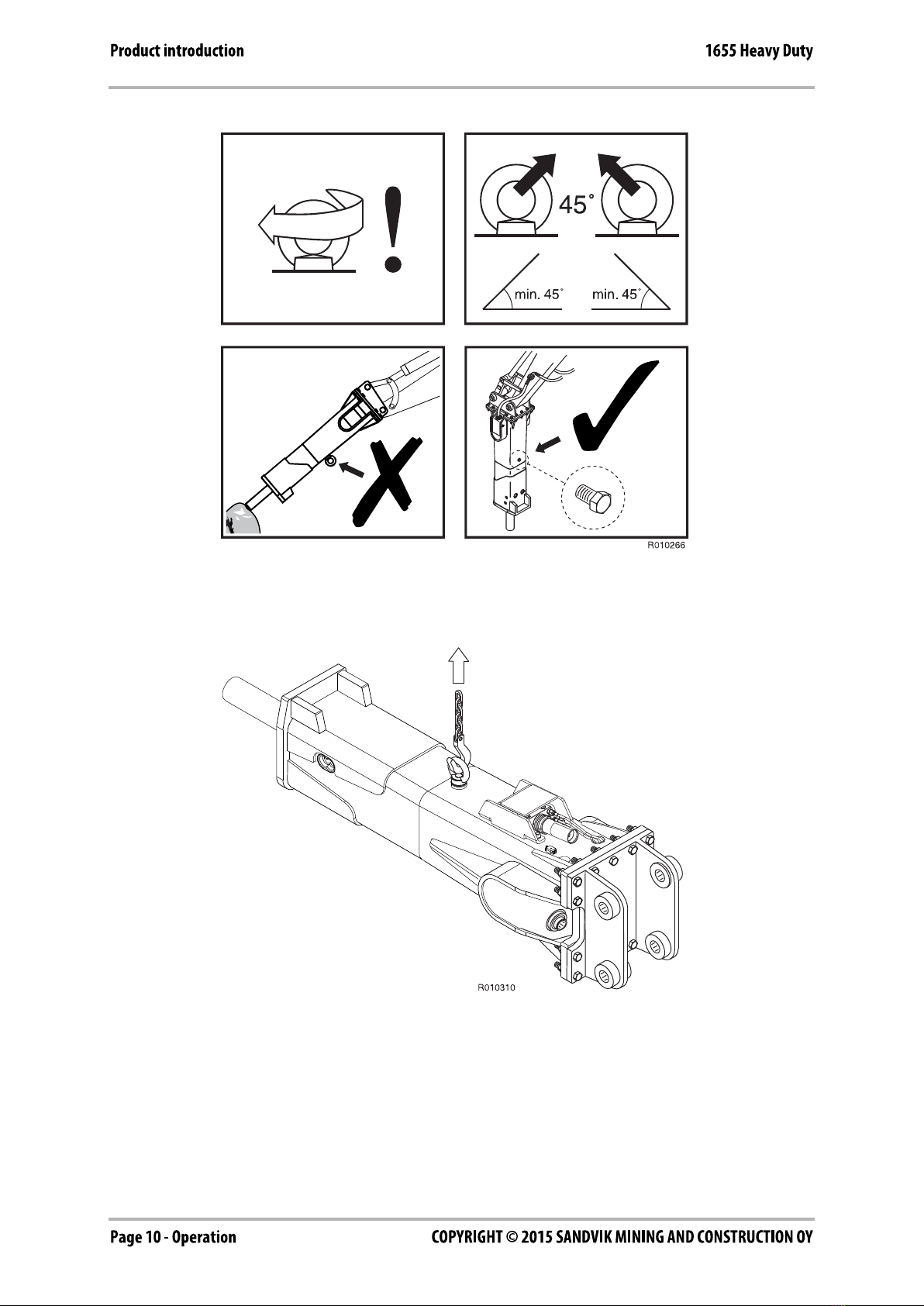

Use the lifting eyes located on the product housing only to lift or handle the product

itself. The lifting capacity calculation is based on the product's working weight

including a normal working tool and an average sized mounting bracket.

Warning! To avoid falling objects, do not use the product to lift other products.

Use the lifting eyes located on the product housing only to lift or handle the

product itself.

