Puch 1970-1971 Puch User manual

PUCH

1970and

1971

MOPEDMAINTENANCE

MANUAL

Includes

•TechnicalData

•Description

•Maintenanceandservice

•TroubleShooting

Steyr- Daimler-

Puch

PUCH

SERVICE-AUSTRIA 907.1.71.033.1

i

PUCH-Motor-Cycles

mm

DESCRIPTION

AND

MAINTENANCE

STEYR- DAIMLER- PUCHAKTIENGESELLSCHAFT

AUSTRIAAUTRICHE

TABLEOFCONTENTS

1.

TechnicalData

(seeattacheddatasheet)

2.

Description

3.MaintenanceandService

4.TroubleShooting

5.Index

V

FIRSTREAD— THENDRIVE!

I

!

Takethismottotoheartandletyourvehiclehavethat

minimumofmaintenanceandcareitneedstogiveyou

fullsatisfactionandsecurity.

Wepresentyouthereforetogetherwithyournew

PUCHMOTOR-CYCLE

theseoperatinginstructions.

Thebookletisintendedasanintroductiontohandling,

tendingandmaintenanceofthevehicle.

Shoulditbeyourfirstmotorvehicle,weadviseyouin

yourowninteresttoreadtheseoperatinginstructions

carefully.Mostdamagesarecausedbyignoranceand

hencecouldeasilybeavoided.Regularmaintenancewill

preventtroublesandrepairswhichmaycostyoumuch

timeandmoney.

Thesectionontroubleshootingwillinformyouabout

manysourcesoffaults.Butdonotundertakefumbling

thingsthatcanonlybeexecutedexpertlybya reliable

workshop.A widespreadserviceorgansiationaswellas

ourownservicedepartmentintheworksatGrazwill

bepleasedtobeusefultoyou.

Whenrequestinginformationororderingspareparts

pleaseneverforgetquotingtheenginenumber.

Numbersinbracketswithinthetextrefertotheillustra-

tions.

Outoftwonumbers,theoneontheleftofthe

obliquelineindicatesthenumbersofthefigure,theone

ontherightoftheobliquelinereferstothenumbers

withinthefigure.

Nowwewishyoua goodstartanda goodtimewith

yourPUCHmotor-cycle!

STEYR-DAIMLER-PUCH

Aktiengesellschaft

VI

2.

DESCRIPTION

—..,".-..........-—

H

7%

I

2.1

CONTROLS

Locationandworkingof

thecontrolsmaybeseen

fromthedatasheethereto

attached.

2.2FIRSTPUTTINGINTO

SERVICE

2.3BEFOREEVERYTRIP

2.4DRIVING

INSTRUCTIONS

2—1

2—2DESCRIPTION

2.2FIRSTPUTTINGINTOSERVICE

Afterfinalassembly,everyPUCHmotor-cyclehasto

undergoa trialtrip,itisthereforereadyforuse.Itis

nonethelessstronglyrecommendabletocarrytroughthe

followingcheckingsbeforeputtingthevehicleintooper-

ationforthefirsttime.

2.21Comparingthecharakteristicnumbers

Beforethefirsttrip,comparethecharacteristicnumbers

ofthevehiclewiththoseindicatedontheregistration

papers.

2.22Checkingtheoillevelinthegearbox

Areprovidedforthepurposeeitheranoilcontrolplug

ora dipstickontherighthandsidegearboxcover.

a)Oilcontrolplugversion

(fig.

1)

Withthevehicleinhorizontalposition(normal

posi-

tion),

oillevelingearboxshouldcomeuptothebot-

tomedgeoftheoilcontrolplug

(1/2,

2a/2).Incase

thatmarkisnotreached,takeofftheoilfillerplug

(1/1,

2a/l)and

fill

inmotoroil(seesection3.21)until

oilcomesoutoftheoilcontrolhole.Theoilcontrol

plug(1/2)shouldbescrewedinagainonlywhenno

moreoilpoursoutofthehole.

b)Dipstickversion(fig.2)

Checkoillevelathorizontal(normal)position.Screw

outdipstick(2/1),wipeitdryandputitandpull

outagain.Oilleveliscorrectwhenbetweenthetwo

DRIVINGINSTRUCTIONS2—3

marks.

If

oillevelisunderthelowermark,

fill

in

motoroil(seesection

3.21).

If

oillevelcomesuptoovertheuppermark,loosen

oildrain

pliug

(2/2)anddrainsomeoil.Before

measuringagain,wipethedipstickdry.

