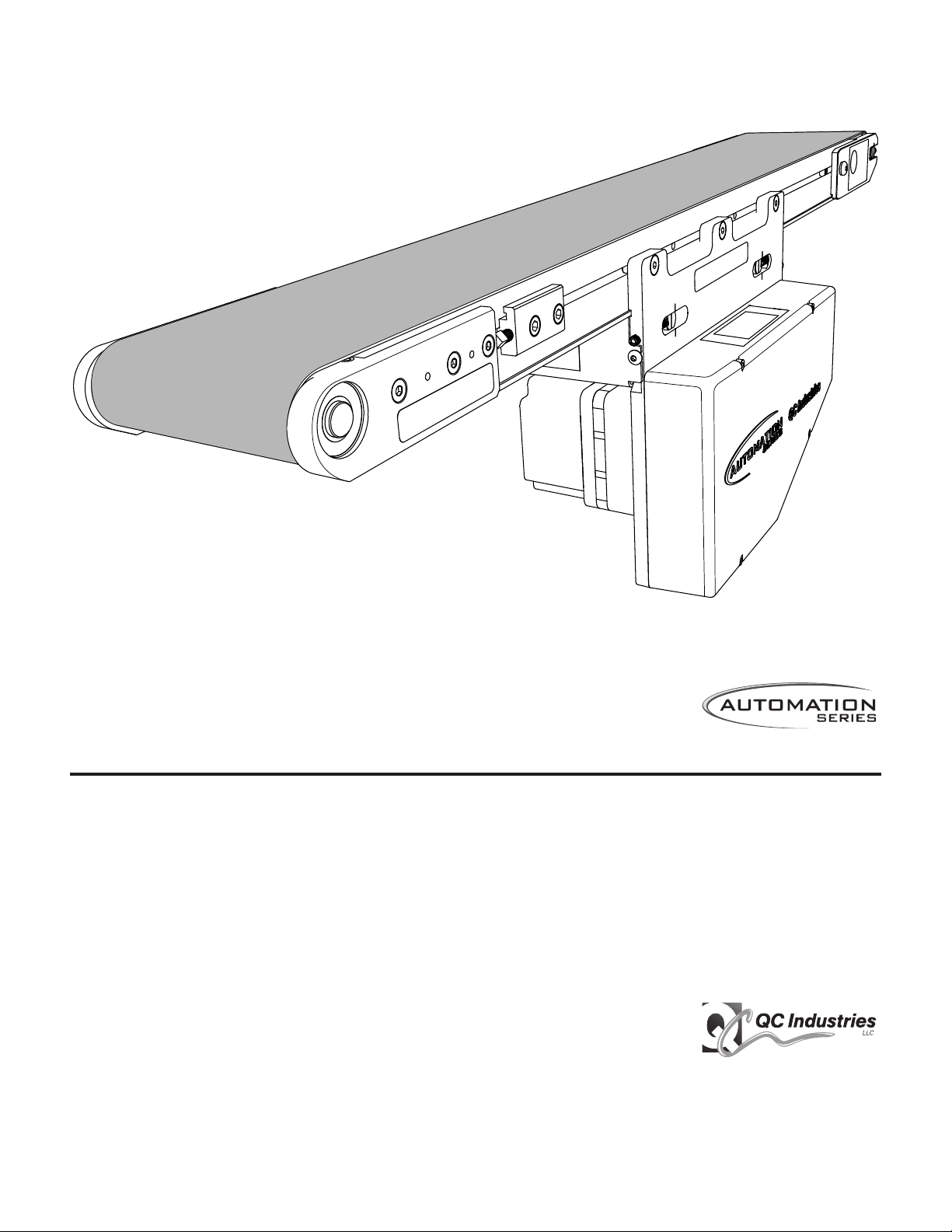

QC Industries Automation Series Installation and operating instructions

AS65 Conveyors

Installation & Maintenance Instructions

QC Industries, LLC

4057 Clough Woods Dr.

Batavia, OH 45103 USA

+1 (513) 753-6000

qcconveyors.com

Contents

Warnings 2

Tools 3

Installation 4

Maintenance 11

Recommended Spare Parts 18

Troubleshooting 19

Exploded Views 20

Warranty Information 29

Service Record 32

2AS65 Conveyors | Installation & Maintenance Instructions

Warnings

When used improperly, conveyor

rollers can pinch or maim

Lock out power before servicing

conveyor

Do not use with guards removed Read this manual before operat-

ing

DANGER WARNING WARNING WARNING

Climbing, sitting, walking or riding

on conveyor at any time will cause

severe injury or death

Exposed moving parts can cause

severe injury; DISCONNECT

POWER before removing guard

Equipment may start without

warning - can cause severe injury.

KEEP AWAY

Servicing moving or energized

equipment can cause severe

injury LOCK OUT POWER

AS65 Conveyors | Installation & Maintenance Instructions 3

Tools

uRequired Tools

Set of Metric Wrenches (3mm-

13mm)

Tape Measure 10" Adjustable Wrench Screw Gun and T-30 Torx Bit

Aluminum cutting hack saw or

equivalent

Set of Metric allen wrenches

(3mm, 4mm & ball head 5mm)

Bubble level

uOptional Tools

3/8" Torque wrench QC Industries bearing removal

tool (part# 1A0077A)

Electric Chop Saw

4AS65 Conveyors | Installation & Maintenance Instructions

Installation

uCheck Your Shipment

Before opening the shipment, visually inspect the outside of the crate/box for shipping damage. Carefully unpack the crate/box, inspecting for component damage which

may have occurred inside the packing materials. Contact the carrier and QC Industries regarding any damage that may have occurred during shipment. Check the contents

of your shipment against the supplied packing slip and inform QC Industries of any discrepancies.

uGeneral Sequence of Installation

1Mount conveyor to stands or

compatible mounting brackets. 2Attach sides, guides or un-

derside idlers to conveyor and

adjust as needed.

3Install drive motor to mount-

ing package. (If not already

installed)

4Lag conveyor to floor / engage

caster locks and inspect

conveyor before use.

uAssistance

If you need assistance, please contact QC Industries customer service department Monday through Friday, 8am-5pm EST at (513) 753-6000. In addition, your local dis-

tributor has been trained at the factory and can provide support in many ways. You can also visit our website - qcconveyors.com - for additional information and technical

documents.

