Introduction

This console mount control provides complete one

hand operation of the shift and throttle control. The

control is equipped with a neutral start switch which

must be connected to prevent accidental in-gear start-

ing. The shift and throttle cables are not supplied with

control; order cables separately after position of con-

trol is determined.

Quicksilver throttle and shift control cables are recom-

mended for use in this remote control.

These installation instructions provide complete in-

formation for installing the remote control. Please read

them carefully and thoroughly before starting installa-

tion.

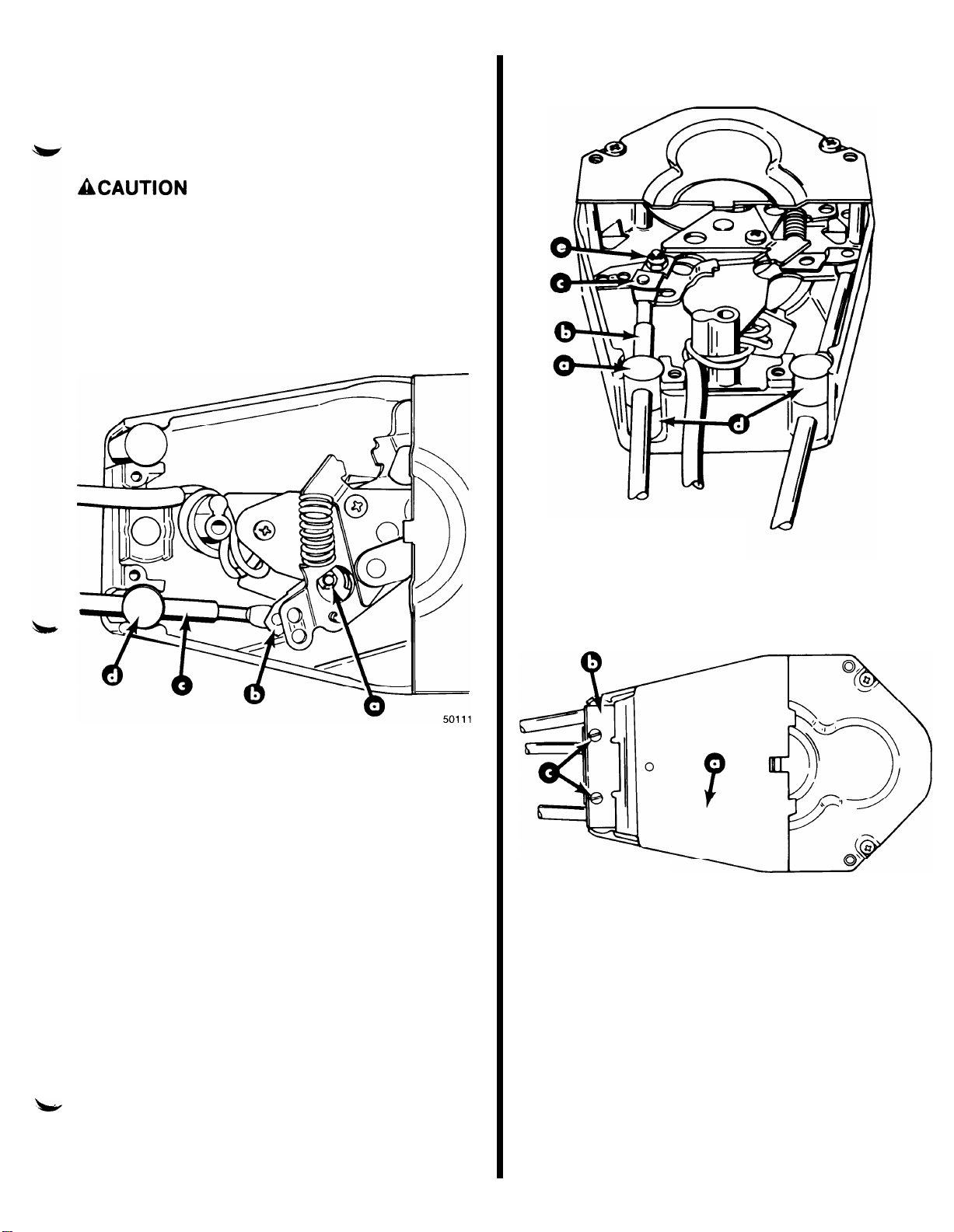

Installation

1. Determine position of remote control. Refer to

“Mounting Remote Control”.

IMPORTANT: Control mechanism will have to be

changed if control will be on port side. Refer to

“Remote Control Alteration”.

AWARNING

If control handle is removed and reinstalled for any

reason. The set screw in handle must be retorqued to

60 lb. in. (7 N.m). Failure to tighten screw securely

could allow control handle to disengage with subse-

quent loss of throttle and shift control.

2.

Install control cables to remote control. Refer to

correct cable installation procedure in this manual.

Note that cable installation is different, depending

on which side the control will be installed.

On some boat installations, it may be helpful to first

make the cutout for remote control (using the at-

tached template) and routing the control cables

thru the boat before installing cables to control.

