bluechem Clear Flow User manual

CLEARFLOW - AIR

INTAKE & INJECTOR

CLEANING 2000X

INSTRUCTIONS

CLEARFLOW - AIR INTAKE & INJECTOR CLEANING 2000X INSTRUCTIONS

Made in Germany now in Australia. www.bluechemaustralia.com.au

The bluechemGROUP has developed a completely new chemical formulation for air

intake and injector cleaning in its own in-house laboratory. Modern compact direct injection

engines, equipped with both a turbocharger and exhaust gas recirculation, are becoming

more common as they meet the current customer demand, for adequate performance

while at the same time complying with current emission standards. However, the

disadvantages of this technology include stubborn deposits i.e. carbonization. Which

accumulate in the combustion chamber, intake and the exhaust system. This results in

poor performance, higher fuel consumption and increased emissions.

TRIPLE X PLUS used with CLEARFLOW - Professional Cleaning is the solution to this

problem. Before the vehicle owner has to deal with costly repairs. This is exactly why

TRIPLE X PLUS was developed. With only one application, the product reduces all

operational deposits in these areas. This is provided by performing a complete cleaning of

the air intake system leading up into the combustion chamber and exhaust. This special

new chemical formulation allows for application in both diesel and petrol engines. Ensuring

smoother engine running, low emissions, powerful performance and reduced fuel

consumption.

What has to be considered before applying?

Read the instructions thoroughly and acquaint yourself with the CLEARFLOW. Watch the

video on our website before you start. www.bluechemaustralia.com.au

Inspect EGR.

If the EGR Valve is over 30% blocked with carbon, please remove the EGR and clean off

vehicle to avoid Diesel Engine run on (Pre- ignition) Run on in a Diesel is when engine

Rev’s uncontrollably rise during application due to carbonization in the EGR Valve taking

over from the Diesel Fuel. You must remove EGR and clean with CARBON X (34140) for

the run on to be minimalised.

Air Intake Cleaning - What engine temperature is required?

TRIPLE X PLUS requires surface heat to achieve best results. Start the cold engine and

let it idle for 10 minutes. Then stop the engine and apply Oil System Cleaner (P/N 33018)

into the engine at operational temperature. You will be required to do an Oil change upon

completion. Run for a further 5 minutes then commence the cleaning procedure with

CLEARFLOW AIR INTAKE.

Further steps are recommended before and the after the CLEARFLOW AIR INTAKE

CLEANING.

We recommend the use of these in tank technical fluids as below for best results.

COMMON RAIL SYSTEM CLEAN & PROTECT (P/N 33098)

FUEL SYSTEM CLEANER Unleaded (P/N 33028)

OXICAT Petrol or Diesel Dissolves resin, gum and carbon deposits while driving. (P/N

33230) before using the CLEARFLOW and after for heavy contamination. Further steps,

clean the Air Flow Sensor (P/N 35006) and Throttle Body Plate (P/N 37012)

Air intake cleaning procedure (recommended every 20 - 30,000 KM)

Use in a well ventilated area or use exhaust recovery device.

Set up 1. Run the engine to normal operating temperature, switch off and pull on the

hand brake. (Making sure you have used Oil System Cleaner (P/N 33018) before

commencing.)

2. Open the intake system as close as possible to the throttle body chamber, Especially for

diesel engines.

3. Close valve 7 and fill the CLEARFLOW with the TRIPLE X PLUS.

4. Before installation connect an airline and adjust pressure to 30 PSI. With the S-PIPE

valve closed. The S-PIPE can be fitted to either of the outlets, 5 or 6

5. Open valve 7, make sure that there is a fine mist from the S-PIPE into a bucket. Do not

adjust the pressure over 30 PSI. If the product is not atomising correctly, clean the S-PIPE

internal mesh filter and re-check for a fine mist.

6. Installation –Shape & fit the S-PIPE adaptor pointing towards the throttle body, (not to

interfere with the throttle body plate 2 - 3cm away.) SEE PAGE 7

7. Hang the CLEARFLOW with bonnet hook 10. Make sure that the S-PIPE is securely and

safely positioned at the air intake area by the existing entry point i.e. hose clamp

externally. Or physically held in position to the throttle body by the operator.