AS65 Conveyors | Installation & Maintenance Instructions 5

Stand Installation

Mounting Aluminum Stands to Conveyor

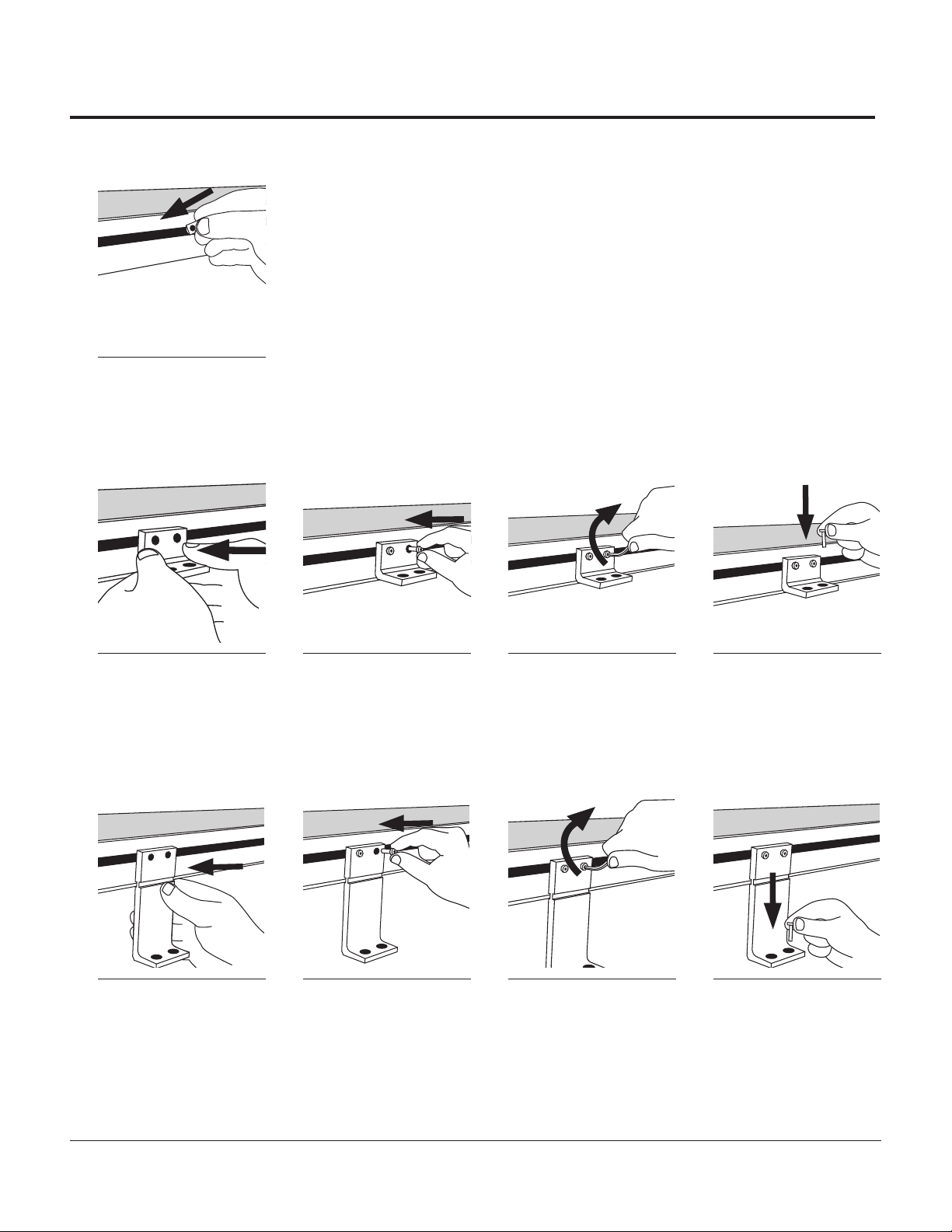

uMounting Aluminum Exact Width Stands

Stands should be placed as close to ends of conveyor as possible. Stands may be placed a maximum of 10’ apart for conveyors 6” wide or less with a load less than 20

lbs,; conveyors 8”-12” wide with a load less than 25 lbs.; conveyors 18”-24” wide. For all other conveyors, stands should be placed a maximum of 6’ apart.

1Remove the nuts holding the

stand attachment brackets to

the top of the stand and remove the

brackets.

2Insert drop in nuts into t-slot

on conveyor frame. 3Attach stand attachment

brackets to conveyor using a

5mm allen wrench.

For Conveyors 6” wide or less:

flange should point outboard;

spacer must be installed between

stand attachment bracket and

conveyor frame.

For conveyors more than 6” wide:

flange should point inboard; no

spacer is necessary

4Place stand attachment

brackets atop stands.

5Replace nuts and tighten.

6AS65 Conveyors | Installation & Maintenance Instructions

uStand Height Adjustment

1Loosen four screws in each

stand bracket using a 5mm

allen wrench.

2Adjust stand height by

turning bolt using a 3/4”

wrench. Turn clockwise to lower or

counter-clockwise to raise. Ensure

conveyor is level.

3Tighten jam nut against top

plate of stand. 4Tighten four screws in each

stand bracket using a 5mm

allen wrench.

uInstalling Cross Ties

For applications using a single cross tie, the cross tie should be installed between the cross bars of the stands. For applications using two cross ties, the cross ties should

be installed between the uprights of the stands.The installation process is the same for each.

