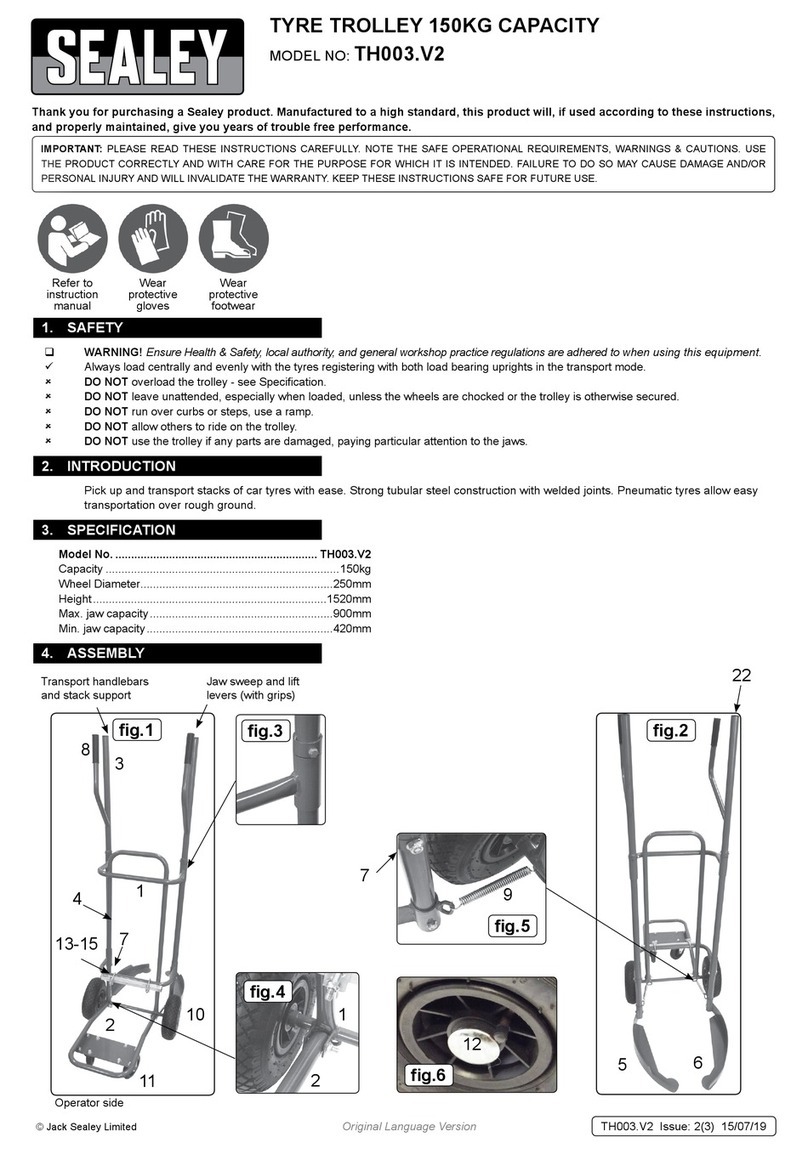

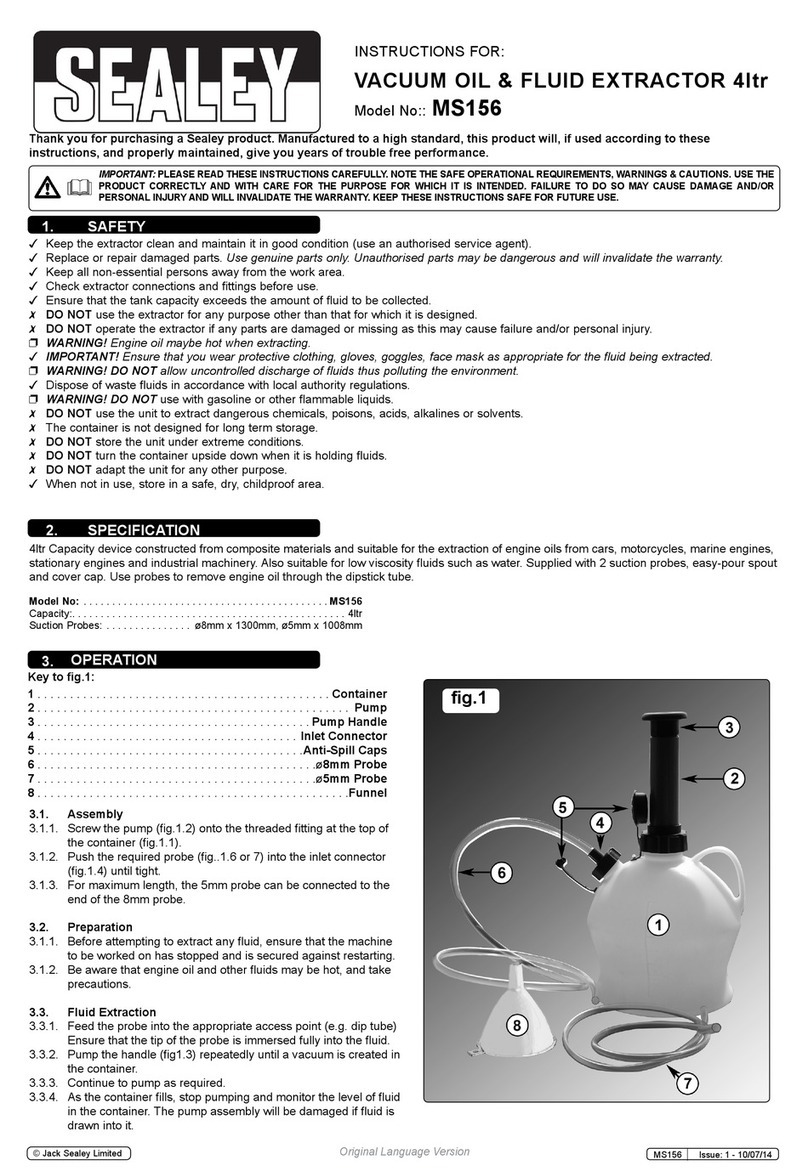

4. ASSEMBLY

(The numbers in brackets refer to the parts diagram.)

4.1. WHEELS

4.1.1. Slide a fixed wheel (30) onto each stub axle and retain them with the circlips provided (29). Bolt the two castors (24) to the front

brackets at the base of the tank using the two washers (23) and two dome nuts provided (22).

4.2. HANDLE

4.2.1. Slide the chrome handle (37) into the two tubular retainers welded onto the back of the tank. Retain the handle using the two socket

cap bolts provided.

4.3. PROBE STORAGE TUBE

4.3.1. Screw the self tapping screw provided into the hole halfway down the probe container tube (12). Insert the tube into the retaining

rings welded to the side of the tank until the screw head comes to rest on the upper ring. Insert the set of three probes (10),