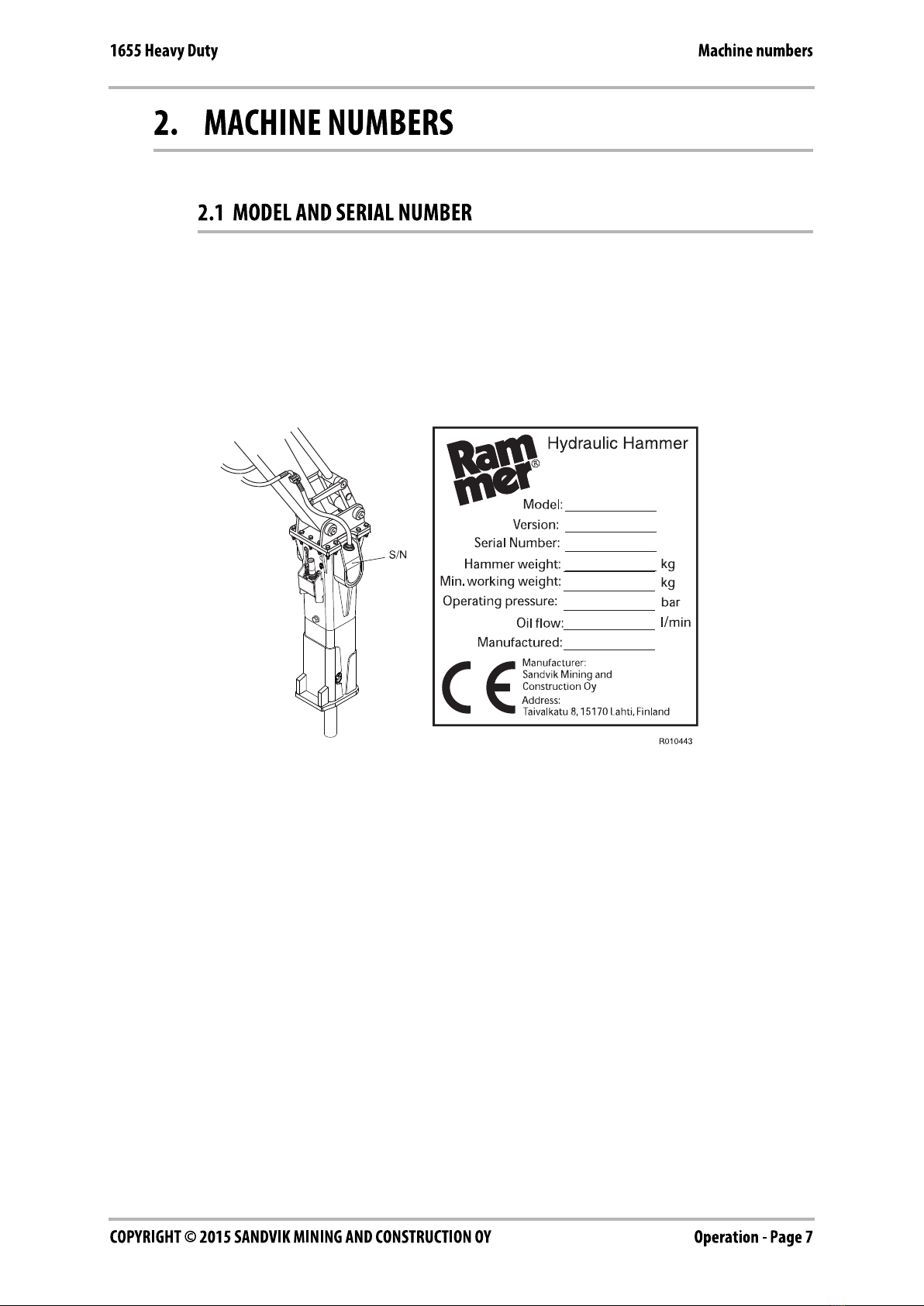

The maximum allowed total weight is shown on the product's CE-plate and

specification page. See “Hammer specifications” on page 66. If the weight exceeds

the maximum allowed total weight shown on the CE-plate and specification page,

you have to use other lifting points/methods than originally provided on the product.

The other threaded holes on the product (for example on the hammer powercell) are

intended for handling single parts only. It is forbidden to lift the entire assembly by

using these threaded holes (for example on the cylinder outer surfaces). For

handling the parts, see product workshop documentation for suitable lifting

methods and lifting adapters.

Tighten the lifting eye screws completely. Put a burden on the lifting eye only if the

screw is properly tightened to the housing.

Failure to properly tighten the screw before allowing load pressure on the

lifting eye may cause lifting eye to break and free fall of the product.

If you use mechanical tools for tightening, make sure not to overstrain the shank.

Before lifting make sure that the rope and/or hook is stretched.

When two lifting eye screws are used, the lifting capacity depends on the angle of

the lifting chains. The angle should not be less than 45°, as shown in the illustration.

When the lifting eye screws are tightened, both rings should be aligned.

The loading capacity calculation applies to temperatures between -10 °C (14 °F)

and 40 °C (104 °F).

Before reuse of lifting eye screws make sure there are no surface flaws (for example

rust, pits, voids, folds and seams, deformation of the ring, or missing or broken

threads).

The local, national safety standards for machines and lifting-equipments must

always be strictly observed.

Note: Before starting to operate the hammer, always replace the lifting eye with a

blanking screw.