Whenevermeasuringoillevel,screwinentirelythe

dipstick!

2.23Checkingtheairfilter(forlocationseedatasheet)

Theintakemufflerairfiltermustbewettedbymotoroil

SAE40vor50,exceptvehicleswithdryairfilter.

2.24Checkingtheinflatingpressure

Forpressurefigures seedatasheet.

2.25Gasoline-oilmixturerefuelling

MixgasolinewithbrandedmotoroilSAE40or50(See

lubricantschart)ina

1

: 25 ratio

(=

4%),thatis40c.c.

on1 literofpetrol.

Important!Neverfill inpurepetrol!

2.3BEFOREEVERYTRIP

Youshouldcheck:

0

Fuelprovisions

9

Tyreinflatingpressure

0

Brakingefficiency

•

Lighting

•

Toolkit

2—4DESCRIPTION

2.4DRIVINGINSTRUCTIONS

2.41Startingtheengine

0

Openfuelcock.

#

Putinignitionkey(modelswithignitionlock).

%

Operatethechokeonlywenengine

cold,

ifneces-

sary,

operatethetickler.

0

Whenre-startinga hotengine,donotoperateeither

chokenotrickler.

0

Inautomaticmodelswithpedalswatchpositionof

changeleverfortreadle(seedatasheet).

0

Openthethrottleby

1A

(turnthrottletwist-gripbyone

thirdofitstravel).Attention:inautomaticmodels

openthrottleonlyslightly.

0In

automaticmodelswithpedalspullleverforrelease

ofstartingdevice(seedatasheet).

0

Crankenginebymeansofpedalsorkick-starter.

0In

casethechokehasbeenoperated,pushinpro-

portionasenginewarmsitselfup.

0

Aftera fewhundredyards,thechokeshouldbeturned

off!(Incaseofa Bing-carburetterwith

14

mm0 and

17

mm0,choketurnesoffautomaticallybyfully

openingthethrottle

manentarily.)

2.42Movingoff(Inautomaticmodelsjustopenthrottle)

£

Pullclutchcontrollever;engage

1

stgear.

%

Releaseclutchleverslowly,simultaneouslyopen

throttletwistgrip.

2.43Gearshifting(Inautomaticmodelsresultsautomatic-

allyaccordingtonumberofenginerevolutions)

DRIVINGINSTRUCTIONS2—5

Thebottomgearwhichyouarenowusingrepresentthe

startingandclimbinggear.Assoonascircumstances

willallow,youwillchangeup.Proceedasfollows:

0

Throttledown.

#

Operateclutchcontrolleveralmostatthesametime

andengagethenextgear.

0

Releaseclutchcontrollever.

#

Openthrottle.

Afterreachingmaximumspeedbyfullyopeningthe

throttletwistgrip,throttledowntoabout

3A;

thefallin

speedwillbehardlyperceptiblewhereasfuelconsump-

tionwillthusbeconsiderablyreduced.Throttleopening

shouldbeturnedtowhattheenginejustneeds-sharp

openingofthethrottletwist-griponlyincreasesfuel

consumption.Whendrivingspeedhastobereducedbe-

causeofa slopeortrafficcircumstances,changedown.

Proceedasfollows:

0If

necessary,applythebrakesandthesametime

0

throttleback,

9

operateclutchcontrolleverandchangedown,

0

releaseclutchcontrollever,

#

givethrottleagain.

Hintforownersofautomaticmodels

Whenrapidaccelerationrequiresevenquickergearshift-

ing,

throttledowncompletelyafterreachingabout

25km/handopenthrottleagainshortlyafterwards.Thus

secondgearshiftedmorequickly.

2—6DESCRIPTION

2.44Applyingthebrakes

Throttleback,

applyhandandfoot-operatedbrakesimultaneously.On

sandy,wetorslipperyroads,useprimarilythefoot-

operatedbrake.

Alwaysapplythebrakescautiously.Lockingwheels

reducethebrakingefficiencyandentailskiddingand

crashing.

2.45Stoppingandparking

#

Throttleback,

%

applythebrakes,

%

(Inapplicableinautomaticmodels)justbeforestopp-

ing,

operatetheclutchcontrolleverandengage

neutralgear.

In

ordertoshutofftheengine:

0

Press

short-circuiting

button.Pulloutignitionkey

(modelswithignitionlock),

%

shutfuelcock,

<0

shutoffthevehicle.

2.46Drivingdownhill

Whendrivingdownhill,theidlingengineactsasa brake.