Be aware of the throttle body plate angle, so the fine mist has a clear unobstructed

entry past the throttle body plate.

8. Start the engine, rev to 2000 - 2500 rpm (2nd person for diesel) to make sure there is

enough intake suction.

OPERATING PROCEDURE

PETROL ENGINE: You can use an accelerator tensioner, rev to 2200 - 2800 rpm, switch

on the valve 7 (2-3 min.) and off (2-3 min.) until the liquid is finished.

DIESEL ENGINE: (2nd person is required for diesel to hold and adjust the rev’s at 2000

RPM during application.) To start, switch on the valve 7 for (1-3 sec) and off (3 -5 sec) for

1 minute. This is to confirm how much carbonization in the EGR exists.

If the engine RPM starts too uncontrollably rise close valve 7 and wait until the

engine runs normal again.

When the engine is running without RPM dramatically increasing with valve 7 open,

increase valve on to (5-10 sec) on and off (10 - 20 sec) appropriately.

If the engine RPM starts to uncontrollably rise and pre ignition occurs, close valve 7

and wait until the engine runs normal again, by reducing dosage interval.

- LESS IS MORE!

CLEARFLOW - AIR INTAKE & INJECTOR CLEANING 2000X INSTRUCTIONS

Made in Germany now in Australia. www.bluechemaustralia.com.au

If this continues remove EGR and clean with CARBON X (34140) for run on to be

minimalised.

Once you have applied for 3-4 minutes in total with valve 7 open, close the valve and let

the RPM remain at 1500 RPM for 5 minutes. (This is PRE SOAKING the Diesel carbon for

improved results)

9AIR INTAKE - PETROL & DIESEL. Continue the procedure until all of the TRIPLE X has

been applied through the S-PIPE adaptor. Close valve 7 and leave the engine to idle for 10

minutes DO NOT REV THE ENGINE OVER 2000RPM WHILE STATIONARY.

10. Turn off the engine.

11. Remove the airline. Open valve 7. Release the pressure in the CLEARFLOW with the

valve at the back of the regulator.

12. Remove S-PIPE adaptor from the CLEARFLOW.

13. Remove the S-PIPE from the vehicle.

14. Precaution - Check for any fluid / obstructions in the air intake, intercooler and arches.

(If so Throttle Plate angle has obstructed the mist clean and re-apply.) Refit all parts to

normal operation.

15. Re-start the engine and take the vehicle immediately for a 5 to10 minute test drive until

exhaust fumes are clear.

16. Upon completion of test drive check ECU for fault codes and clear.

17. Perform an oil change due to the additional carbonfrom the Air Intake cleaning.

CLEARFLOW - INJECTOR CLEANING PETROL / DIESEL

CLEARFLOW - Common Rail injection systems. / Petrol Direct Injection engines equipped

with oxygen sensors, catalytic converters or fuel injection.

CLEARFLOW will improve • Loss of efficiency • Higher fuel consumption • Hesitation of

response • Excessive smoke emissions • Increased air flow at the intake valve and better

mixture of air and petrol.

CLEARFLOW INJECTOR CLEANING TECHNICAL FLUIDS USED

FUEL SYSTEM CLEANER Unleaded (P/N 33028)

DIESEL SYSTEM SUPER CLEAN Diesel (P/N 33398)

The CLEARFLOW becomes the vehicles fuel supply only. SEE PAGE 6

CLEARFLOW INJECTOR CLEANING - Petrol or Diesel. Use in a well ventilated area or

use exhaust recovery device.

Apply to the fuel tank.

1 X FUEL SYSTEM CLEANER UNLEADED (P/N 33028) or

1 x COMMON RAIL DIESEL SYSTEM CLEAN & PROTECT DIESEL (P/N 33098)

1 X OXICAT PETROL or DIESEL (P/N 33230)

1. Start the engine run to operating temperature, switch off and pull on the hand brake.

2. Disconnect the fuel lines from the tank to the motor at a suitable place. SEE PAGE 6

3. If the tank supply has a return line, using the correct adaptor (supplied) loop and return

to the tank. Alternatively, the fuse or relay can be removed, shutting off the fuel supply to

the in tank pump. Typically this is easily done at the fuel filter.