4

x2

x

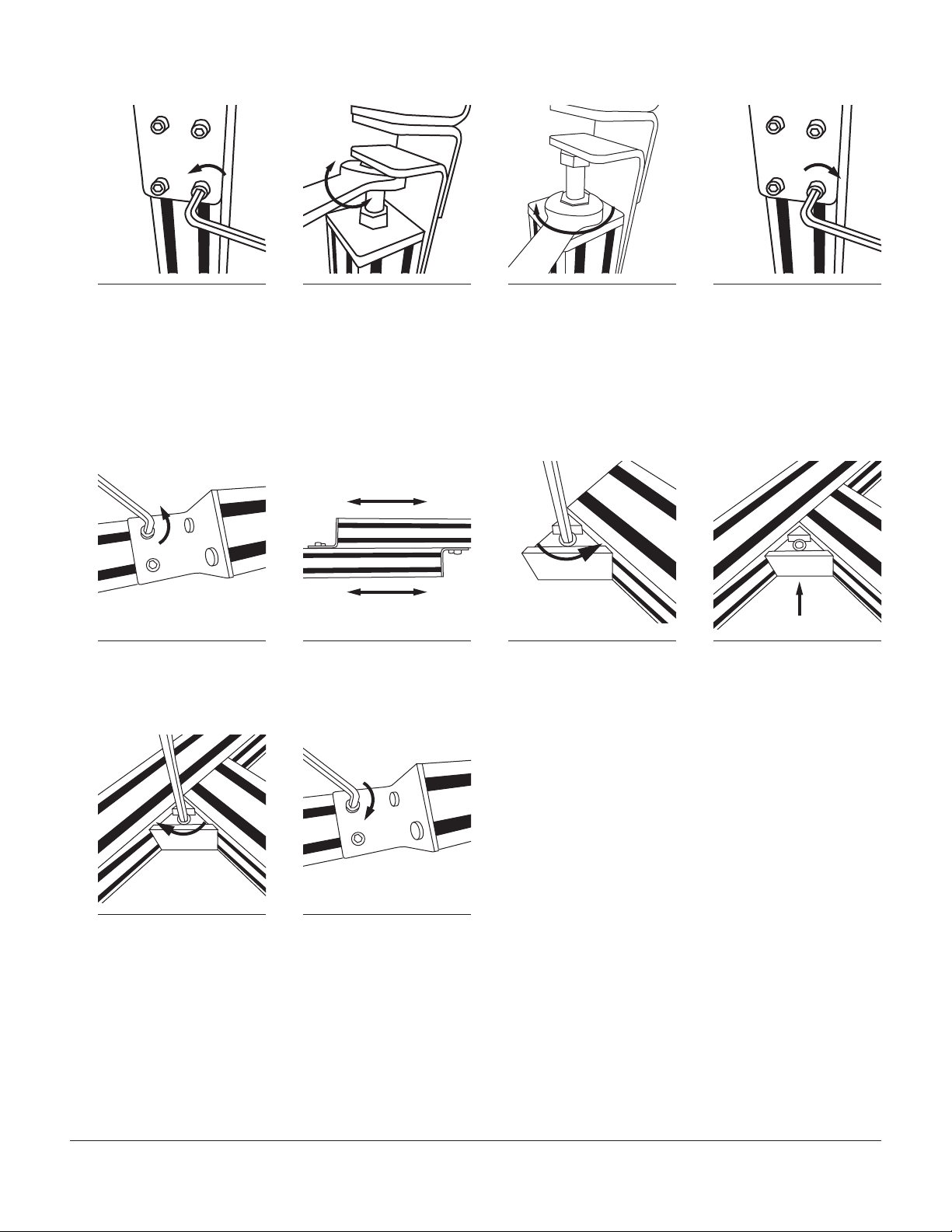

1Using a 5mm allen wrench,

loosen two socket head cap

screws in each cross tie adjustment

plate.

