www.QSPONLINE.com 3

SAFETY INSTRUCTIONS

Ensure that SC-4000 is level and secured to

floor.

Wear gloves & eye protection.

Before using the device, cycle the piston to

equalize air pressure & avoid an abrupt thrust.

Be watchful of pinch points on SC-4000 & strut

assembly; keep extremities out of these areas

to avoid injury.

Prior to starting the compression of any spring,

it is imperative to make sure the spring is

securely placed between the opposing arms.

If a spring begins to deflect or “bow” while

under compression, STOP,

relieve the

pressure & reset the clamps closer together.

Do not place fingers or hands in, on, around,

or near moving components while strut

compressor is attached to air supply.

The SC-4000

features a safety valve that

prevents operation if the safety cag

lowered.

Never allow untrained or unauthorized

personnel to operate strut compressor.

Fully train all employees on

and care of your strut compressor.

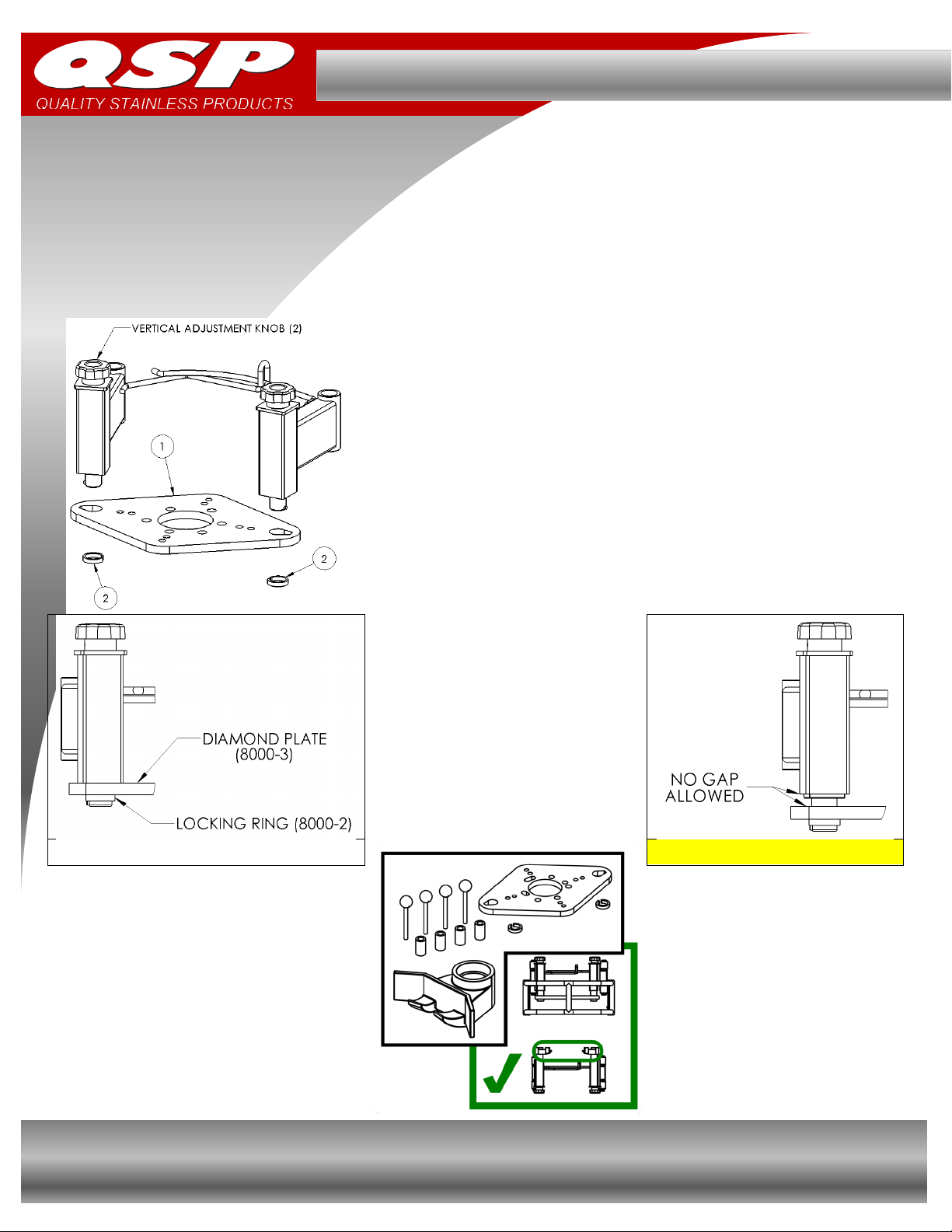

*If using a Diamond Plate kit, skip to page 9. *

One single finger hook and one double finger

hook should be used at the top of the unit and

MAINTENANCE INSTRUCTIONS

To avoid personal injury and damage to strut compressor, permit only qualified personnel to perform

maintenance on strut compressor(s). If you are not completely familiar with general automotive equipment

maintenance procedures, stop and contact manufacturer for instructions.

DAILY:

Inspect & repair or replace all loose bolts & damaged or broken components.

Inspect strut compressor clamp hooks for excessive wear or damage & replace as needed.

Inspect air system for leaks and basic function.

Inspect retention arms, knobs, foot pedals, and safety cage for damage and wear, replace as needed.

MONTHLY:

Inspect support tray & spring retention arm assemblies for damage, wear & tear, and dirt and debris in

mechanism. Clean, lubricate, repair & replace components as needed.

Lubricate cylinder rods with marine grade grease above seals, cycle unit twice to incorporate grease.

Clean strut compressor & inspect for rust.

EVERY 2YEARS:

Check all labels on strut compressor for legibility & make sure no labels are missing. Replace as

needed.