3

Warning!

Products manufactured by us are safe provided they are installed, used and maintained

in good working order in accordance with our instructions and recommendations.

Caution!

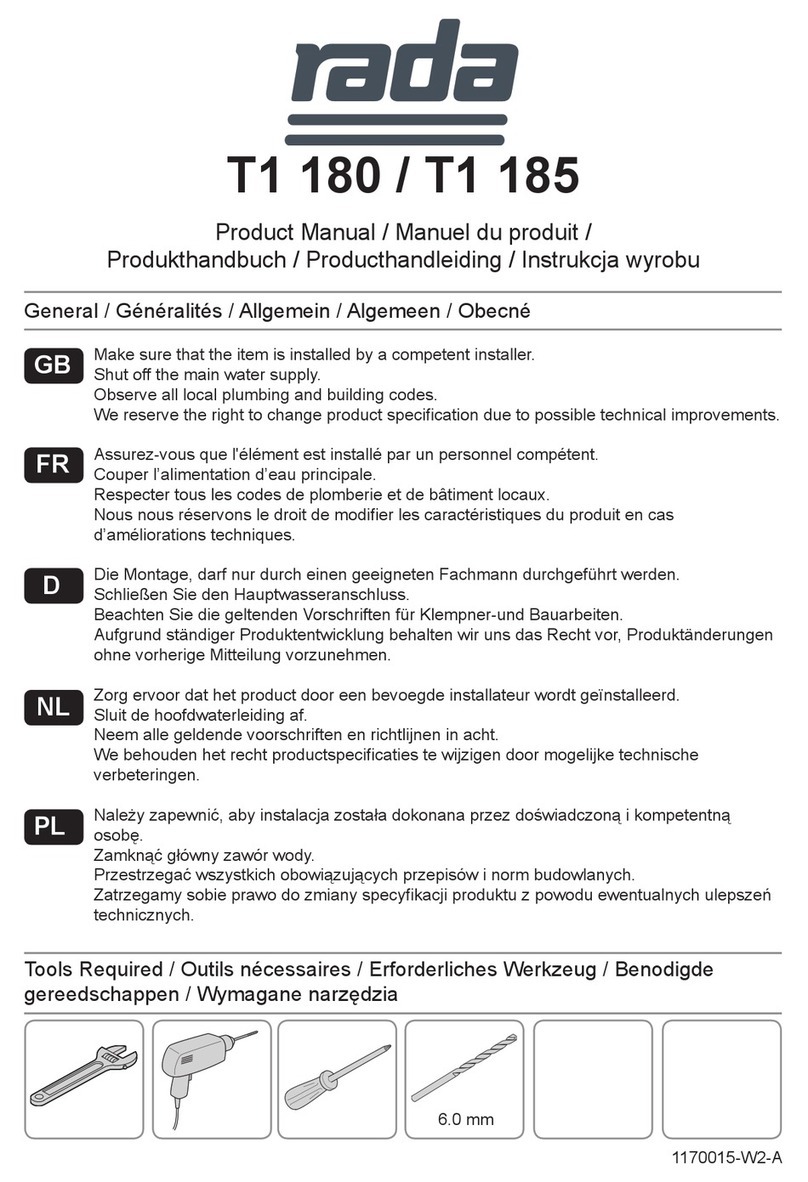

1. Read all of these instructions.

2. Retain this guide for later use.

For Type 3 installations, valves are only to be used for applications covered by

their approved designations, refer to the TMV3 Requirements Manual.

3. Pass on this guide in the event of change of ownership of the installation

site.

4. Follow all warnings, cautions and instructions contained in this guide.

5. The plumbing installation must comply with the requirements of UK Water

Regulations/Bye-laws (Scotland), Building Regulations or any particular

regulations and practices, specied by the local water supplier. The installation

should be carried out by a plumber or contractor who is registered or is

a member of an association such as:

i) Institute of Plumbing (IOP), throughout the UK.

Congratulations on purchasing a quality Rada product. To enjoy the full potential of

your new product, please take time to read this guide thoroughly; having done so,

keep it handy for future reference.

