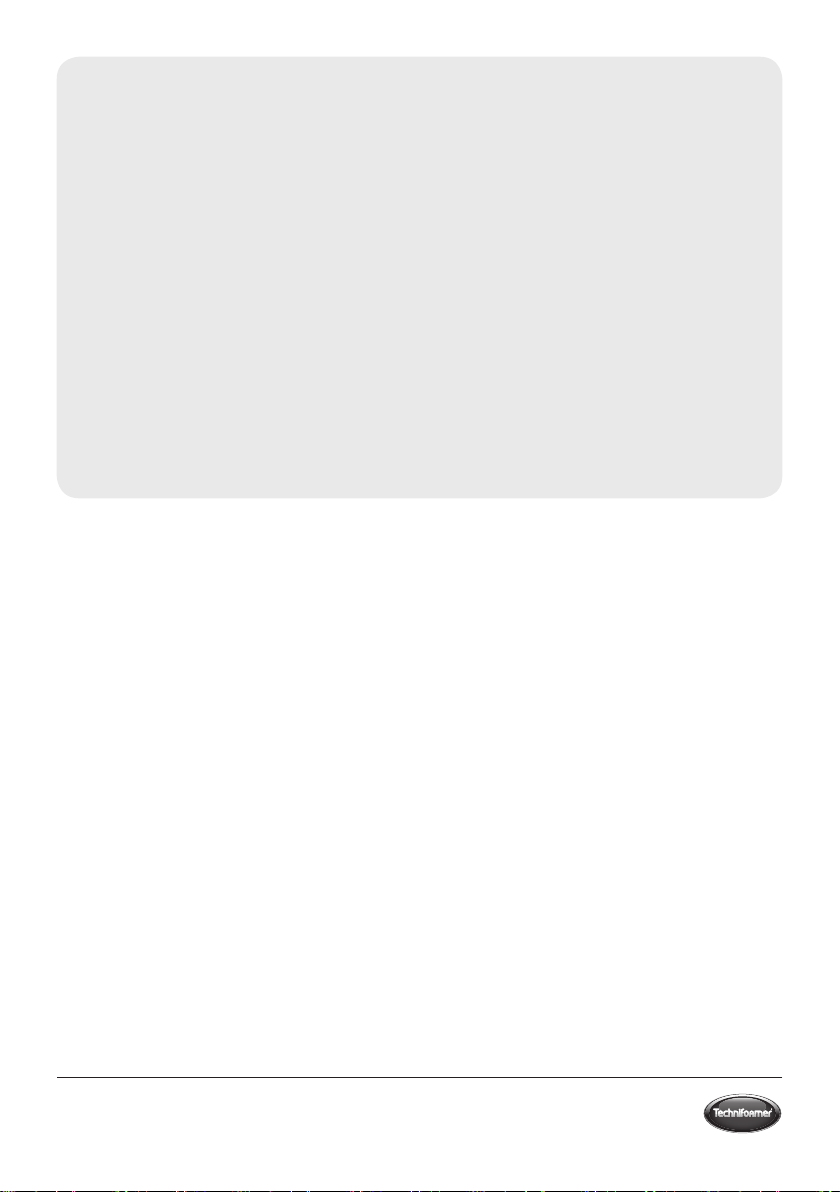

POSITION DESCRIPTION ORDER CODE

1 Technifoamer StSt Foam Outlet Hosetail 9188

2 1/2 St St Equal Tee 9115

3 3/8 Hose Tail - 1/2BSP PP 9198

4 Reducing Bush 1/2M-1/4”F Polypropolene 9084

5 1/4m - 6mm push fit elbow 9421

6 Technifoamer Filter Regulator* 9285

7 1/4 St St Ball Valve (TF Air Inlet) 9287

8 1/4-1/4 SS LP Adaptor 9000T

9 G57 Series Port Kit, 10/13 mm (3/8) Barb, Viton 9167

10 12mm Blue ChemTube Pick Up 11cm 9096

11 Technifoamer Blue Chem Tube 20cm 9095

12 Technifoamer Blue Chem Tube 24cm 9094

13 TF40 6mm tube kit 9413

14 Technifoamer Air Diaphragm Pump Viton* 9147

14 Technifoamer Air Diaphragm Pump Santoprene* 9129

15 Technifoamer StSt Needle Valve 9119

16 Technifoamer 8mm Tube Kit 9177

17 6 x 6 x 8mm push fit tee 9442

18 Technifoamer Non Return Valve* 9117

19 1/4m - 6mm push fit adaptor 9425

20 3/8 Stainless steel chemical suction strainer 1854T

21 POM Bulkhead Fitting 9168

22 Viton 75 Washer 32mm x 13mm x 1mm 9246

23 M16 A2 Stainless Steel Half Lock Nut 9247

24 Technifoamer Hygienic Wheel 9186

25 1/2 st st twist grip valve 9410

26 Technifoamer 40 st st axle 9402

27 Technifoamer Lid Ring 9182

28 Technifoamer Basket Filter 9183

29 Technifoamer Lid 9184

30 Technifoamer 40 red tank 9404

30 Technifoamer 40 blue tank 9403

31 Technifoamer 40 handle 9289

32 Stst oclip 22-25 0585B

33 Technifoamer 10m Red Foam Hose* 9194

33 Technifoamer 10m Blue Foam Hose* 9192

34 Technifoamer Valve Hose Tail 9191

35 Technifoamer Foam Valve* 9189

36 Technifoamer 200mm Foam Tube 9190

37 Technifoamer 65150 3/8 St St Nozzle 8043

6

3SPARE PARTS

* Wearing parts