2Slide adjustable cross tie

pieces to fit between stands. 3Loosen triangular Quick Clamp

on each end of cross tie. 4Ensuring the socket head cap

screw is facing you, slide Quick

Clamp into tee slot at desired mount-

ing position.

4

x

5Using a 5mm allen wrench,

tighten Quick Clamp. 6Using a 5mm allen wrench,

tighten two socket head cap

screws in each cross tie adjustment

plate.

AS65 Conveyors | Installation & Maintenance Instructions 7

uMounting Angle Braces

2

x2

x2

x

1Insert two drop in nuts into

inner stand leg t-slots. 2Insert drop in nuts into

conveyor frame’s t-slot. 3Align angle brace over drop

in nuts in stand. 4Insert socket head cap screws

through angle brace and into

drop in nuts on stand (do not fully

tighten).

2

x

2

x

2

x

5Slide up and align angle

brace with drop in nuts in

frame.

6Insert socket head cap screws

through angle brace and into

nuts in conveyor frame.

7Tighten socket head cap

screws on frame. 8Tighten socket head cap

screws on stand.

9Check with bubble level to

ensure conveyor is level.

>Repeat for opposite side.

Injury is possible if the stands are not lagged to the oor, cross ties are not used, or angle braces are not present. Never place a conveyor in operation until all proper

mounts are installed and secured.

Warning: Moving conveyors with casters can create dynamic forces that could tip the conveyor. Use caution when moving a conveyor with casters.

8AS65 Conveyors | Installation & Maintenance Instructions

Mount Installation

Ensure mount placement on mounting surface allows clearance for drive package.

2

x

1Insert drop in nuts into t-slot.

>Proceed to correct mounting type.

