3

JUN 2020

USER GUIDE

1

SAFETY STANDARDS COMPLIANCE

DS-200iQ / DS-600iQ

REV 00

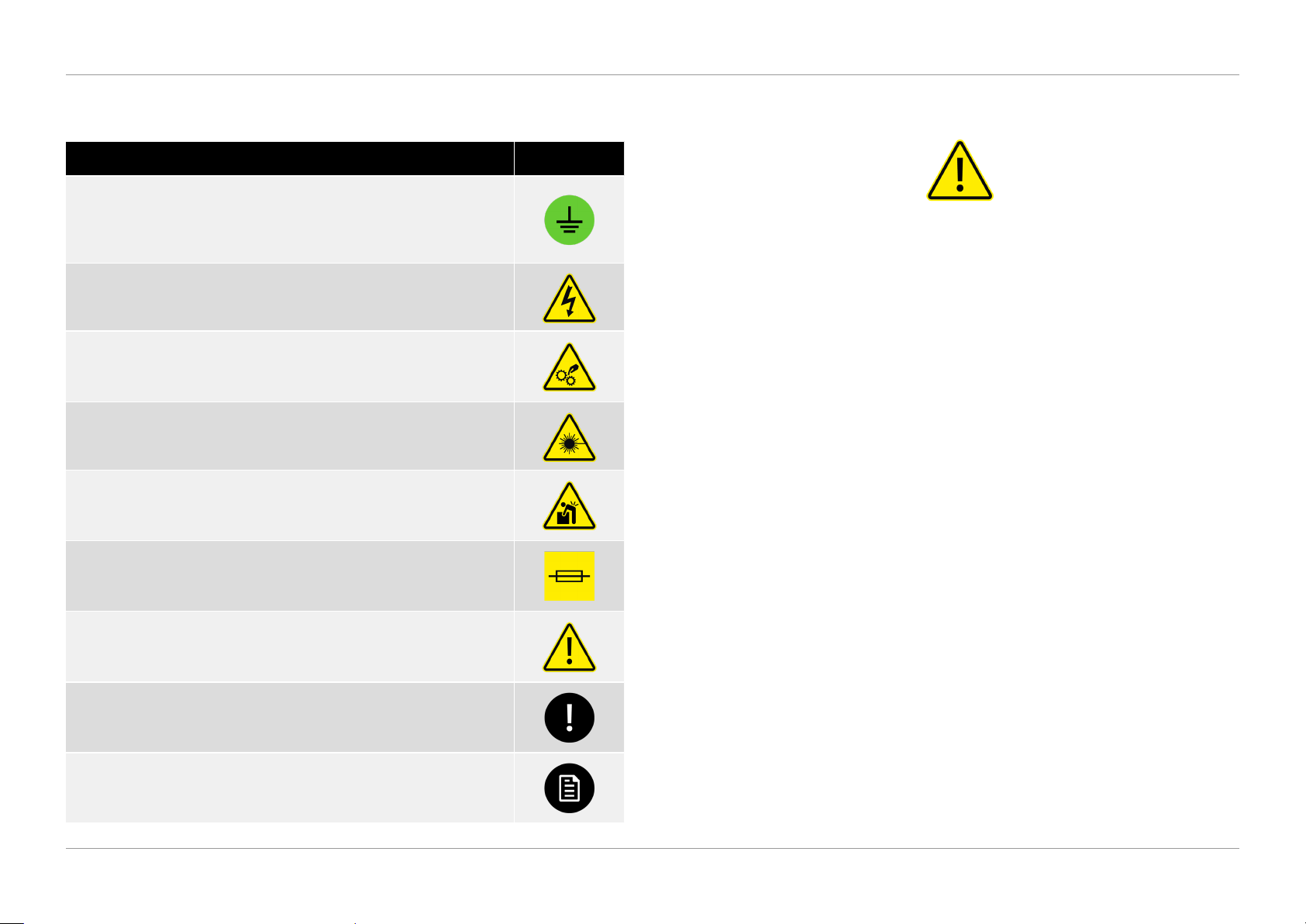

1.3.1 SAFETY SYMBOLS

Description Symbol

Protective Earth (Ground)

or protective earth (ground) electrodes, protecting against electric

shock in case of a fault.

Caution - Risk of Electric Shock

Caution - Moving Parts

Indicates the instructional safeguard to keep away from moving

parts.

Caution - Laser Beam

Indicates warning of a laser beam.

Caution - Heavy Object

Indicates the object is heavy, adhere to the safety instructions for

provisions of lifting and moving.

Caution - Fuse

where possible before replacing.

Caution/Warning

Indicates a situation in which minor, moderate, or serious injury

could occur because of the hazard present.

Important Note

Refers to the important note referenced/detailed within the

manual.

Refer to Manual

Refers to the relevant instructions referenced/detailed within the

manual.

1.3.2 GENERAL SAFETY NOTES

WARNING

▪Keep the work area around the machine clean. A minimum one metre of clear

unobstructed working space is always required around the machine.

▪The machine must be used only as intended by the manufacturer and should

not be tampered with or altered in any form.

▪The machine must be operated, maintained and or serviced only by trained

and authorised personnel.

▪Do not operate the machine unless all of the covers are in place and

undamaged, and all warning labels are in place and legible. If any external

cover is damaged, it must be replaced only by authorised personnel or

▪

interlock safety switches, and do not attempt to operate the machine without

covers, or if any of the interlock safety switches are inoperable.

▪Do not wear any loose clothing or jewellery, and long hair must be tied back

or tucked under a hat when working near the machine, as they may become

caught in any one of the moving parts resulting in injury.

▪Before any cleaning, maintenance and or servicing, the machine must be

completely isolated from the power source, by pressing the toggle switch

mains power cable completely from the electrical power supply.

▪

outside the cabinets. If paper dust is collecting inside the machine, open the

duster only.

▪Although the manufacturer takes care to eliminate sharp edges to reduce

danger, please handle all manufactured parts with care to avoid any risks of

cutting.

▪When the machine is not in use, the mains power cable should be completely

disconnected from the electrical power supply, stored and positioned safely.