through the probe seat (11) at the top of the probe container tube.

4.4. COLUMN AND OIL COLLECTION BOWL

4.4.1. Take the steel collection tube (9) and wrap the threaded end with PTFE tape. Connect the tube to the Collection Bowl (1) by

screwing it into the valve fitting on the underside of the bowl and fully tighten. Slide the locking ring (4) onto and up the steel tube (9)

and hold it in place with the locking bolt (5). Insert the tube with bowl attached through the clamp fitting (6) and down into the tank. Set

the required height for the bowl and tighten the clamp fitting (See also fig.2D). Loosen the locking ring (4). Slide it down onto the clamp

fittingandre-tighten.

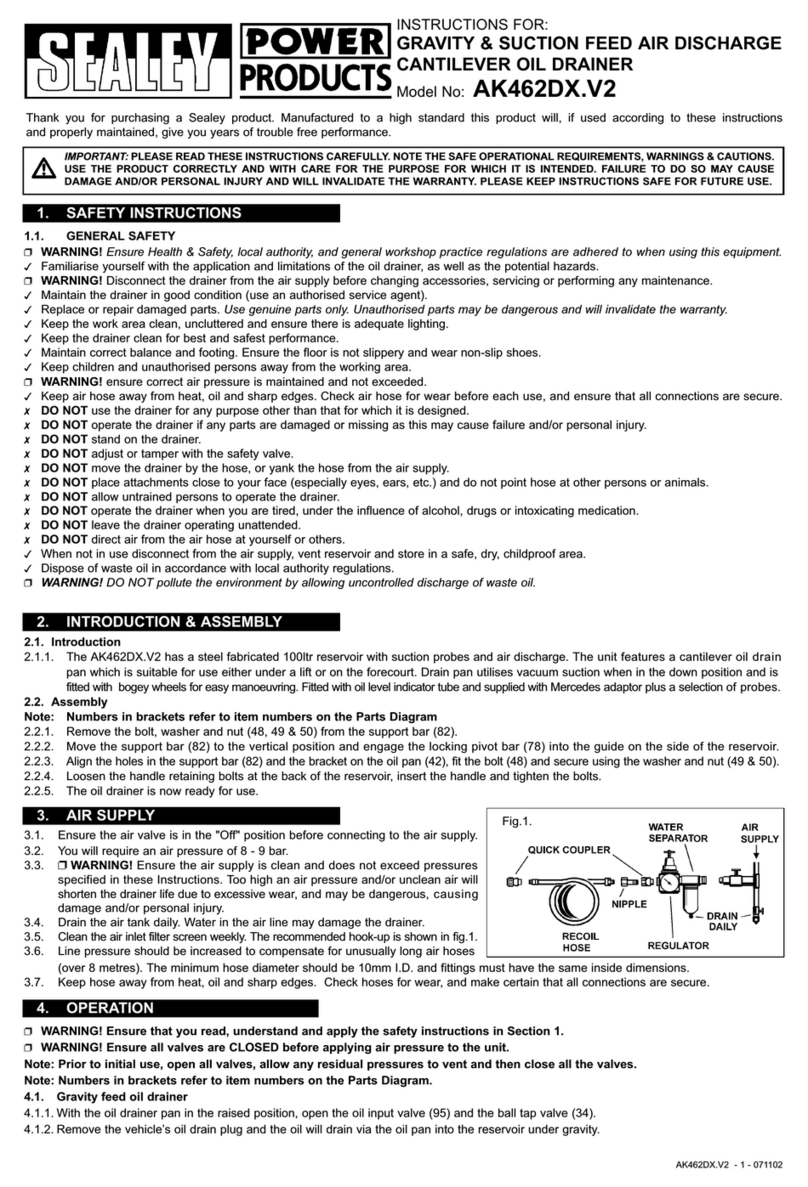

5. AIR SUPPLY

Therecommendedhook-upisshowninfig.1.

