1.2 Positioning

Figure 1.1: The 5o[deg] half top

angle of the F08 antenna beam.

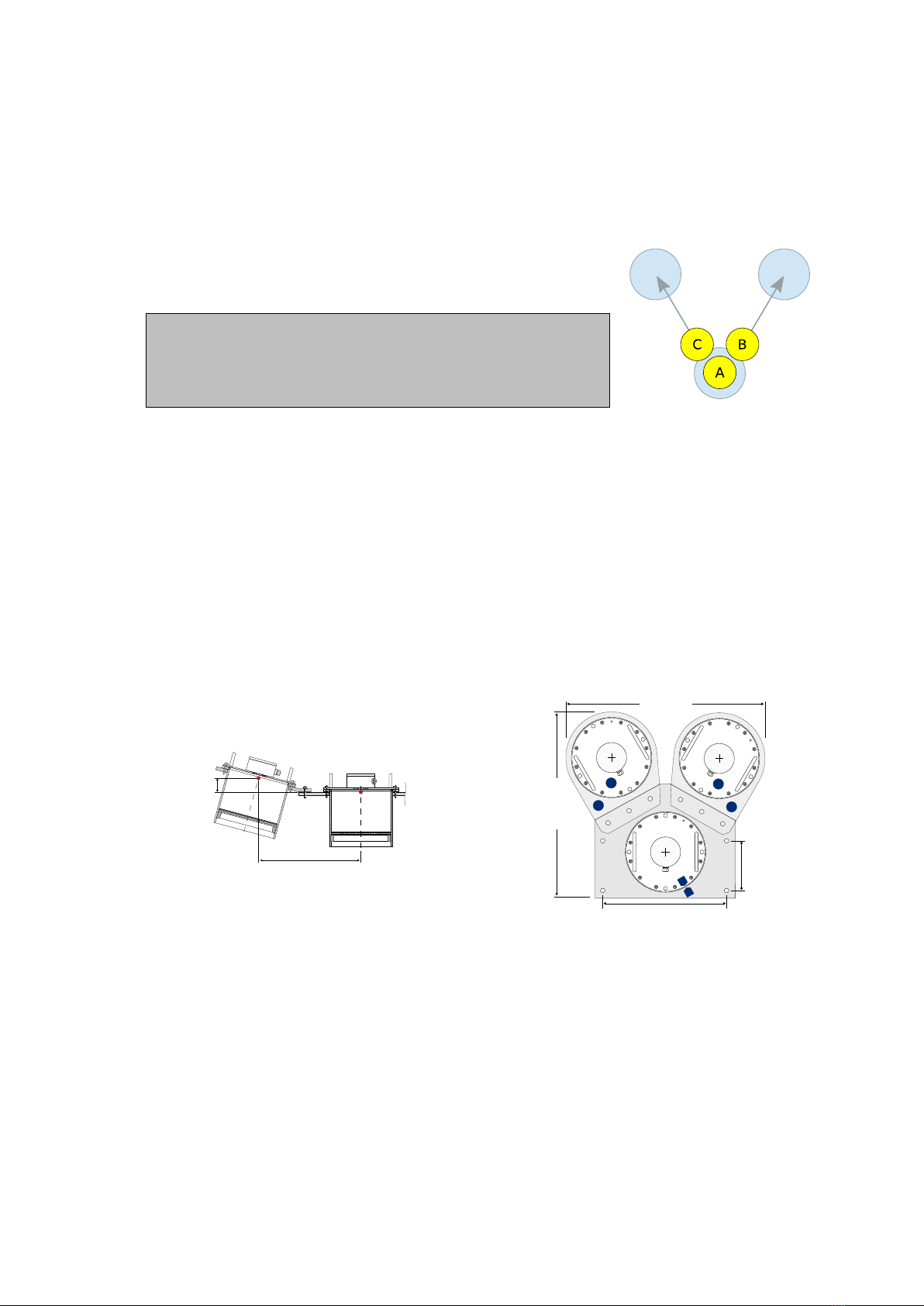

Figure 1.2: Radar dimensions

and the zero reference point.

Note that the reference point is

located at the crossing of the cen-

tral axis with the lower surface of

the mounting flange.

For obtaining the best results from each WaveGuide sensor, the

following positioning criteria must be taken into account:

• It is advised to choose a mounting position such that the

WaveGuide radar beam is free of large reflecting obstacles

(the beam of the F08 antenna can be approximated to a

conical shape having a 5◦[deg] half top angle as shown

in Fig. 1.1). The minimum horizontal distance between

a sensor and any obstacle in the beam’s path should be

at least 10% of the vertical distance between the sensor

and the obstacle. This does not only include horizontal

objects in the beam’s path but also vertical structures.

• Any structure that the WaveGuide sensors are mounted

to might have some influence on the waves progressing

around it. Hence, it is advised to mount the sensors at

a position facing the mean wave direction so that they

can measure the least disturbed water surface. As each

vessel has a unique shape, it is the user’s responsibility

to carefully identify the best position for mounting the

WaveGuide radar. In most cases the vessel’s bow provides

the optimal mounting position.

• The minimum measuring distance is at 2 meter. As such,

the sensor should be mounted with its reference point at

least 2 meter above the highest expected waterlevel during

the period in which the water surface is monitored. The

reference level for the mounting height of the radars is

shown in Fig. 1.2.

• The expected roll and pith motion of the vessel should

be taken into account when mounting the sensor. For

optimal performance, the resulting sensor attitude during

operation must not exceed 15◦[deg] of tilt from vertical. It

is good practice to align the sensor’s tilt axis with the most

stable vessel axis. For example, tilting the sensor along a

ships longitudinal axis when the expected maximum pitch

angles are lower than the maximum roll angles. At the

same time the sensor must be pointed away from the vessel

to avoid radar reflections from the vessel’s body.

4