Duringlongerdescents,openthethrottleeverynowand

theninordertogreasetheengine(thelubricantbeing

inthefuel).Ifnecessary,applythebrakes.Whendes-

cendingsteepgrades,engagebottomgear.

2.47Treadingwithshut-offengine

(Possible

onlyinmo-

delswithpedals,inautomaticmodelswithpedals

adjustchangeleverfortreadle[seedatasheet]).

DRIVINGINSTRUCTIONS2—7

0

Operateclutchcontrolleverandengage2ndgear

(3rdgear)whilstpedalling.

%

Mounttheauto-cycleandsetitgoinglikea bicycle

whitpulled-downclutchlever.

%

Beforestopping,engageneutralgear.

3.MAINTENANCEANDSERVICE

3.2LUBRIFYINGTHE

VEHICLE

3.3MAINTENANCE

OPERATIONS

3.4CLEANINGTHE

VEHICLE

3.5LAYINGUP

3—1

3—2MAINTENANCEANDSERVICE

SERVICE

Anumberofmaintenanceoperationsarebeyondthe

amateur'sreachashelacksthespecialdevicesnecessary

fortheirexecution.

Werecommendthereforetoentrustsuchoperationsto

one

ofthemanyservicestationssetupbyPUCHin

Austriaaswellasabroad.Theirskilledpersonelldis-

posingofspeciallytestedworkingmethodsandevery

workingfacilitywillcarryoutanyoverhaulingandrepair

workrationally,economicallyandrapidly.

ThePUCH-ORGANIZATIONwillalwaysbepleasedto

giveyoufurtherinformationandadvice.

SPAREPARTS

Correctandswiftexecutionofallsparesordersis

con-

ditionedbytheexactquotingofchassisandengine

numbersandfulltypedesignationontheorderform.

Belowwillbegivena descriptionoftherecurrentmainte-

nanceworks.Thelubricationandmaintenanceschedules

willbefoundonthedatasheetheretoattached.

