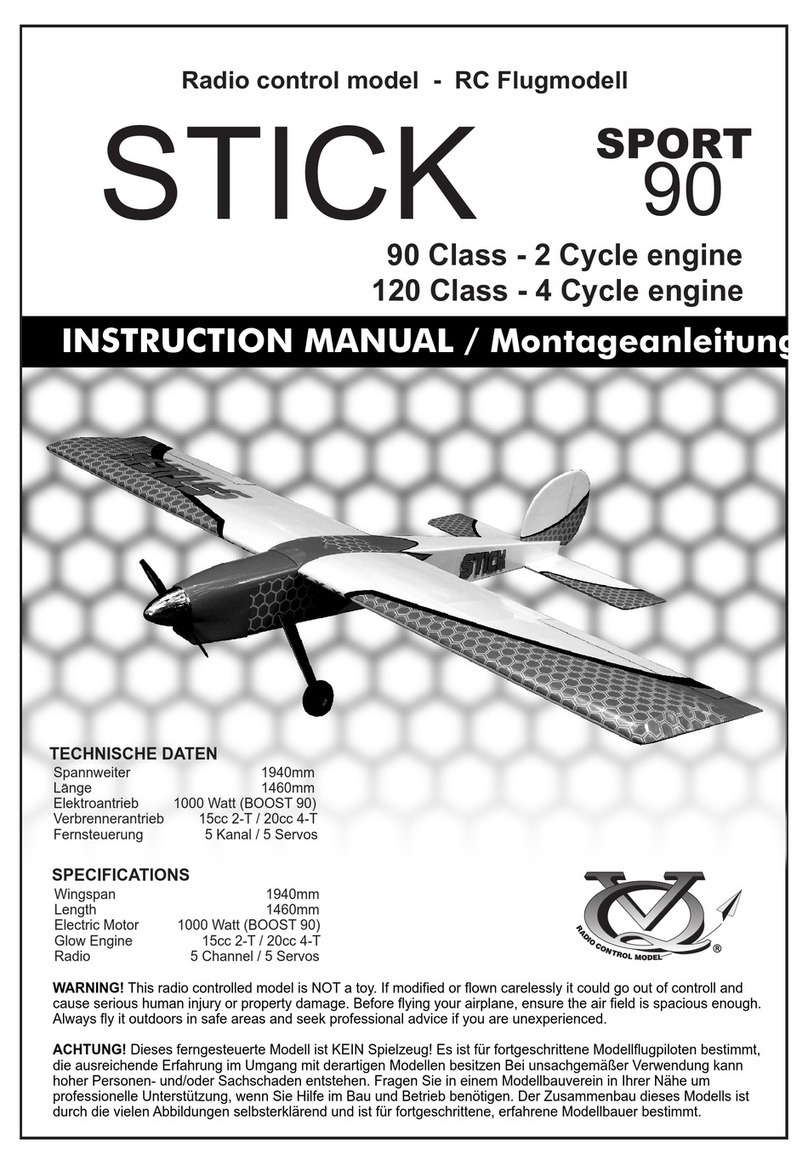

The recommended C.G (Center of Gravity) location for the Stick is 89 ~ 91mm

Adjust the location of the battery pack as required to achieve this C.G location.

If necessary , add weight to either the tail or nose until the correct balance is achieve.

CG

WARNING ! Securely install the receiver and power pack, ensuring they will not come loose or rattle

during flight. Never fly before checking the Cg’s required position.