4. Fit the correct connectors for the vehicle from the fitting kit, on the supply and return if

applicable.

5. Close valve 7 and fill the CLEARFLOW with the correct technical fluid for the vehicle,

(see product recommendations.) Open Valve 7 to purge the air from the line, close Valve 7

6. Hang the CLEARFLOW safely with the hook 10, on the open bonnet.

7. Connect the terminals 5 or 6 with the adapters to the fuel injection system. Connect an

airline and adjust the pressure to 30 PSI pre starting. Check for any leaks.

8. Start the car and adjust the pressure until engine has a smooth idle. The pressure from

the airline has to be equivalent to or slightly more than the fuel pressure regulator on the

return of the fuel rail to obtain a smooth idle. (Adjust Air regulator 9.) Once idles correctly

then use an accelerator tensioner to adjust between 2200 rpm to 2800 rpm.

9. Allow the engine to run until you see the clear inspection tube emptying, once the fuel is

finishing in the tube, the engine should be switched off immediately. Close valve 7.

10. Remove the compressed airline, Release the pressure in the CLEARFLOW unit with

the release valve 2 at the back of the regulator. Before removing fittings De-pressurize the

entire CLEARFLOW. Open valve 7. Disconnect the CLEARFLOW and fittings.

11. Refit all parts to normal operation, and perform a test drive.

12. Upon completion of test drive check ECU for fault codes and clear.

13. Change the fuel filter especially for Diesel.

These further steps are recommended after the Injector Cleaning?

For optimal results, clean the air intake system pre turbo using Fuel Applicator Spray

(P/N 33139) or Diesel Applicator Spray (P/N 33149) This will remove oily residue from the

Turbo, or a subsequent intake system cleaning with Triple X PLUS (33648) using the

CLEARFLOW and S-PIPE Adaptor (Product Data Instructions)

www.bluechemaustralia.com.au/technical-data/msds/

CLEARFLOW - AIR INTAKE & INJECTOR CLEANING 2000X INSTRUCTIONS

Made in Germany now in Australia. www.bluechemaustralia.com.au

DISCLAIMER

By misuse of the application, every kind of warranty has to be refused. The

Manufacturer shall not be liable for failures or other consequences deriving from

incorrect procedures on the part of the user.

Never leave the vehicle unattended while using the CLEARFLOW.

Use the CLEARFLOW AIR INTAKE equipment with TRIPLE X PLUS (P/N 33648) only.

INJECTOR equipment with FUEL SYSTEM CLEANER Unleaded (P/N 33028) or

DIESEL SYSTEM SUPER CLEAN Diesel (P/N 33398) only.

SAFETY PRECAUTIONS

•Maximum operating pressure CLEARFLOW: 8 Bar-116 PSI.

•Cleaning of the air intake only at 2500 RPM DIESEL & 2800 RPM PETROL

•Regularly check all hoses and valves for wear or damage and replace as necessary.

•Make sure all connections are tight and secure before connecting the system to

pressured air supply.

•After use, release the pressure through air regulator. Make sure that hoses do not touch

hot or moving parts of the engine.

•Regularly check condition of the fuel filter in the aluminum cylinder. You may clean the

system by applying pressured air in the counter-flow direction.

1. Avoid spilling product on the painted surfaces. If spillage does occur,

immediately flush with water.

2. Use in a well ventilated area or exhaust recovery device.

3. The fuel system on the vehicle must be leak-tight.

4. Also check if there any leaks at the connections before starting the treatment.

5. Do not leave the engine unattended when operating with the product.

6. Do not smoke during treatment.

7. Protect the hot parts (and the parts which will be hot with the engine running)

from splashes of product or Petrol which might occur.

