rada 320 c User manual

Other rada Plumbing Product manuals

rada

rada 52/1 User manual

rada

rada bsr-s 300 User manual

rada

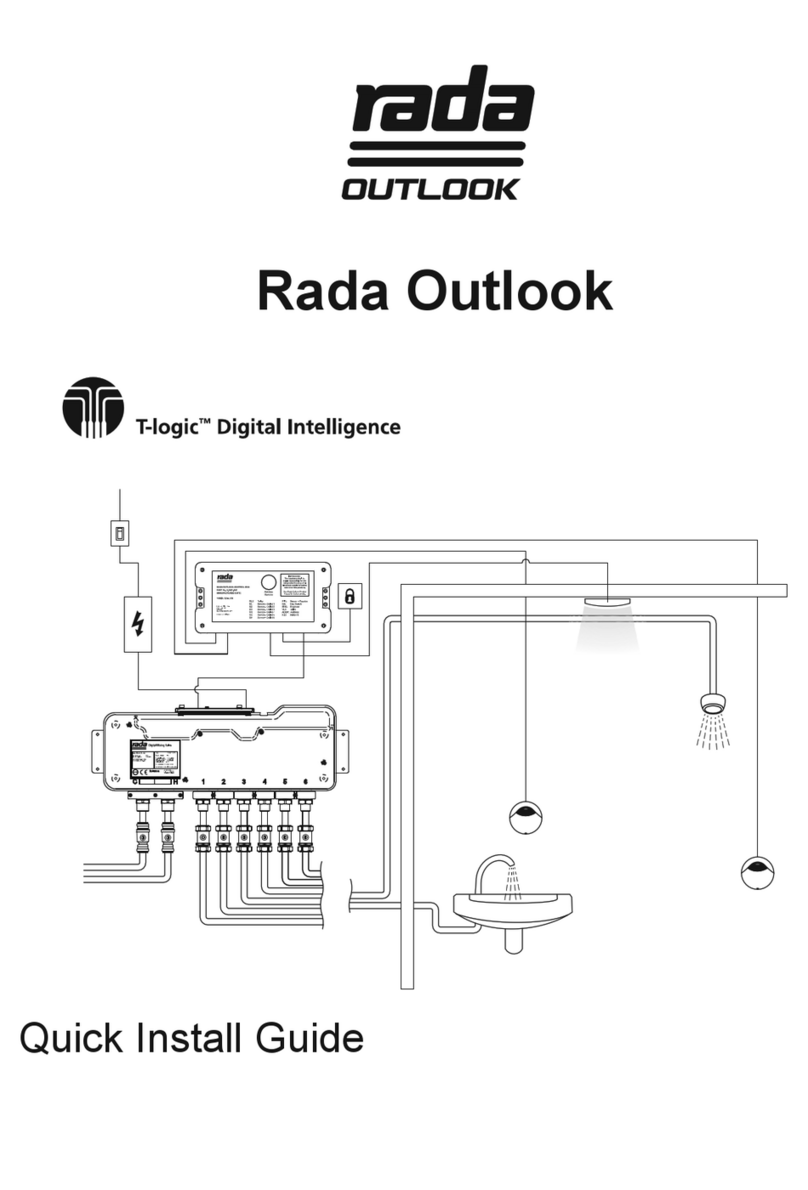

rada Outlook 1621.099 User manual

rada

rada Safetherm User manual

rada

rada 215-t3 Series User manual

rada

rada 320 User manual

rada

rada V12 User manual

rada

rada VR2-CC User manual

rada

rada Autotherm-3 BSM User manual

rada

rada Rada Outlook 150 1.1621.136 User manual

Popular Plumbing Product manuals by other brands

Weka

Weka 506.2020.00E ASSEMBLY, USER AND MAINTENANCE INSTRUCTIONS

American Standard

American Standard DetectLink 6072121 manual

Kohler

Kohler K-6228 Installation and care guide

Uponor

Uponor Contec TS Mounting instructions

Pfister

Pfister Selia 49-SL Quick installation guide

Fortis

Fortis VITRINA 6068700 quick start guide

Elkay

Elkay EDF15AC Installation, care & use manual

Hans Grohe

Hans Grohe AXOR Citterio E 36702000 Instructions for use/assembly instructions

baliv

baliv WT-140 manual

Kohler

Kohler Mira Eco Installation & user guide

BELLOSTA

BELLOSTA romina 0308/CC Installation instruction

Bristan

Bristan PS2 BAS C D2 Installation instructions & user guide