91143923-W2-E

2. For stud partitions alternative xings may be

required.

3. Isolating valves must be installed close to the

Mixer for ease of maintenance.

4. Pipework must be rigidly supported and avoid

any strain on the connections.

5. Pipework dead-legs should be kept to a

minimum.

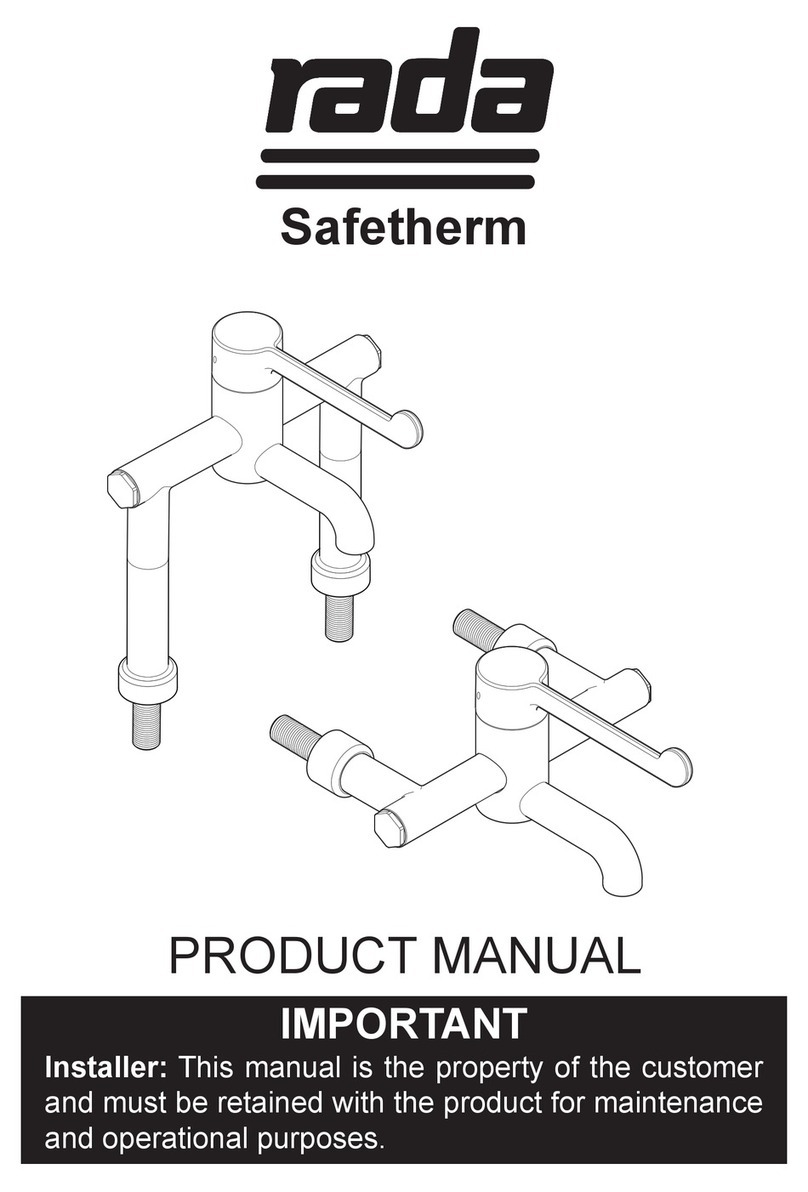

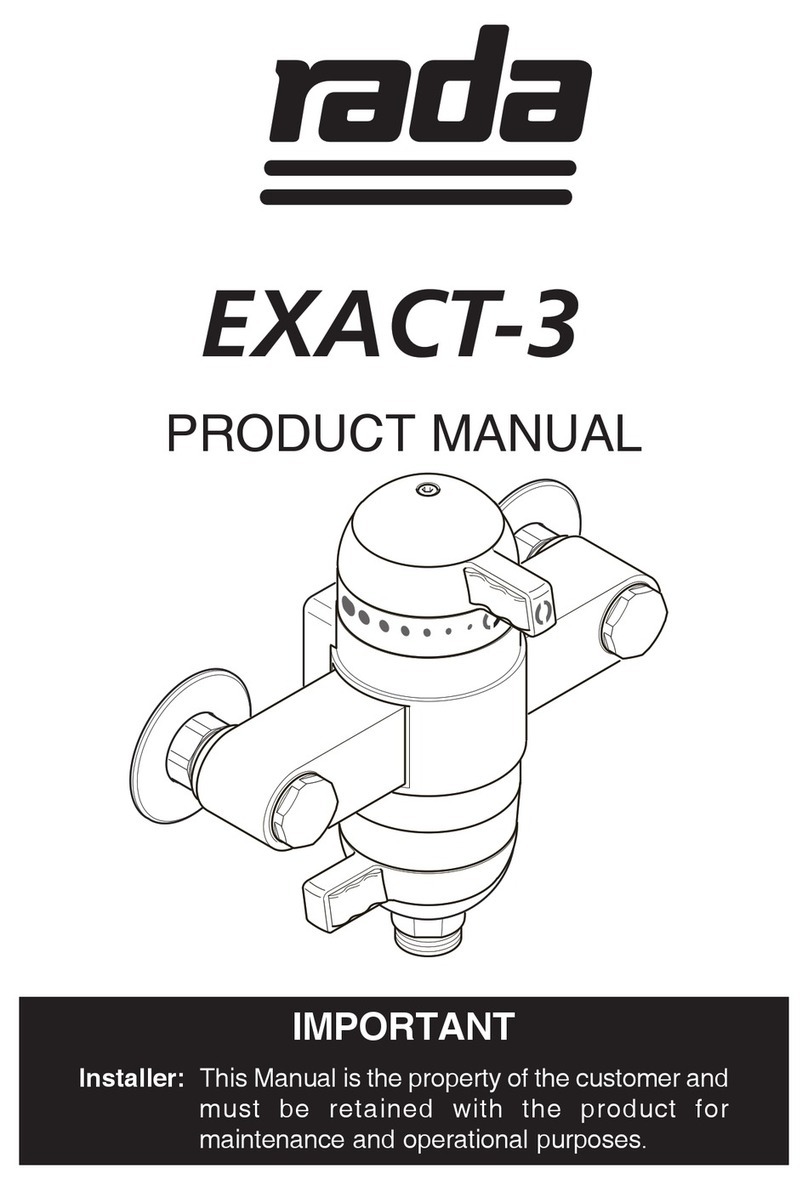

6. Decide on a suitable position for the Mixer.

The position of the Mixer and the Shower

Fittings must provide a minimum gap of 25 mm

between the spill-over level of the shower tray/

bath and the showerhead (refer to illustration).

This is to prevent back-siphonage. For further

information on the installation of your Shower

Fittings, refer to the Fittings Installation and

User Guide.

Note! Only use Shower Fittings recommended

by the manufacturer or supplier.

Note!The thermostatic mixing valve will be

installed in such a position that maintenance of

the TMV and its valves and the commissioning

and testing of the TMV can be undertaken.

Suitable Plumbing Systems

Gravity Fed:

The thermostatic mixer must be fed from a cold

water cistern (usually located in the loft space) and

a hot water cylinder (usually located in the airing

cupboard) providing nominally equal pressures.

Mains Pressurised Instantaneous Hot Water

System (Combination Boiler):

The thermostatic mixer can be installed with

systems of this type with balanced pressures.

(Recommended Minimum Maintained Pressure:

1.0Bar).

Note! On combination boiler systems we

recommend that the thermostatic mixer is

operated in the maximum ow position in order to

achieve the minimum ow rate required to ignite

and run the boiler.

Unvented Mains Pressure System:

The thermostatic mixer can be installed with an

unvented, stored hot water system.

Pumped System:

The thermostatic mixer can be installed with an

inlet pump (twin impeller). The pump must be

installed in a suitable location and in accordance

with its instructions.

General

Installation must be carried out in accordance

with these instructions, and must be conducted by

designated, qualied and competent personnel.

The installation must comply with the “Water

Supply (Water Fittings) Regulations or Scottish

Byelaws” or any particular regulations and

practices, specied by the local water company

or water undertakers.

Note! Make sure that all site requirements

correspond to the information given in section:

‘Specications’. For Type 2 Valves see also

supply conditions in the TMV2 Requirements

Manual.

1. The Mixer must not be installed in an area

where it may freeze.

Hose Retaining Ring

25 mm

Spill Over

Level

INSTALLATION