8. In case of fire, immediately shut of the CLEARFLOW and the car’s engine.

9. This device was designed for the specified purposes. Please read carefully the

safety sheet and follow its instructions. This device was designed specifically for

the given materials. Please contact our technical support if advice is needed.

10. Should any product be taken or swallowed, please refer to the MSDS sheet. All

11. MSDS sheets are available for download at www.bluechemaustralia.com.au

TROUBLESHOOTING –why use the CLEARFLOW?

•Sticky valves, performance loss, irregular idle running, high fuel consumption Use the

Clear Flow device with FUEL SYSTEM CLEANER for petrol engines or DIESEL SYSTEM

SUPER CLEAN for diesel engines connected to injection.

•High fuel consumption, poor response, too high emission level Use the CLEARFLOW

device with TRIPLE X PLUS connected to the air intake.

•Engine speed too high during use on injection Recalibrate the accelerator tensioner or

reduce the air pressure using the regulator 9. If no change stop the engine and close

valve 7.

•Engine speed too low during use on injection Recalibrate the accelerator tensioner or

increase the air pressure using the regulator 9.

•Engine running harder during use. This is normal for the application.

•Engine continues to run, despite the ignition is off. Brake, turn into the first gear and

declutch if manual. Or turn ignition key on and off twice to close throttle body.

Safety Equipment.

Outside of normal O H & S equipment which should be used within the workshop, we

recommend that the following be used whilst using the CLEARFLOW. • Safety Glasses •

Gloves • Overalls, any product should be removed immediately if it comes into contact with

skin. Have a fire extinguisher nearby (suitable for fuel).

Product Data Instructions and Material Safety Data Sheets (MSDS) are available from our

website - www.bluechemaustralia.com.au/technical-data/msds/

ENGLISH

INTRODUCTION

The Clear Flow is a cleaning device for cleaning injector valves and nozzles which

are contaminated orgummed with resin. Additionally, problems caused by carbon

deposits oninlet or outlet valves can be solved lastingly. With the appropriate

of petrol engines.