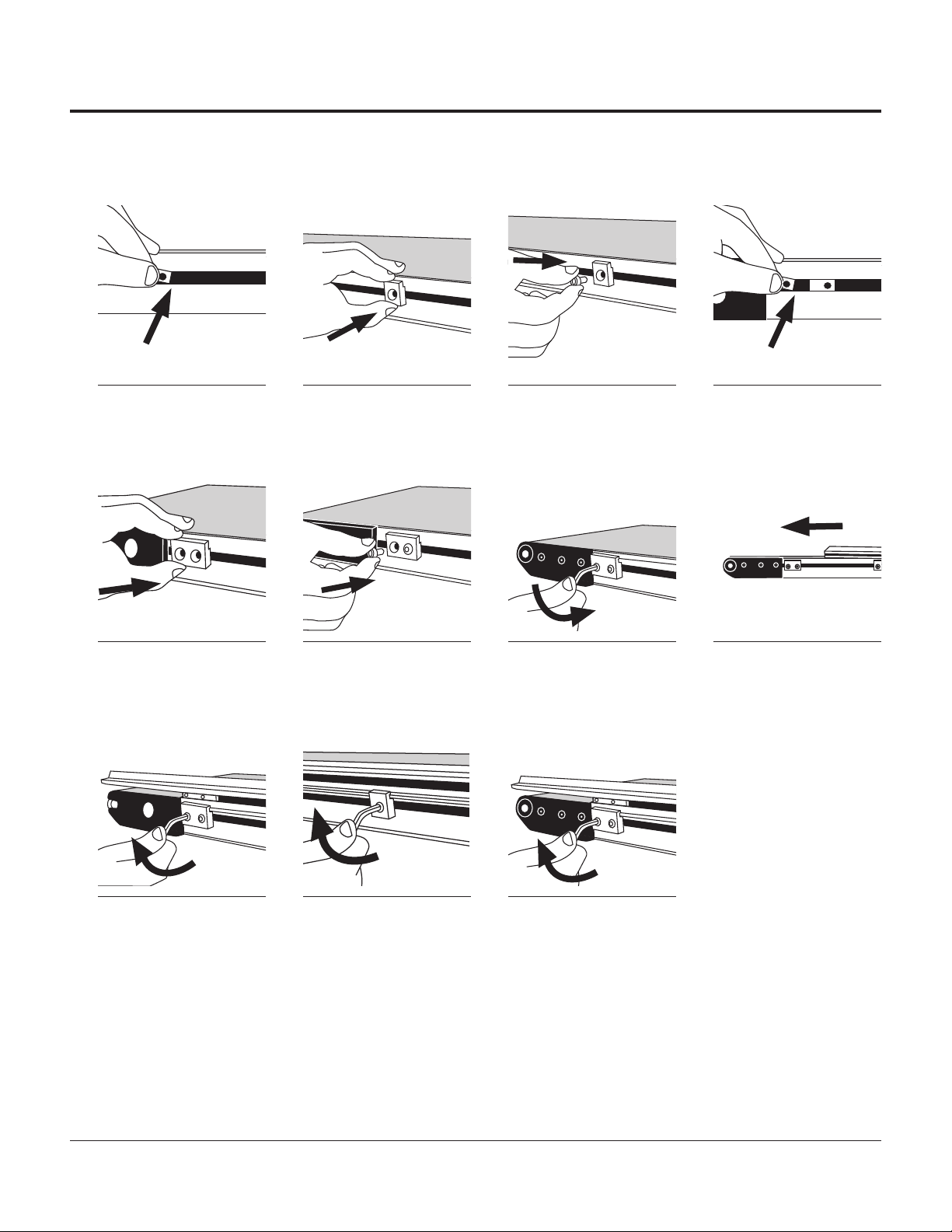

uFlush Mount

2

x2

x2

x

1Line up mount to drop in nuts. 2Insert socket head cap

screws through mount and

into drop in nut.

3Tighten screws to secure

mount to frame. 4Insert screws (not provided)

into desired mounting surface

and tighten.

uRaised Mount

Mounts’ foot can be placed facing inward or outward depending on application.

1Line up mount to drop in nuts. 2Insert socket head cap

screws through mount and

into drop in nut.

3Tighten screws to secure

mount to frame. 4Insert screws (not provided)

into desired mounting surface

and tighten.

AS65 Conveyors | Installation & Maintenance Instructions 9

Side /Guide Installation

Guide brackets can not be placed over drive assembly mounting brackets.

uInstalling Fixed Side Rails

2

x

1Insert drop in nuts into t-slot

on frame. 2Align guide brackets with

drop in nuts. 3Insert socket head cap screw

through guide clamp and into

drop in nuts.

4insert two drop in nuts into

t-slot at tail end of frame.

2

x2

x

5Align clamping block to drop

in nuts. 6Insert screws through clamp-

ing block and into drop in

nuts.

7Loosen tracking block screws.

(Do not remove) 8Slide guide rail in between

clamps and frame until in

place.

2

x2

x

9Tighten screws in clamping

blocks. 10Tighten screws in guide

clamps. 11Retighten screws in track-

ing block.

If sides have seals, speed of conveyor should be no faster than 30 feet per minute.

Side seals are designed for use with MAA Standard Urethane Belts.

10 AS65 Conveyors | Installation & Maintenance Instructions

uInstalling Adjustable Guide Brackets

2

x

1Insert economy nuts into

t-slot of guiderail and slide

into position

2Loosely thread adjusting rod

into nuts. 3Place a cross block onto

each guiderail and set aside. 4Insert drop in nuts into t-slot

on frame.

2

x

2

x

5Align guide bracket, keeping

the larger hole up, with drop

in nuts and insert screws.

6Tighten socket head cap

screws. 7Insert a rod vertically through

the larger hole on top of

guide bracket.

8Secure rod from below with

socket head cap screw.

9Tighten cap screw. 10Slide guiderail assembly

over vertical rods on

frame.

11Adjust guides to desired

width and tighten rods. 12Tighten screw on cross

block to secure rod.

13Install guiderail and block

assembly over vertical

rods and adjust to desired height.

(Guide should NOT touch belt)

This manual suits for next models

1

Table of contents

Other QC Industries Accessories manuals