LUBRIFYING

3—3

3.2LUBRIFYINGTHEVEHICLE

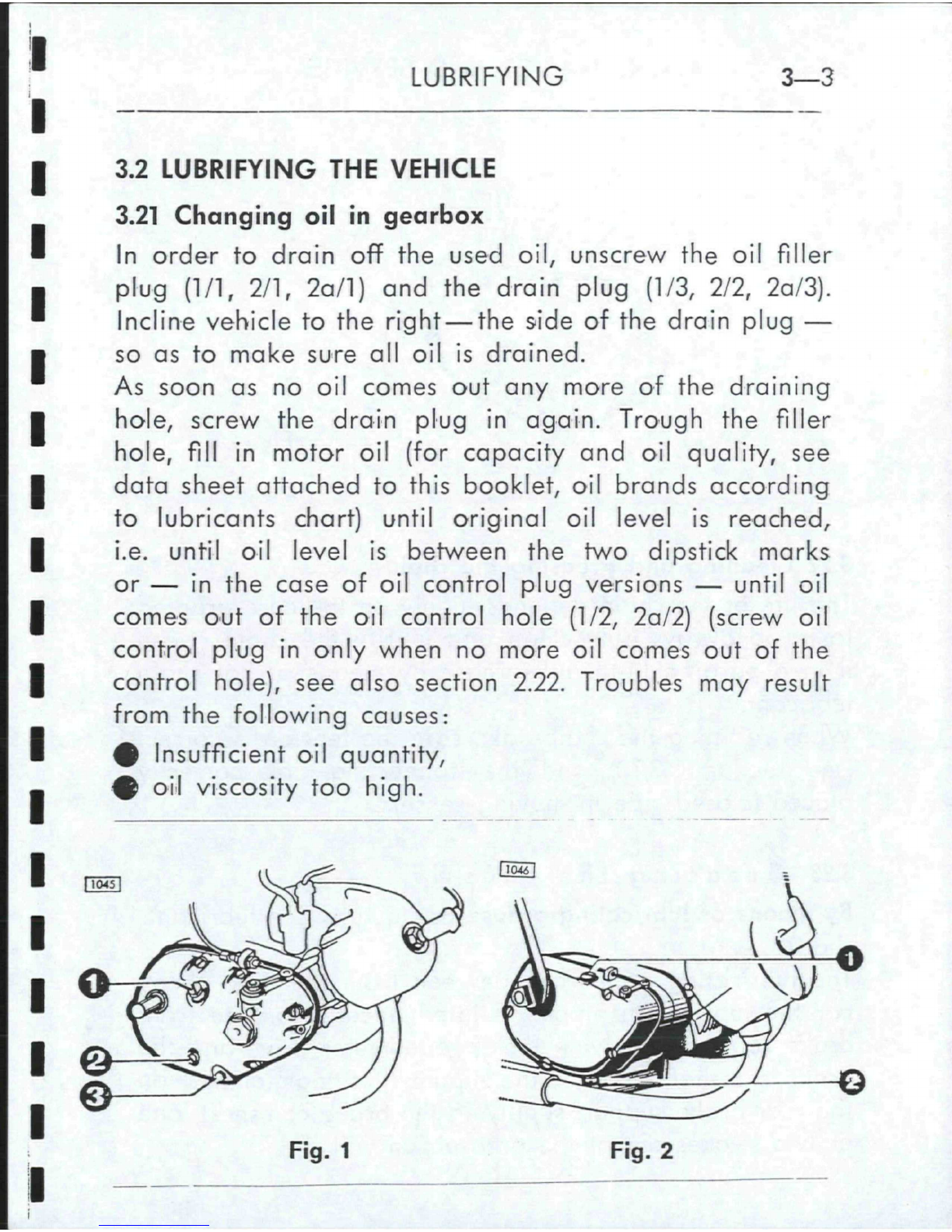

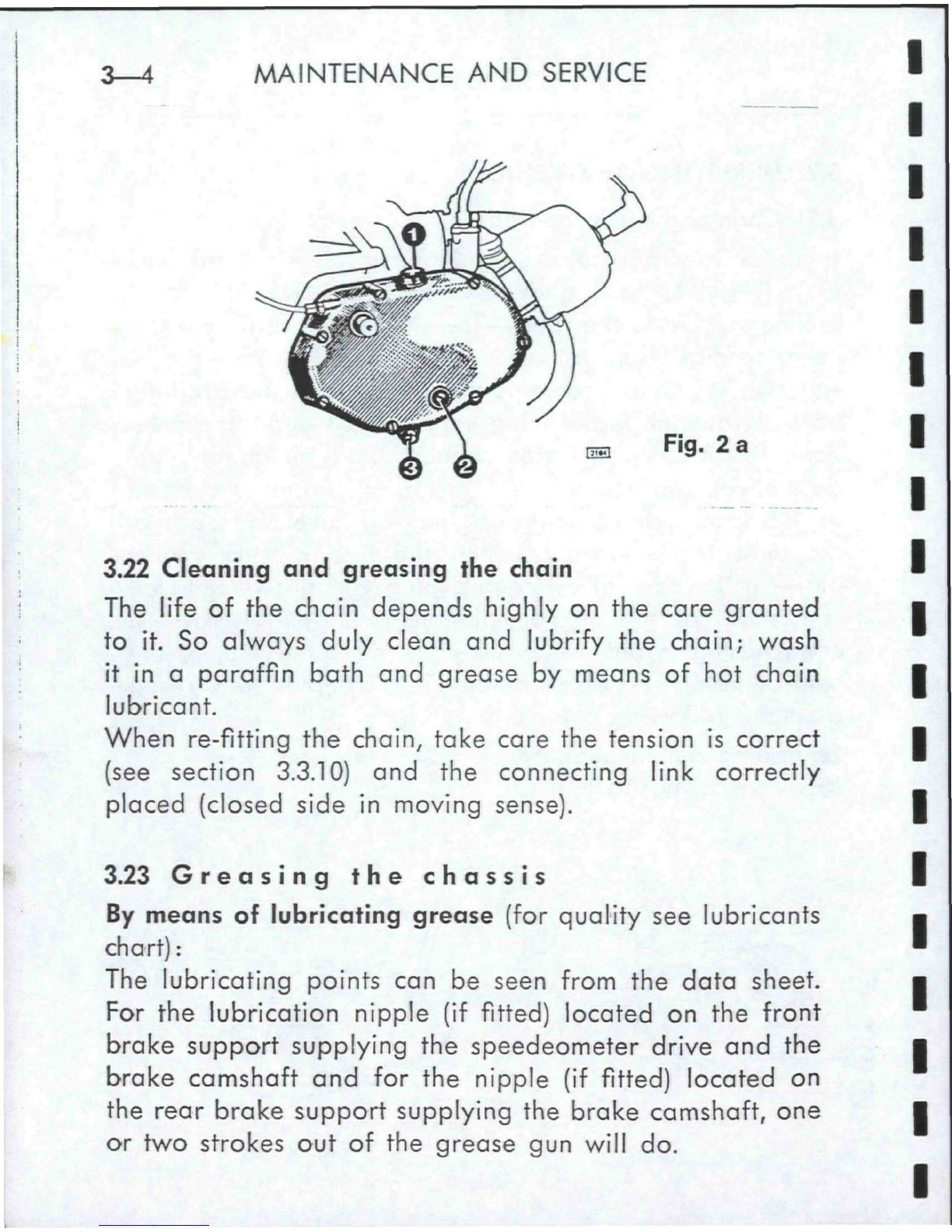

3.21Changingoilingearbox

In

ordertodrainofftheusedoil,unscrewtheoilfiller

plug

(1/1,

2/1,

2a/l)andthedrainplug(1/3,2/2,2a/3).

Inclinevehicletothe

right—

thesideofthedrainplug—

soastomakesurealloilisdrained.

Assoonasnooilcomesoutanymoreofthedraining

hole,

screwthedrainpluginagain.Troughthefiller

hole,

fill

inmotoroil(forcapacityandoilquality,see

datasheetattachedtothisbooklet,oilbrandsaccording

tolubricantschart)untiloriginaloillevelisreached,

i.e.untiloillevelisbetweenthetwodipstickmarks

or— inthecaseofoilcontrolplugversions— untiloil

comesoutoftheoilcontrolhole(1/2,2a/2)(screwoil

controlpluginonlywhennomoreoilcomesoutofthe

controlhole),seealsosection2.22.Troublesmayresult

fromthefollowingcauses:

0

Insufficientoilquantity,

%

oilviscositytoo

high.

[ToSI

DwU

h

c~-

[

\

0

I

<>

©

3

€>

Fig.

1 Fig.2

3—4MAINTENANCEANDSERVICE

Fig.

2 a

3.22Cleaningandgreasingthechain

Thelifeofthechaindependshighlyonthecaregranted

toit.Soalwaysdulycleanandlubrifythechain;wash

itina paraffinbathandgreasebymeansofhotchain

lubricant.

Whenre-fittingthechain,takecarethetensioniscorrect

(seesection3.3.10)andtheconnectinglinkcorrectly

placed(closedsideinmovingsense).

3.23Greasingthechassis

Bymeansof lubricatinggrease(forqualityseelubricants

chart):

Thelubricatingpointscanbeseenfromthedatasheet.

Forthelubricationnipple(iffitted)locatedonthefront

