FCS300-R-2G-H (163-03535)

Complete Manual Conformal Coating System

Thank you for purchasing the coating system from PVA. Before attempting to

operate the unit, we recommend that you take a few minutes and read the following

operation and setup manual. This will assist in familiarizing you with the product and

ensure a successful installation.

As always, if any questions or problems arise, do not hesitate to contact PVA’s

Service Department for support. This department can be reached at PVA headquarters by

telephone at (518) 371-2684.

Again, thank you for your purchase, and we look forward to assisting you in the

future as you continue to improve your dispensing processes.

Theory of Operation

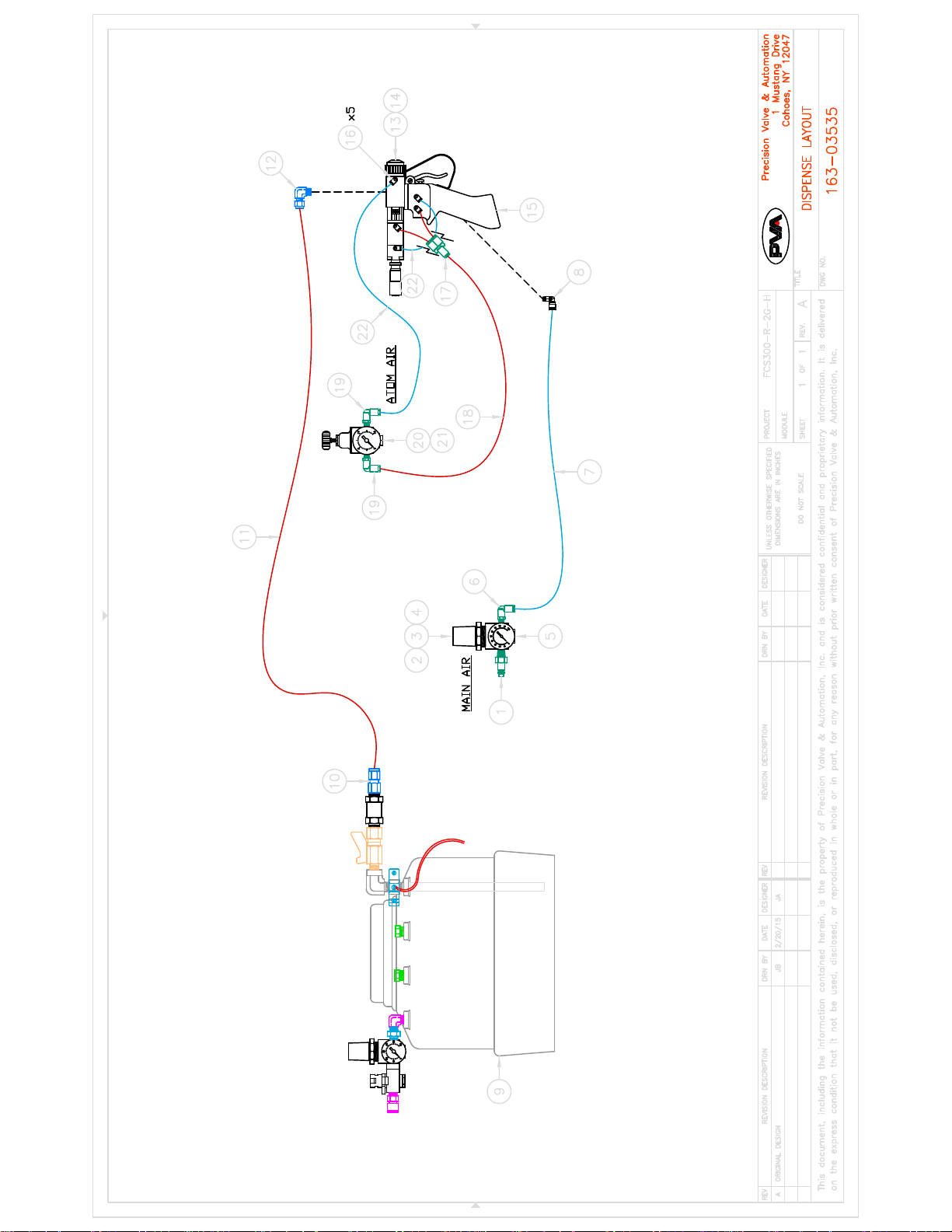

This manual conformal coating system is designed to allow operators to utilize

PVA’s high quality spray valve technology in a hand held applications. The system

utilizes a 2-gallon stainless steel pressure tank to hold fluid that can be placed on a bench

top or on the floor to feed the valve. An FCS300-R spray valve is mounted to a pneumatic

trigger handle which allows the operator to easily articulate the valve over the part and

utilize the trigger activate the spray.

When the trigger is depressed, the valve will activate to begin fluid flow and

simultaneously turn on the atomizing air in order to spray the coating to the substrate. As

soon as the trigger is released, the flow of fluid and atomizing air will cease.

The system is designed with Stainless Steel components and a UV safe, Teflon

fluid line to provide the greatest level of compatibility with a wide variety of fluids.

Chemistries that can be used in this system include, but are not limited to Acrylics,

Urethanes, Silicones, Epoxies, Solvent basted coatings, etc.

All wetted components of the system include:

- 303, 304 stainless steel

- Teflon

- Kalrez