slot has tightened down on the copper

wire and not on the rubber insulation. There should be no

copper wire showing outside of the terminal slot. Gently tug

the wires to verify that they are tightly held inside the terminal

slot.

9

Repeat this process with each of the remaining wire connections

as shown in “Drawing 11: Terminal block P1 wiring” on page

13. Insert both black wires into terminal slot 2 on P1.

Ensure that both wires are seated all the way inside the slot.

10

For terminal block p4 “Drawing 12: Terminal block P4

wiring” on page 14 The right (relay) terminal block is used

for the relay connections. Pins 1, 2, and 3are for the rst

relay and Pins 4, 5, and 6are for the second.

Terminal Block P4 (Right)

1. Relay 1 Normally Open Wire

2. Relay 1 Common Wire

3. Relay 1 Normally Closed Wire

4. Relay 2 Normally Open Wire

5. Relay 2 Common Wire

6. Relay 2 Normally Closed Wire

Drawing 12: Terminal block P4 wiring

APEX Access Device

14 114A3863.E rev. 7-2017

11

Refer to the gate or door strike manufacturer’s instructions to

determine whether it needs to be connected to the normally

open and common or to the common and normally closed.

12

Relay 2 can be programmed to serve any of a number of

functions using both the internal APEX programming and/or

the software.

13

The earth ground wire is connected in locations where the

keypad is mounted on a wall that is wood, stone, or other

nonconductive material. It is not always necessary when it is

mounted on a grounded bollard or gooseneck.

14

To connect the ground wire, run a copper wire from a grounded

water pipe or from a copper rod in the ground to the keypad

and connect it to the green earth ground wire using a wire nut.

In this case, Jumper J1 should be set to ‘Normal’.

15

This installation must meet applicable code as the type of wire,

depth of burial, and size of the rod may vary by municipality

16

Connect any additional features such as an intercom, gate

operator, or pinhole camera. Details are on page 16 to

page 22.

17

After all wiring is complete, gently push the excess wire

back through the hole in the wall or gooseneck, leaving just

enough slack to allow the keypad to be opened for service

or maintenance. Seal the back wire hole with outdoor-rated

silicone sealant and then screw the housing back together.

Loose uninsulated wires (Typically used for earth ground)

cannot be located inside the unit’s case. Make connections for

uninsulated ground wire outside the case.

APEX Access Device

15

rev. 7-2017 114A3863.E

Connecting Additional Features

The VP keypad may have additional features and functions. They

need to be connected after steps 1 - 16

Intercom

Connect the wires to terminal block P2 in the upper left corner

of the board as shown in “Drawing 13: Intercom wiring layout” on

page 17 The connection and jumper settings will vary depending

on whether the intercom is LEF Single Master Station, LEF Multiple

Master Station, or NEM type intercom. Refer to the manufacturer’s

instructions.

Remember to set the jumper settings as shown in “Drawing 14:

Intercom jumper settings” on page 17.

The APEX device can be connected to an Aiphone LEF or Aiphone

NEM intercom.

• The intercom wiring must be separate from all other wiring to

the APEX. Use 18 AWG, 2- or 3-conductor shielded cables for

the intercom depending on the type of intercom being used.

• The intercom type jumpers on the APEX circuit board must

be set to match the type of intercom being used. Refer to the

Aiphone specifications for more detail.

• The intercom type jumpers on either keypad circuit board must

be set to match the type of intercom that you are using, so

reference the configuration table in Drawing 14 on page 17.

APEX Access Device

16 114A3863.E rev. 7-2017

Table of contents

Other PTI security systems Keypad manuals

Popular Keypad manuals by other brands

Honeywell

Honeywell 6150 - Ademco Fixed - Display Keypad Installation and setup guide

AES global

AES global MultiCOM Cellular Series Installation & user's instructions

Russound

Russound A-K3 installation manual

Vasco

Vasco Digipass 270 user manual

Eaton

Eaton i-rk01 installation guide

DMP Electronics

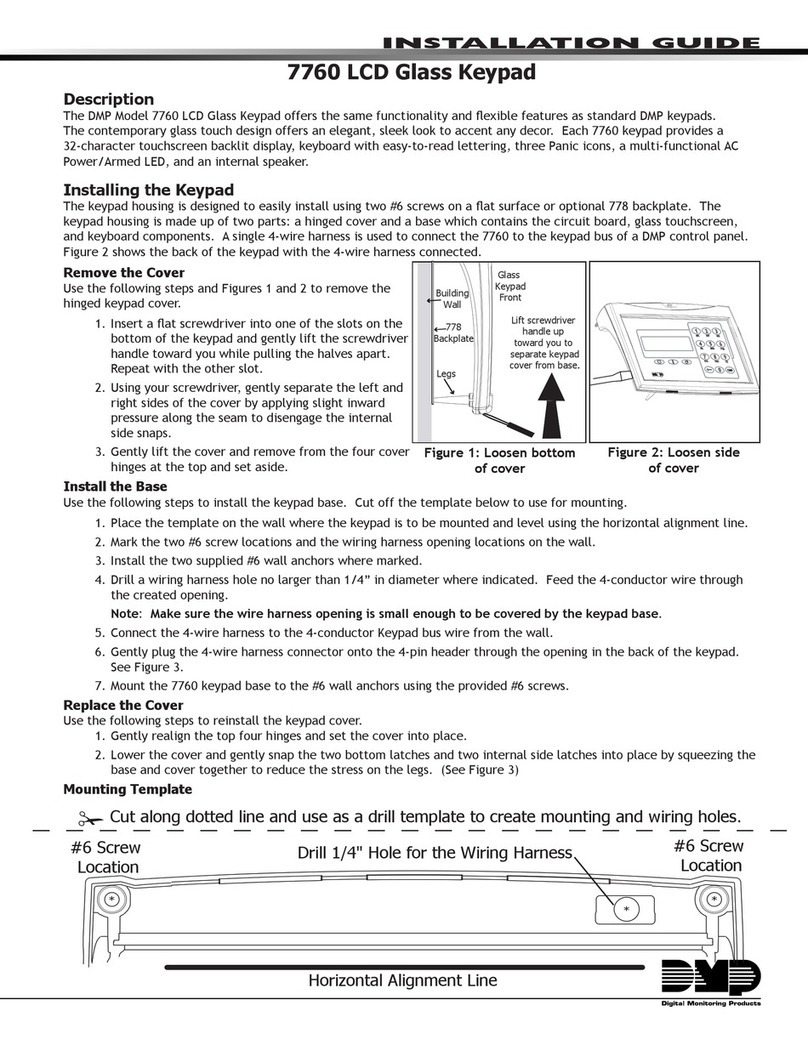

DMP Electronics 7760 installation guide