brakesupportsupplyingthe

speedeometer

driveandthe

brakecamshaftandforthenipple(iffitted)locatedon

therearbrakesupportsupplyingthebrakecamshaft,one

ortwostrokesoutofthegreasegunwilldo.

MAINTENANCEOPERATIONS3-5

Bymeansoflubricatingoil(qualityseelubricantschart):

0

Brakeadjustingscrewonfrontandrearwheel

0

Chaintensioningscrews

#

Gearshiftlinksandbearingpoints(iffitted)

4

Centralpropbearing

#

Saddlebearingpoints(iffitted)

0

Brakepedalbearing

#

Workingsurfacesofbrakeandclutchcontrollevers

#

Bowdencables(ifnecessary,takeoffheadlight

bracket)

3.24Changingoilinrearsuspensionunitandtelescopic

fork

Thisoperationshouldonlybecarriedout— accordingto

theinstructionsgivenintherepairmanual— bya

PUCH

servicestation(capacitiesgiveninthedatasheetattached

tothisbooklet).

3.25Lubrifyingthegreasefeltsupplyingtheignitioncams

LubrifythegreasefeltbymeansofBOSCHgrease

Ft!

v4.

Thelubricantmustnotreachthe

make-and-break

contacts

whereitwouldcauseexcessivewear.

3.3MAINTENANCEOPERATIONS

Entrustallworksthatyoufeeltobeoutofyourreach

toa PUCHrepresentative;hewillbepleasedtohelp

andadviseyou.

3.3.1Checkingthespark-plug

Screwthespark-plugoutofthecylinderandholditby

itsthreadedendagainstearth,e.g.thecylinderhead

3—6MAINTENANCEANDSERVICE

(plug

still

beingconnectedwiththeplugwire).Ifthe

startingdeviceisnowoperated,a powerfulsparkshould

flashoverbetweentheelectrodes.Oilyplugsorplugs

withdirtdepositsbetweentheelectrodeswillnotpro-

duceanysparkandmustbecleaned(woodensplinteror

steelbrush).