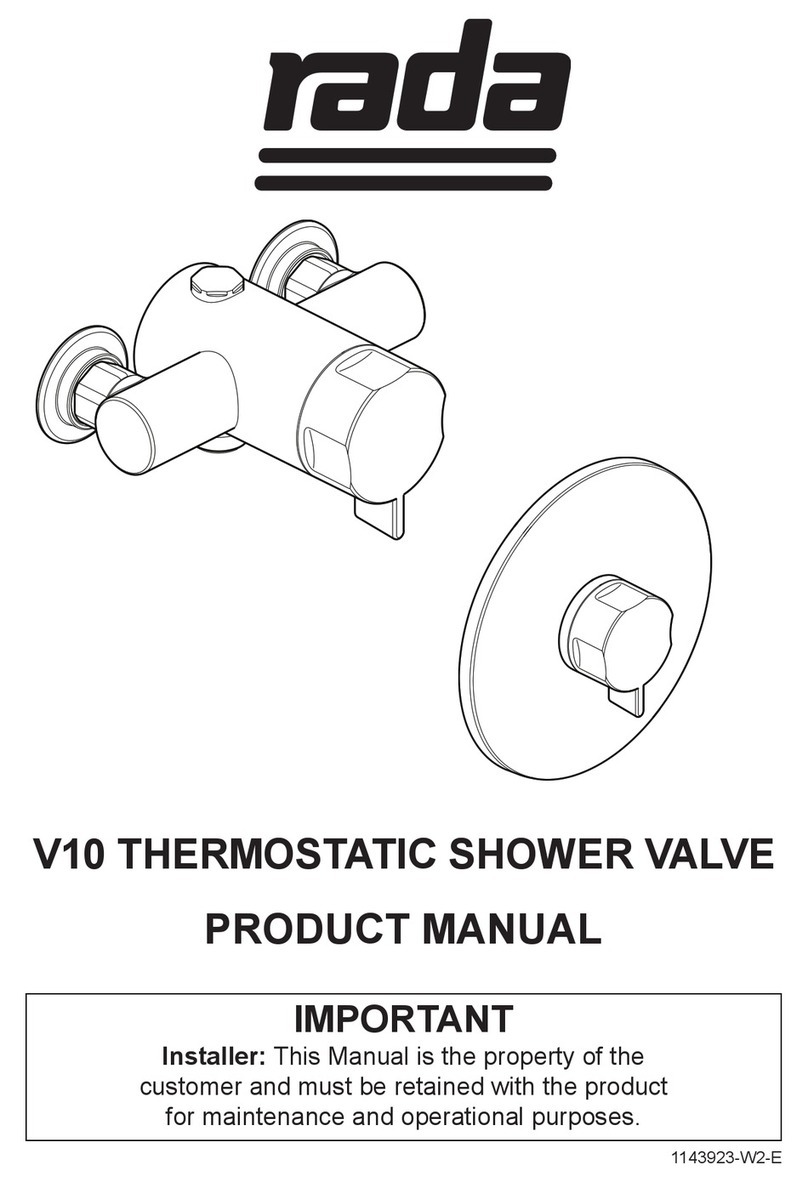

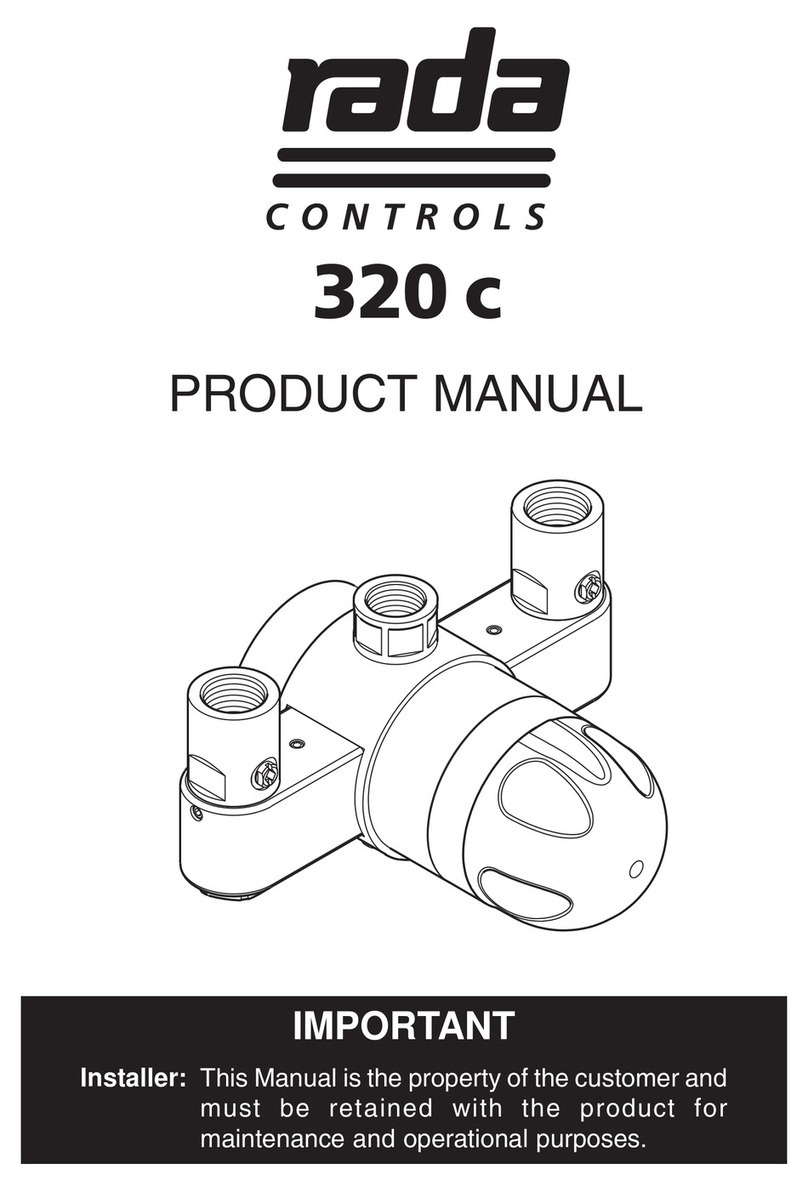

The Rada Safetherm is an exposed thermostatic control for connection to entry

pipework from various directions. The thermostatic control incorporates a wax capsule

temperature sensing unit. This provides an almost immediate response to changes

in pressures or temperature of the incoming water supplies to maintain the selected

temperature. An adjustable maximum temperature stop is provided which limits the

temperature to the desired level. The Safetherm also includes checkvalves, lters

and inlet ow regulators limiting the outlet ow to 8 L/Min.

The Rada Safetherm has been certied for use in UK Healthcare premises as a

Type 3 valve under the BUILDCERT TMV3 scheme. For Healthcare* installations

refer to the TMV3 Requirements Manual. This product also complies with the Water

Supply (water ttings) Regulations 1999.

*Healthcare applications are hospitals, aged person facilities, residential care homes,

etc. and any other application where the user is similarly at risk.

The approved designations for Type 3 Valves are as follows:

Model Designation Code

Rada Safetherm HP-WE, LP-WE

INTRODUCTION

SAFETY : WARNINGS