89 ~ 91mm

19- Balance

3-33/64” ~ 3-19/32”

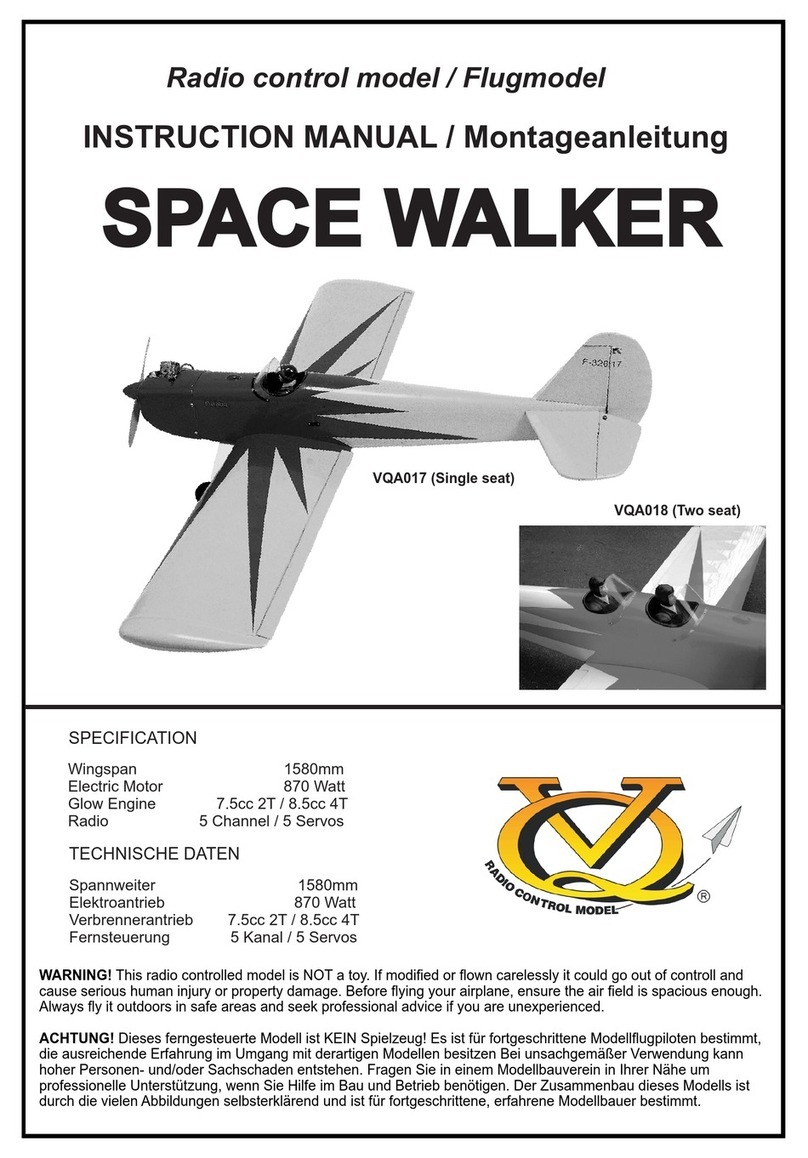

ELEVATOR AILERON

RUDDER

21-Pre-Flight check

RANGE TEST YOUR RADIO

Turn on the radio in your plane. With your plane on the ground, you should be able to walk 30 paces away

from your plane and still have complete control of all functions. If not, do NOT attempt to fly.

Be sure that your batteries are fully charged per the instructions included with your radio.

BEFORE FLYING

1-Fully extend the transmitter antenna.

2-Switch ON the transmitter.

3-Switch ON the receiver.

4-By moving the throttle control stick, ensure the carburetor opens and closes without effort.

FLYING

1-Take-off your airplane INTO THE WIND.

2-Do not fly your airplane above people standing around.

AFTER FLYING

1-Always land your airplane INTO THE WIND.

2-Switch OFF the receiver.

3-Switch OFF the transmitter.

AILERON STROKE ELEVATOR STROKE RUDDER STROKE

25/64”(10mm) 51/64”(20mm)

20-Control Surface

25/64”(10mm)

25/64”(10mm)

25/64”(10mm) 51/64”(20mm)

IMPORTANT: Please do not clean your model with strong solvent or pure alcohol, only use liquid soap with

water or use class cleaner to clean on surface of your model to keep the colour not fade.