Whenreplacing,onlyusea spark-plugwhosethermal

valuecorrespondstothefigureindicatedinthedata

sheet.Thesparkgapshouldbebetween0,5to0,6mm.

If

thegapiswider,regapbybendingtheouterelec-

trode.

Whenscrewingtheplugin,takecareit

fits

well

intothethreadandmayeasilybeturned.Neverhave

recoursetoforcewhenscrewingin:Screwinbyhand

2or3 turns,onlythenyoumayusethespark-plug

wrench.

Standardplugaccordingtodatasheet.

3.3.2Decarbonizingtheengine

Theconstitutionofdepositsoncylindercover,piston

headandexhaustportisa necessarycorollaryofthe

workingofourcombustionengines(two-strokeengines),

buta lengthisa sourceoftroubles.Combustionpro-

ductsoriginatingfromoilaswellasfromfuelmust

thereforeberemovedfromtimetotime.

Cylindercoverandpistonhead

Removingthecarbondepositsfromcylindercoverand

pistonheadmustbecarriedoutbymeansofa blunt

edgedinstrument(screwdriverorthelike).Assurface

hardnessoflightalloysisrelativelylow,theirsurfaces

mayeasilybescratched.Scratchingistobeavoidedas

everynewscratchentailsinevitablytheconstitutionof

MAINTENANCEOPERATIONS 3—7

Fig.

3

newcarbondeposits.Fromthepistonhead,removeonly

scalydeposits;a uniformlytenuouslayerofoilcarbon

neednotberemoved.Beforerefittingthecylindercover,

thoroughlyremoveallcarbonremainsfrominnersideof

cylinder(clothusedshouldnotberavelling),rubwith

motoroil.Thenmakesurebyturningtheengineover

afewtimesthatenginerunseasily.Cleanfayingsur-

facesoncylinderondcylindercoverbywipingthem

andre-fitwithoutgasket.Tightenthefourcylinderhead

nutscrosswise.

Exhaustport

Inordertocleantheexhaustport,takeofftheexhaust.

Engagehighestspeedandturnengineoverbymeans

oftherearwheel(spark-plugunscrewed)tillpiston

reacheslowestpoint.Inautomaticmodelspossibleonly

bymeansofstartingdevice.Coutiouslyremoveoilcar-

bonfromexhaustport;takecarenottodamagepiston

orcylinderworkingsurfaces.Whencleaningtheexhaust

portitwillbepracticalalsotocleantheexhaustmuffler

(seefollowingchapter).

3—8 MAINTENANCEANDSERVICE

!!!}}):!'-»>llllUJll>l.im))nmn„:»,lM>»

K>.

•

',.

n|i

|||ff|^

"®^(K

Fig.

7a

MAINTENANCEANDSERVICE3—9

3.3.3Cleaningtheexhaustmuffler

It

isadvisabletocleantheexhaustmufflerafterhaving

cleanedtheexhaustport.

Dismantleanddisassembleexhaustmuffler:

Cleanexhaustpipebymeansofspecialbrushprovided

forthispurpose.Oilcarbondepositsmustberemoved.

Inthecaseoftherectangularexhaustmufflerfittedunder

theengine,stripandcleanonlyexhaustpipes.Inthe

caseofthelonglaterallymountedexhaustmufflers,

disassemblethemufflerafterscrewingoffthecentral

mufflerfastening.

Usea scraperforremovingtheoilcarbondepositsfrom

themufflerinside.

Oildepositsonfasteningdeviceandinthepipesofthe

after-silencermustcarefullyberemoved.Ifnecessary,

renewgaskets.

Wewarnagainstmodifyingthesilencerinside,especially

againstremovingthebaffleelements.Thiswouldonly

reduceengineoutputandraisefuelconsumption.Itisby

nomeanstruethatbydoingsooneachievesa higher

engineperformance.Moreoverchangesarelegallyfor-

bidden,

asthemodelhasbeenlicensedonlywiththe

originalmufflersonit.Incaseofalterations,boththe

ownerofthevehicleastheonewhoactuallycarried

throughthealterationareliabletoprosecution.

3.3.4Cleaningtheairfilter

Changefilterinmodelswithdryfilter.

Locationandaccessibilityoftheair

filter

ore illustrated

onthedatasheetattachedtothisbooklet.

This manual suits for next models

2

Other Puch Scooter manuals