5.1. Ensuretheairvalveisinthe“O”positionbeforeconnectingtothe

air supply. You will require an air pressure of 7bar.

WARNING! Ensure the air supply is clean and does not exceed pressures

specified in these Instructions. Too high an air pressure and/or unclean air

will shorten the drainer life due to excessive wear, and may be dangerous,

causing damage and/or personal injury.

5.2. Drain the air tank daily. Water in the air line may damage the drainer.

5.3. Clean the air inlet filter screen weekly.

5.4. Line pressure should be increased to compensate for unusually long air hoses

(over 8 metres).

5.5. The minimum hose diameter should be 10mm I.D. and fittings must have the same inside dimensions.

5.6. Keep hose away from heat, oil and sharp edges. Check hoses for wear, and make certain that all connections are secure.

6. OPERATION

WARNING! Ensure that you read, understand and apply the safety instructions in Section 1.

WARNING! Ensure the oil level never rises above the top fixing point on the discharge tube attached to the side of the tank.

6.1. GRAVITY DRAINAGE

6.1.1. Close all valves as shown in fig.2 (V1, V2, V3, V4 & V5). All valves are closed when the valve lever is at 90º to the direction of flow.

6.1.2. PositiontheoildrainerbeneathavehiclesituatedonaliftandopenthevalvebeneaththeOilCollectionBowl.Seefig.2-V1.

6.1.3. Remove the engine sump plug and allow the oil to drain. Monitor the oil level in the tank by observing the discharge hose fixed to the

side of the tank.

6.1.4. WhendrainageiscompleteitisimportanttoclosethevalvebeneaththeOilCollectionBowl.Seefig.2-V1.

6.2. SUCTION PROBE DRAINAGE

6.2.1. Close all valves as shown in fig.2 (V1, V2, V3, V4 & V5). All valves are closed when the valve lever is at 90º to the direction of flow.

6.2.2. Connect the compressed air at 7bar (100psi) to the quick coupling on the vacuum pump (see fig.2C) and open the valve beneath the

VacuumGauge(fig.2C-V2).Airwillbeexpelledfromthemuffleronthevacuumpumpduringthecreationofthevacuuminthetank.

6.2.3. Whenthearrowonthevacuumgaugeapproachesthetopofthegreenarea,after2.5-3minutesclosethevalveandshutoffthe

compressed air. (DO NOTallowtheneedletoreachtheredarea.)Theunitisnowde-pressurisedandreadyforuse.

NOTE: Oilshouldberemovedwhenhot(70-80°C).Keephands,faceandbodyprotectedusingsuitablepersonalprotectiveequipment

(PPE). The suction capacity of the unit is equal to 2/3 of its reservoir capacity.

6.2.4. Choose one of the three probes depending on the internal diameter of the dipstick tube and push it onto the suction probe handle with

atwistingactiontoensureitisfullyseated.Seefig.2-A.

6.2.5. With the engine still warm, remove the dipstick and insert the probe as far down as it will go.

6.2.6. Openthevalveonthehandle(fig.2A-V3),keepingtheprobeimmersedintheoilwithinthesump.Assoonasthesumpisemptied,

close the valve.

6.2.7. When suction drainage is complete, and before using the air discharge, dispel any remaining vacuum in the tank by slowly opening

valve V1 beneath the oil collection bowl. Close the valve when the vacuum is relieved.

6.3. EMPTYING

6.3.1. Close all valves as shown in fig.2 (V1, V2, V3, V4 & V5). All valves are closed when the valve lever is at 90º to the direction of flow.

6.3.2. Remove the plug from the end of the discharge tube with a twisting action. See fig.2E. Hook the discharge tube into a suitable

container such as an oil drum and open the valve on the handle (V5).

6.3.3. Connect compressed air (0.5Bar/7.25psi) to the quick coupling on the air discharge fittings (See fig.2B). Open the valve on the

dischargefittings(seefig.2B-V4)untilalltheoilhasbeentransferredfromthetanktothecontainer.Closethevalve.Inserttheplug

into the end of the discharge tube with a twisting action

6.3.4. Disconnecttheairsupplyandventanypressureremaininginthereservoirbyopeningthedrainpanvalve(fig.2-V1).

NOTE: The unit storage tank has been fitted with a safety valve, factory calibrated to 0.5Bar/7.25psi.

g.1

AK456DX Issue 1 (3) 11/06/19

Original Language Version

© Jack Sealey Limited