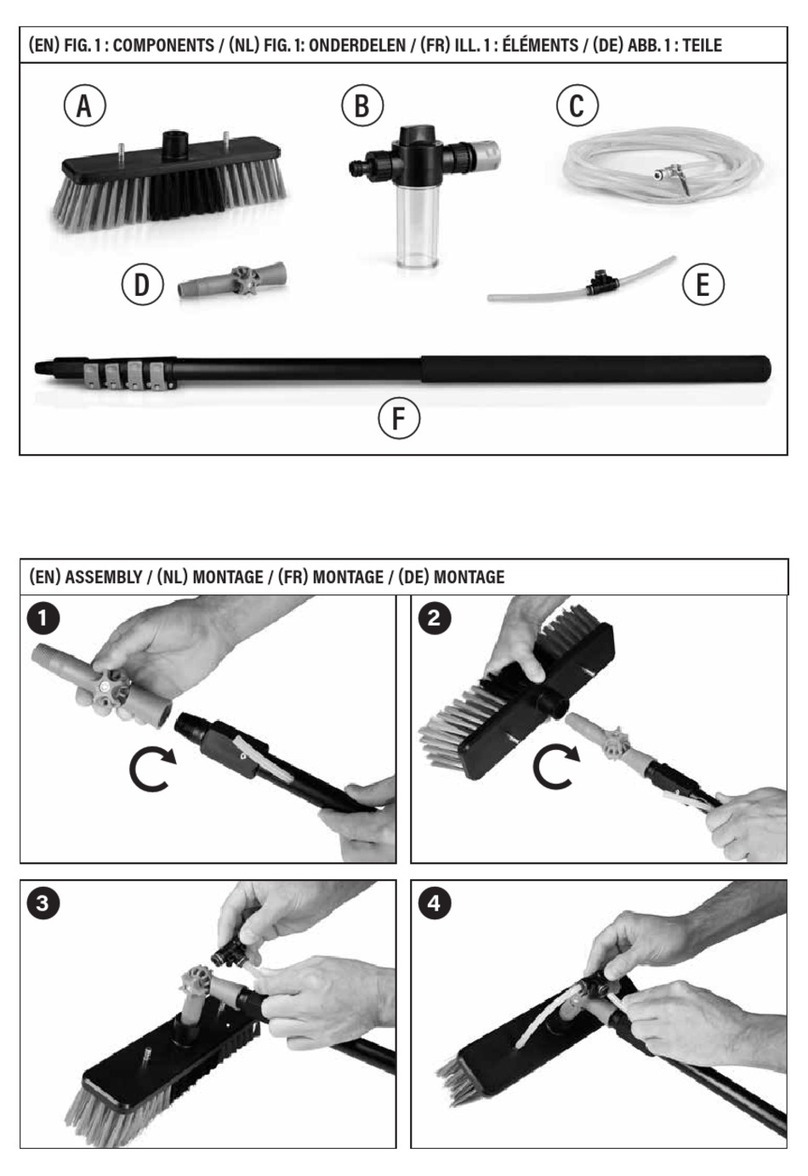

STRUCTURE

1. High pressure intake

2. Pressure meter

3. Can top

4. Pipe

5. Fuel return hose joint

6. Fuel supply hose joint

7. Fuel supply valve

8. Can body

9. Pressure regulator

10. Hook

1

2

3

4

5

6

7

8

9

10

ENGLISH

APPLICATION

1.Application diagram of Clear Flow Machine

Engine

Return

hose

Connect to supply & return hose

using bypass hose or stoppers

Supply

hose Filter

Fuel pump

Return hose

Note:

• For vehicle without return hose, only connect to the supply hose, remove the fuel pump fuse.

• For diesel car connect the feed and return fuel line (because of high pressure fuel tank pump), connect 6 and 7 of the

Clear Flow Machine to supply and return lines of the injector pump and adjust to the correct air pressure on the Clear

Flow pressure meter 2.

OPEN

CLOSE

Supply hose

Connect to air

compressor

Adjust the correct

air pressure

The pipe can be bent to suit the position for Air

Intake Cleaning. (as below)

Insert nozzle into the steel hose.

Nozzle facing toward Throttle Body 3cm away

from Plate.

AIR INTAKE CLEANING –ADAPTOR

TRIPLE X PLUS

Triple X plus can be used on all engines equipped

with oxygen sensors, catalytic converters, DPF or

fuel injection.

• Completely dissolves and removes most stubborn

deposits •Cleans and lubricates the complete air

intake system, especially inlet valves, piston rings,

piston crown as well as the entire combustion

chamber •Ensures a powerful and smooth running

engine •Significantly optimizes fuel consumption

and exhaust emissions

Professional use only: applied solely using Air Intake

Cleaning CLEARFLOW S-PIPE with Triple X plus

P/N 33648 - 375ml

CLEARFLOW - AIR INTAKE & INJECTOR CLEANING - Fluids used with the application.

FUEL SYSTEM CLEANER

Properties of the liquid driven to injection system

Petrol engines Cleaning of • injectors

• valves and combustion chambers • fuel

distributor • pressure regulator • fuel lines and

ramps • optimum spray pattern • accurate setting

of fuel/air mixture (λ value) is possible • better

combustion and increased engine efficiency

• elimination of pinging • better cold starting

• higher compression • Bind condensed water

• allows adjustment of CO and HC values in the

exhaust gases in accordance with required

standards • lower fuel consumption • increased

injector life, valve life, and all other parts of the

fuel system • the product is harmless to catalytic

convertors and oxygen sensors.

• Treats up to 80 litres of Fuel or used with

CLEARFLOW

P/N 33028 - 300ml

DIESEL SYSTEM SUPER CLEAN

Properties of the liquid driven to injection system

Diesel engines Cleaning of • injectors

• combustion chambers • injection pump

• fuel lines Results • optimum spray patterns

• better combustion and increased engine efficiency

• less diesel knocking and engine noise

• better cold starting • lower fuel consumption and

improved engine performance • less smoke

• optimum functioning of the injection pump

• prevention of premature wear and replacement of

the injectors and pump • better acceleration

• the product is harmless to catalytic convertors,

DPF and oxygen sensors .

