3

TD-001517-01

K.2 Series Service Manual

Table of Contents

1. Introduction..................................................................................................................................................................................5

1.1 Restriction of Hazardous Substances Directive (RoHS) ...................................................................................................................................................... 5

1.2 Revision history......................................................................................................................................................................................................................... 5

1.3 Service manual contents.......................................................................................................................................................................................................... 5

1.4 Service bulletins ........................................................................................................................................................................................................................ 5

1.5 Serial Numbers.......................................................................................................................................................................................................................... 6

1.6 Required equipment for service ............................................................................................................................................................................................. 6

2. Product specification and images ................................................................................................................................................7

3. Firmware & software....................................................................................................................................................................8

3.1 Firmware revision history ....................................................................................................................................................................................................... 8

3.2 Firmware update instructions................................................................................................................................................................................................. 8

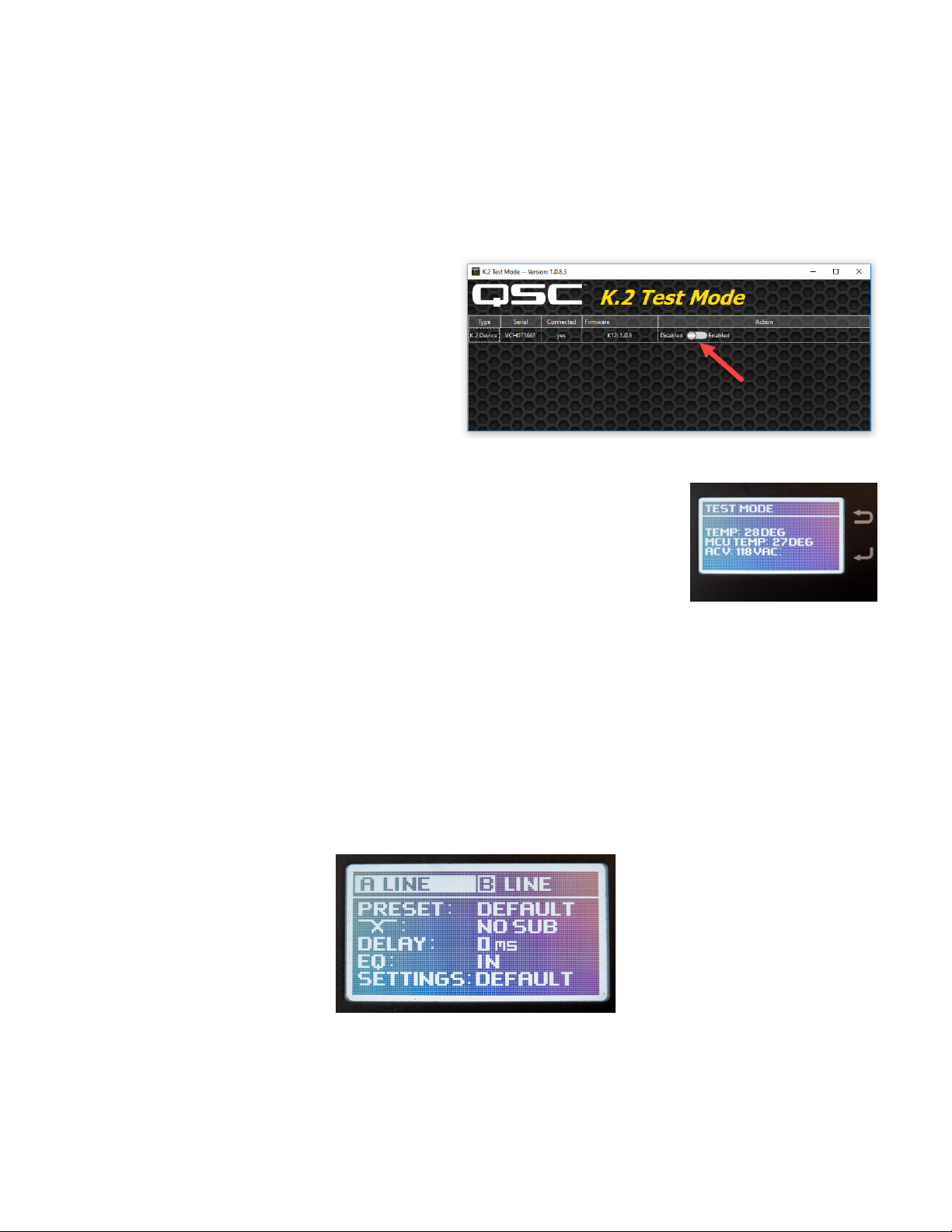

3.3 Test Mode application.............................................................................................................................................................................................................. 9

4. Operational description ............................................................................................................................................................. 11

4.1 Series description.....................................................................................................................................................................................................................11

4.2 Model descriptions..................................................................................................................................................................................................................11

4.3 Amplifier module.....................................................................................................................................................................................................................12

5. Loudspeaker disassembly & repair instructions ....................................................................................................................... 17

5.1 Amplifier module .....................................................................................................................................................................................................................17

5.2 Front grille ................................................................................................................................................................................................................................19

5.3 Front baffle...............................................................................................................................................................................................................................19

5.4 High frequency transducer.................................................................................................................................................................................................... 20

5.5 Low frequency transducer .....................................................................................................................................................................................................21

5.6 Handles, feet, and pole mount..............................................................................................................................................................................................21

6. Amplifier module disassembly & repair instructions ...............................................................................................................23

6.1 Back cover................................................................................................................................................................................................................................ 23

6.2 AMP/PSU board...................................................................................................................................................................................................................... 24

6.3 Input/DSP board..................................................................................................................................................................................................................... 27

6.4 LCD board................................................................................................................................................................................................................................ 28

6.5 EMI shield and AC line filter board...................................................................................................................................................................................... 28

6.6 Fan ............................................................................................................................................................................................................................................ 30

6.7 Amplifier module reference...................................................................................................................................................................................................31

7. Testing.........................................................................................................................................................................................32

7.1 Requirements........................................................................................................................................................................................................................... 32

7.2 Amplifier module testing........................................................................................................................................................................................................ 33

7.3 Loudspeaker testing................................................................................................................................................................................................................ 36

8. Troubleshooting tips...................................................................................................................................................................38

8.1 General tips.............................................................................................................................................................................................................................. 38

8.2 Testing the AC mains fuse and line filter components...................................................................................................................................................... 39

8.3 Bypassing the AC line filter ................................................................................................................................................................................................... 40

8.4 Power supply MOSFETs and repair.......................................................................................................................................................................................41

8.5 Amplifier MOSFETs................................................................................................................................................................................................................. 42

8.6 LF and HF amplifier LEDs...................................................................................................................................................................................................... 43

8.7 +12VLOW voltage rail failures............................................................................................................................................................................................... 43

8.8 Testing the input/DSP and LCD boards ............................................................................................................................................................................... 44

8.9 LCD ribbon............................................................................................................................................................................................................................... 45

8.10 Input section failure.............................................................................................................................................................................................................. 46

8.11 Fan issues and overheating................................................................................................................................................................................................. 46

8.12 Front LED................................................................................................................................................................................................................................ 47

8.13 Internal wiring harness......................................................................................................................................................................................................... 47

8.14 Transducer issues.................................................................................................................................................................................................................. 48

9. Schematics, exploded-view drawings, and BOM ......................................................................................................................49