Mount the remote control following instructions.

Make remote control wiring connections following

“Wiring Diagram”.

Install and adjust shift and throttle cables to power

package following instructions which accompany

the power package or refer to the Product Service

Manual.

Final Checks and Adjustments

a.

Re-check tightness of control handle set screw.

Set screw should be torqued to 60 lb. in. (7 N.m).

b. Before remote control is securely fastened,

make sure parts are in place. Check to see that

control cables are routed correctly.

ACAUTION

Do not try to shift remote control into “Reverse” on

outboard installations when outboard is not running.

Forcing the shift mechanism into reverse may damage

the mechanism.

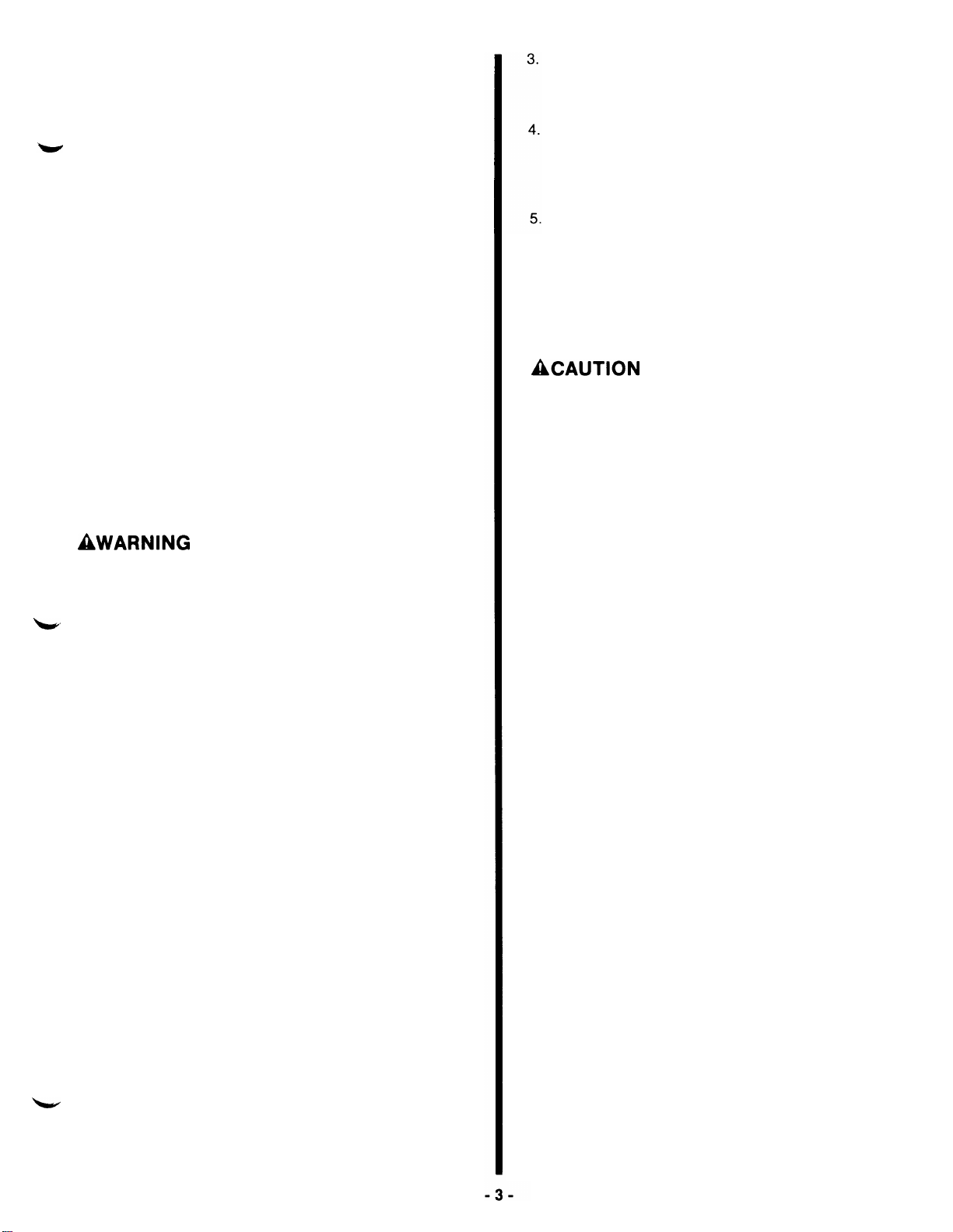

C.

d.

e.

Operate control handle several times (see “Cau-

tion” preceding). Adjust control handle friction

adjustment screw to desired tension. Any bind-

ing or stiffness in the operation of the control

handle is usually caused by the following.

1

-

Bends or tension on control cables, close to

the control.

2

-

Excessive number of bends in cables.

3

-

Bends are too small in cables.

4

-

Tight engine linkage.

Adjust the control handle detent adjustment

screw to desired tension.

Check operation of neutral start switch. Engine

must only be able to start when control handle is

in neutral position. Make sure water intake in

lower unit is in water when starting engine.