• Treats up to 80 litres of Diesel or used with

CLEARFLOW

P/N 33398 - 375ml

CLEARFLOW - AIR INTAKE &

INJECTOR CLEANING

Common Rail injection systems or

Petrol Direct Injection engines

equipped with oxygen sensors,

catalytic converters or fuel injection.

Mainly the CLEARFLOW will improve:

• Loss of efficiency • Higher fuel

consumption • Hesitation of

response • Bad slide and tension

behaviour • Excessive smoke

emissions • increased air flow at the

intake valve and better mixture of air

and petrol

S-PIPE

CLEARFLOW - Further steps are recommended during and the after the application.

www.bluechemaustralia.com.au

OXICAT

Applied to fuel tank Petrol /

Diesel before CARBON X

• New cleaner for the whole

exhaust system (oxygen sensor,

catalytic converter, turbo

charger and EGR as well)

• Dissolves resin, gum and

carbon deposits while driving.

OIL SYSTEM CLEANER

Applied to Engine before CARBON X

Cleaning - 300ML Treats up to 6 Litres

of Oil. (Change oil after CARBON X

Cleaning Completed)

• Removes residues on piston rings

and in the upper cylinder area.

• Reduces exhaust emissions and

improves engine performance.

• Unique cleaning action.

• Contains no simple alcohols.

• Reduces friction and wear.

• Fresh oil will be cycled through a

clean engine.

• Reduces fuel and oil consumption

• Extends the life span of the catalytic

converter.

• Treats up to 6 litres of oil

P/N 33018 –300ml

BENEFITS

Avoids OBD failure caused through

high contamination

Increases fuel efficiency and reduces

exhaust emissions

For all petrol / diesel / hybrid

engines, Treats up to 80 litres

P/N 33230 –300ml

FUEL APPLICATOR SPRAY - PETROL

• Cleans the entire air intake system

of petrol engine

• This product is vaporised and

flows though the air intake system

cleaning inlet, inter-cooler, inlet

and outlet valves and combustion

chambers • Improves smoother

engine running • Reduced exhaust

emissions • Improves fuel economy

P/N :33139 - 500ml

FUEL SYSTEM CLEANER –

PETROL

• Bind condensed water

• Ensures a clean and

powerful combustion, good

performance,

• Low fuel consumption

• Optimum values of the

exhaust emissions

• Treats up to 80 litres of Fuel

P/N :33028 - 300ml

COMMON RAIL DIESEL

SYSTEM CLEAN & PROTECT -

DIESEL

• Removes operational caused

contamination in the entire

system. • Increase of

compression pressure.

• Removal of harmful moisture.

• Total lubrication of the entire

fuel system including the high

pressure fuel pump • Increased

fuel economy & power

• Treats up to 80 litres of Diesel

P/N 33098 - 375ml

DIESEL APPLICATOR SPRAY

• Cleans the entire intake system

of diesel engines

• This product is vaporised and

flows though the air intake

system cleaning inlet, inter-cooler

EGR-valve, inlet and outlet valves

and combustion chambers

• Improves smoother engine

running

• Reduced exhaust emissions

• Improves fuel economy

P/N 33149 - 400ml

CARBON X K1 & K2

Professional use only - We present a system that specifically and

precisely removes even stubborn deposits in the cylinder head area,

in particular at the inlet and outlet valves, the piston crown and

piston top lands, thus ensuring quiet engine running, low emissions,

powerful performance and economical fuel consumption.

Remove EGR over 30% blocked with carbon, and clean off vehicle

with CARBON X (34140) to avoid Diesel Engine run on with the

CLEARFLOW before TRIPLE X. In the case of disorders or RUN ON

(DIESEL) Cleaning the EGR valve and intake manifold off vehicle.

We recommend for the removal of these components before

performing the cleaning procedure with CARBON X making sure that

all parts are dry before reassembly.

P/N 34140 –2 x 500ml

Other bluechem Cleaning Equipment manuals