5

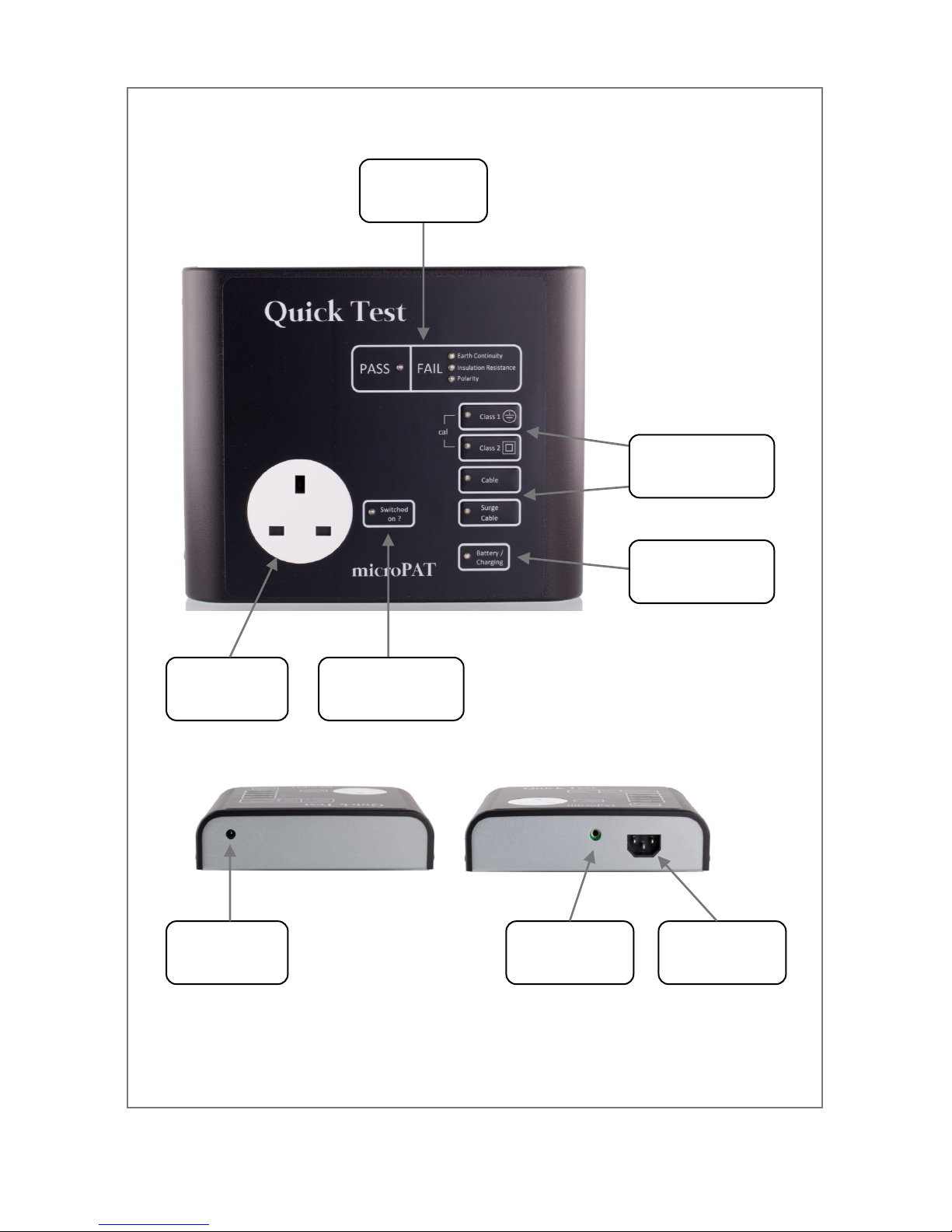

Controls

Results Display

Switched On Indicator

The microPAT is very simple to operate. The only controls

are four buttons used to select the required test.

To operate, simply press and release the appropriate test

button.

The indicator next to the test button will flash amber while

the test is being performed.

The test results are displayed for ten seconds after the test

is completed, the microPAT then shuts down.

When the test is complete the results appear on the results display.

If all the required tests pass, the green PASS indicator will light up.

If any of the required tests are a fail, the corresponding red FAIL indicator

will light up.

Additionally the indicator next to the test button will be green or red.

A new test can be started as soon as the results are being displayed,

there is no need to wait until the microPAT has shut down.

Any appliance switch must be in the ‘on’ position during

testing.

When testing Class 1 or Class 2, the microPAT will attempt

to determine if the appliance is switched on.

If it is unable to detect the appliance is switched on, the

‘Switched on ?’ indicator will flash red. If the appliance is

then switched on within five seconds the test will continue.

However because of the design of some appliances it is not

always possible for the tester to determine if it is switched

on. In this case pressing the corresponding test button will

continue the test immediately.