Quest IQ Dry Cooler OMM 6September 2020

External Systems Connection

Normally, the only systems need to be connected to the dry cooler are cooling media piping and electrical power

(control wiring connection is required also, unless dry cooler is self-controlled).

Cooling Media Piping Connection. Normally dry cooler is provided with two piping connections (one –inlet,

another –outlet) for cooling media. Connections are normally identified/labeled in respect to cooling media flow

direction (hot/warm media entering the dry cooler –IN, cool media leaving the dry cooler –OUT).

•If dry cooler is provided with pump package option, cooler connections might be located within pump package

–refer to specific dry cooler labels and submittal documentation (drawings etc.).

Electric Power and Control Connection. Electric power is normally brought to the dry cooler disconnect (if cooler is

equipped with one) or to power distribution block, located in cooler’s electrical box. Control wiring is normally

brought to the control terminals within electrical box.

•Dry coolers, equipped with multiple electrical boxes, normally required power and control connection only to

one box (indicated as”main”) – power and control wiring between boxes is normally done at the factory.

•Self-controlled dry coolers normally do not require external controls connected.

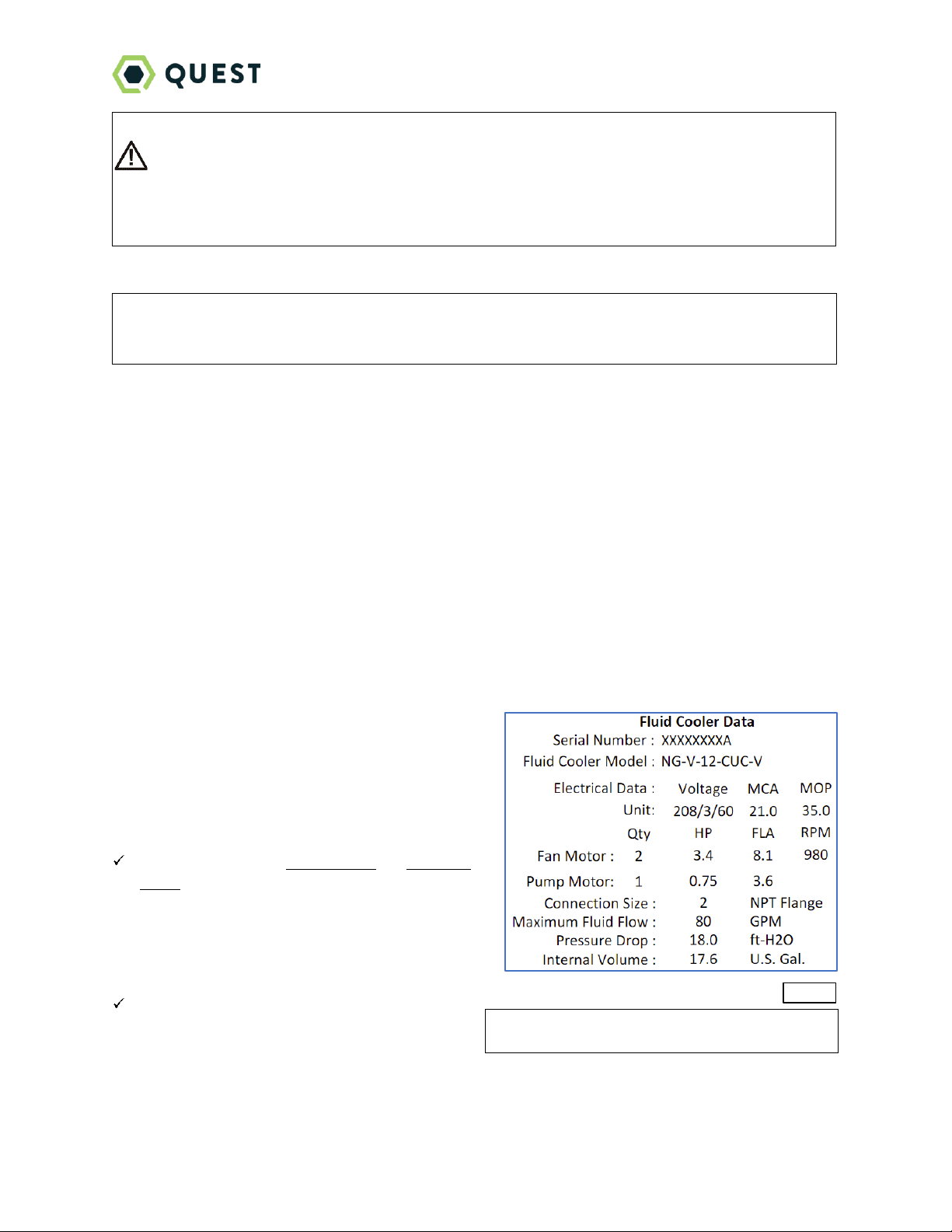

Equipment Specific Data

Specific information for individual dry cooler is provided in

the following methods:

System Nameplate (Pic. C.3):the manufacturer tag

attached to the dry cooler, that includes its most critical

data:

General data including Serial Number and Dry cooler

Model (nomenclature)

oSerial Number is usually composed of 8 digits.

Additional letter “A”, placed at the end of

serial number, usually indicates that given dry

cooler is provided together with another

equipment it serves (dehumidifier etc.).

Operational data:

oElectrical (voltage, amp draw, HP etc.)

oCooling media (GPM, connection size etc.)

CAUTION! Current manual refers to/depicts general/default external systems connection location. For details

regarding specific dry cooler’s connections (location/elevation, piping sizes, flow direction, wiring terminals etc.),

refer to the submittal documentation as well as dry cooler diagrams, labels and stickers.

Attention! Equipment Clearances!

CAUTION! Proper clearances should be maintained for adequate airflow and heat rejection, as well as for

maintenance and service of the equipment! Generally, up to 36” sides (all around) and 96” top clearances are

required. For more information on clearances as well as equipment dimensions and other details, refer to the

submittal documentation.